Slide fastener

A zipper and zipper element technology, applied in the field of zipper, can solve the problems such as inability to insert the cannula 123, inability to insert the cannula 123 fully, and inability to mesh the left and right fastener elements 122.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

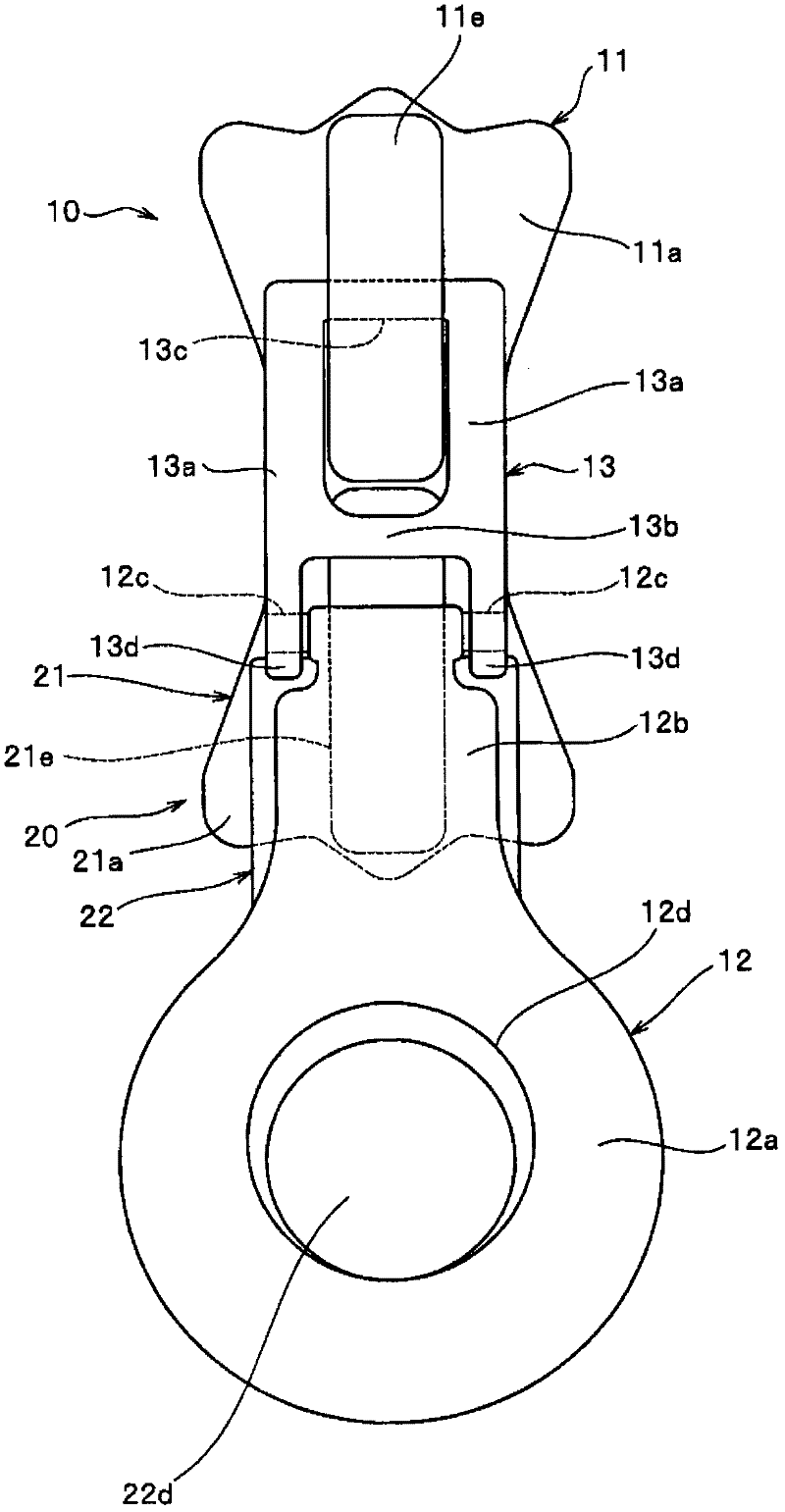

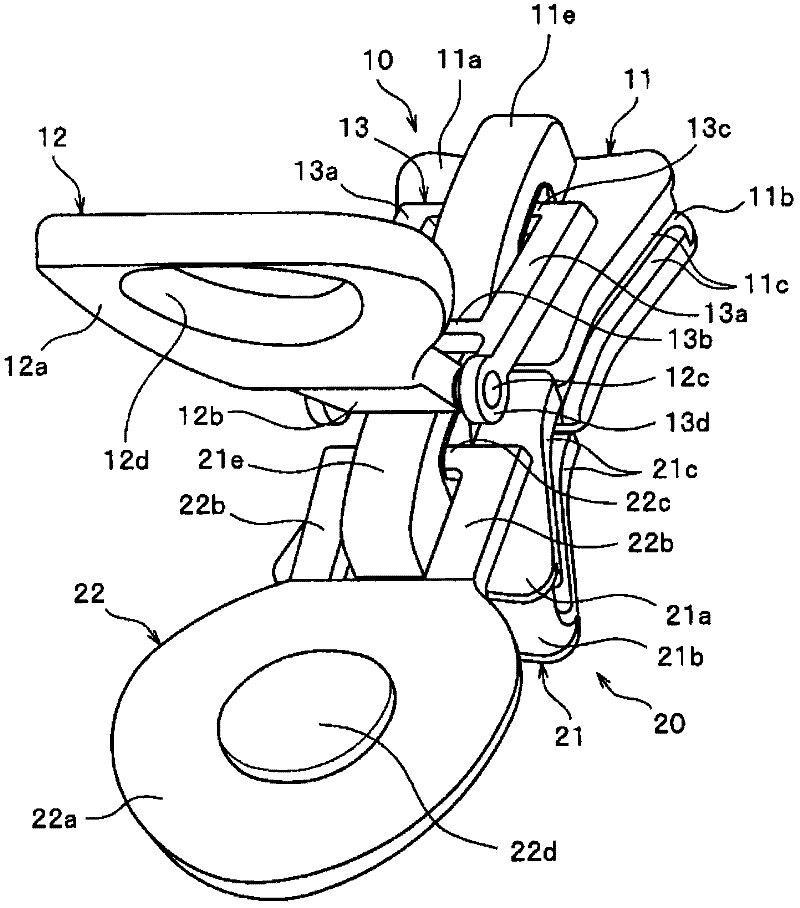

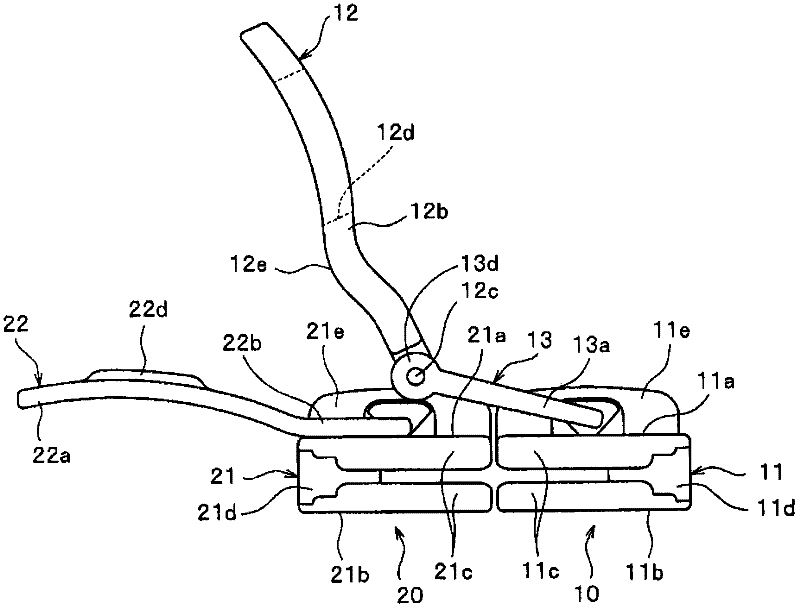

[0146] The slide fastener of Example 1 of this invention is demonstrated. here, figure 1 It is a front view which shows the 1st and 2nd slider in the slide fastener of this Example 1, and the state which handles are engaged. figure 2 It is a perspective view of the first and second sliders in a state where the tab is not engaged, image 3 It is a side view of the first and second sliders in a state where the tab is not engaged.

[0147] in addition, Figure 4 ~ Figure 7 It is a perspective view or a side view of the first and second sliders showing the engaged state of the handle. and, Figure 8 ~ Figure 10 It is a sectional view explaining the operation of inserting the insertion pin into the first and second sliders to mesh the left and right element rows.

[0148] In addition, in the description of the following examples, the tape width direction of the slide fastener in the state where the left and right element rows are engaged is defined as the left-right directio...

Embodiment 2

[0191] Next, the slide fastener according to Example 2 of the present invention will be described. here, Figure 11 to Figure 14 It is a perspective view or a side view which shows the 1st and 2nd slider in the slide fastener of this Example 2, and the state which a handle is engaged.

[0192] The structure of the zipper 41 of the second embodiment is substantially the same as that of the zipper 1 of the first embodiment, except that the second handle 52 of the second slider 50 is connected to the second slider body 51 through the second connecting portion 53. same as above. Therefore, in this Example 2, the parts and members which have the same structure as the slide fastener 1 of the said Example 1 are shown with the same code|symbol, and the description of these parts and members is abbreviate|omitted.

[0193] Furthermore, the referenced in the description of the first embodiment Figure 8 and Figure 9 In the description of the slide fastener of the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com