Binding machine

A binding machine and compression mechanism technology, applied in the field of binding machines, can solve problems such as dislocation of joints, hooking of cut pieces, and large thickness dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0064] A first embodiment of the invention will be described below with reference to the drawings.

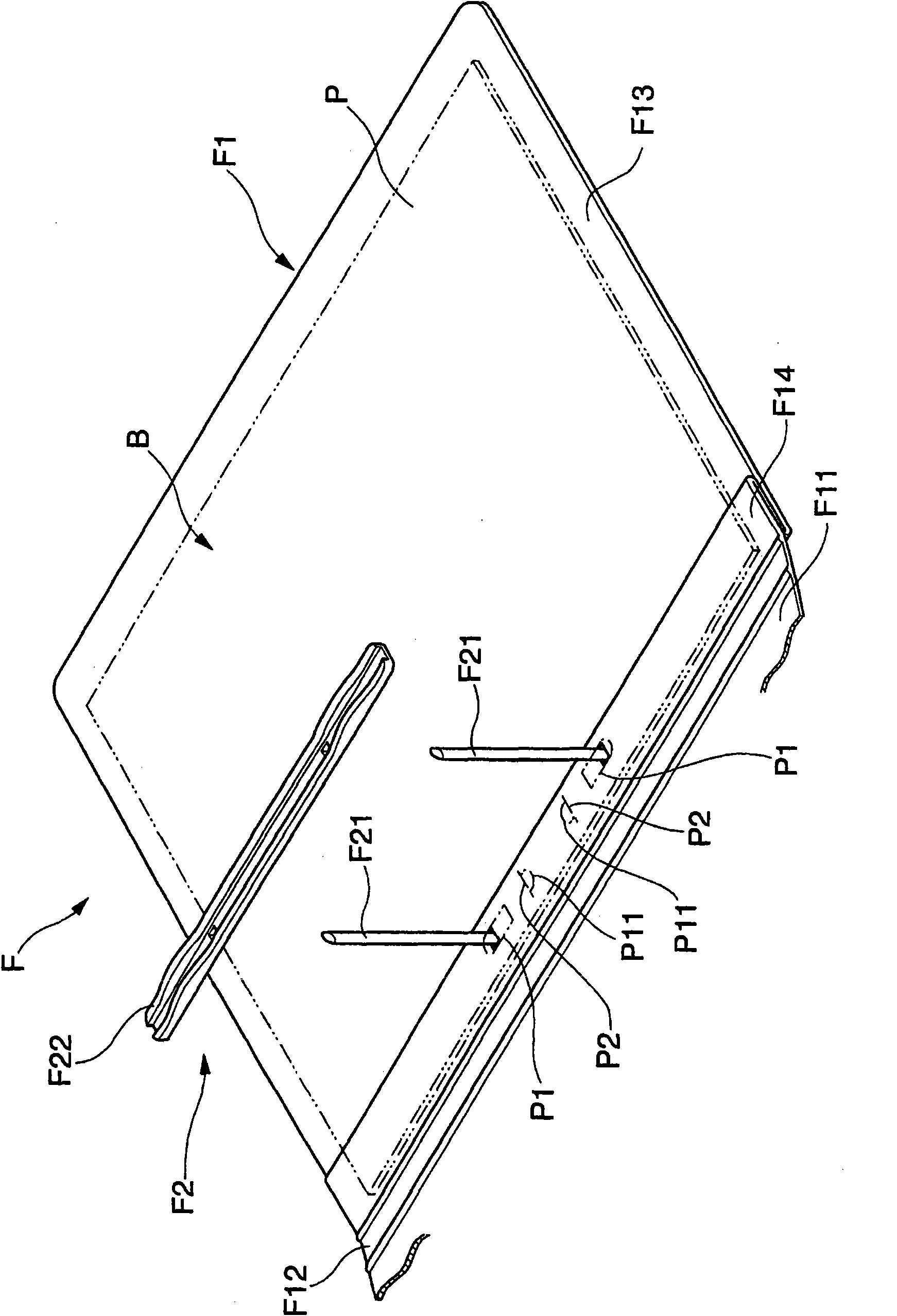

[0065] The binding machine 1 that this embodiment relates to, as Figure 1 to Figure 3 As shown, it can be suitably applied to the folder system of the booklet B in which one or more volumes are bound by the folder F. FIG.

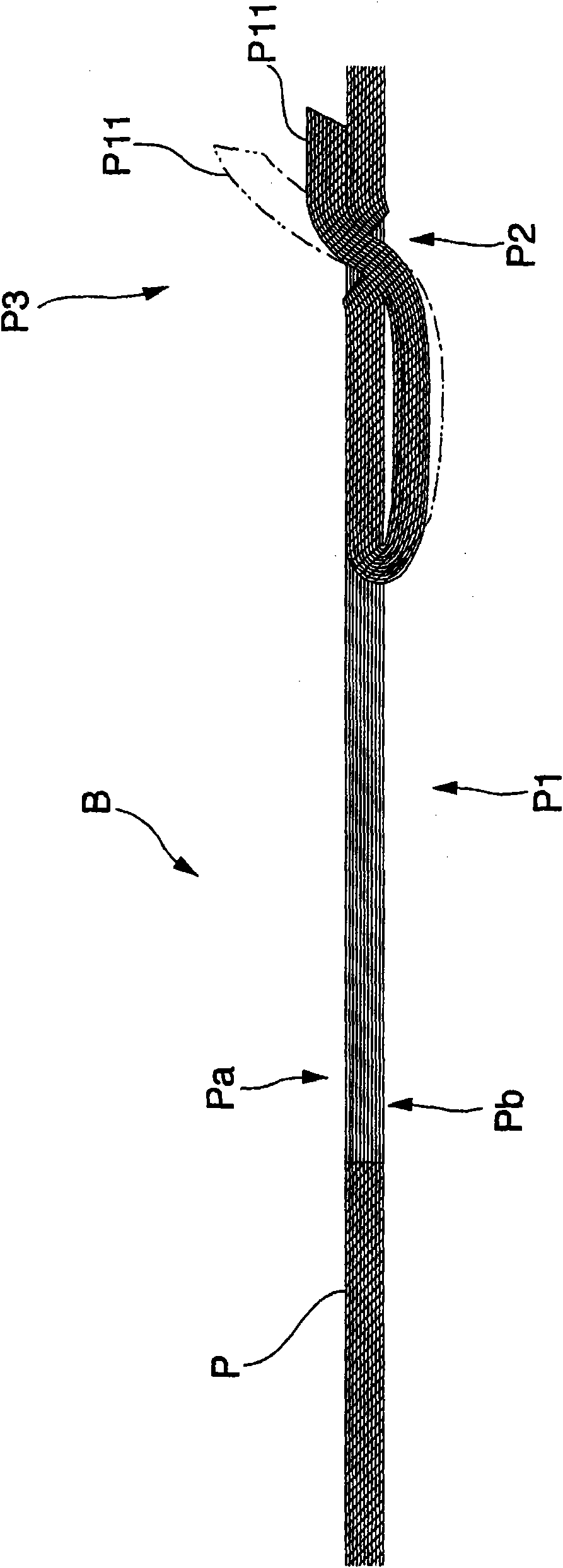

[0066] Such as figure 1 with figure 2 As shown, the booklet B is formed by bundling a plurality of sheets made of homogeneous materials, for example, a plurality of sheets P, and these sheets P are joined to each other at two joining portions P3 set on the binding side. Each joint portion P3 is composed of: a binding hole P1 formed on each paper P by a punching blade 92 penetrating from the side Pa of the paper P; a pull-up cutting hole P2 adjacent to the binding hole P1 and Formed on each of the above-mentioned paper sheets P; the cut-out piece P11 is cut from the above-mentioned binding hole P1 toward the reverse side Pb of the paper sheet P. Then, b...

no. 2 approach

[0113] Next, refer to Figure 21 to Figure 37 The binding machine A1 that is directly used for implementing such a file system will be described.

[0114] This bookbinding machine A1 is a device for joining a plurality of sheets of paper P as sheets to produce the above-mentioned booklet B, such as Figure 21 As shown, it is equipped with: a stage A2 placed on the table; a main body A3 fixedly arranged on the stage A2; ユニツト), which can be lifted and accommodated in the main body A3 and equipped with a punching blade A92 and a cutting blade A91 described later; a paper holder A8 (paper base, paper tape reel seat), which ends the perforation at the blade changing unit A4 When moving up, it is used to lift the above-mentioned bound paper P; the operating handle A5 is installed on the above-mentioned main body A3 so as to be rotatable up and down in order to make the paper holder A8 and the blade changing unit A4 move.

[0115] Such as Figure 21 , Figure 25 with Figure 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com