Fermented soybean meal production process suitable for large-scale production

A technology for fermented soybean meal and production process, applied in the field of fermented soybean meal production process, can solve the problems of large-scale solid-state fermentation process stability, poor product stability, uneven material distribution, etc., to avoid bacterial growth restriction and improve production performance , Increase the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

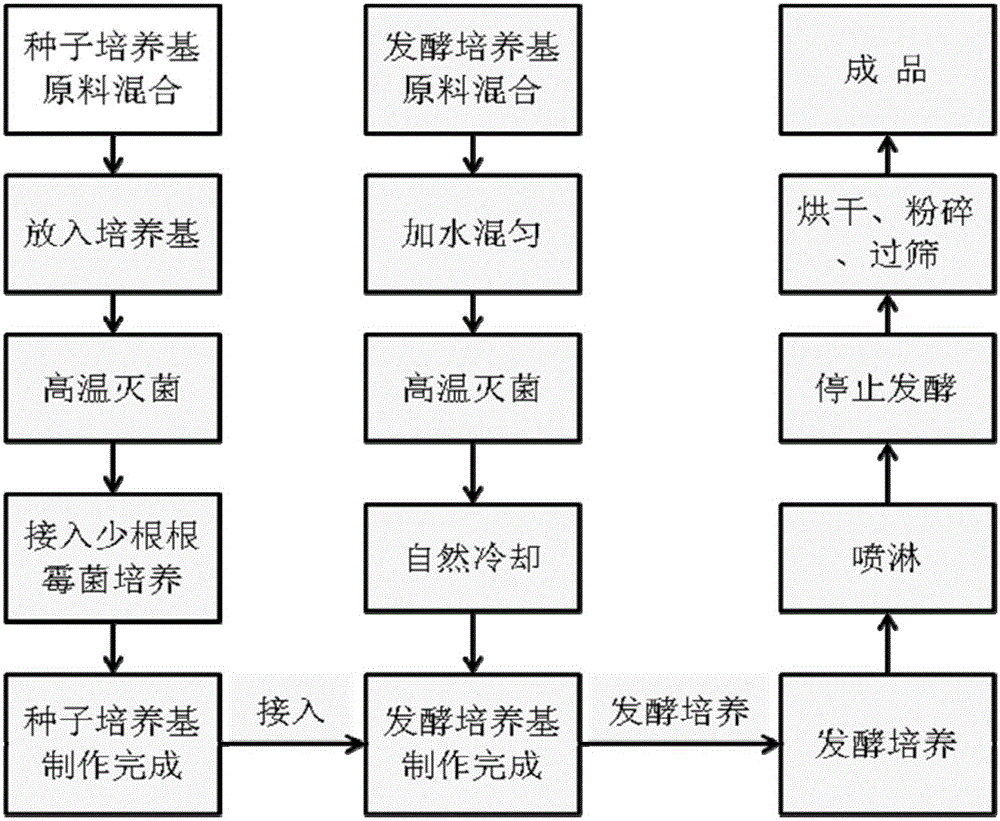

Method used

Image

Examples

Embodiment 1

[0085] Step 1. Preparation of seed liquid in seed medium: tryptone 1.5g, glucose 3.0g, yeast extract 1.5g, sodium chloride 0.5g, water 100mL, medium filling volume 100mL / 500mL Erlenmeyer flask, 121°C After 20min of sterilization, the concentration was 10 8 The rhizopus aureus of each / mL was inserted into the seed medium according to the inoculum amount of 5%, and cultivated at 30°C for 20 hours, and the thalline concentration reached 25;

[0086] Step 2, preparation of fermentation medium: 70% of soybean meal, 24% of bran, 5% of sucrose, 1% of betaine hydrochloride, adding water to make the material-water ratio reach 0.8, mixing evenly; after that, high-temperature sterilization at 121°C for 1 hour, and natural cooling;

[0087] Step 3. Fermentation culture: In step 1, the seed solution was inserted into the fermentation medium with an inoculation amount of 5%, and fermented at 30°C; after 16 hours of fermentation, spray and add 0.5% microfiltration sterilized Betaine hydroch...

Embodiment 2

[0092] The difference between this embodiment and embodiment 1 is that step 1 is omitted, and 10 8 Rhizopus aureus per mL was inserted into the fermentation medium according to the inoculum size of 5%.

[0093] In this example, the use of a single strain of Rhizopus aureus to ferment soybean meal greatly reduces the probability of fermentation contamination, and can effectively eliminate trypsin inhibitors, phytic acid, soybean hemagglutinin, urease, oligosaccharides, and lipoxygenase in soybean meal , soybean antigenic protein (allergenic factor) and goiter and other anti-nutritional factors and achieve a good protein degradation effect, the content of small molecular proteins and small peptides accounts for more than 70% of the total protein, and promote small peptides and their binding minerals The absorption of elements promotes the growth of animals.

Embodiment 3

[0095] The difference between this embodiment and embodiment 1 is that the amount of betaine hydrochloride added by spraying in step 3 is 1%, and the others are the same as in embodiment 1.

[0096] In this example, compared with Example 1, the amount of betaine was increased, based on the following reasons: adding betaine with sweet taste in soybean meal fermentation can reduce the surface interfacial tension of the material and increase the uniformity of material mixing; In addition, betaine can regulate the permeability of the cell membrane of the bacteria, avoiding the growth restriction of the bacteria caused by dissolved oxygen;

[0097] Moreover, although the fermented soybean meal with a single strain of Rhizopus pachyrhiza has greatly reduced the probability of fermentation contamination, and can effectively eliminate anti-nutritional factors in the soybean meal and achieve a good protein degradation effect, its palatability and food-attracting effect are slightly poor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com