Steel belt reinforced composite lap joint belt material for plastic-steel wound pipe

A plastic-steel coiled pipe, reinforced composite technology, applied in the direction of pipe/pipe joint/pipe fitting, pipe, rigid pipe, etc., can solve the problems affecting the pipe ring stiffness, leakage, easy cracking, etc., to improve ring stiffness, strengthen strength, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

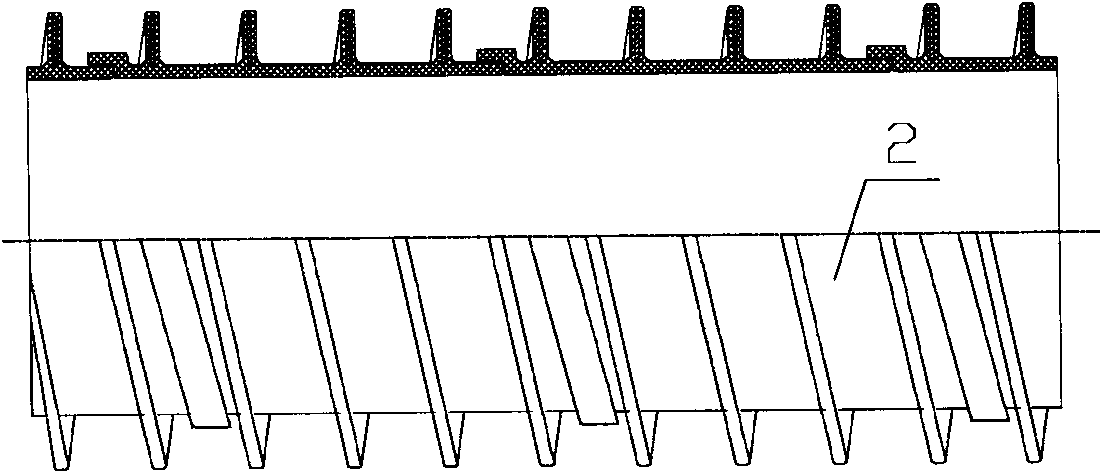

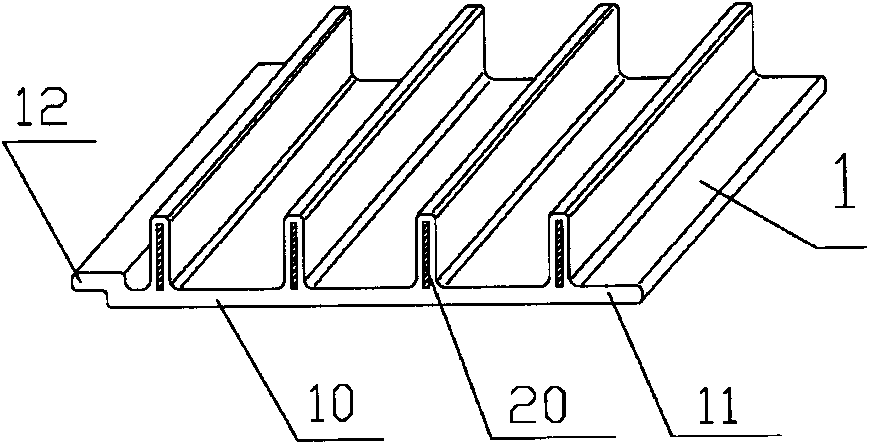

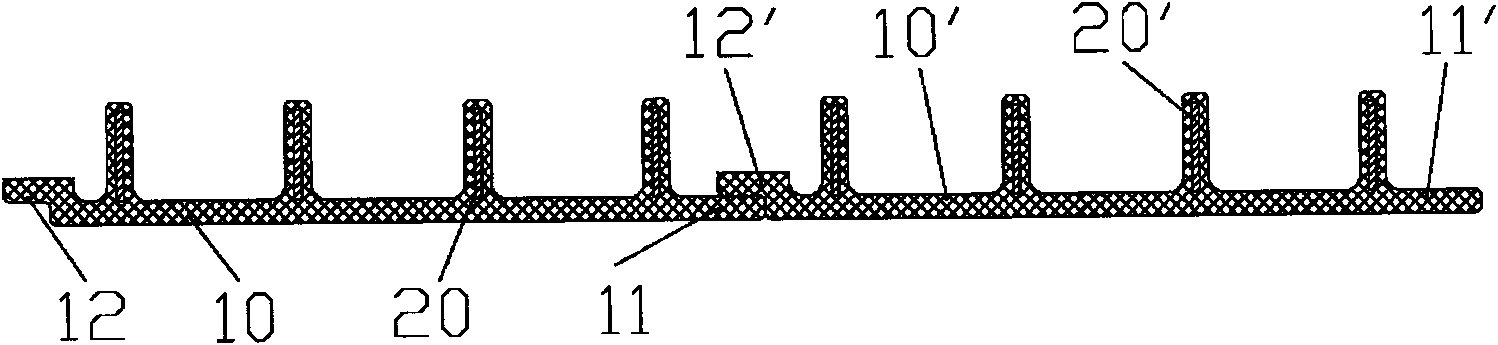

[0035] attached Figure 4 to attach Image 6 It is the embodiment 1 of the plastic-steel winding pipe strip of the present invention.

[0036] The strip body includes a base plate 30 and vertical reinforcing ribs 40 (ie rib plates). The reinforcing rib 40 includes a vertical metal reinforcing rib 401 and a plastic layer 402 covering the vertical metal reinforcing rib 401 . In this embodiment, the plastic material is polyethylene, and the metal material is steel strip. The cross-section of the vertical metal reinforcing ribs 401 is an inverted T-shaped cross-section. The shape of the reinforcing rib 40 is a hemispherical head.

[0037] The two ends of the tape and the overlapping parts of the adjacent tape are respectively the protruding platform 31 and the protruding boss 32 (that is, the engaging protrusion). The joint surface protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com