Method of obtaining characteristic parameters of aerobic composting microstructure

A technology of aerobic composting and characterization parameters, applied in the direction of permeability/surface area analysis, measuring devices, instruments, etc., can solve the problems of producing malodorous gas, restricting energy saving, emission reduction, synergistic reaction mechanism engineering technology and equipment, and complex fermentation environment etc., to achieve the effect of reducing hardware requirements, improving feasibility and applicability, and optimizing composting process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

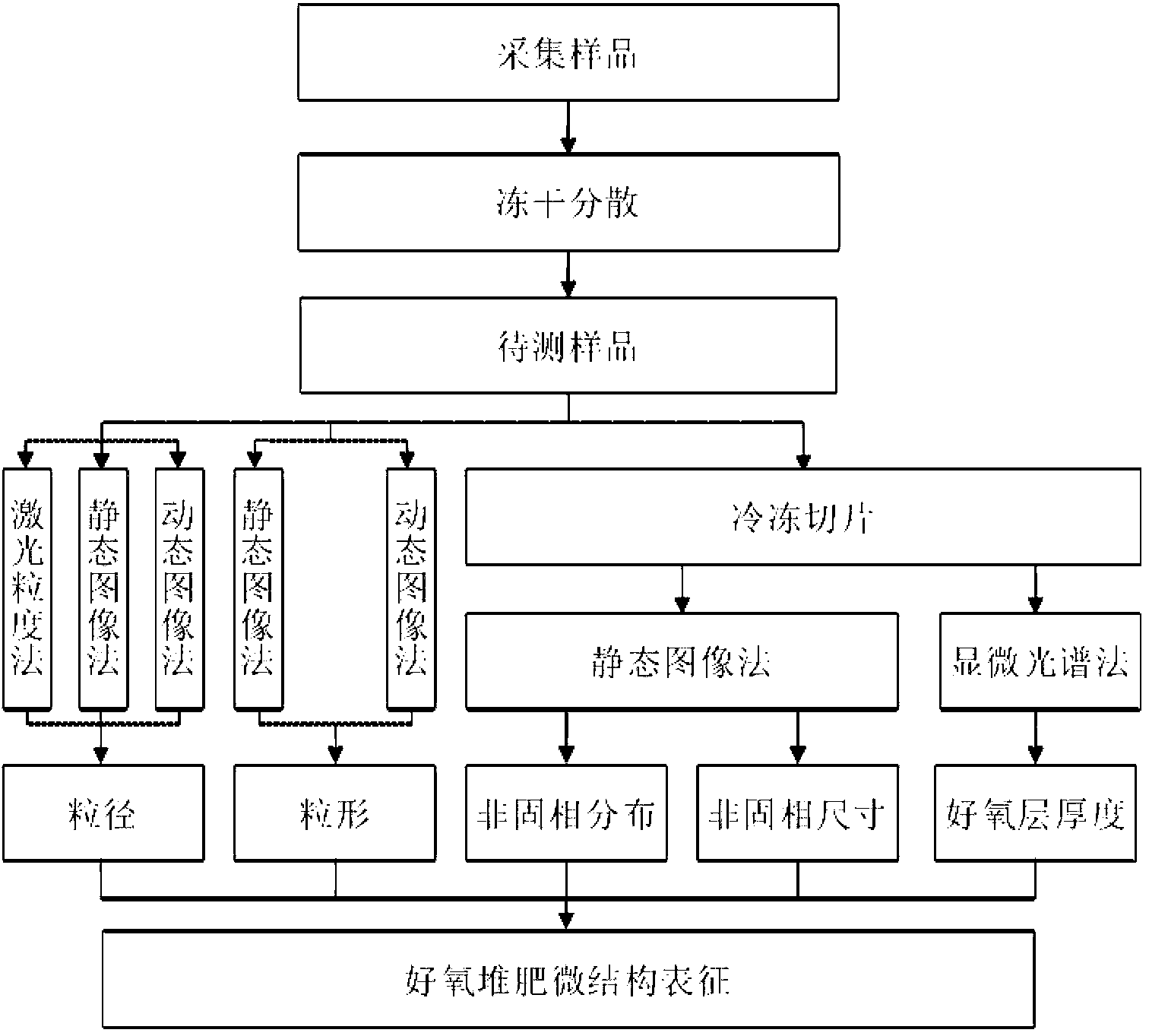

Method used

Image

Examples

Embodiment 1

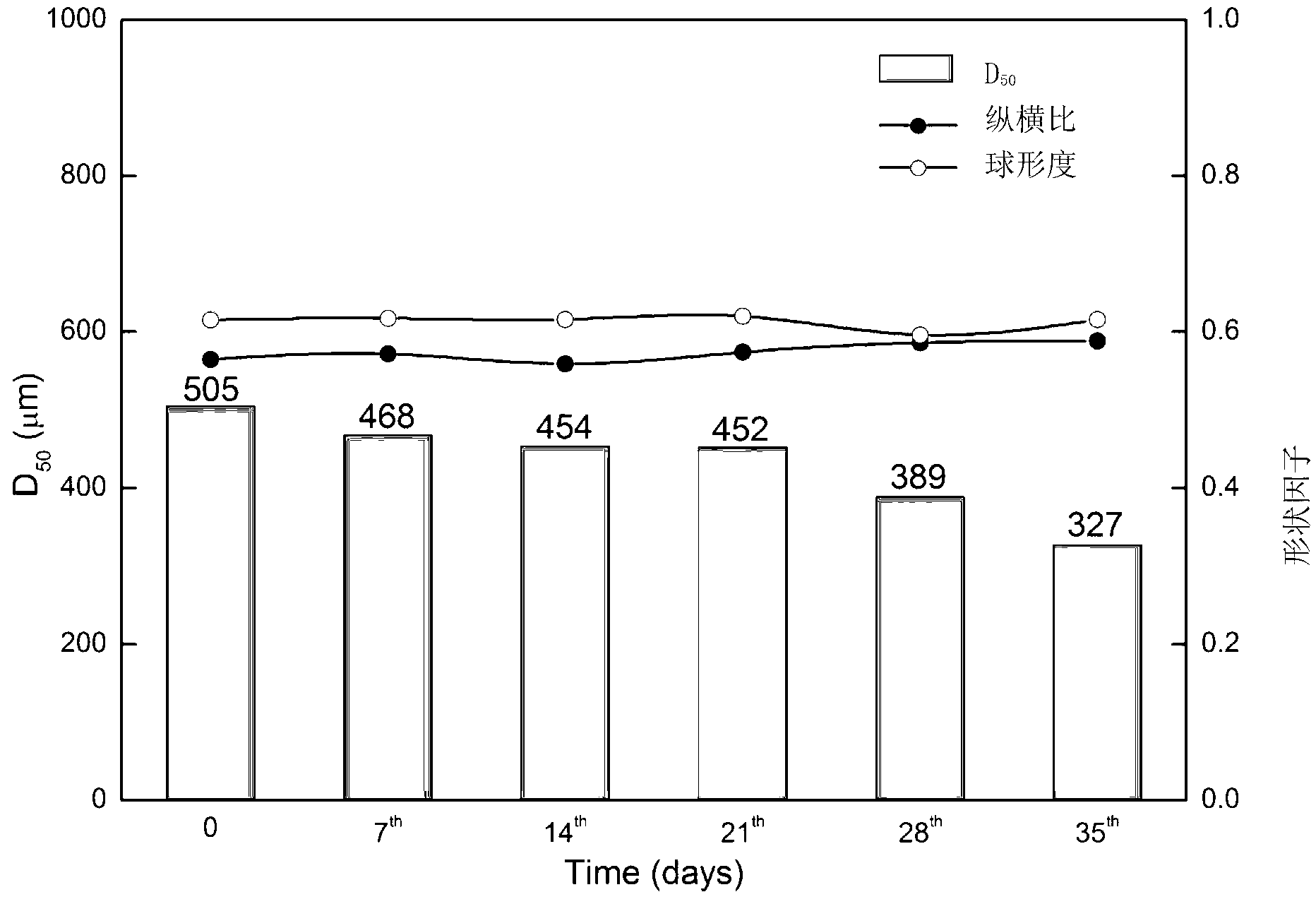

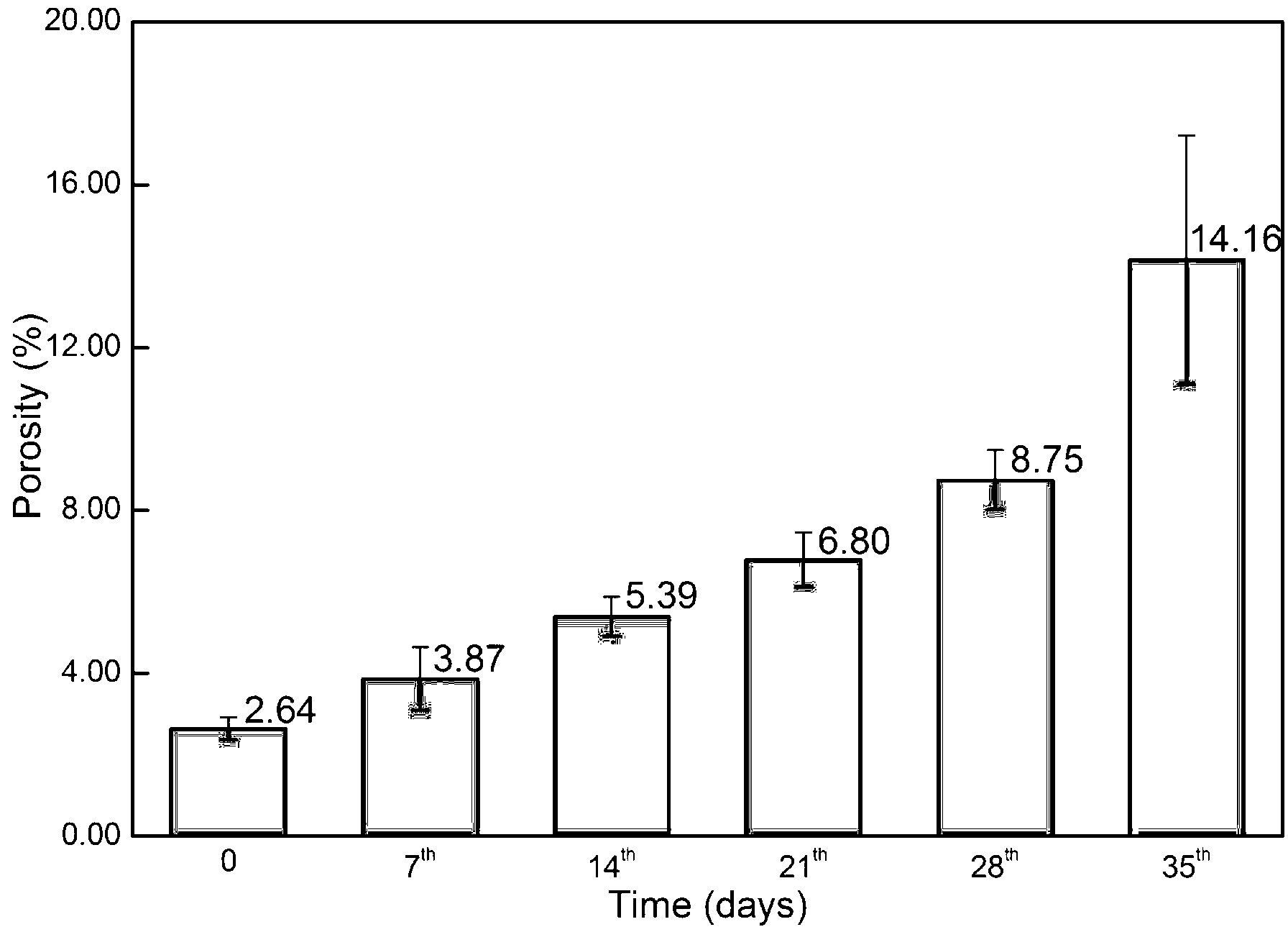

[0048] In this example, pig manure and crop straw were used as compost materials, and aerobic composting reactor system was used for aerobic composting to construct and characterize the microstructure of aerobic composting.

[0049] 1. Mix 8 parts by mass of pig manure and 1 part by mass of wheat straw crushed to less than 3cm, which is the initial mixed material; before composting, take 100g of the initial mixed material for moisture content, organic matter content, total carbon content, and total nitrogen Determination of content and carbon-nitrogen ratio (see Table 1 for the determination method).

[0050] Table 1 Determination method

[0051] Analysis Project

test methods

moisture content

Hot air drying method (70°C, 24h)

Muffle furnace combustion method (540°C, 6h)

total carbon content

Combustion method, determined by elemental analyzer

total nitrogen content

Combustion method, determined by elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com