Curved teeth cylindrical gear, machining method and apparatus thereof

A technology of cylindrical gears and arc teeth, which is applied in the field of gears and its processing, can solve problems such as lack of both sides of arc teeth, poor load-carrying capacity, and uneven meshing of gear pairs, and achieve large meshing overlap, strong load-bearing capacity, and smooth meshing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

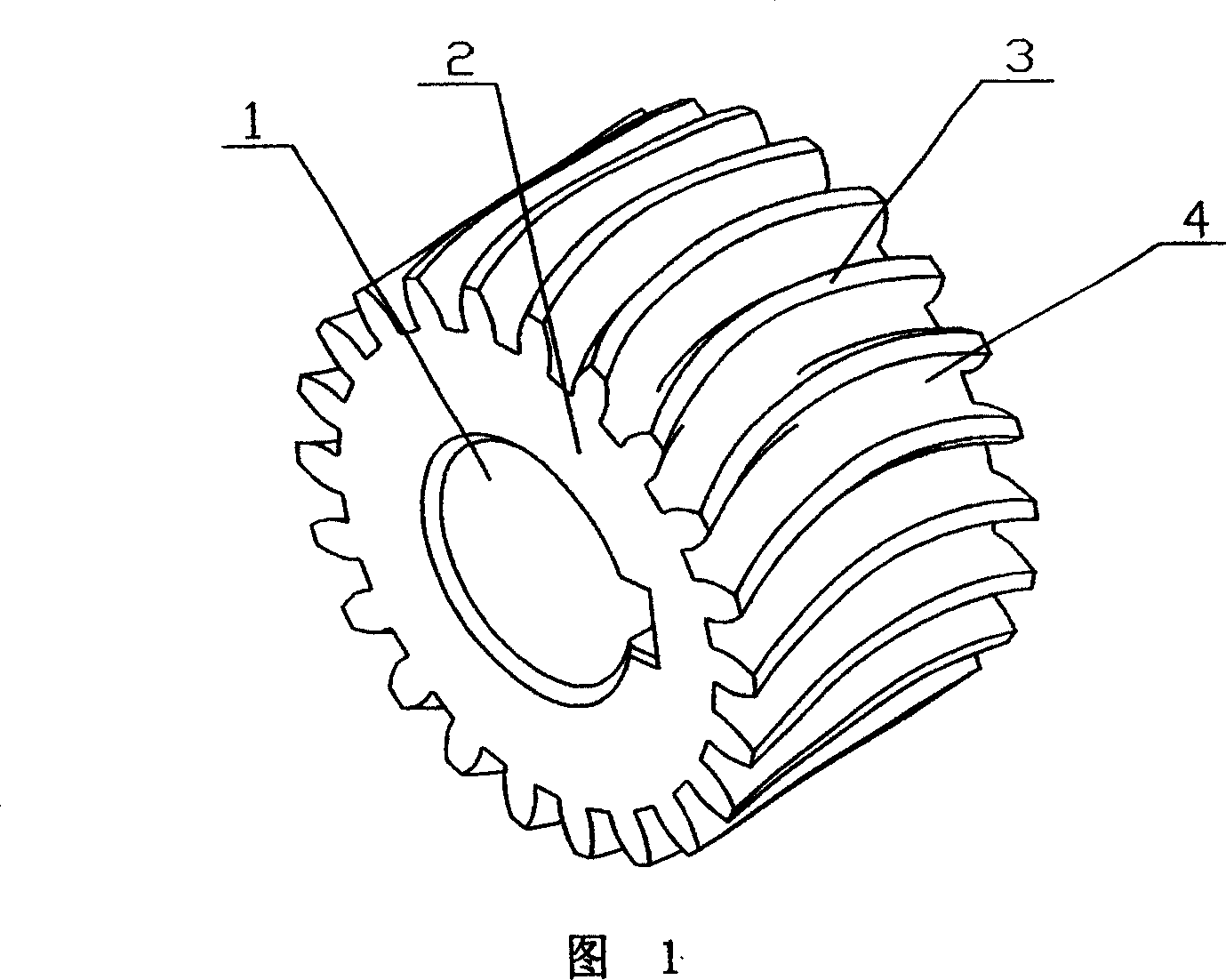

[0024] As shown in Figure 1, the spur gear 2 is a form of a spiral gear. The outer circumference of the gear is provided with a number of teeth 3 whose tooth lines are arcs. The tooth profile of the gear is involute or arc. , The tooth thickness at any position in the circumferential direction of the gear is equal, and the width of each tooth slot 4 in the circumferential direction of the gear is also equal; the tooth line is a symmetrical arc along the middle section of the gear, and the axis of the gear is provided Gear hole 1 for easy installation.

Embodiment 2

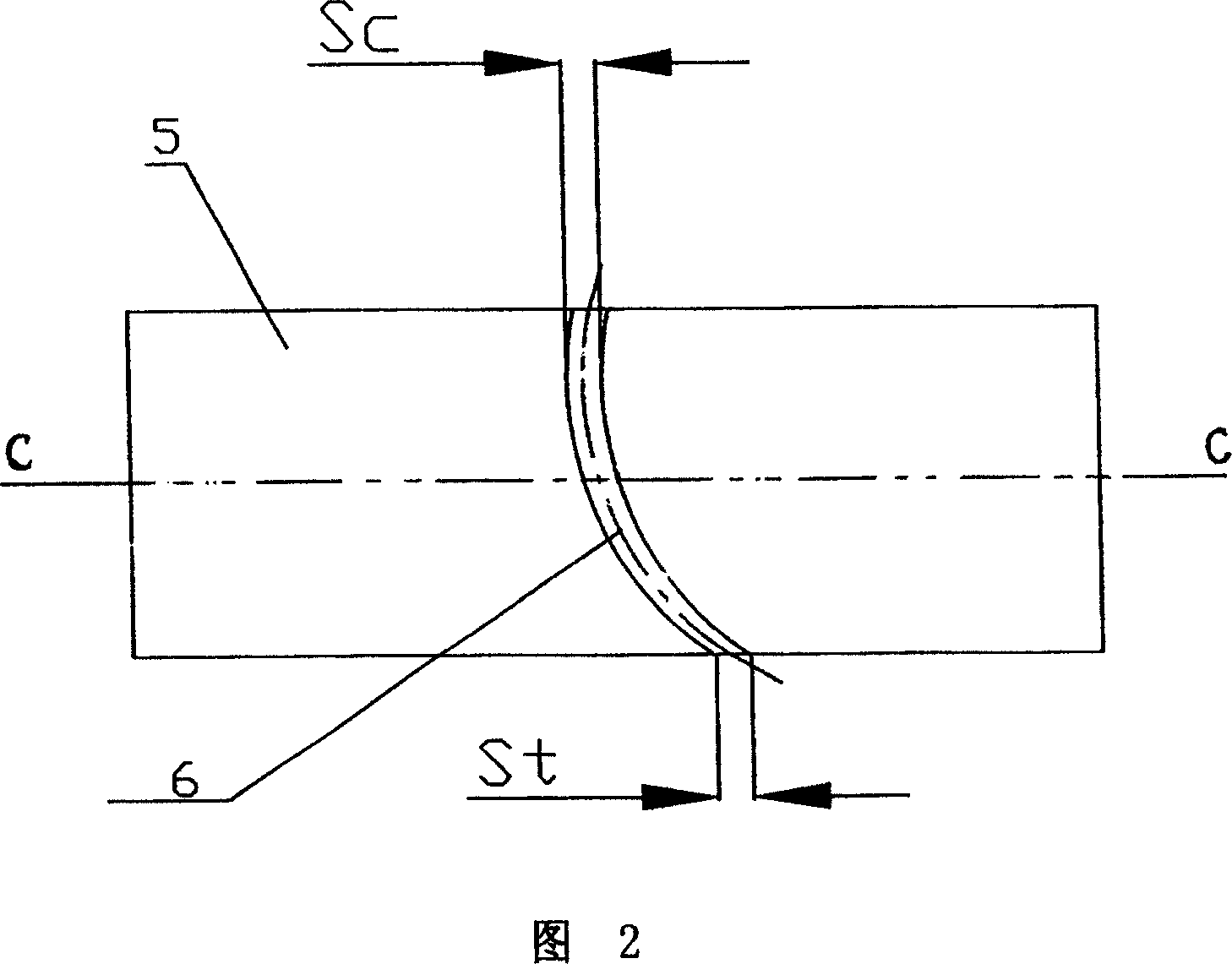

[0026] As shown in Figure 2, the helical arc toothed cylindrical arc gear 5 is also a form of arc toothed cylindrical gear. Its tooth line 6 is a part of the arc, and the tooth profile is an involute or arc, and the tooth thickness is on the circumference of the gear. The thickness is equal in the axial direction, that is, Sc=St, and the tooth line 6 is an asymmetric oblique arc along the middle section CC of the gear.

Embodiment 3

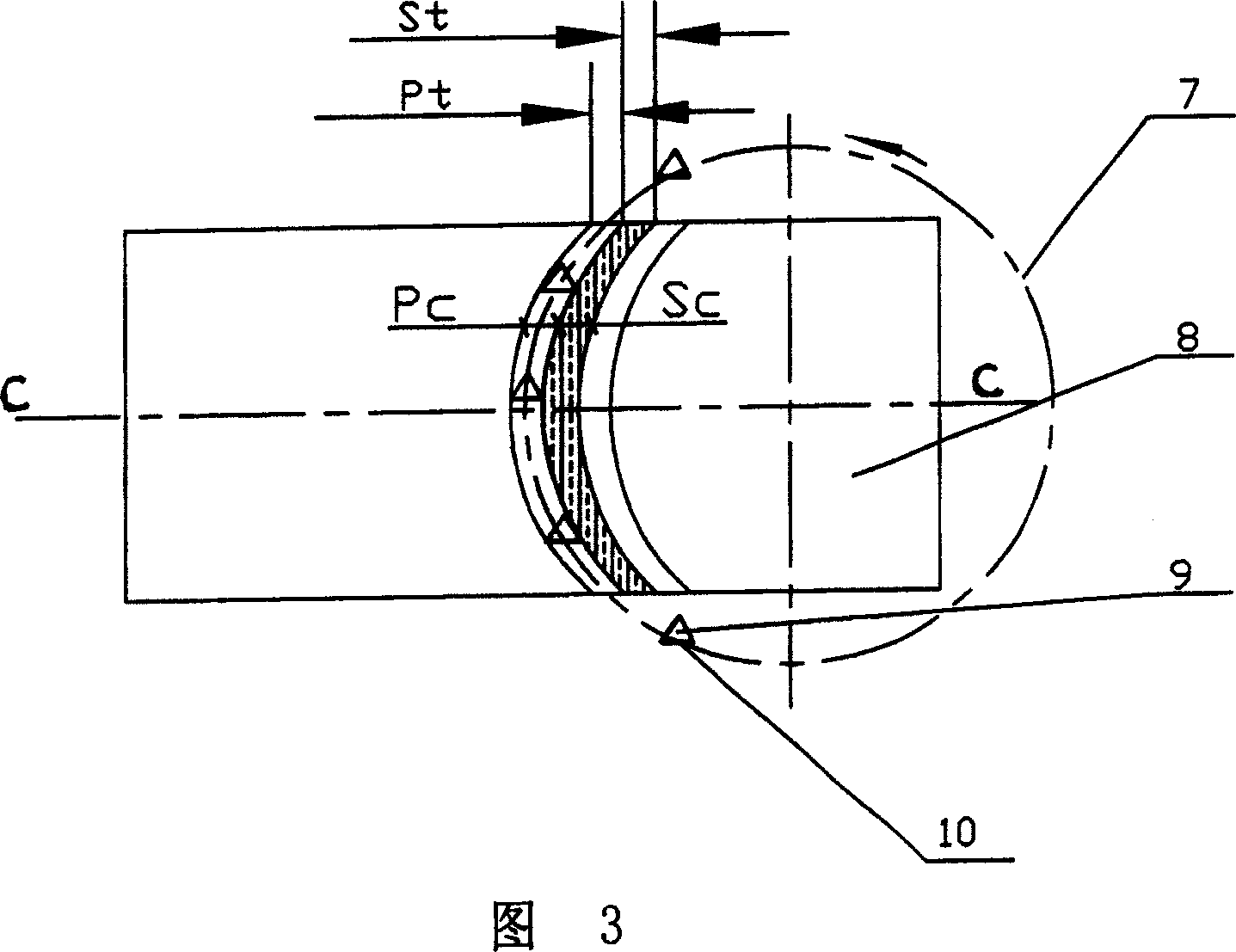

[0028] As shown in Figure 3, for a cylindrical gear with equal tooth thickness in the circumferential direction, the wheel blank is cut by a rotary blade during processing. The radius of gyration of the blade is equal to the arc radius of the tooth line, but the blade does not rotate with it, that is, the blade The normal direction of the working base surface remains unchanged. The spiral cylindrical gear processed by this processing method has the same circumferential groove width, that is, Pt and Pc are equal; so the circumferential tooth thickness St and Sc between the two tooth grooves are also equal. The specific production method may include the following steps:

[0029] (1) Fix the wheel blank 8 so that the wheel blank 8 moves in a circle along the axis of the wheel blank, and adjust the distance from the center of the wheel blank to the tool post according to the index circle radius of the wheel blank;

[0030] (2) Fix the tooth-shaped blade on the tool holder so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com