Grinding workbench for cylindrical casting machining

A casting and cylindrical technology, which is applied in the direction of manufacturing tools, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of low efficiency of manual grinding, grinding, etc., and achieve low efficiency and reduce noise , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

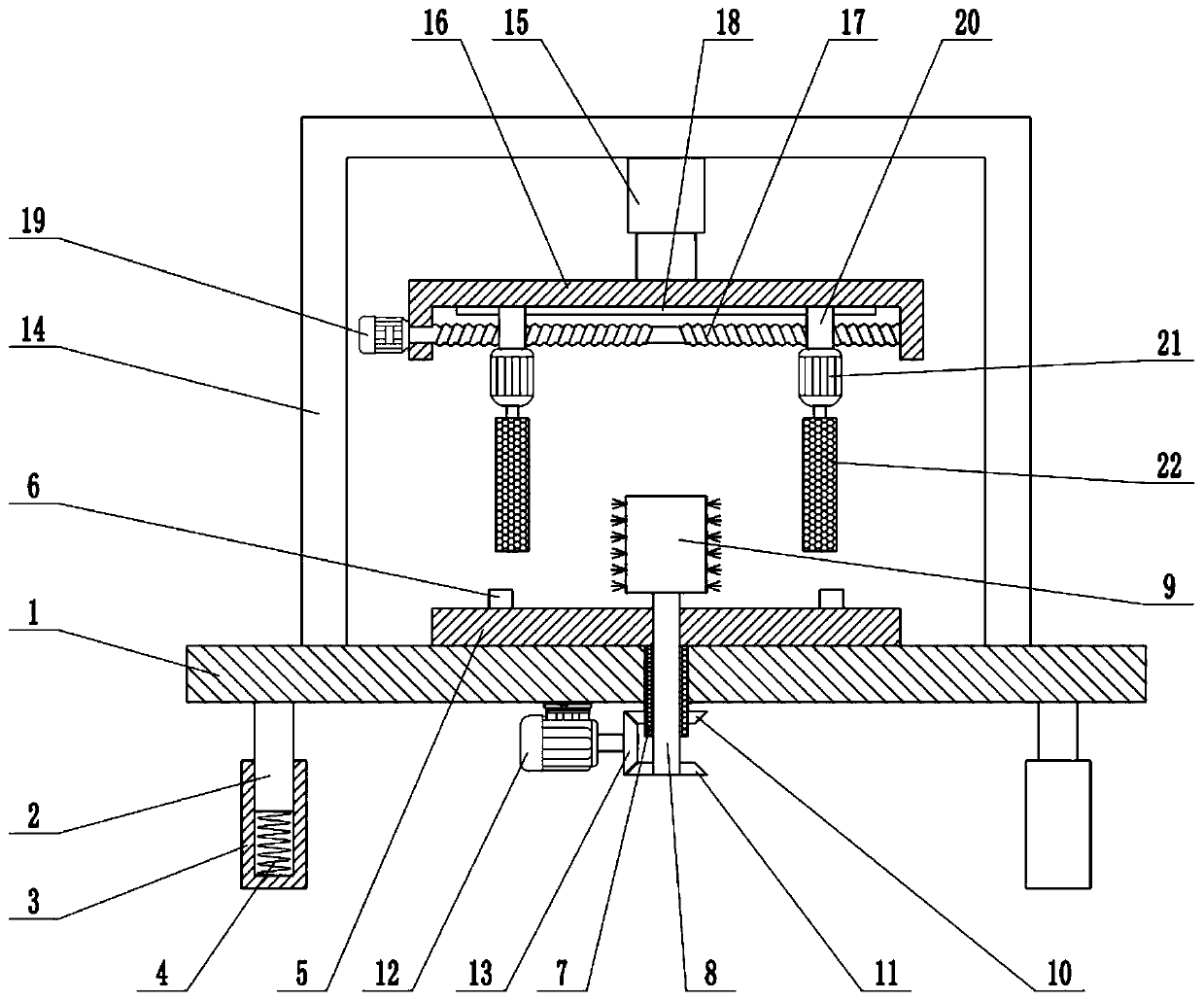

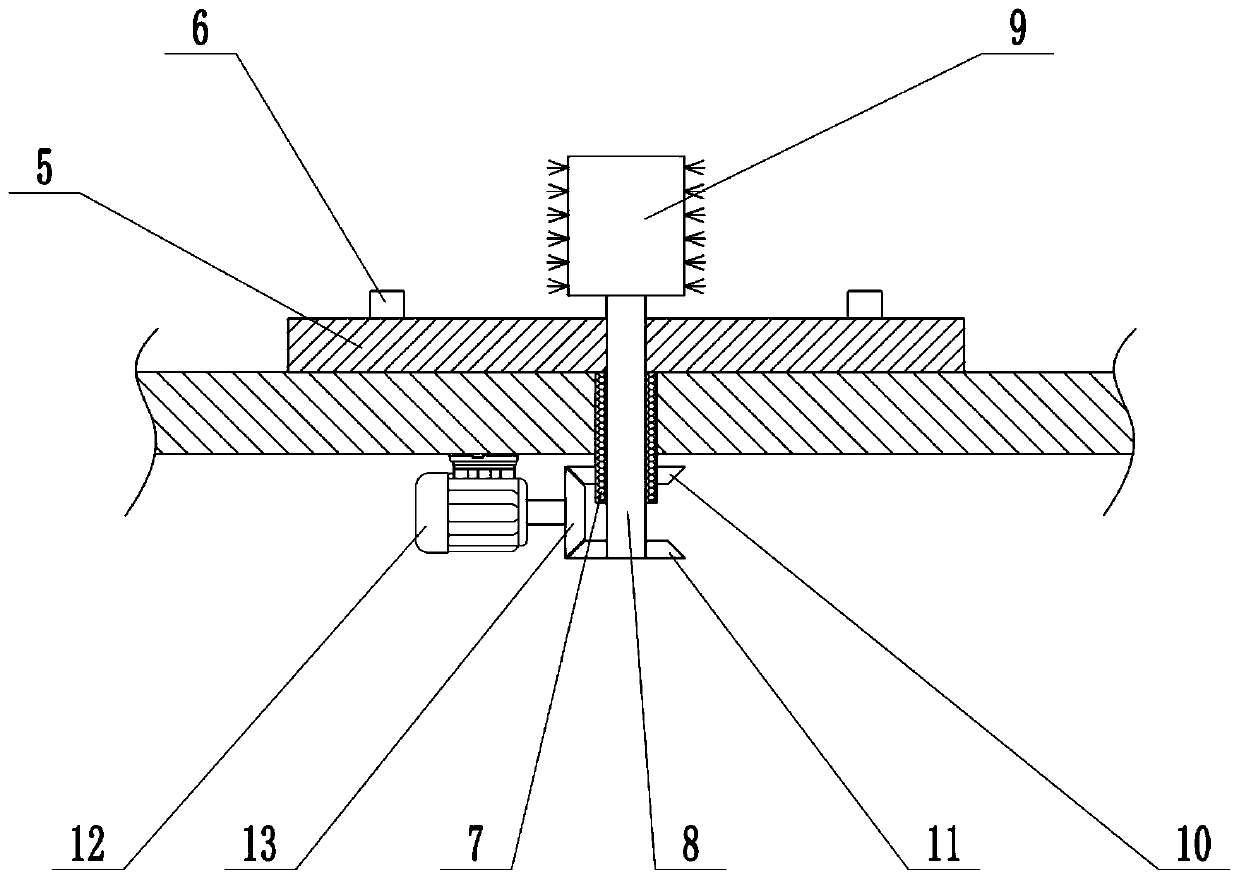

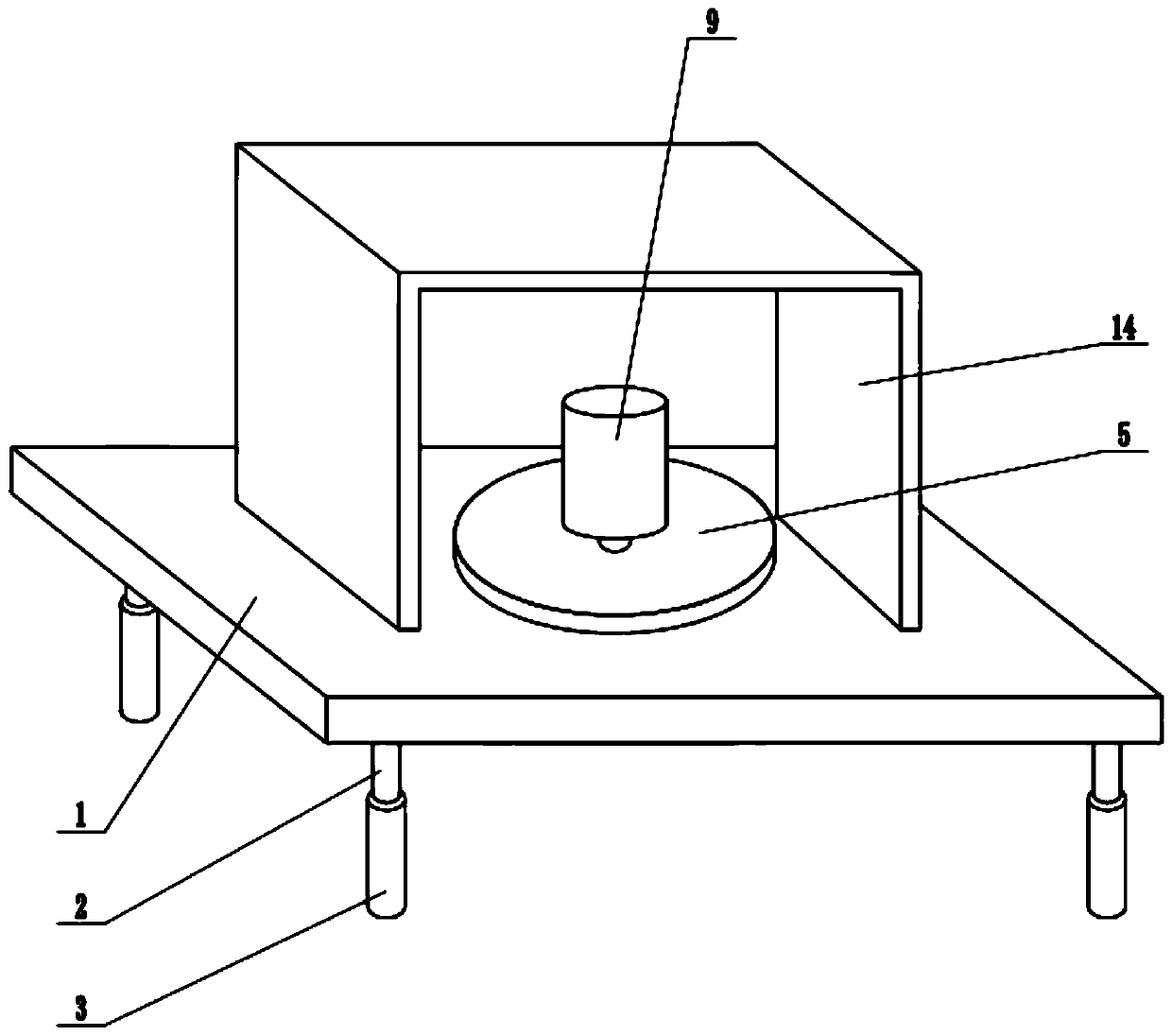

[0022] see Figure 1-3 , in an embodiment of the present invention, a grinding workbench for processing cylindrical castings includes a tabletop 1, a foot 2, a fixed frame 14, a telescopic mechanism 15 and an outer grinding roller 22, and the upper surface of the tabletop 1 is rotatably connected with Rotary table 5, the upper surface of the rotary table 5 is distributed with movable buckles 6, and the cylindrical casting to be polished can be fixed on the rotary table 5 by using the movable buckles 6, and the bottom of the rotary table 5 is equipped with a rotating cylinder 7, which The top of the cylinder 7 is fixedly connected to the rotary table 5, the lower end of the rotary cylinder 7 extends through the table top 1 to the bottom of the table top 1, the rotary cylinder 7 is connected to the table 1 in rotation, and a rotating shaft 8 is installed inside the rotary cylinder 7, and the rotary cylinder 7 and The rotating shaft 8 is rotationally connected, and the top of the...

Embodiment 2

[0024] On the basis of Embodiment 1, a shock absorbing mechanism is installed at the lower end of the leg 2, the shock absorbing mechanism includes a sleeve 3 and a spring 4, the lower end of the leg 2 is provided with a sleeve 3, the sleeve 3 is slidingly connected with the leg 2, and the sleeve A spring 4 is installed inside the cylinder 3, and the vibration generated during the operation of the device can be reduced by using the spring 4, so as to achieve the effect of reducing noise.

[0025] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: the cylindrical casting to be polished is placed on the rotary table 5, fixed by the movable buckle 6, the inner wall of the casting and the outer surface of the inner grinding roller 9 The surface abuts, the telescopic mechanism 15 is controlled to expand and contract, the height of the outer grinding roller 22 is adjusted, the adjustment motor 19 is controlled to run, and the two-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com