Fuel supply device

A fuel supply device and fuel technology, which is applied to the arrangement combined with the fuel supply of an internal combustion engine, a liquid fuel feeder, a power plant, etc. The effect of increasing the diameter and ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

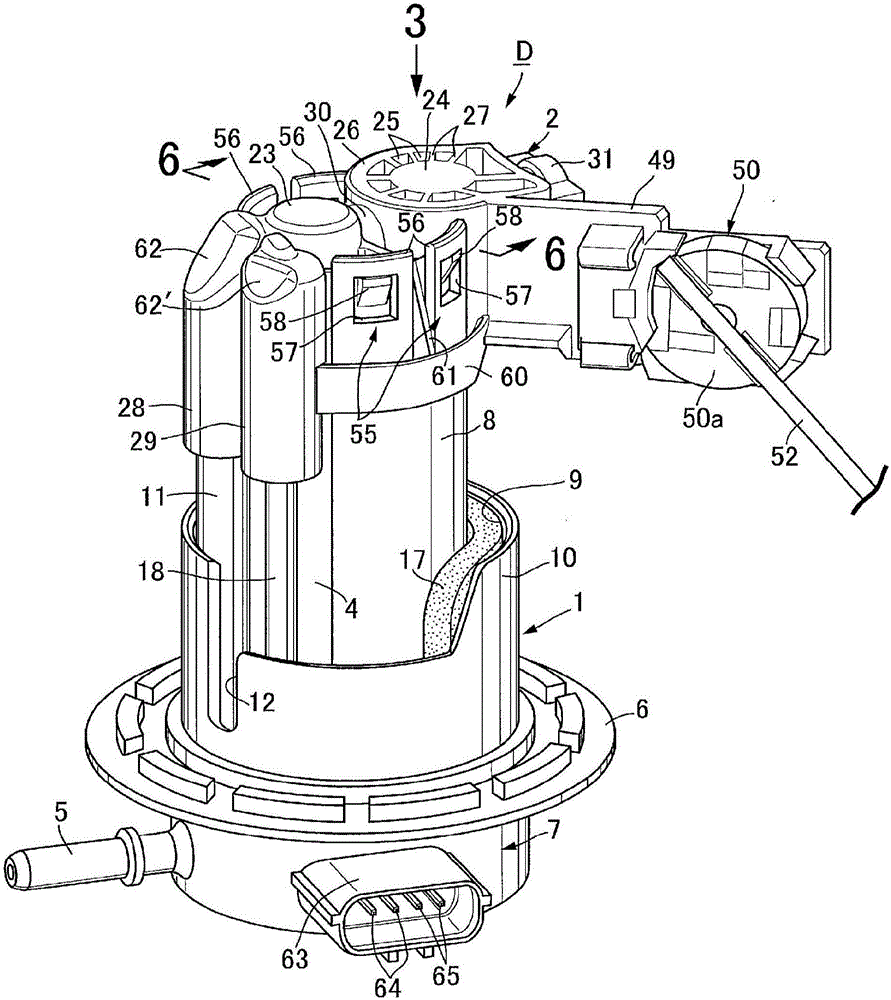

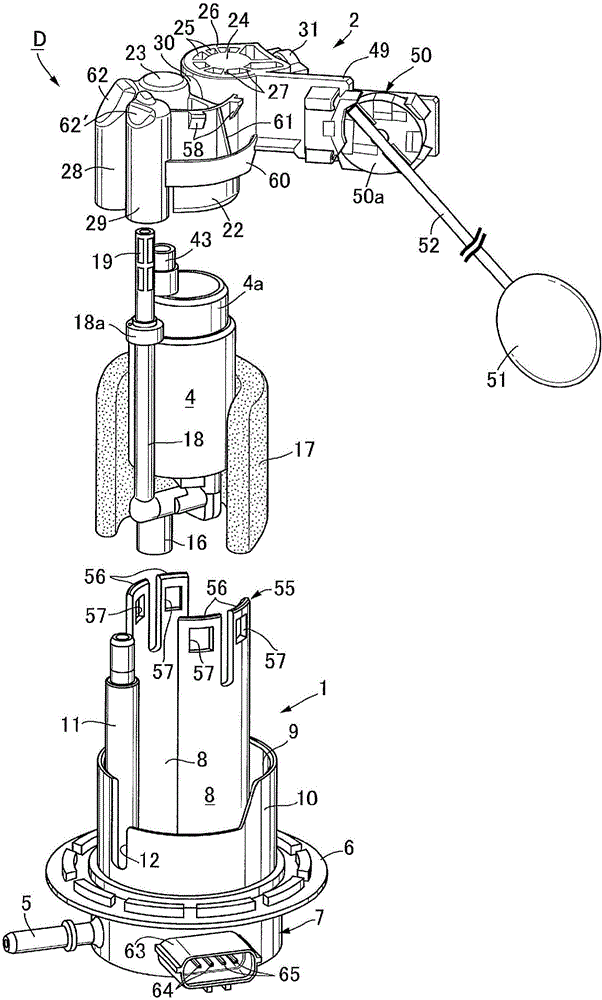

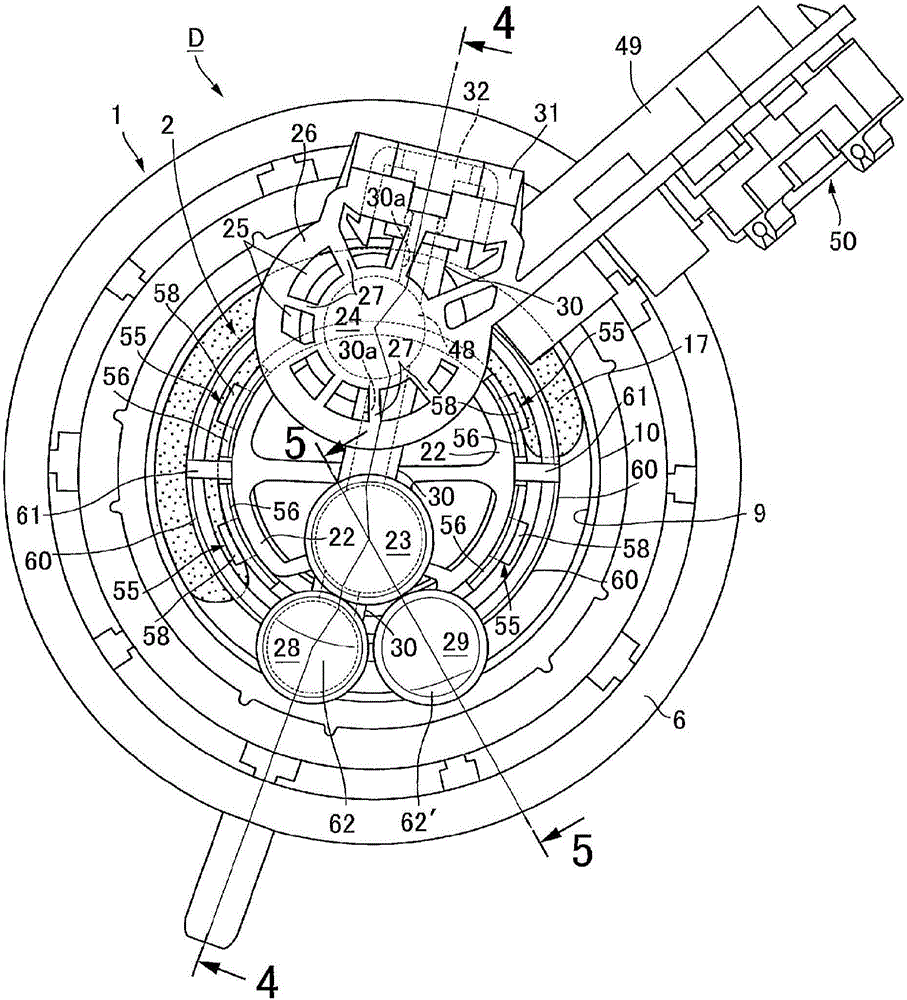

[0028] first, Figure 1 to Figure 6 Among them, on the floor Ta of the fuel tank T mounted on the vehicle (refer to Figure 4 ) is mounted with a fuel supply device D of the present invention that supplies fuel in the fuel tank T to a fuel injection valve (not shown) of the engine.

[0029] This fuel supply device D is composed of the following parts: a first casing 1 made of synthetic resin mounted on the bottom plate Ta of the fuel tank T; a second housing 2 ; and a fuel pump 4 held between the two housings 1 , 2 .

[0030] The first casing 1 is integrally formed with a bottomed cylindrical base portion 7, a fuel take-out pipe 5 is provided at the lower portion of the base portion 7, and an opening portion attached to the bottom plate Ta of the fuel tank T is provided at the upper portion. Mounting flange 6 around Tb, the base portion 7 closing the above-mentioned opening portion Tb; a pair of pump holding walls 8, which stand up from the bottom of the base portion 7; *sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com