Method for producing mono-cell

A manufacturing method and single-cell technology, which is applied in secondary battery manufacturing, secondary batteries, lithium batteries, etc., can solve problems such as ceramic layer peeling, and achieve the effect of inhibiting peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

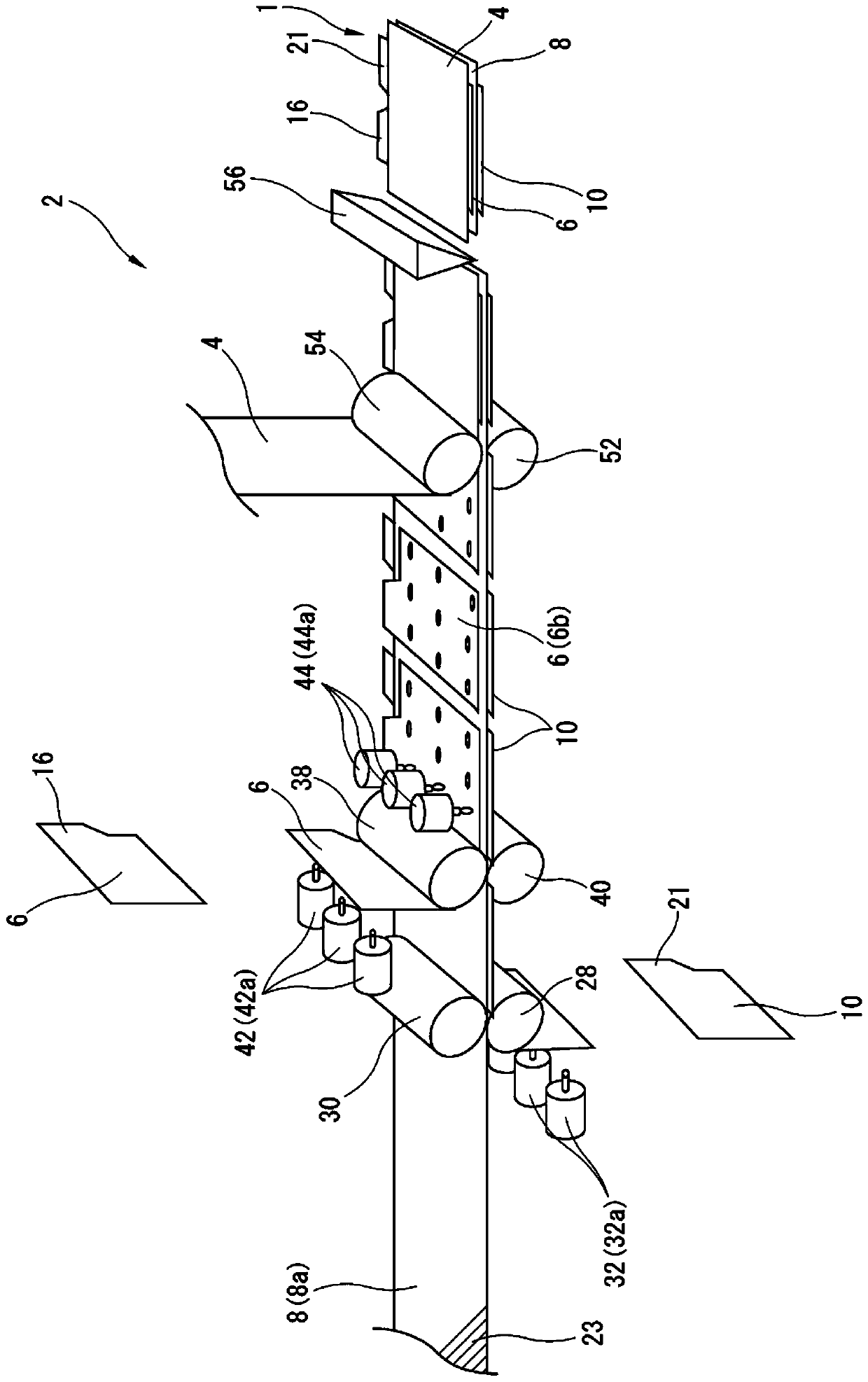

[0015] Hereinafter, an embodiment of the present invention will be described in detail based on the drawings.

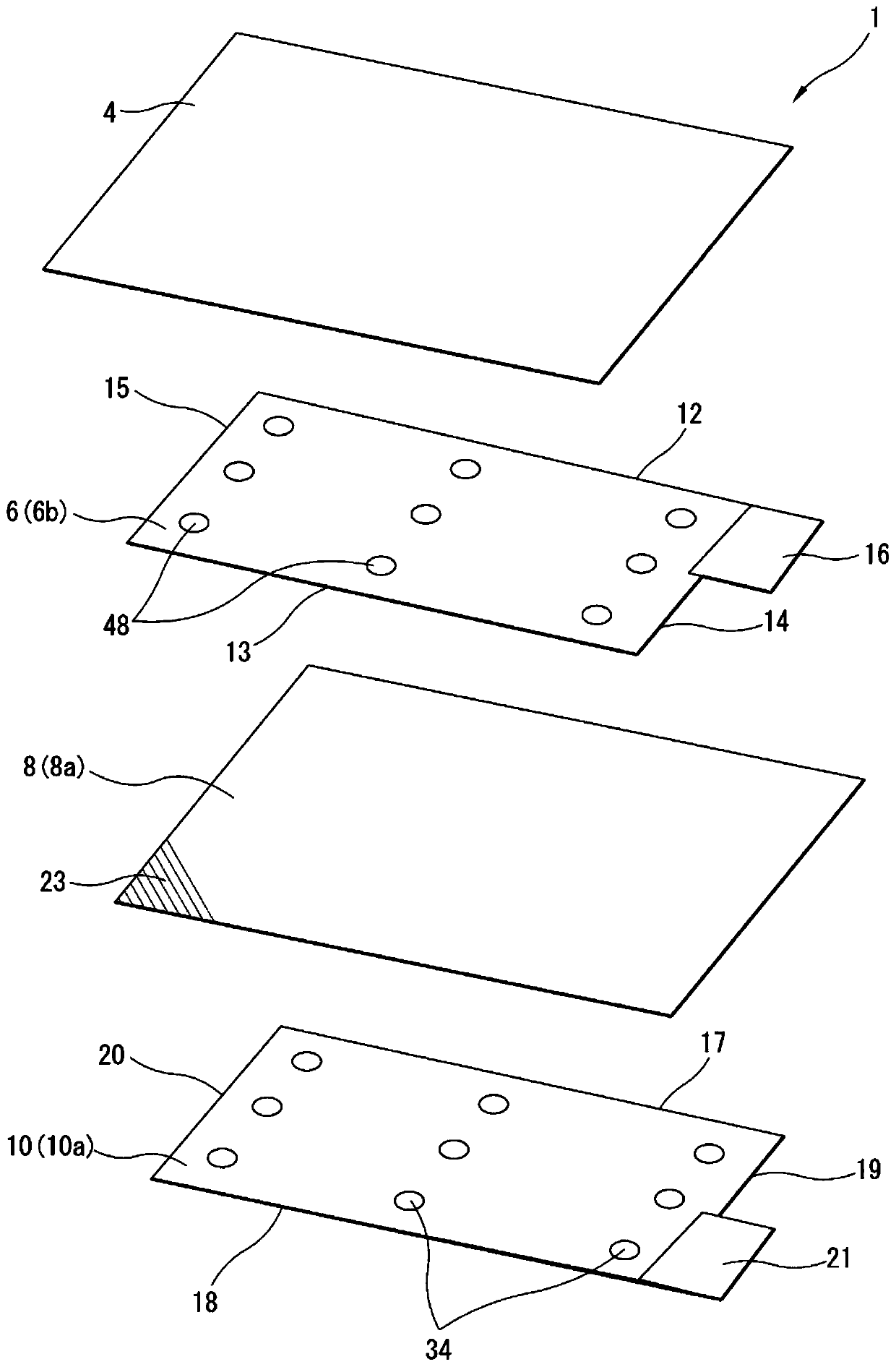

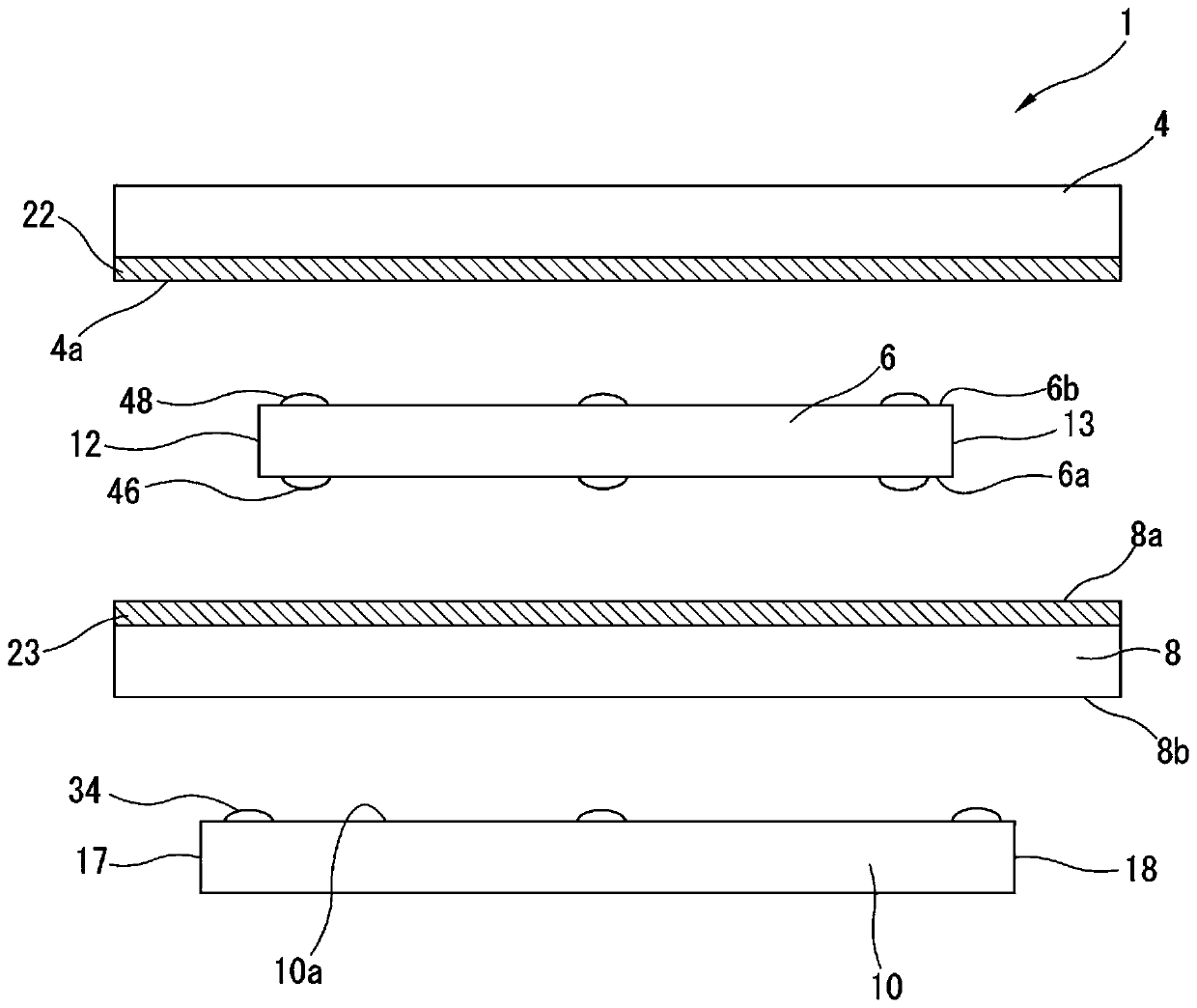

[0016] figure 1 schematically shows an electrode stacking device 2 for continuously manufacturing single cells 1 as a basic stack, figure 2 and image 3 A single cell 1 manufactured by the electrode lamination device 2 is schematically shown. Here, in the following description, for the sake of easy understanding, the single cell 1 and the electrode stacking device 2 are represented as Figure 1 ~ Figure 3 The posture of the body is called "up and down" as a reference.

[0017] Such as figure 2 and image 3 As shown, in the present embodiment, for the unit cell 1, a photo-shaped separator 4, a sheet-shaped positive electrode 6 as an electrode, a sheet-shaped separator 8, and a sheet-shaped negative electrode as an electrode are arranged from the top. 10 layers are stacked in order and joined to each other to form a 4-layer structure integrally.

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com