Backflow suspension type calcining furnace system

A calciner and suspension technology, which is applied in the field of reflux suspension calciner system, can solve the problems of failure to grasp the business opportunities of light calcium carbonate, low energy efficiency, no heat preservation, etc., and achieve the promotion of energy efficiency, high economic benefits, large The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments for practicing the invention are discussed in detail below. The specific embodiments discussed are merely intended to reveal specific ways to use the embodiments and do not limit the scope of the disclosure.

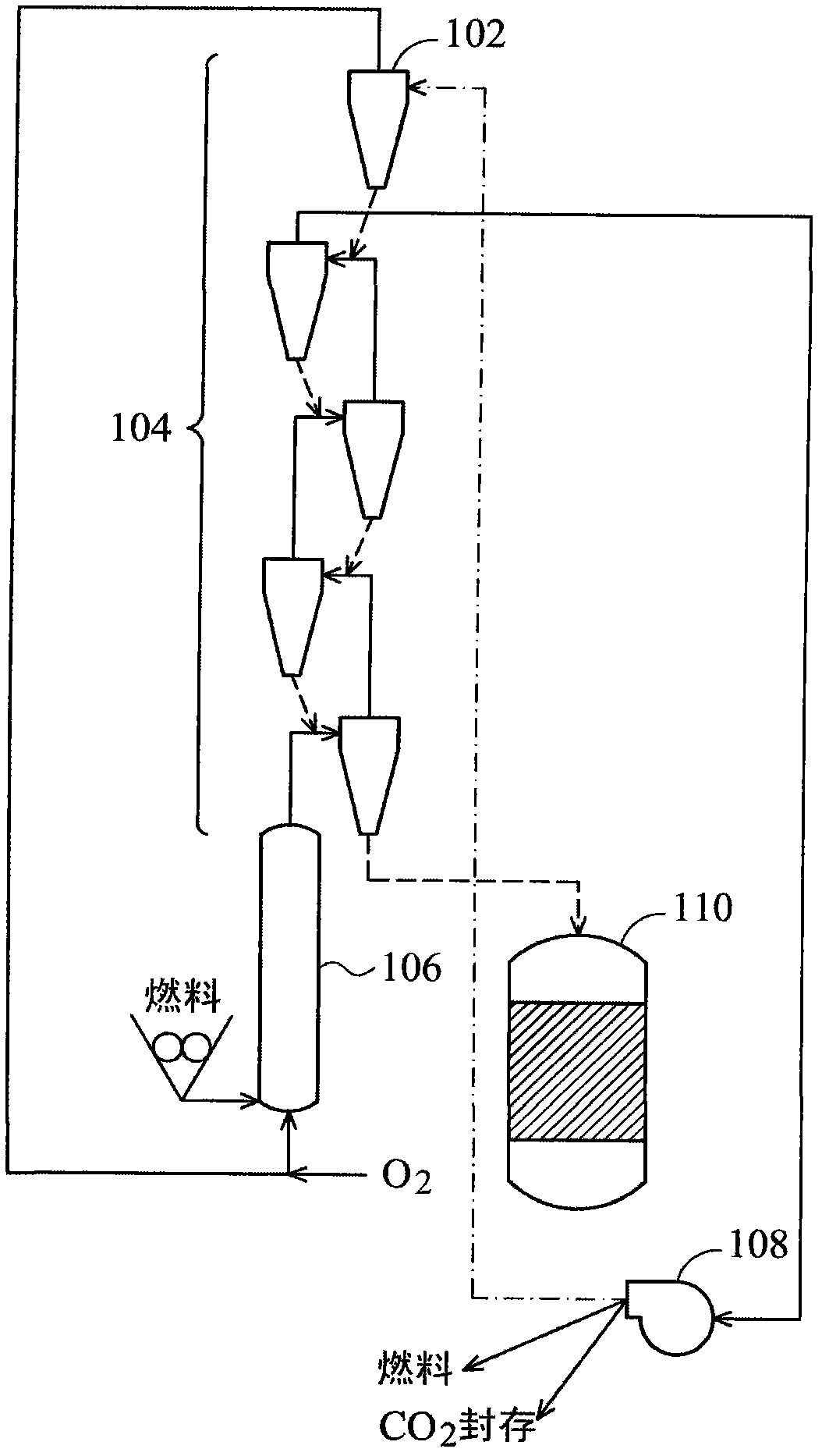

[0014] The present invention discloses calcining equipment related to a carbon dioxide capture system, which captures carbon dioxide in the exhaust gas of a power plant at a high temperature, improves the capture of carbon dioxide, and enables the adsorbent to be continuously reused, reduces reaction time, saves fuel, and reduces the cost of carbon dioxide capture. The present invention utilizes the "reflux suspension calciner" with time and fuel efficiency to calcine absorbents, such as calcined calcium carbonate (CaCO 3 ) to obtain calcium oxide (CaO), so as to make light calcium carbonate or use it for carbon dioxide capture.

[0015] figure 1 For a schematic diagram showing a reflux suspension calciner system according to an embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com