Electrolytic copper foil manufacturing equipment

A technology of electrolytic copper foil and manufacturing equipment, which is applied in the field of copper foil manufacturing, can solve the problems of electrode dimensional stability and flatness deterioration, affect battery capacity, internal resistance and life, and decrease the yield of negative electrode materials, etc., to achieve polishing The effect of small allowance, improving surface finish, increasing elongation and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

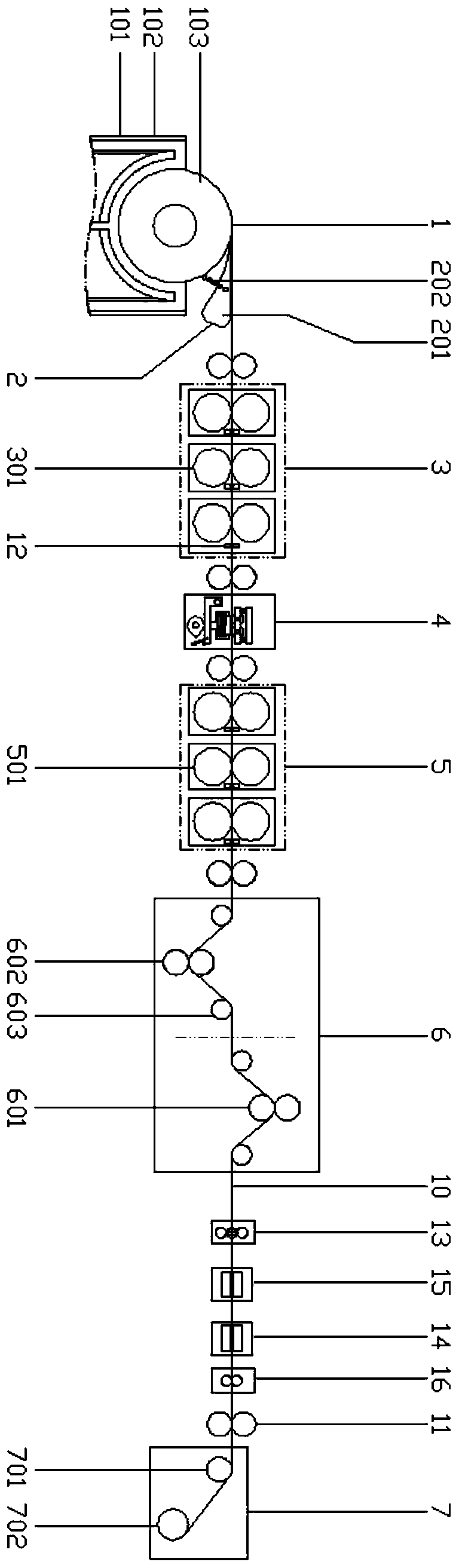

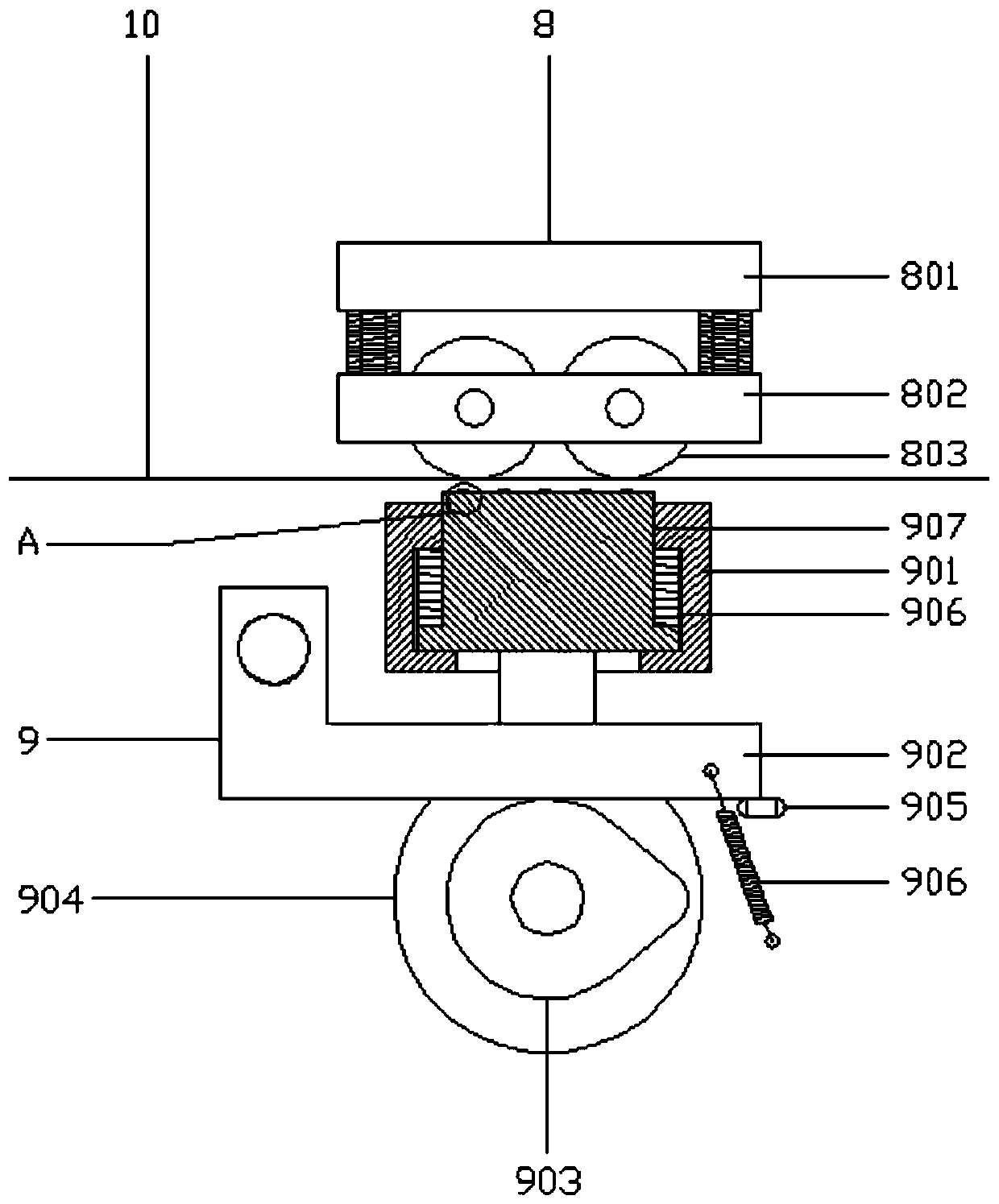

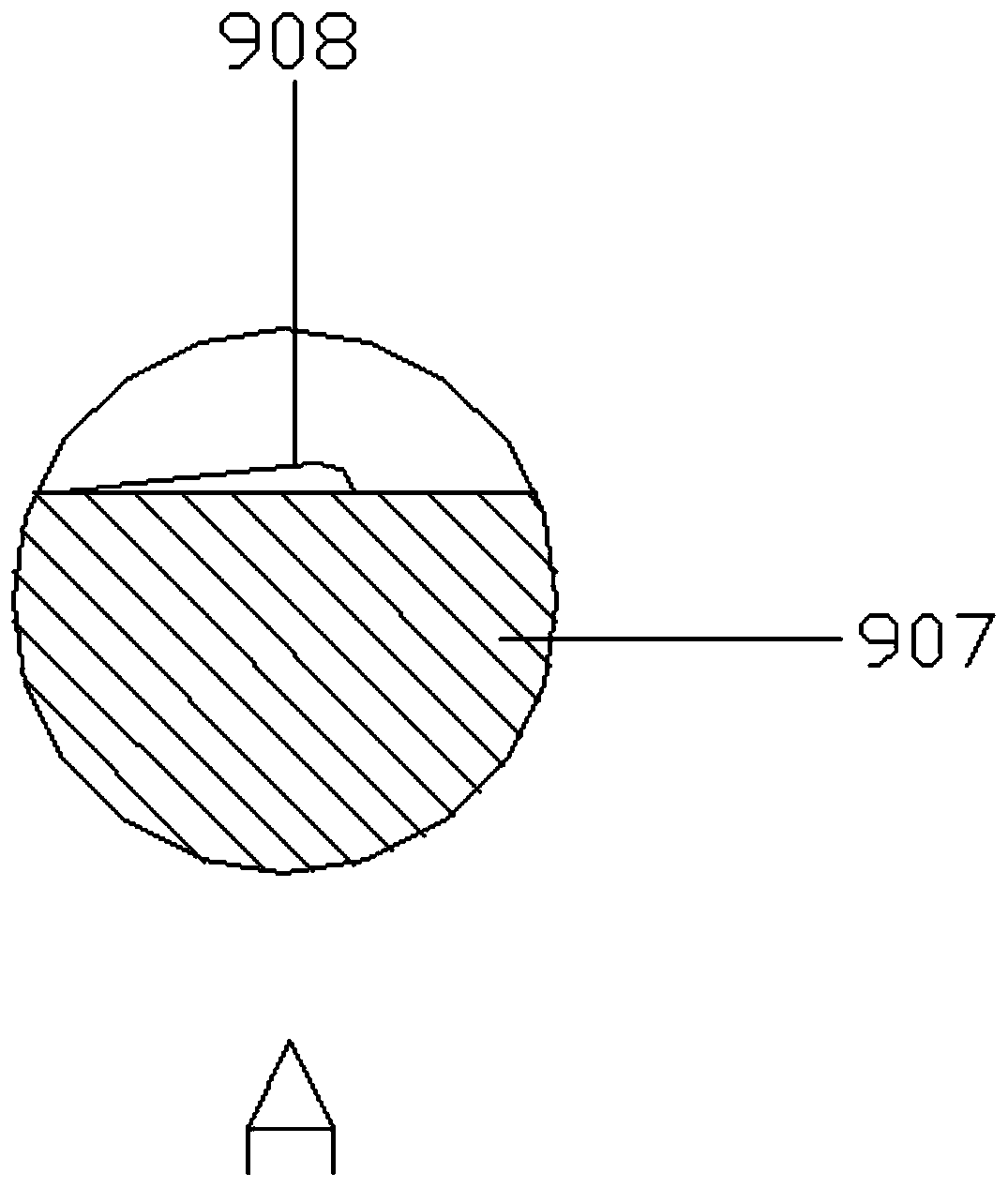

[0057] In actual use, such as figure 1 , Figure 4As shown, the rough copper foil with a thickness of 12 μm is electrolyzed by the cathode electrolytic roller in the conventional electrolytic copper foil mechanism, and then peeled off from the cathode electrolytic roller by the stripping knife, and transported to the coarse roller pre-pressing mechanism by the conveying roller, The rough copper foil is rolled by the pre-pressing roller, and the rough copper foil is initially rolled to 8μm, and then, the high-frequency stamping mechanism is used to punch and form concave-convex points of about 5-6μm on the surface of the pre-pressed copper foil, and then the copper foil with The copper foil with concave and convex points is transported to the fine roller rolling mechanism, and the multiple rolling rollers in the fine roller rolling mechanism will flatten the concave and convex points and roll the copper foil to 6μm, and then transport it to the polishing mill Mechanism, the fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com