Eccentric swing type speed reducer

A deceleration device, eccentric swing technology, applied in the direction of transmission, gear transmission, transmission parts, etc., to achieve the effect of inhibiting peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, an example of the embodiment of the present invention will be described. The same symbols are assigned to the same constituent elements and repeated explanations are omitted. In each drawing, for convenience of description, some components are appropriately omitted, or their dimensions are appropriately enlarged or reduced. Regarding the drawings, view them in conjunction with the orientation of the symbols.

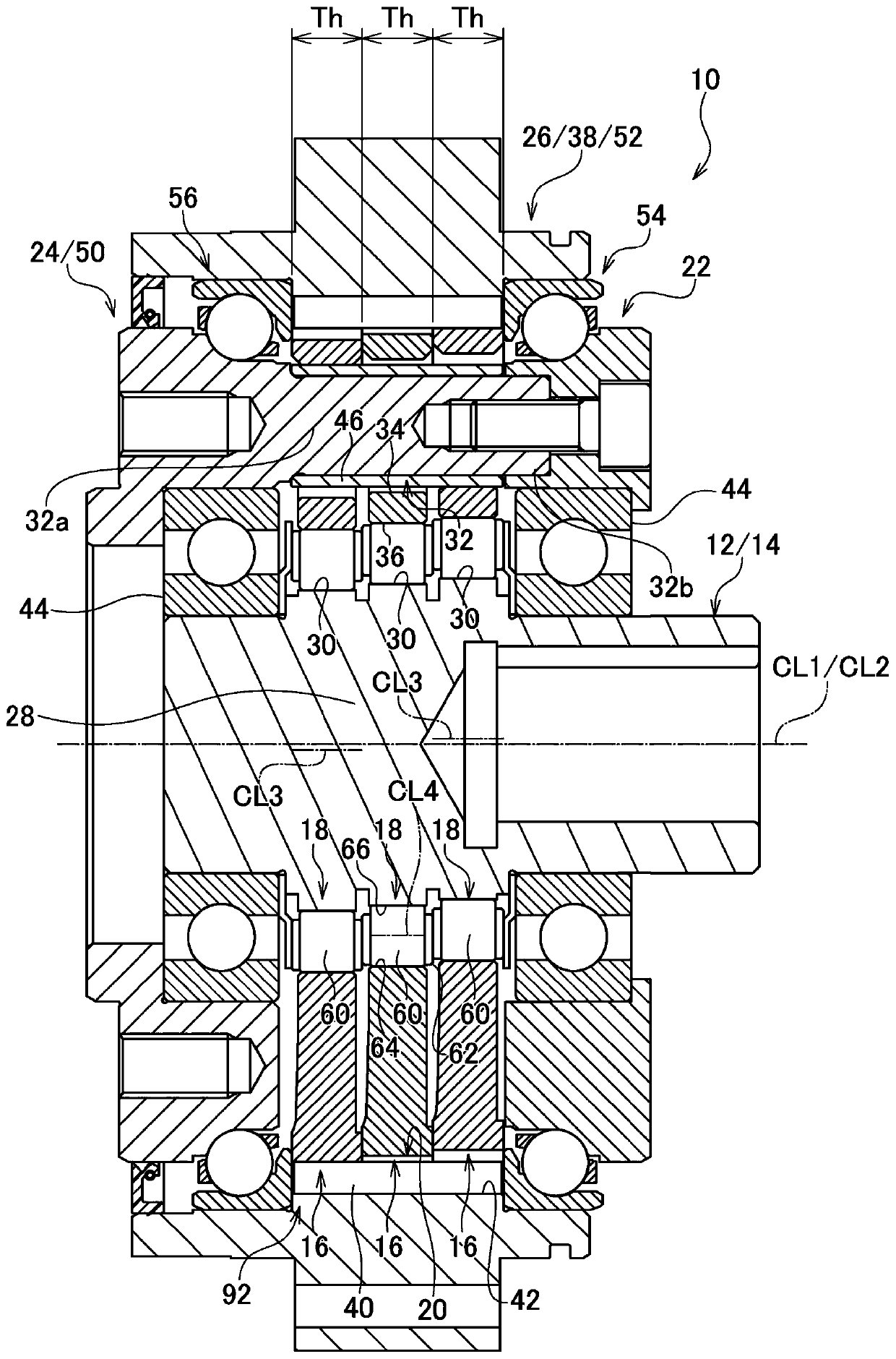

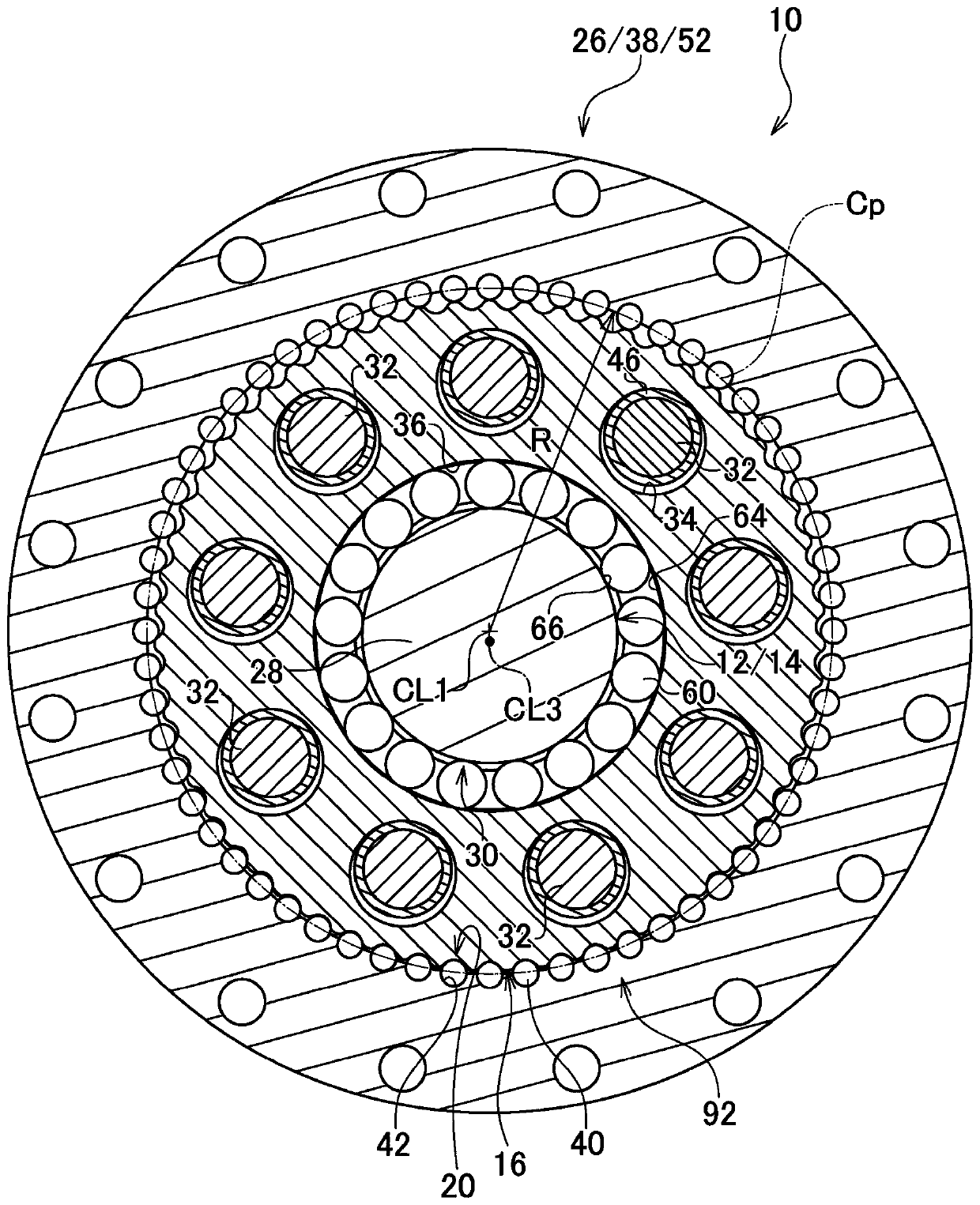

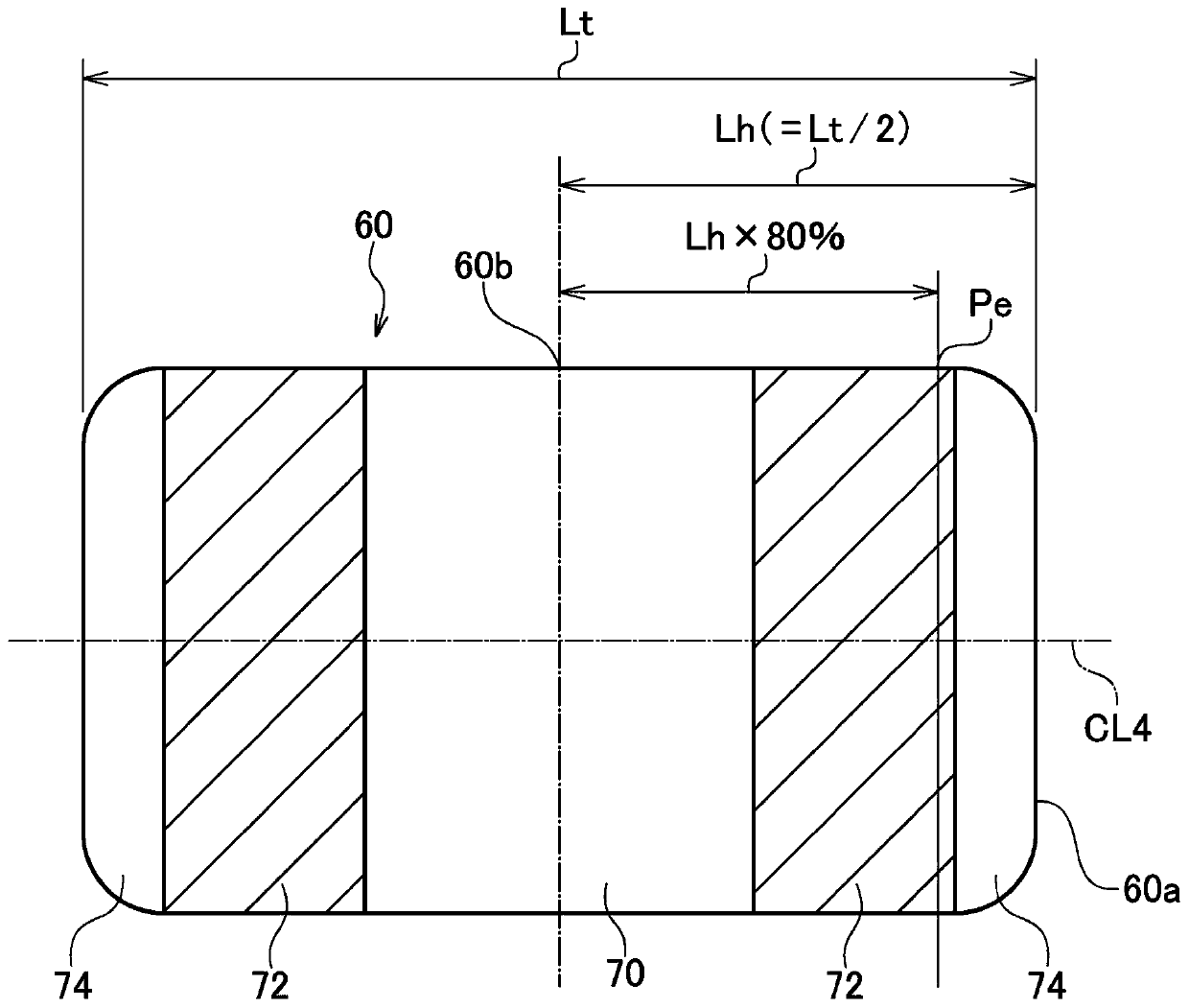

[0018] figure 1 It is a side sectional view of the reduction gear transmission 10 according to the embodiment, figure 2 Its front section view. figure 2 shows the rotational phase of the external gear 16 and figure 1 different diagrams. The speed reduction device 10 is an eccentric oscillating type speed reduction device in which one of the internal gear 20 and the external gear 16 is rotated by itself by swinging the external gear 16 meshing with the internal gear 20 , and output from the output member 50 to the driven device. The resulting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com