Process for liquefaction of natural gas

A technology of natural gas and gas, applied in the field of producing liquefied natural gas (LNG), which can solve the problems of limited expander capacity and experience, and achieve the effect of low power consumption and simple process scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

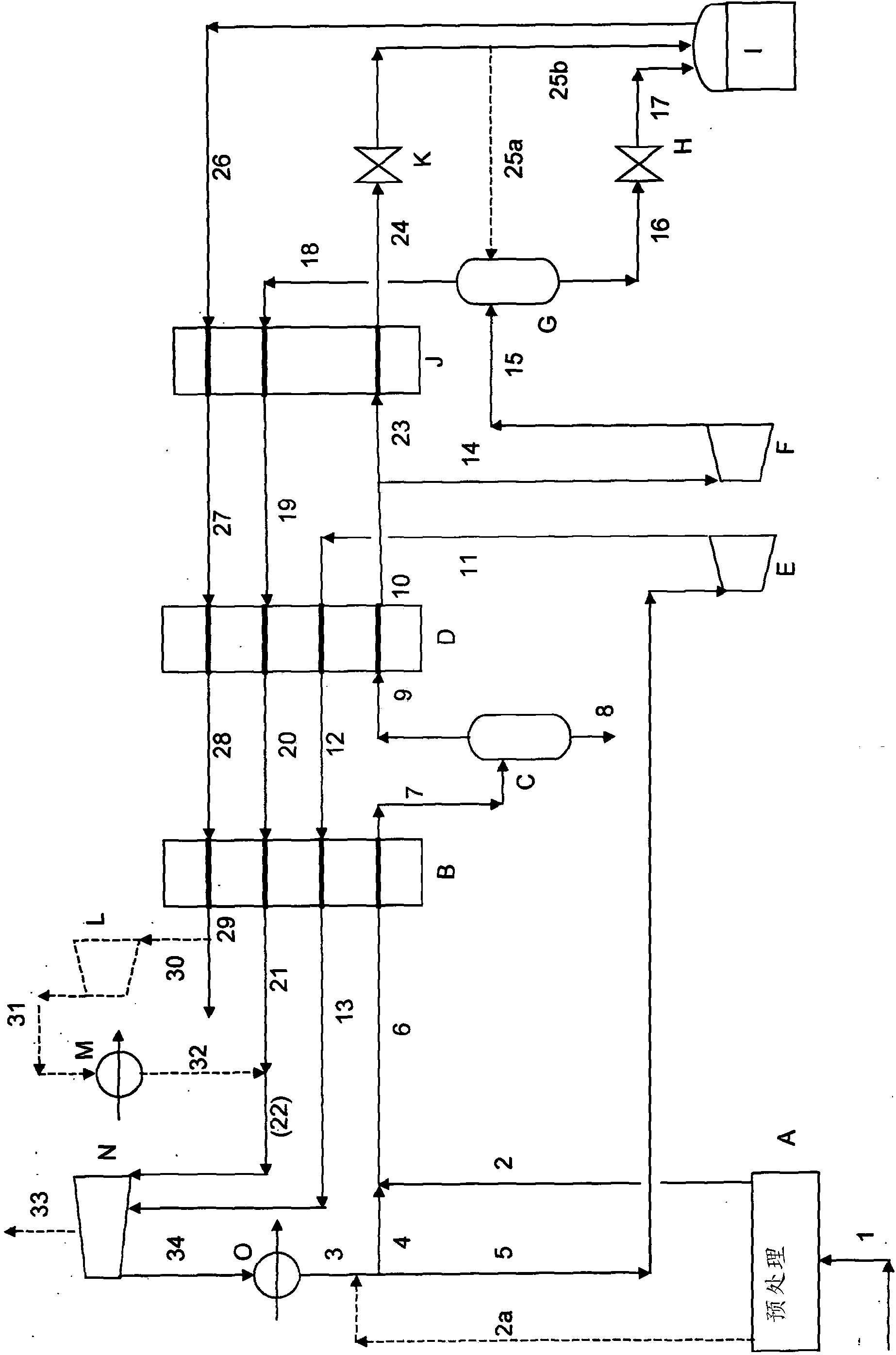

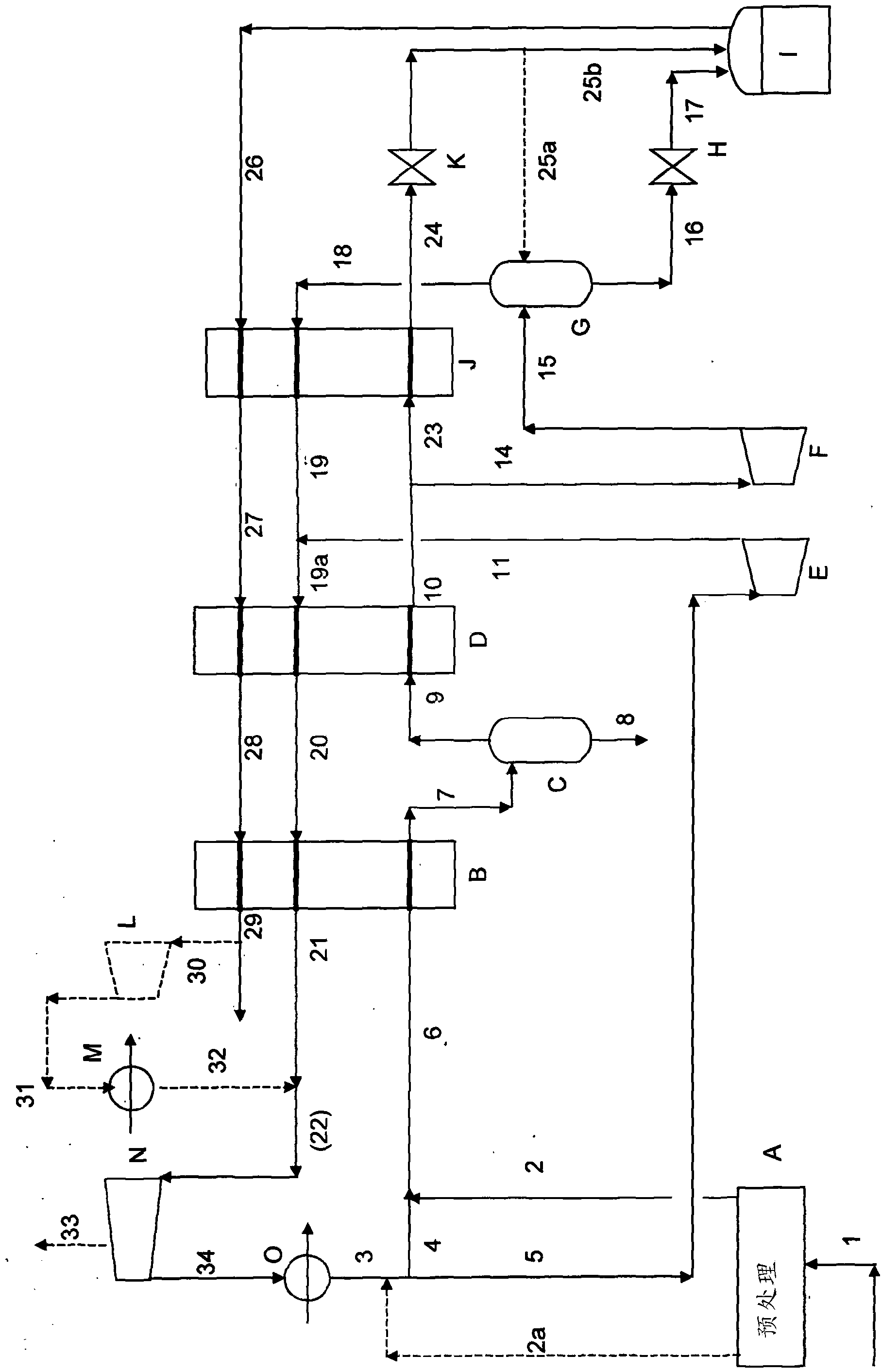

[0020] According to the present invention, there is provided a method for liquefying natural gas or other methane-rich gas. This feed gas, typically at a pressure from 40 (4Mpa) to 100 bar (10Mpa), is liquefied by the expander-based device configuration described above to produce a For LNG products, this expander-based equipment configuration includes:

[0021] - In a first step, feed gas and recycle gas (mentioned below) are passed through a first heat exchanger and cooled in a first work expander; 80°C, preferably an outlet temperature in the range of -60°C to -70°C; the expander has an outlet temperature lower than that of the heat exchanger; the outlet stream of the expander is absorbed in a cold channel of the heat exchanger Reheated and then recompressed to form part of the recycle gas described above.

[0022] - passing part of the cooled outlet stream from said first heat exchanger into a hot channel in a second heat exchanger where it is substantially condensed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com