Process and apparatus for making mineral fibres

A technology of minerals and mineral materials, applied in] such as in US2005/00396, some cyclone flow. It can solve problems such as ineffectiveness, achieve uniform residence time, enhance complete combustion, and reduce the amount of carbon monoxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

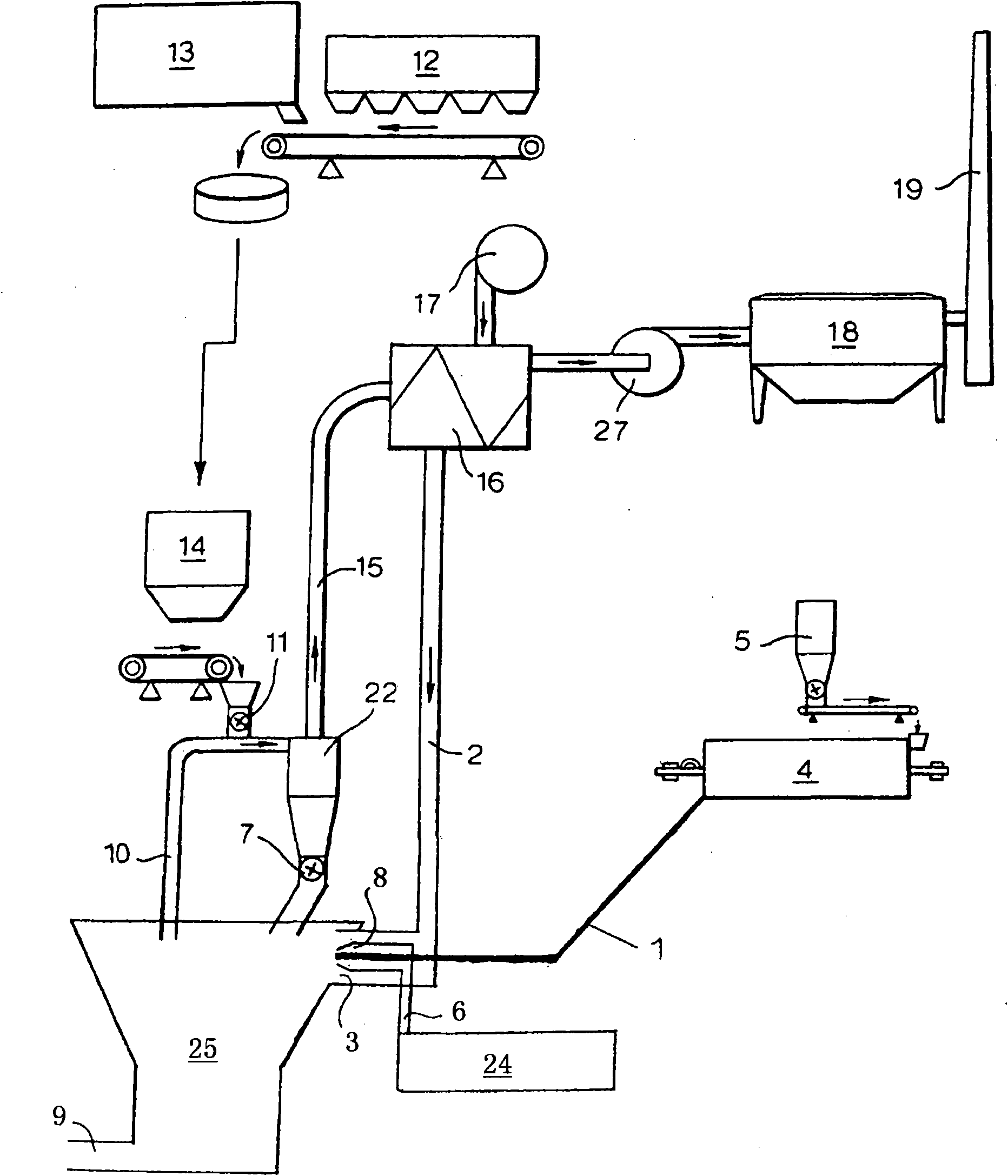

Image

Examples

Embodiment Construction

[0044] The circulating combustor in the present invention is of the type commonly referred to as a cyclone furnace. Preferably the cyclone furnace is water cooled. The construction of suitable cyclone furnaces is described in various patents, including US Pat.

[0045] The particulate fuel used in the present invention is typically a carbonaceous material, and can be any carbonaceous particulate material with a suitable calorific value. The calorific value may be relatively low, for example as low as 10000 kJ / kg, or even as low as 5000 kJ / kg. Thus, it can be, for example, dried sludge or waste paper. Preferably, the pellet fuel has a high calorific value and may be spent pot linings from the aluminum industry, coal containing waste such as tailings, or pulverized coal.

[0046] In a preferred embodiment the fuel is pulverized coal and may be fine coal, however preferably some of the coal, usually at least 50%, preferably at least 80% and usually all of the coal is obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com