Apparatus and method for peeling protective film and method for fabricating stereoscopic image display device

A technology of protective film and peeling roller, which is applied in the direction of chemical instruments and methods, electronic equipment, lamination, etc., can solve the problems of difficult maintenance and management, increase of equipment layout area, etc., and achieve shortening of process time, simplification of process, and process time The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

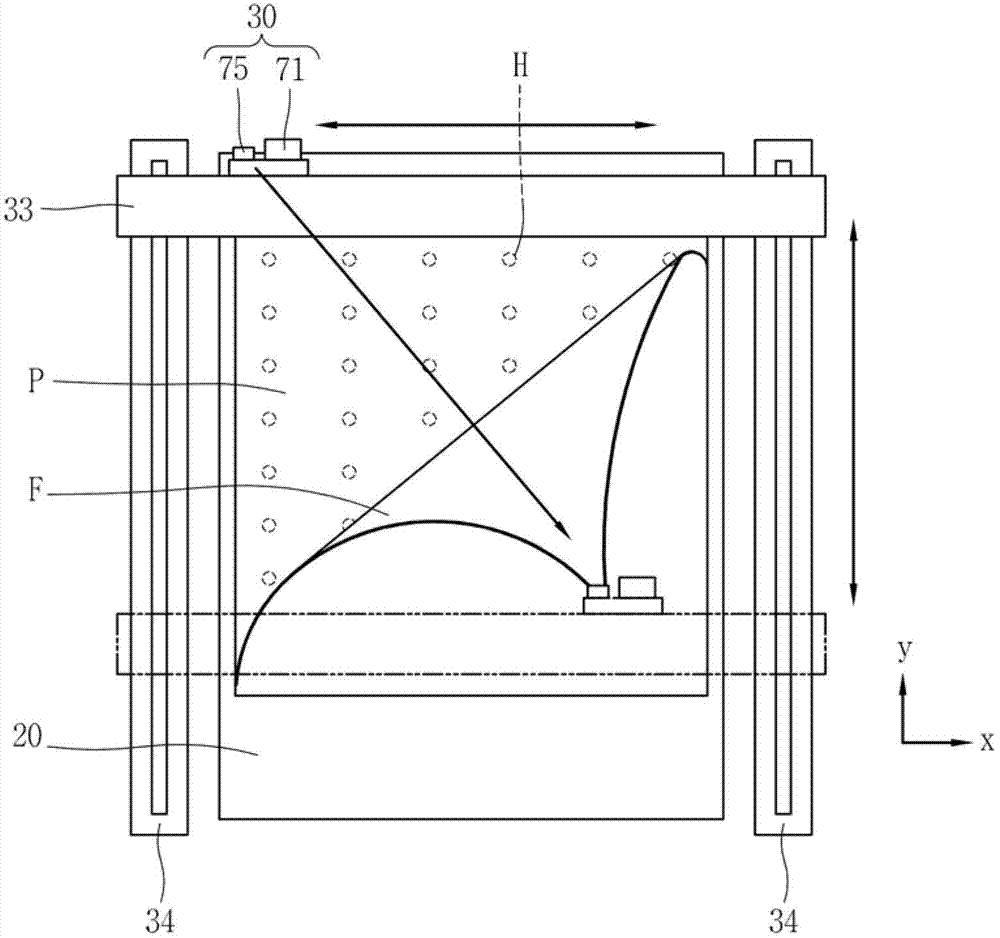

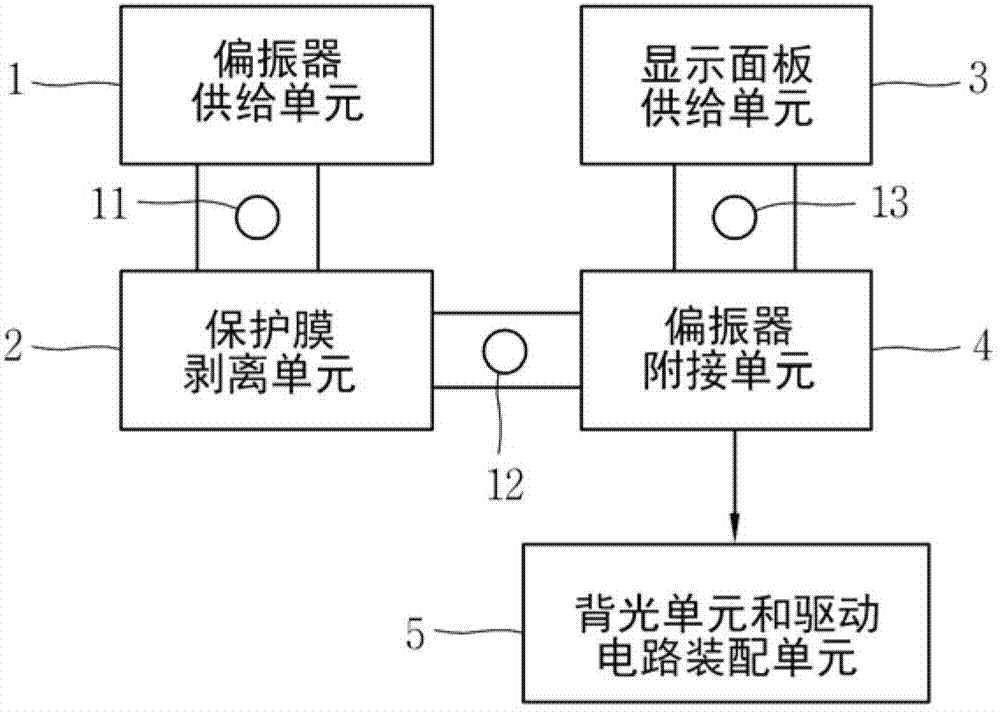

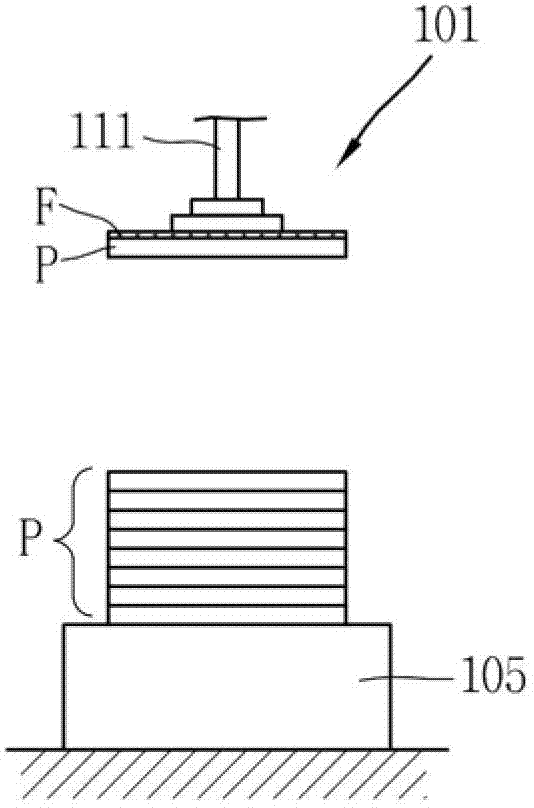

[0040] Hereinafter, an apparatus and method for peeling a protective film and a method of manufacturing a stereoscopic image display device according to embodiments of the present invention will be described in more detail with reference to the accompanying drawings.

[0041] Although the embodiments are different, this specification uses the same or similar reference numerals for the same or similar components, and their descriptions are not repeated.

[0042] Expressions in the singular form in this specification may be interchanged with expressions in the plural form unless clearly indicated in the context.

[0043] In the embodiment of the present invention, the object with the protective film attached on the front surface is a film member, and one aspect of the embodiment of the present invention is to peel the protective film from the film member. Wherein, the film component may be a polarizer that changes the characteristics of light, etc., which will be described below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com