Method of manufacturing tire ply material

A manufacturing method and technology for tire cords, which are used in tires, applications, household appliances, etc., can solve the problems of not easy to high-quality tire cord material c, and it is difficult to fully ensure joint strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

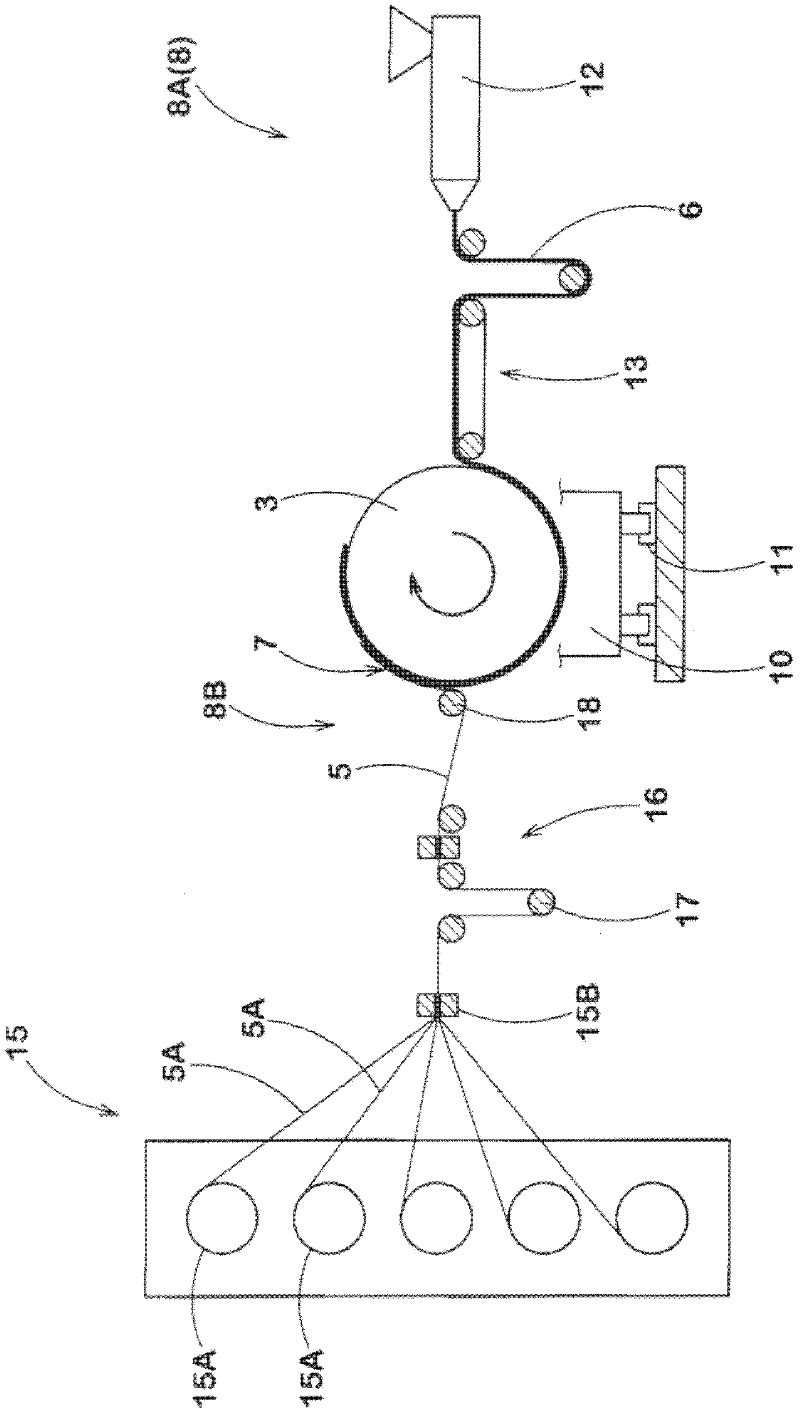

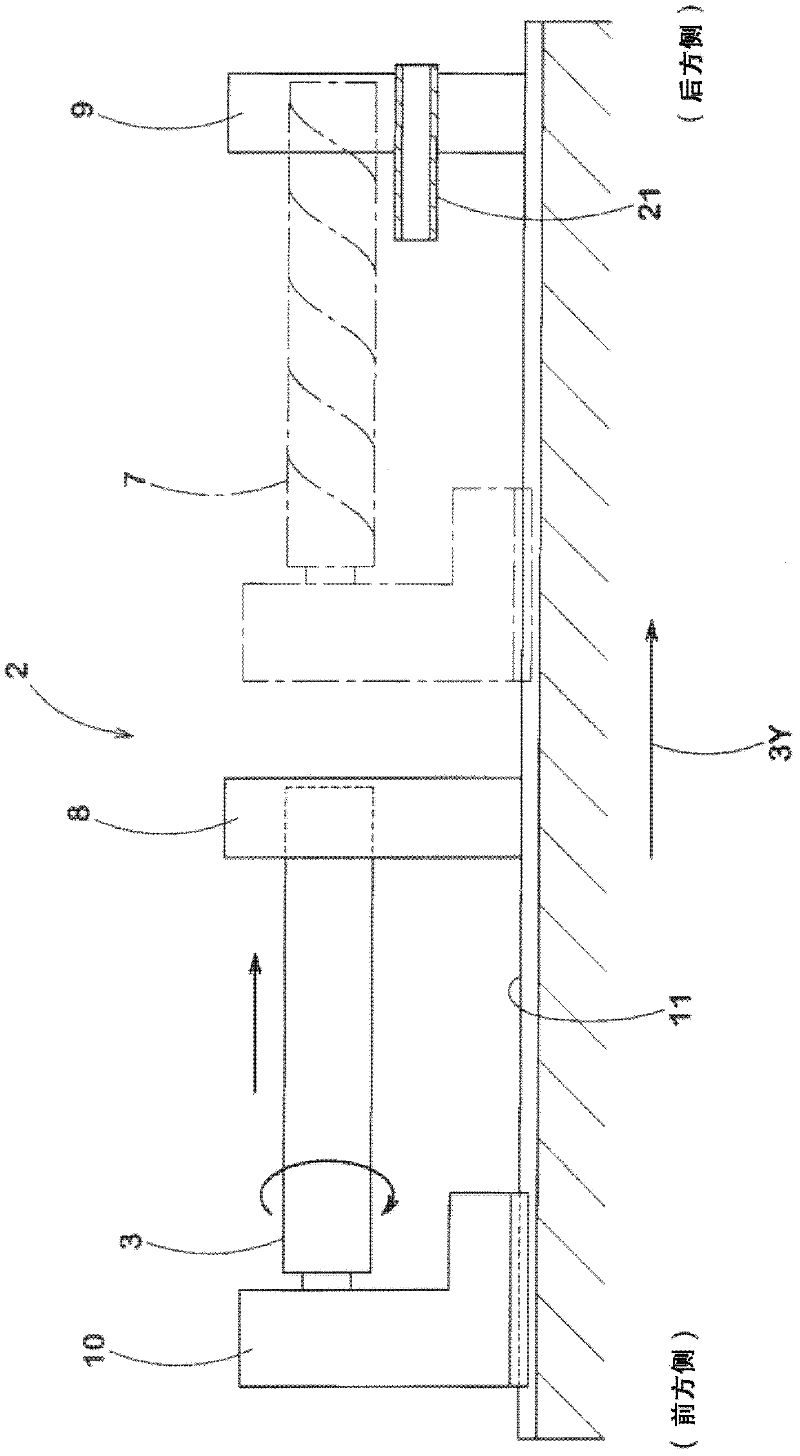

[0037] Next, embodiments of the present invention will be described in detail. figure 1 , 2 It is a front view and a side view which show an example of the manufacturing apparatus 2 which implements the manufacturing method of the tire carcass 1 of this invention.

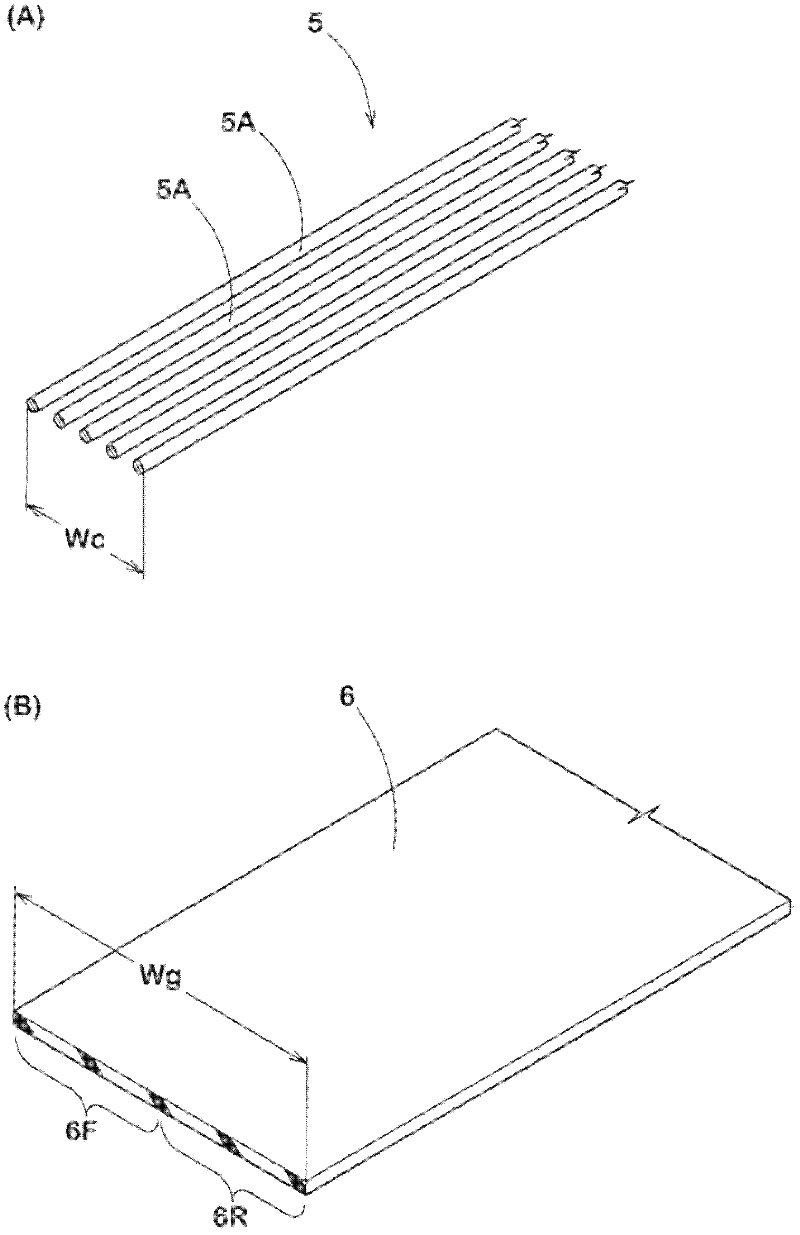

[0038] exist figure 1 , 2 Among them, the manufacturing device 2 includes: a drum 3; a winding unit 8, which continuously winds the cord array body 5 and the rubber belt 6 in a spiral shape on the drum 3 to form the cord array body 5 in the radial direction. A cylindrical cord-containing winding body 7 whose inner and outer surfaces are covered by the rubber belt 6 (in Figure 4 , 5 shown in); cutting unit 9, which cuts the cord-containing winding body 7 to form tire cord material 1 (in Image 6 shown in ).

[0039] In this embodiment, the tire cord material 1 is a cord material 1 for forming a belt cord, Figure 7 A case where the tire cords 5A are arranged at a predetermined angle θ of, for example, 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com