Deep desulfurization method for gasoline

A deep desulfurization and gasoline technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of increased octane number loss, decreased light gasoline yield, and increased olefin content, etc., to reduce the processing capacity and Effects of severity, reduction of octane loss, reduction of sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

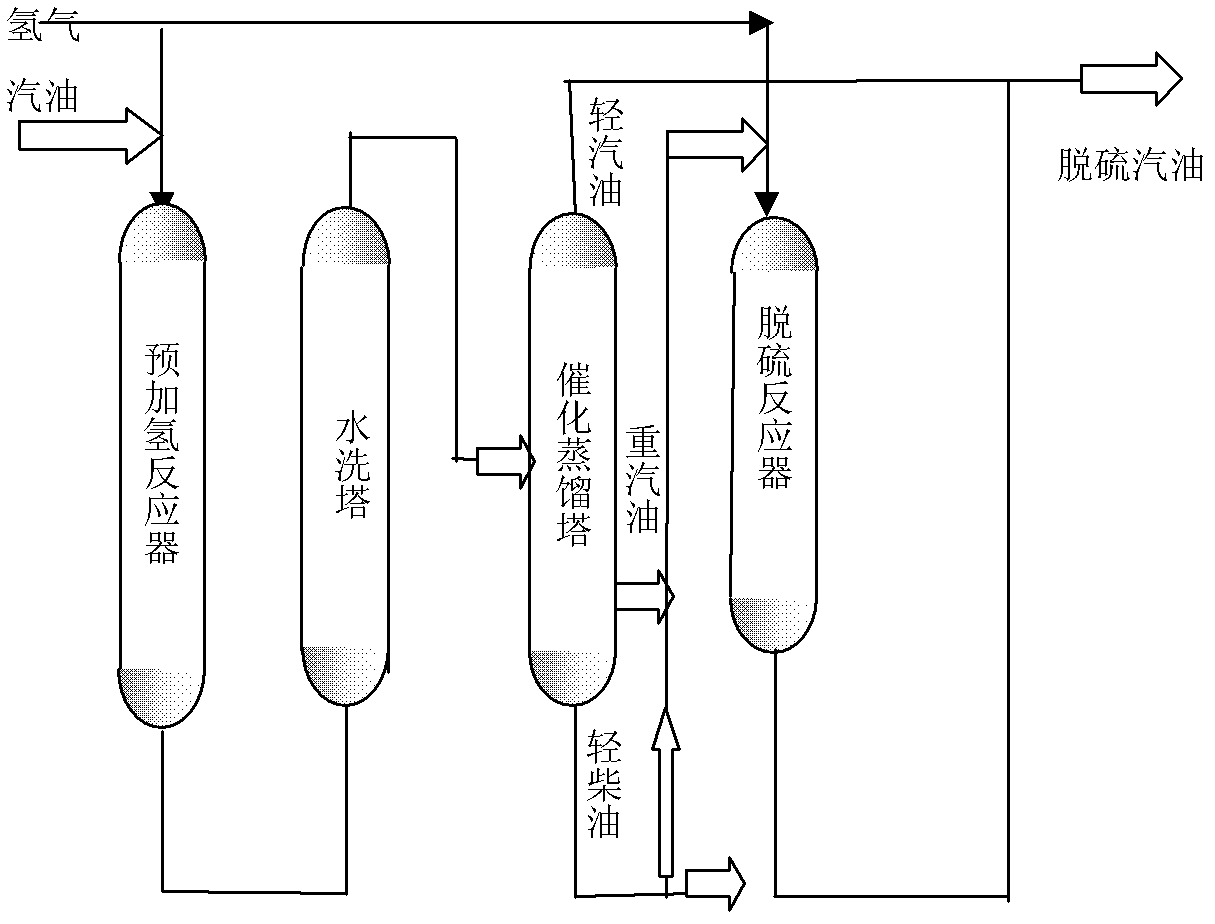

Method used

Image

Examples

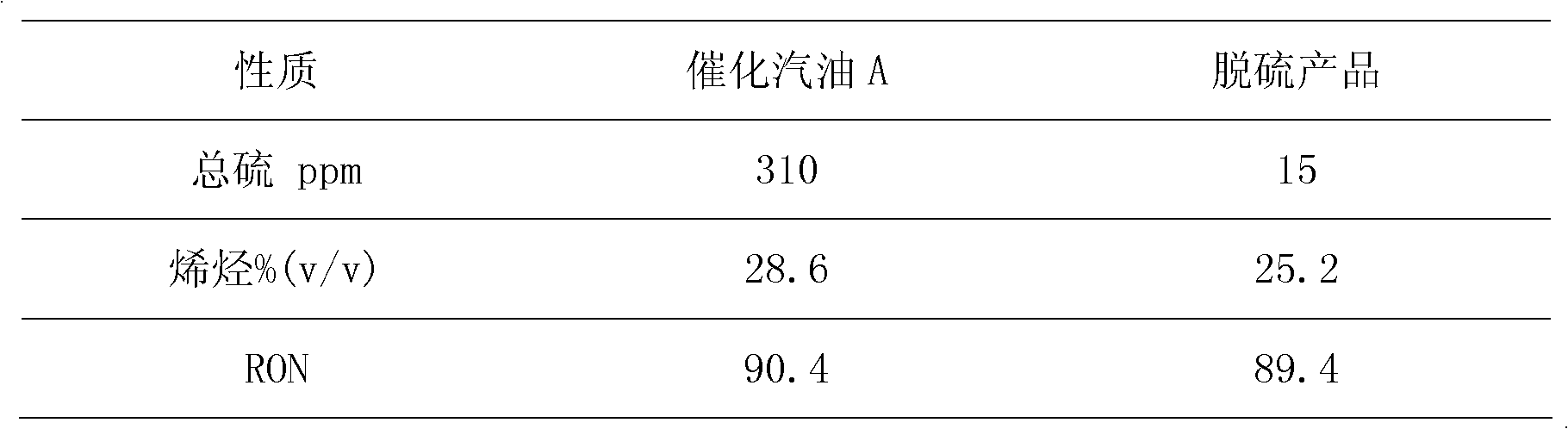

Embodiment 1

[0023]A catalytically cracked gasoline A is used as a raw material, and its properties are shown in Table 1. The pre-hydrogenation reactor is filled with GHC-31 series catalysts developed by the China Petroleum and Petrochemical Research Institute. The catalytic gasoline is first added under the conditions of hydrogen partial pressure 2.4Mpa, temperature 150°C, space velocity 4.0, and hydrogen-oil ratio 10:1. Hydrogen pretreatment, then enter the water washing tower to elute alkali nitrogen, and then enter the catalytic distillation tower, the upper part of the catalytic distillation tower is filled with the GHC-41 series olefin thiophene alkylation catalyst developed by the Petrochemical Research Institute, and the upper part of the catalytic distillation tower is filled with olefin thiophene alkylation catalyst Under the action of base catalyst, some thiophene sulfides in gasoline will increase in weight and be divided into three components: light gasoline, heavy gasoline and...

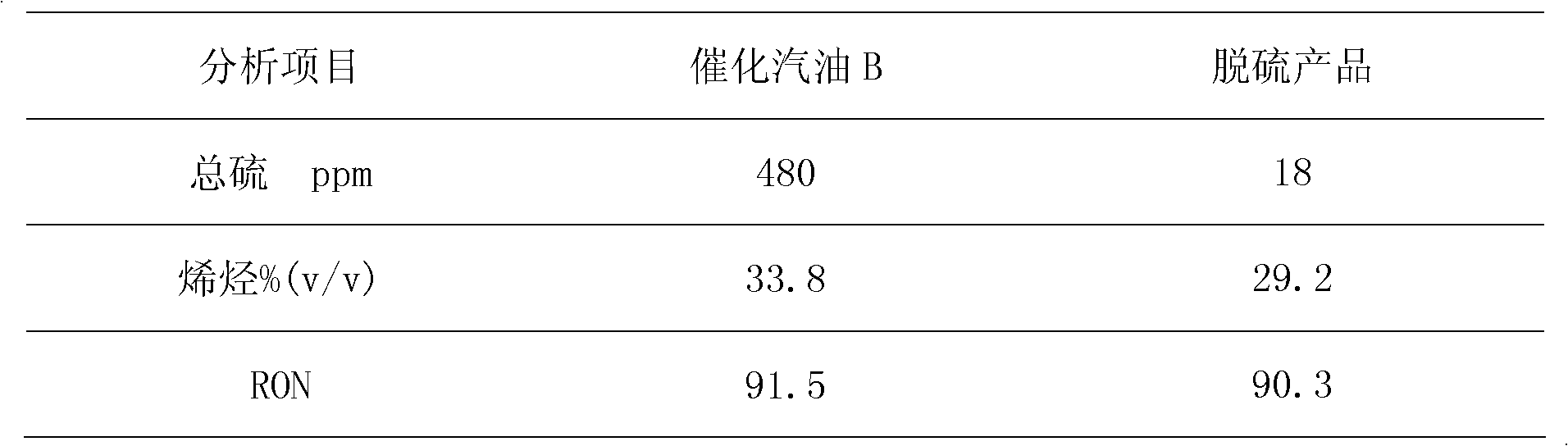

Embodiment 2

[0027] A catalytically cracked gasoline B is used as a raw material, and its properties are shown in Table 2. Catalytic gasoline is first subjected to hydrogenation pretreatment under the conditions of hydrogen partial pressure of 2.4Mpa, temperature of 150°C, space velocity of 4.0, and hydrogen-to-oil ratio of 10:1, then enters the water washing tower to elute alkali nitrogen, and then enters the catalytic distillation tower. Under the action of the olefin thiophene alkylation catalyst in the upper part of the catalytic distillation tower, part of the thiophene sulfides in the gasoline will increase in weight and be divided into three components: light gasoline, heavy gasoline and light diesel oil. The operating conditions of the catalytic distillation tower are: tower top pressure 0.8MPa, feed temperature 145°C, tower top temperature 100°C, tower bottom temperature 210°C. The heavy gasoline from the catalytic distillation tower is mixed with hydrogen and then enters the sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com