Silver nanowire electrode-based efficient flexible quantum dot light-emitting diode and preparation thereof

A quantum dot light-emitting, silver nanowire technology, applied in circuits, electrical components, electro-solid devices, etc., can solve the problems that limit the improvement of the luminous efficiency of flexible QLEDs, the loss of light-emitting devices, etc., to ensure the ability of electronic transmission, low cost, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] In general, the preparation method may include the following steps:

[0067] (1) Preparation of flexible and transparent composite PI / AgNWs electrodes. Specifically, it can be as follows: firstly, AgNWs network structure is formed on the glass substrate by squeegee coating, and annealed; secondly, a PI film is formed on the network structure by squeegee coating or spin coating, and cured at high temperature; finally, the PI film is removed from the Peel off on the glass substrate;

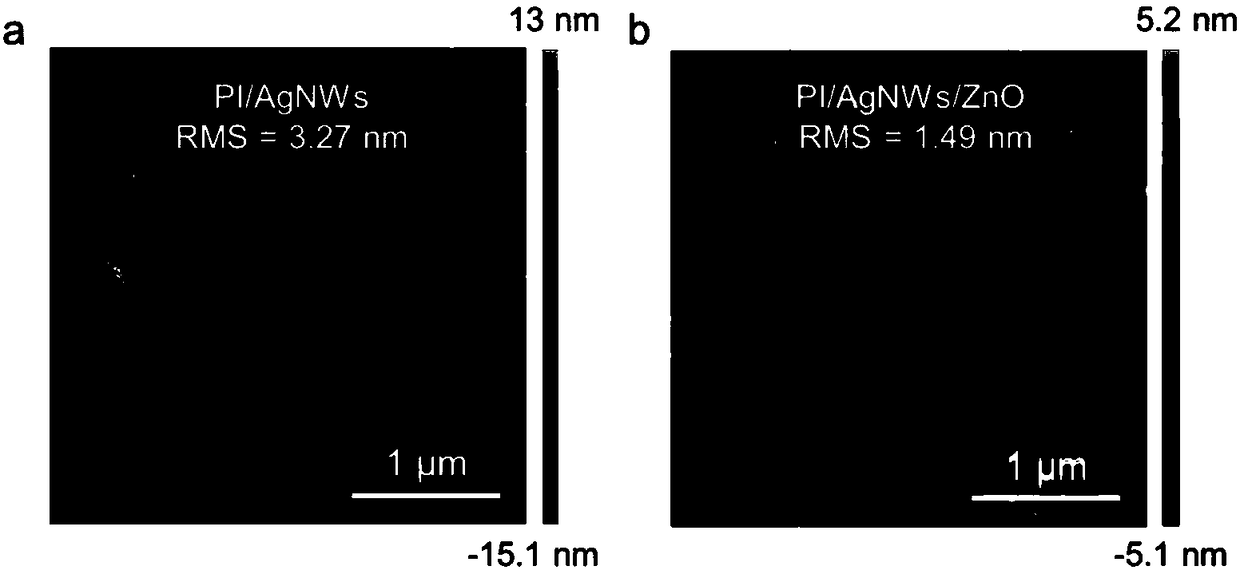

[0068] (2) The electron transport layer is prepared by spin coating on the flexible transparent composite electrode. While ensuring that the electron transport layer can well modify the surface of PI / AgNWs and reduce its surface roughness, it can also carry out electron transport well. The electron transport layer Including but not limited to zinc oxide nanoparticle electron transport layer, annealing;

[0069] (3) Spin coating on the zinc oxide film (ie zinc oxide nanoparticle film) to pr...

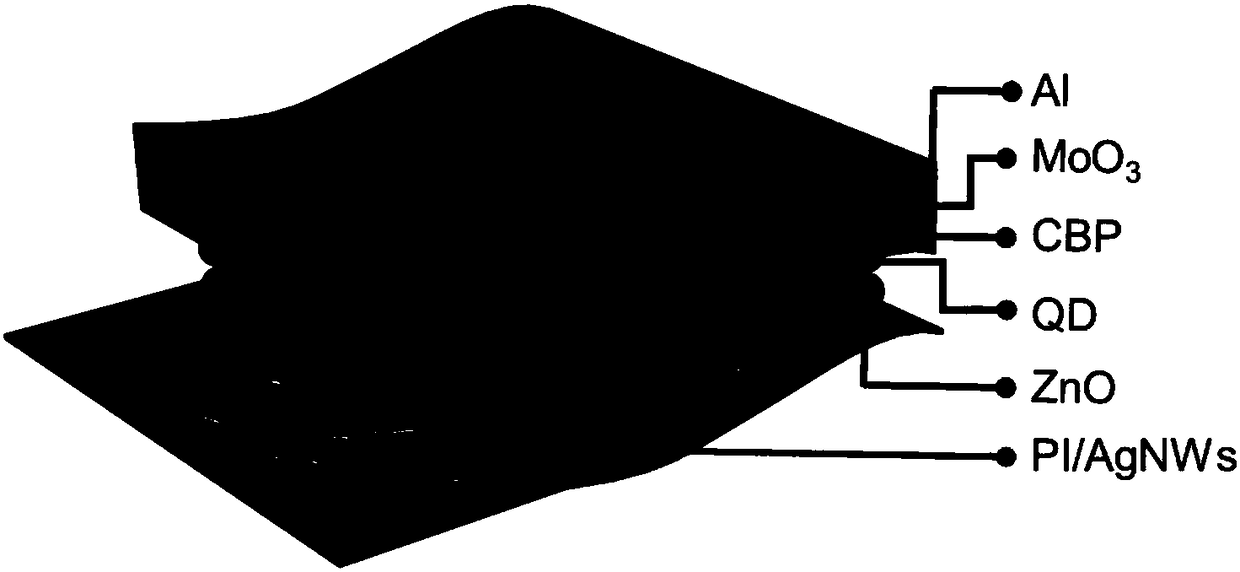

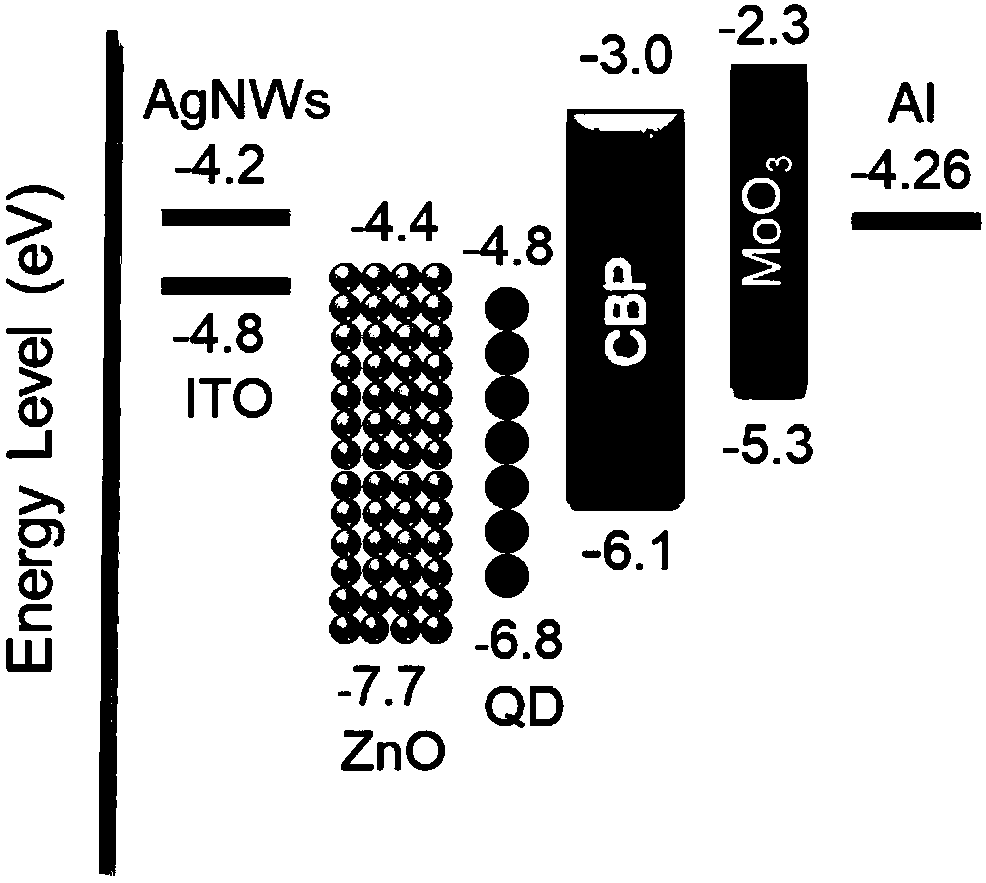

Embodiment 1

[0081] The device structure of the flexible red QLED in Example 1 is that the PI / AgNWs flexible transparent composite electrode is used as the transparent cathode, the zinc oxide nanoparticles are used as the electron transport layer, and the cadmium selenide / cadmium sulfide / zinc sulfide red light quantum dots are used as the light-emitting layer. The organic small molecule 4,4'-bis(9-carbazolyl)biphenyl (ie, CBP) is used as the hole transport layer, the inorganic metal oxidized molybdenum trioxide is used as the hole injection layer, and the metal aluminum is used as the anode. Nano-zinc oxide is a semiconductor material, and its electron transport ability decreases with the increase of thickness. The commonly used thickness is generally between 50-100nm. Considering that the surface of PI / AgNWs needs nano-zinc oxide for filling and modification, the following examples The minimum thickness of zinc oxide is 80nm, and the maximum thickness is 100nm.

[0082] The preparation pr...

Embodiment 2

[0085] In Example 2, a comparative device was prepared using the same device structure as in Example 1 except for the flexible transparent composite electrode PI / AgNWs. The electrode used in this structure was a glass / ITO transparent bottom electrode as a cathode.

[0086] The preparation process of the device is as follows: glass / ITO is cleaned with ultrasonic waves in cleaning agent and deionized water for 30 minutes, and then dried at 105°C for 2 hours. Spin-coat zinc oxide nanoparticle film on the glass / ITO electrode with a thickness of 100nm and anneal at 150°C for 20 minutes; spin-coat a quantum dot light-emitting layer on the zinc oxide film with a thickness of 10nm and anneal at 100°C for 2 minutes; transfer the device into In the evaporation chamber of the evaporation equipment, 60nm organic small molecule 4,4'-bis(9-carbazolyl)biphenyl, 10nm inorganic metal oxide molybdenum trioxide and 100nm metal anode aluminum were respectively evaporated.

[0087] ITO is used as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com