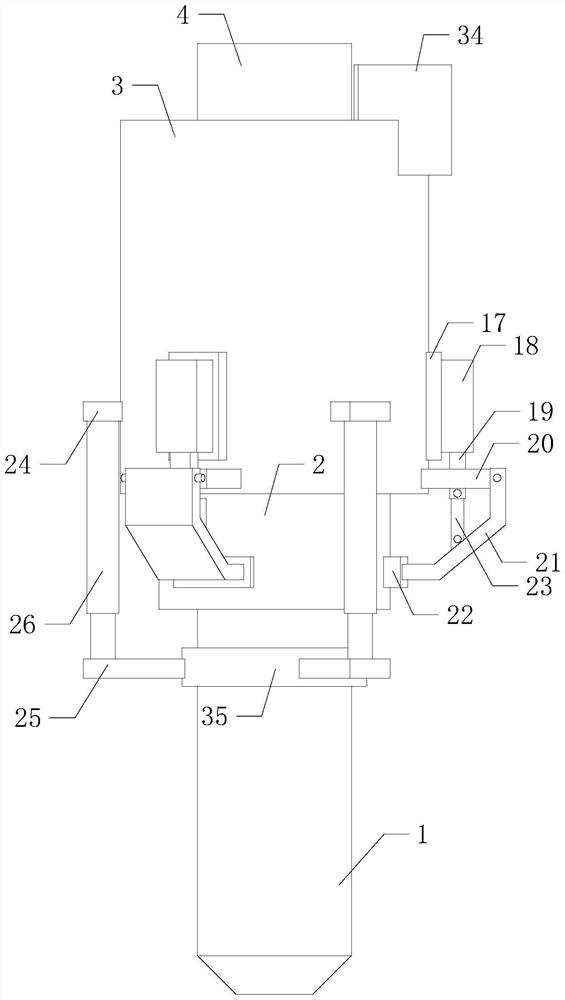

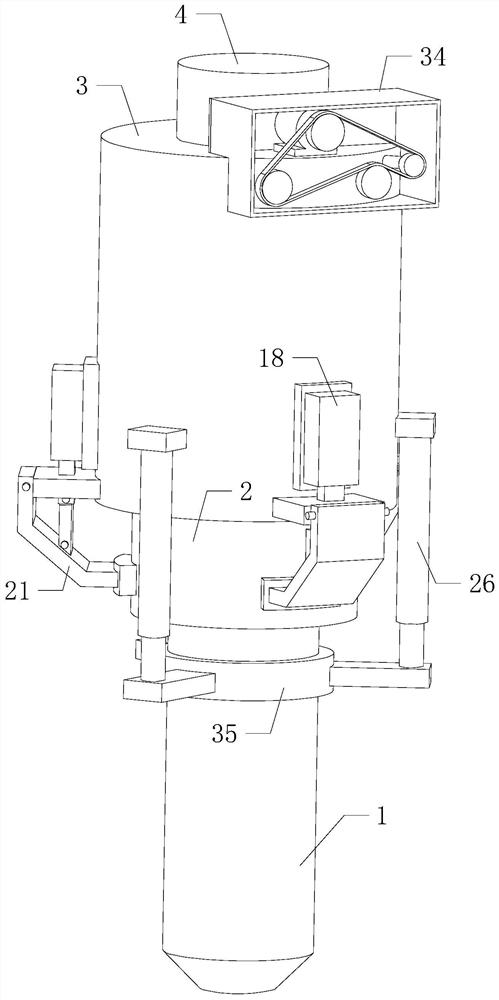

Core roller multi-station device for ring rolling machine

A multi-station, ring rolling machine technology, applied in metal rolling and other directions, can solve the problems of bending deformation damage and low service life of the core roll, and achieve the effects of improving firmness, improving practicability and facilitating adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

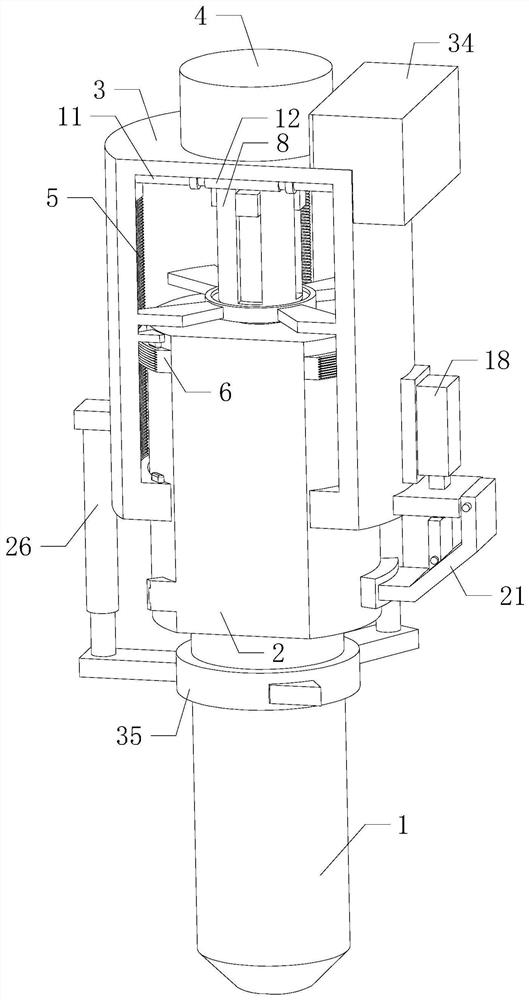

[0021]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0022] Such as Figure 1 to Figure 7 As shown, a core roller multi-station device for a ring rolling machine of the present invention, when it is working, turns on the motor 13, and the motor 13 drives two sets of rotating shafts 11 to rotate through four sets of pulleys 15 and synchronous belts 16, and the supporting shaft 14 The belt pulley 15 mainly carries out circular processing on the synchronous belt 16, and at the same time, the upper side of the outer wall of the pulley 15 on the rear shaft 11 is in contact with the outer wall of the synchronous belt 16, so that the rotation directions of the two groups of shafts 11 are opposite, and the two groups of shafts 11 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com