Wire clamp

A wire clamping device and a wire clamping part technology are applied in the field of wire clamping devices, which can solve the problem that the clamping state cannot be stably maintained, and achieve the effects of stable clamping state, easy operation and stable maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the wire clamp according to the embodiment of the present invention will be described using the drawings.

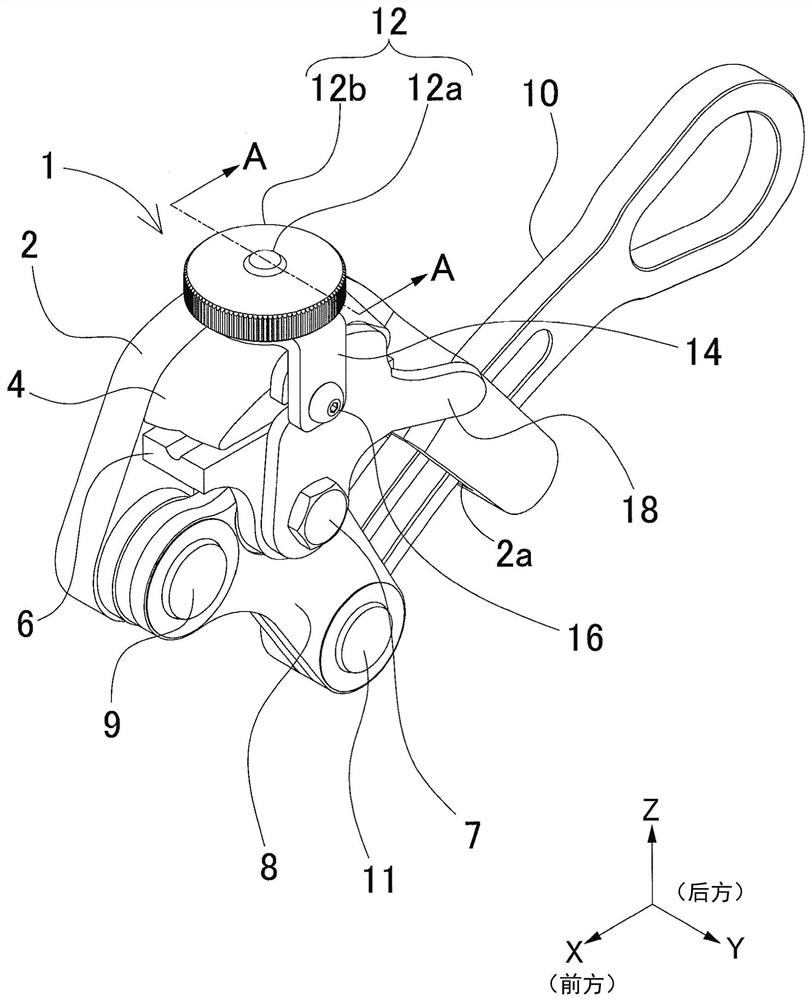

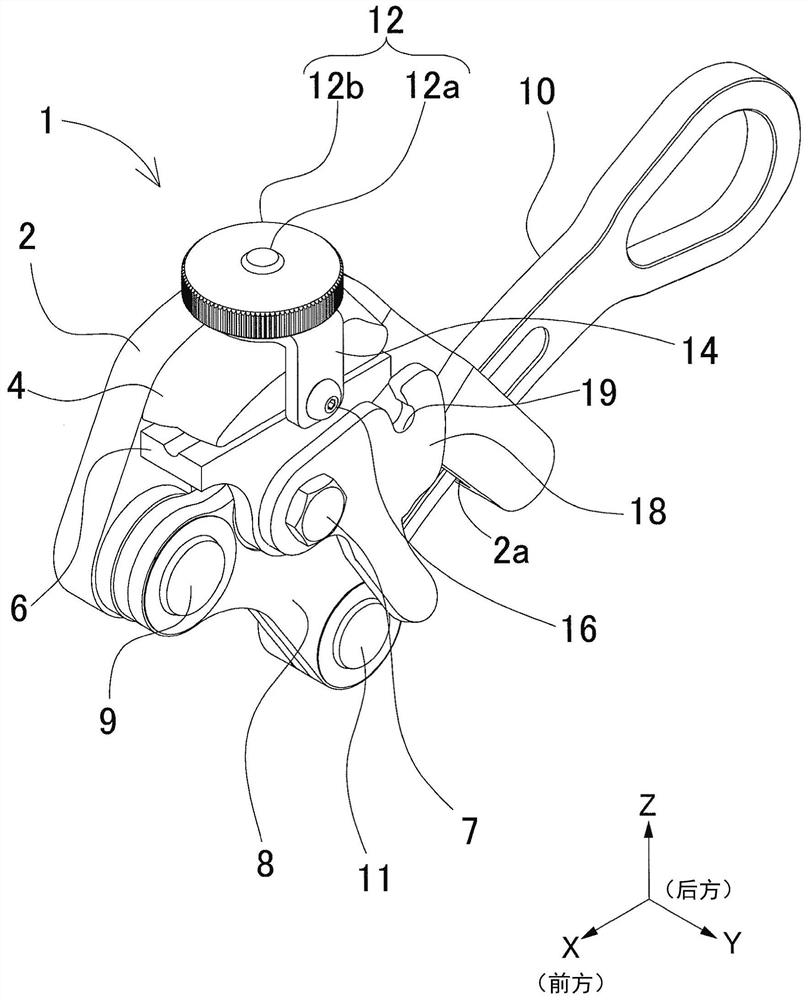

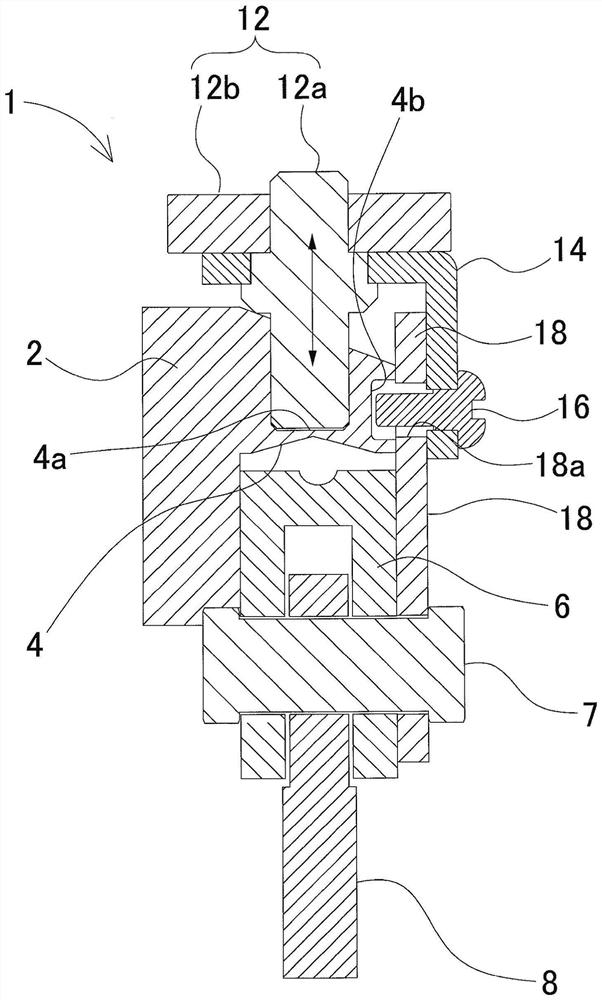

[0042] (first embodiment) figure 1 It is an overall perspective view of the wire gripper 1 of the first embodiment.

[0043] A fixed clamping portion 4 is integrally provided above the substantially flat-shaped main body 2 , and the fixed clamping portion 4 fills one upper side surface of a wire (not shown) that is a linear object to be clamped. The actuating part 8 is swayably supported by the supporting shaft 9 under the fixed thread clamping part 4 . The operating part 10 is pivotally supported on the swing end below the actuating part 8 by the supporting shaft 11 . The swing operation of the operation part 8 is performed by moving the operation part 10 forward and backward. The operation part 10 is slidably disposed through a guide hole 2 a extending rearward of the main body 2 , and is operated back and forth along the guide hole 2 a. At the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com