Gear noise preventing system for manual transmission

A manual transmission, noise prevention technology, applied in the direction of belt/chain/gear, elements with teeth, transmission control, etc. The effect of preventing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

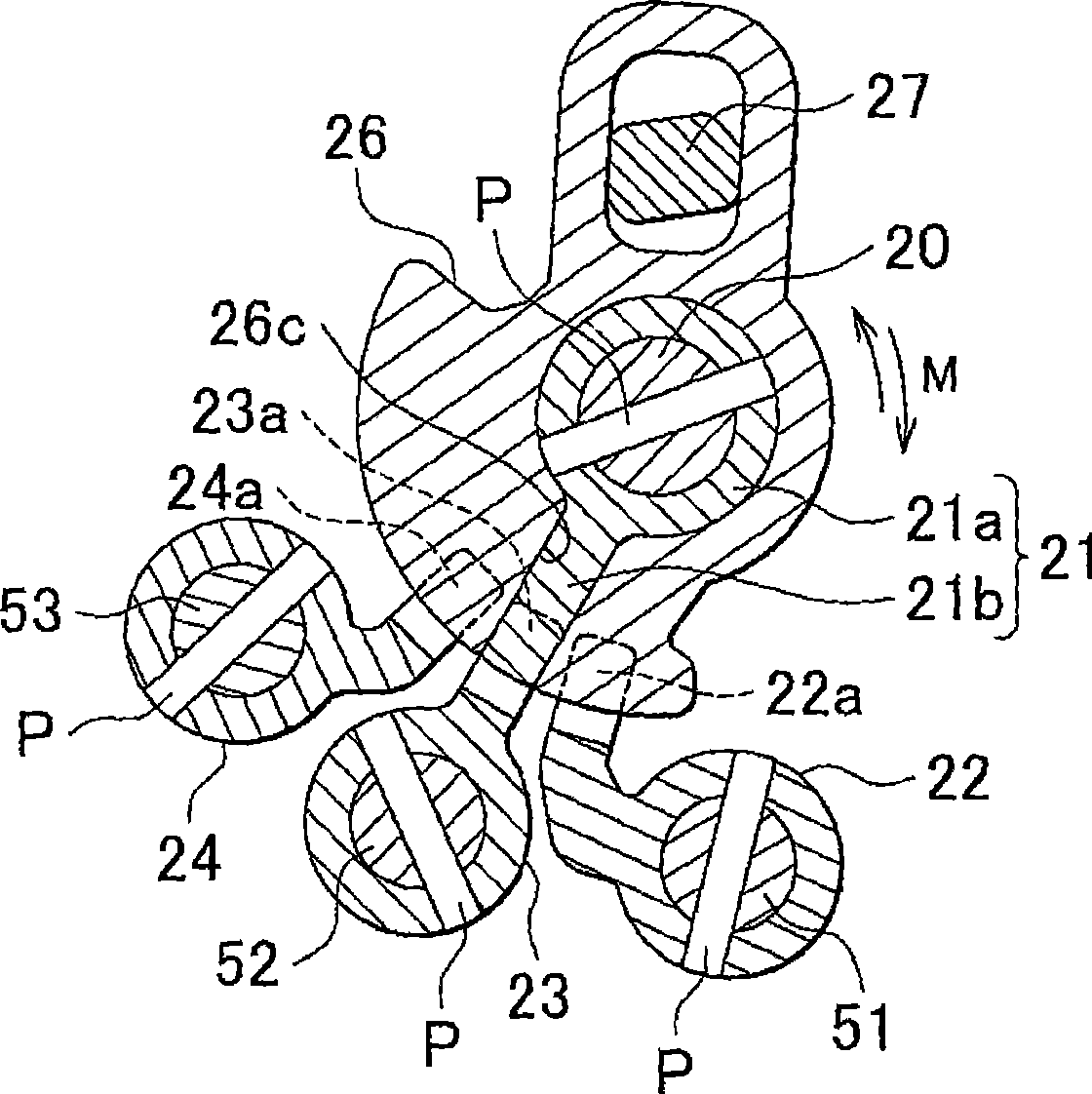

Embodiment Construction

[0042] Referring to the accompanying drawings, exemplary embodiments of the present invention will be described in detail below.

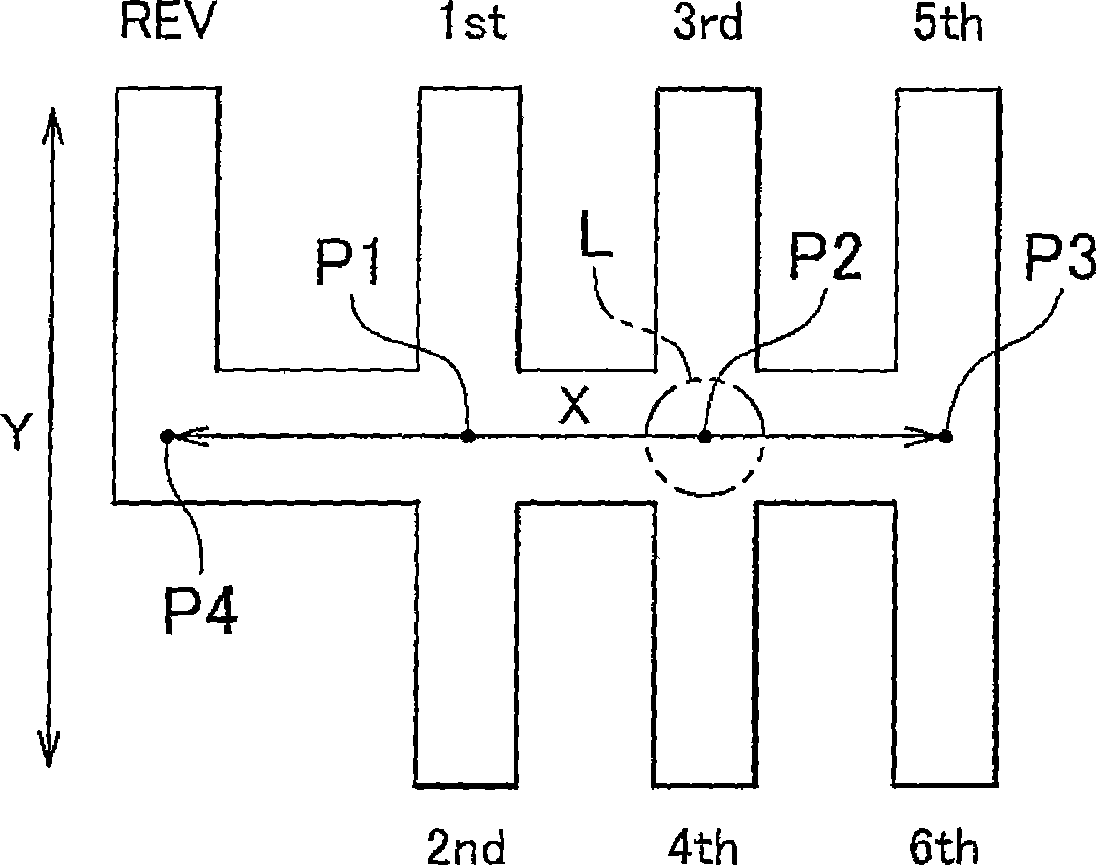

[0043] In an embodiment, the present invention is applied to a synchromesh manual transmission having six forward gears and one reverse gear, which is installed in a front-engine front-drive (FF) vehicle.

[0044] Gear arrangement of manual transmission

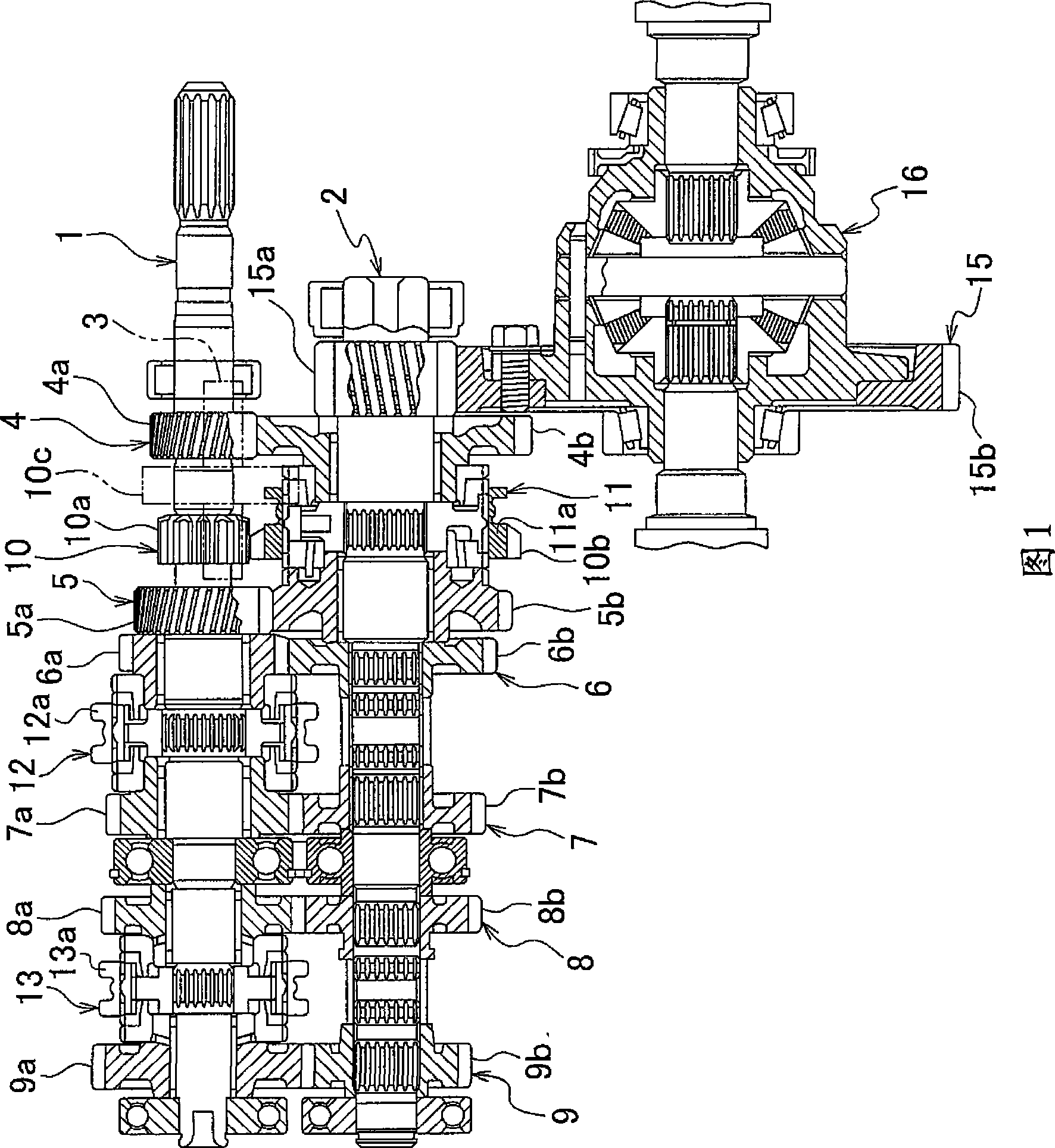

[0045] FIG. 1 is a side view showing a section of a part of a gear arrangement of a manual transmission according to an embodiment of the present invention. As shown in the gear arrangement in Fig. 1, the input shaft 1, the output shaft 2 and the reverse shaft 3 (marked with a two-dot chain line in Fig. 1) are accommodated in a gearbox (not shown) and arranged parallel to each other , rotatably supported by the gearbox.

[0046] The input shaft 1 is connected to a crankshaft (not shown) of the engine via a clutch mechanism. When the clutch mechanism is engaged, rotational driving force from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com