Improved cartridge for feeding a stereolithography machine, stereolithography machine comprising said cartridge and stereolithography method employing said machine

A technology of stereolithography and feeding, which is used in accessories for processing main materials, chemical instruments and methods, mixers, etc., and can solve problems such as deterioration, pollution, and unsuitability of machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

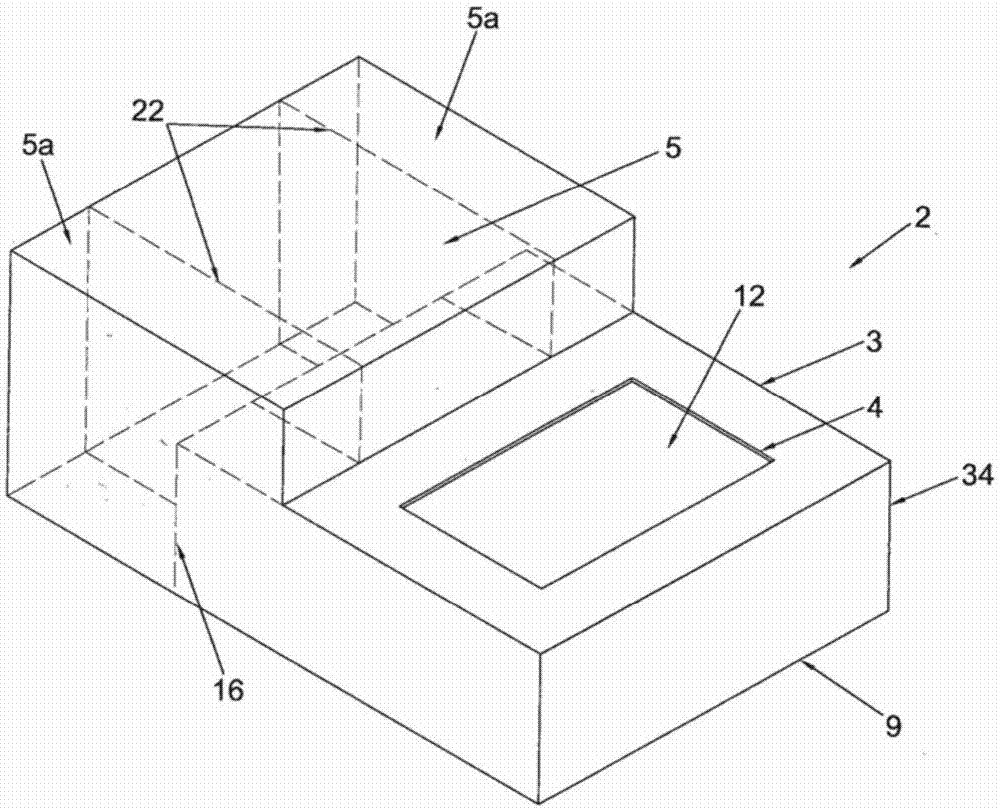

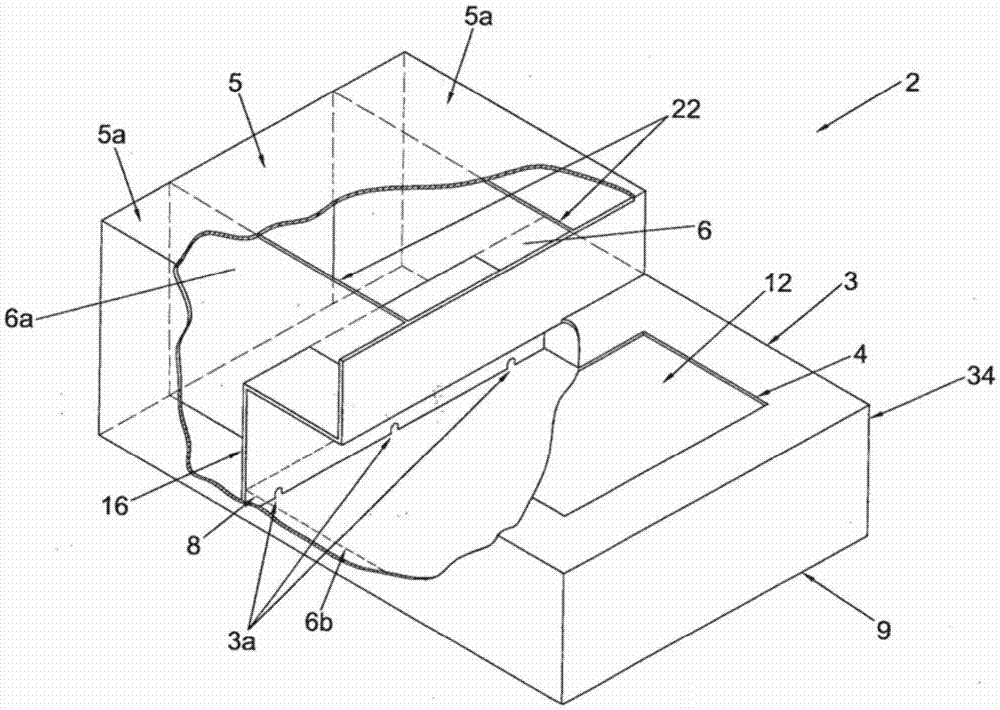

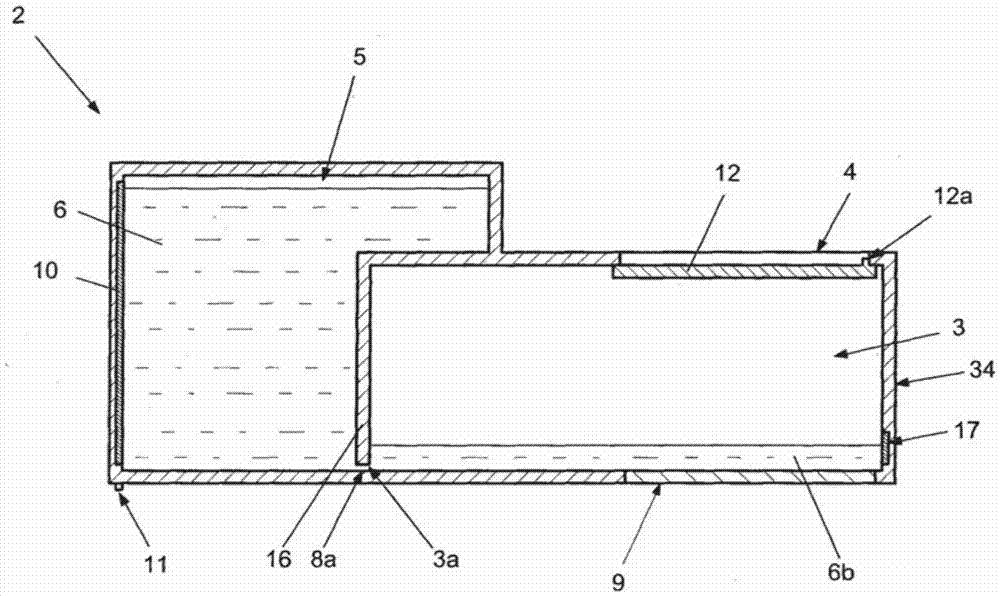

[0046] Cassette for feeding a stereolithography machine - this cassette is the subject of the present invention and is described in figure 1 The center is indicated generally by 2 - including the support structure 34 associated with the container 3 .

[0047] Cassette 2 also comprises a first reservoir 5 associated with support structure 34 and adapted to contain a first material 6 in liquid or pasty form, suitable for curing after exposure to predetermined radiation 7 .

[0048] The predetermined radiation 7 is preferably light, but not necessarily light.

[0049] Also preferably, the first material 6 is photocurable resin or photosensitive polymer.

[0050] Cassette 2 also comprises feeding means 8 associated with support structure 34 and suitable for feeding first material 6 from first reservoir 5 to container 3 .

[0051] The support structure 34 is provided with Figure 4 The device for removable connection to the stereolithography machine 1 is schematically shown in ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com