Mold for tyre

A technology of tires and molds, which is applied to household appliances, other household appliances, tires, etc., can solve problems such as the inability to manufacture tires, and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

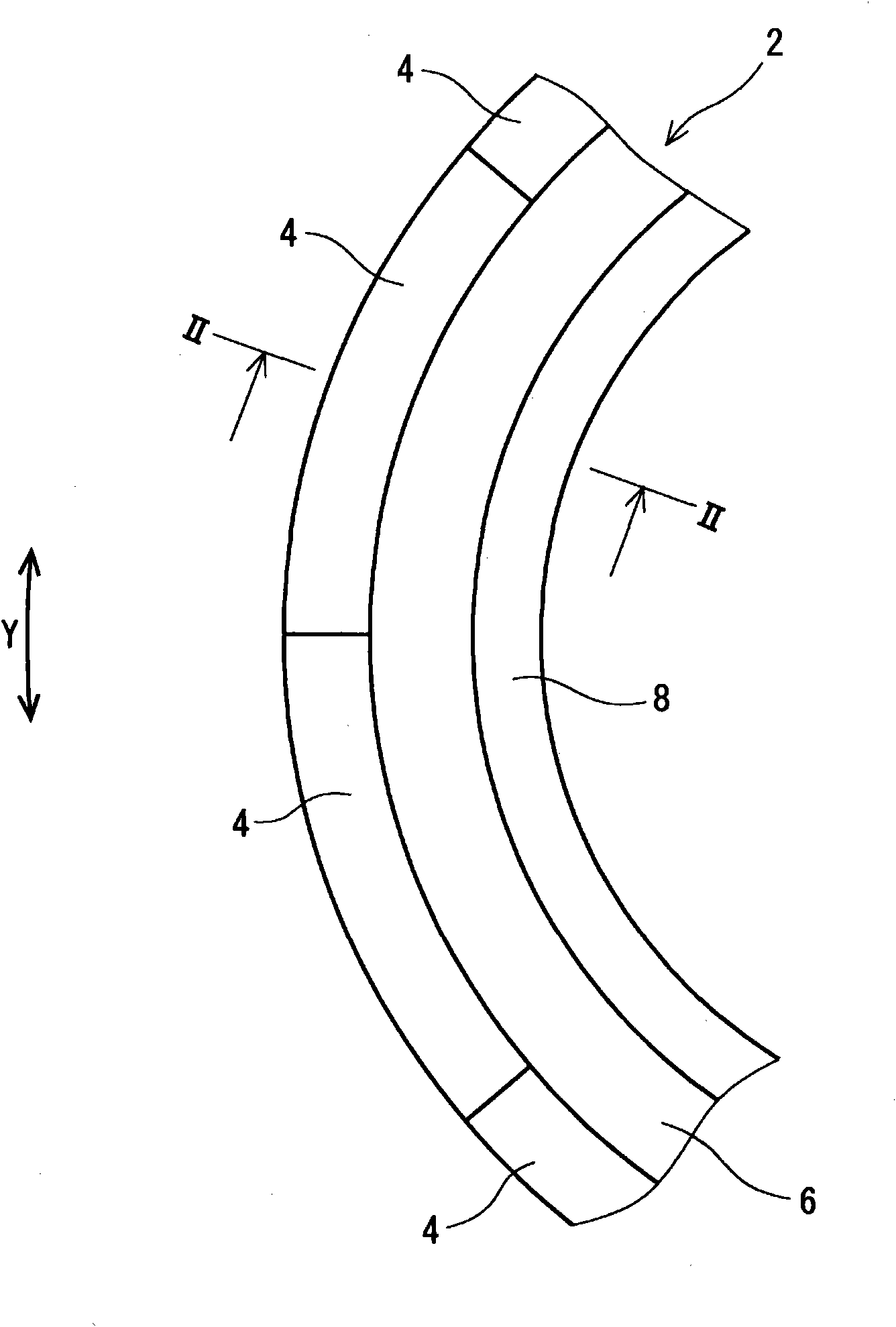

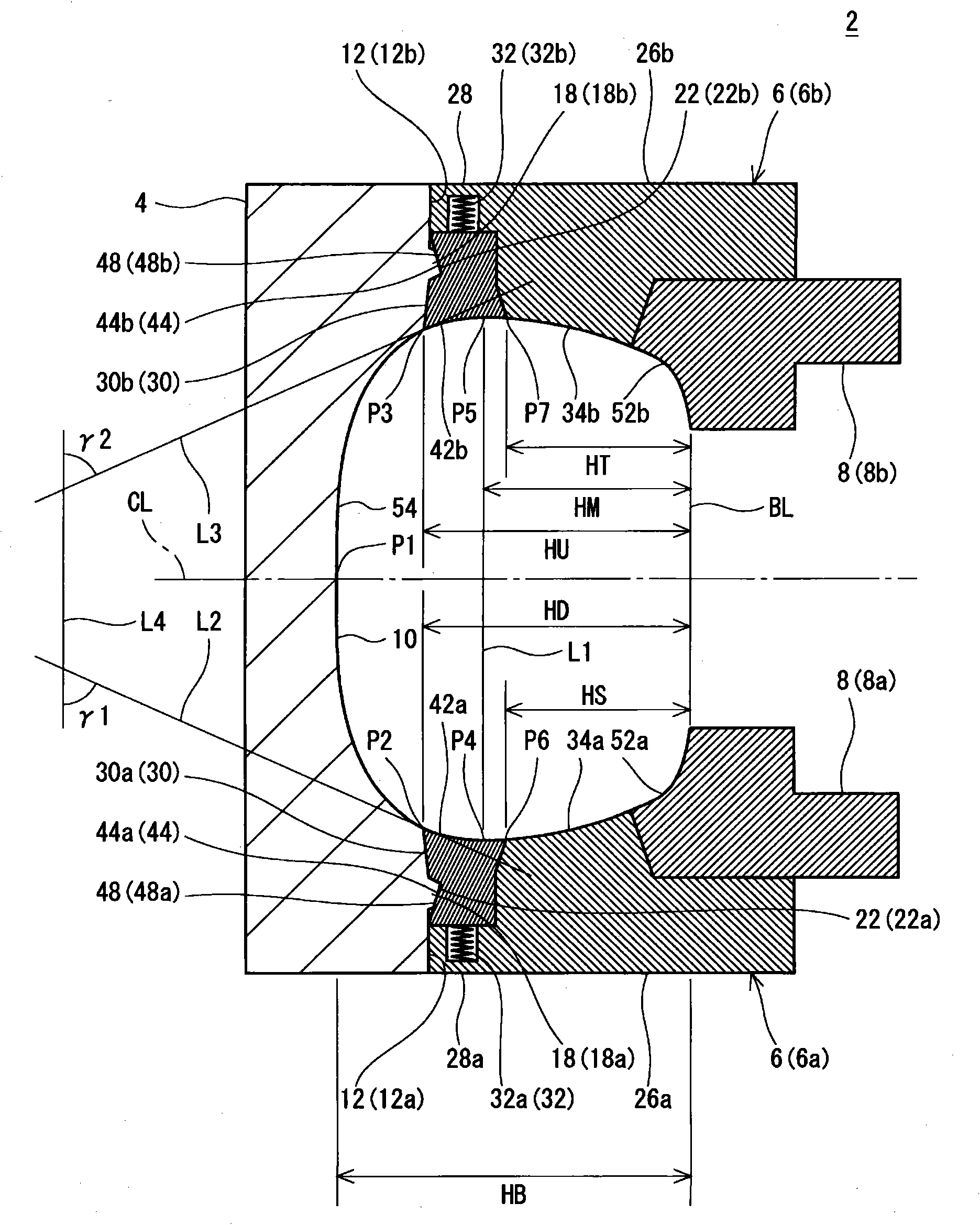

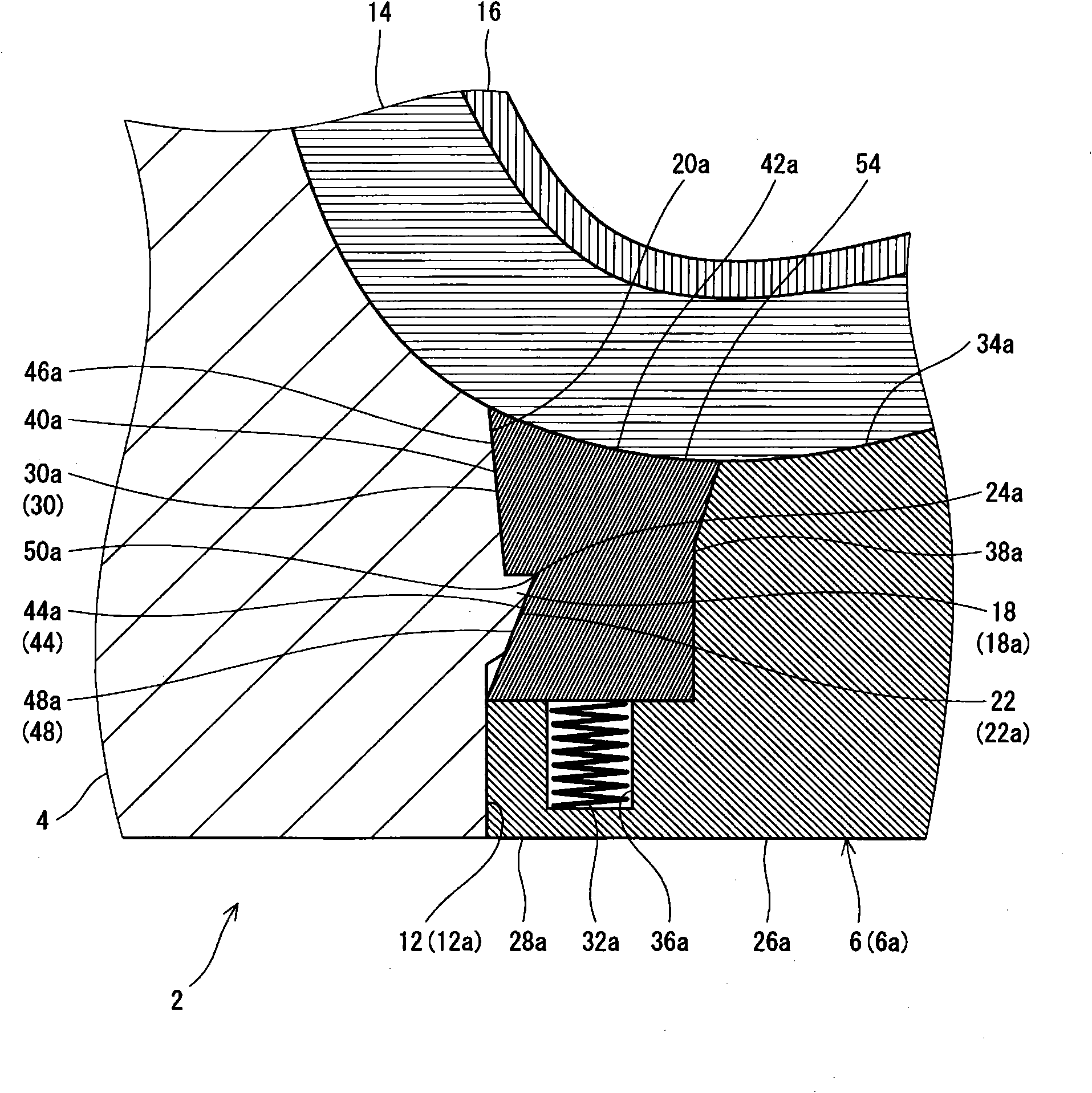

Image

Examples

Embodiment 1

[0065] in possession figure 2 A raw tire was placed in the tire mold of Example 1 having the basic configuration shown and the specifications shown in Table 1 below to manufacture a tire (tire size = 195 / 65R15). In this production, a raw tire is placed in a tire mold in which the split mold is separated from the side plate and the movable ring is moved axially inward. After filling the air bag with gas and shaping the green tire, the combined mold is moved radially inward. Through this movement, the split mold comes into contact with the side plate, and the movable ring moves axially outward while the conical surface of the movable ring slides along the slope of the split mold, and the molding surfaces of the components are combined to form the cavity surface. The mold is thus closed, and the green tire is pressurized and heated in the mold to obtain a tire. The length LD of the molded surface of the lower movable ring was 5 mm. The moving distance (distance SD) of this mo...

Embodiment 2~9

[0067] The length LD, the length LU, the distance SD, and the distance SU were the same as in Example 1 except that they were shown in Table 1 below, and tires were manufactured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com