Method for producing capacitive carbon from rice husks

A technology of capacitive carbon and rice husk, applied in chemical instruments and methods, silicate, inorganic chemistry, etc., can solve problems such as safety production accidents, easy pollution of the environment, and great difficulties, so as to increase energy density and avoid danger and pollution Environment, the effect of reducing the molecular weight of tar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

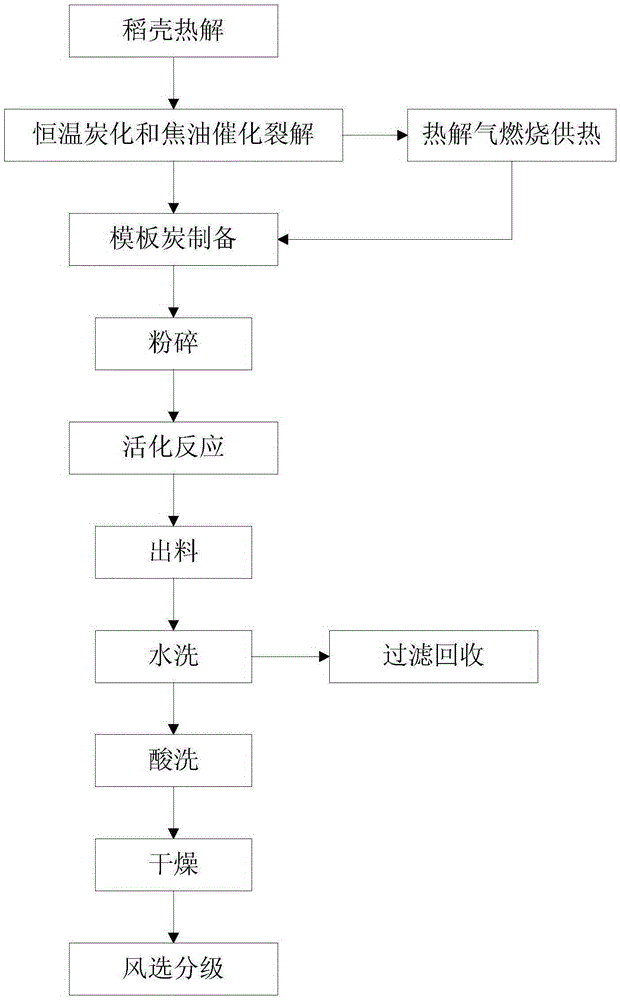

Method used

Image

Examples

Embodiment 1

[0108] (1) Mixing the screened and purified rice husk and sodium hydroxide in a ratio of 100:3 on a dry basis, adding the pyrolysis tower through a Dou elevator, adjusting the induced draft fan speed, and controlling the oxygen content entering the pyrolysis zone, so that The temperature of the pyrolysis section is kept at 650°C, and the pyrolysis is performed for 1.0 hour, and the rice husk is catalyzed and pyrolyzed into pyrolysis gas and pyrolysis charcoal;

[0109] (2) The 650°C pyrolysis gas and pyrolysis charcoal obtained in step (1) continue to descend along the pyrolysis tower, keep the constant temperature for tar removal for 1.0 hour, and the newly generated tar-free pyrolysis gas and pyrolysis charcoal enter the thermal In the water-cooled cooling section of the decomposition tower, the temperature is lowered to 300°C, and separated by a cyclone separator to produce pyrolysis gas with a calorific value of 2100 kcal and pyrolytic carbon containing 2wt% volatile matter...

Embodiment 2

[0113] Change the catalyst to potassium hydroxide, and the remaining conditions are as in Example 1, producing pyrolysis gas with a calorific value of 2200 kcal and pyrolytic carbon containing 1.5wt% volatile matter;

Embodiment 3

[0115] The pyrolytic charcoal obtained in Example 1 is added into the horizontal reaction kettle through a screw propeller, and 5% aqueous sodium hydroxide solution is added in a ratio of 1:5 to the solid-liquid ratio, and the horizontal reaction kettle is rotated to make the pyrolytic charcoal Uniformly mix with lye, pass into Example 1 to obtain boiler steam, keep the steam pressure at 5 atmospheres, react for 3 hours, discharge the material under pressure, put the mixed hydraulic pressure into the No. 1 storage tank, and separate the solid and liquid through the No. 1 centrifuge , recover the sodium silicate solution, the solid enters the No. 2 storage tank through the conveyor belt, adds 80°C purified tap water, stirs and dissolves for 20 minutes, and separates the solid from the liquid through the No. 2 centrifuge, and the solid enters the No. 3 storage tank through the conveyor belt, and adds 70°C purified tap water , stirred and dissolved for 20 minutes, separated from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com