Magnetically-controlled side pressing type screw rod and spring clutch

A spring clutch and clutch technology, applied in clutches, mechanical drive clutches, belts/chains/gears, etc., can solve problems such as inability to achieve high transmission efficiency of gear transmission, difficulty in miniaturizing clutches, and large magnetic attraction of semi-circular barrel magnetic tiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

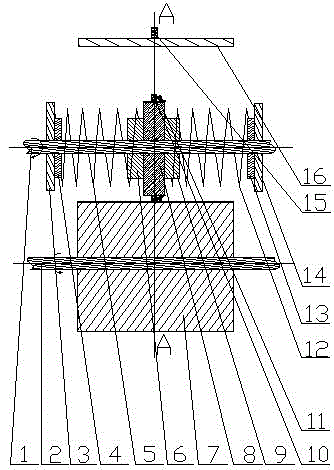

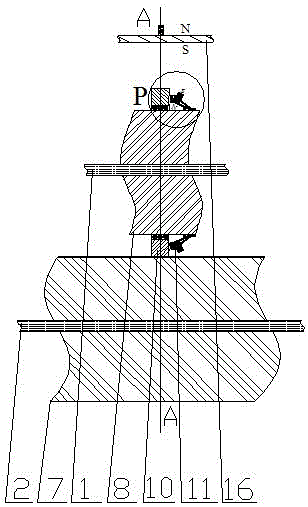

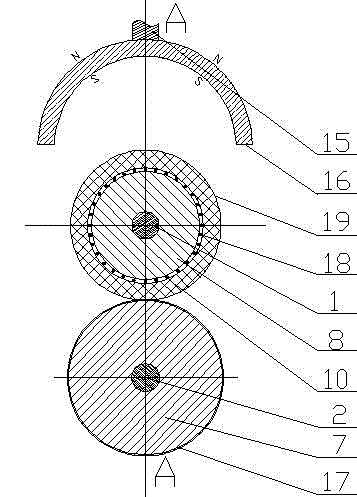

[0021] exist Figure 1-7 In the shown embodiment: the magnetically controlled side pressure screw spring clutch includes a driven shaft 1 with external thread and a driven shaft wheel 8 screwed on the driven shaft 1, and the outer circumference center of the driven shaft wheel 8 has a Passive live wheel 10, a plurality of clutch arm wheels 11 are symmetrically installed on the passive shaft wheel 8 outer circumference of the passive live wheel 10 side, and left auxiliary wheel 6, left buffer wheel 4, left retaining wheel are arranged on the left side of driven shaft wheel 8 3 and left spring 5, there are right auxiliary wheel 9, right buffer wheel 13, right retaining wheel 14 and right spring 12 on the right side of passive shaft wheel 8, and a semicircle magnetic tile 16 is installed on passive live wheel 10 away from driving wheel 7 one side ; It is characterized in that: there is an internal thread in the center hole of the driven shaft wheel 8, and the internal thread of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com