Tyre cord layer jointing device and jointing method

A joining device and joining method technology, applied in tires, applications, household appliances, etc., can solve problems such as inability to maintain joining force, reduced productivity, and separation of joining parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0060] (1) Structure of the joining device for tire cord layers

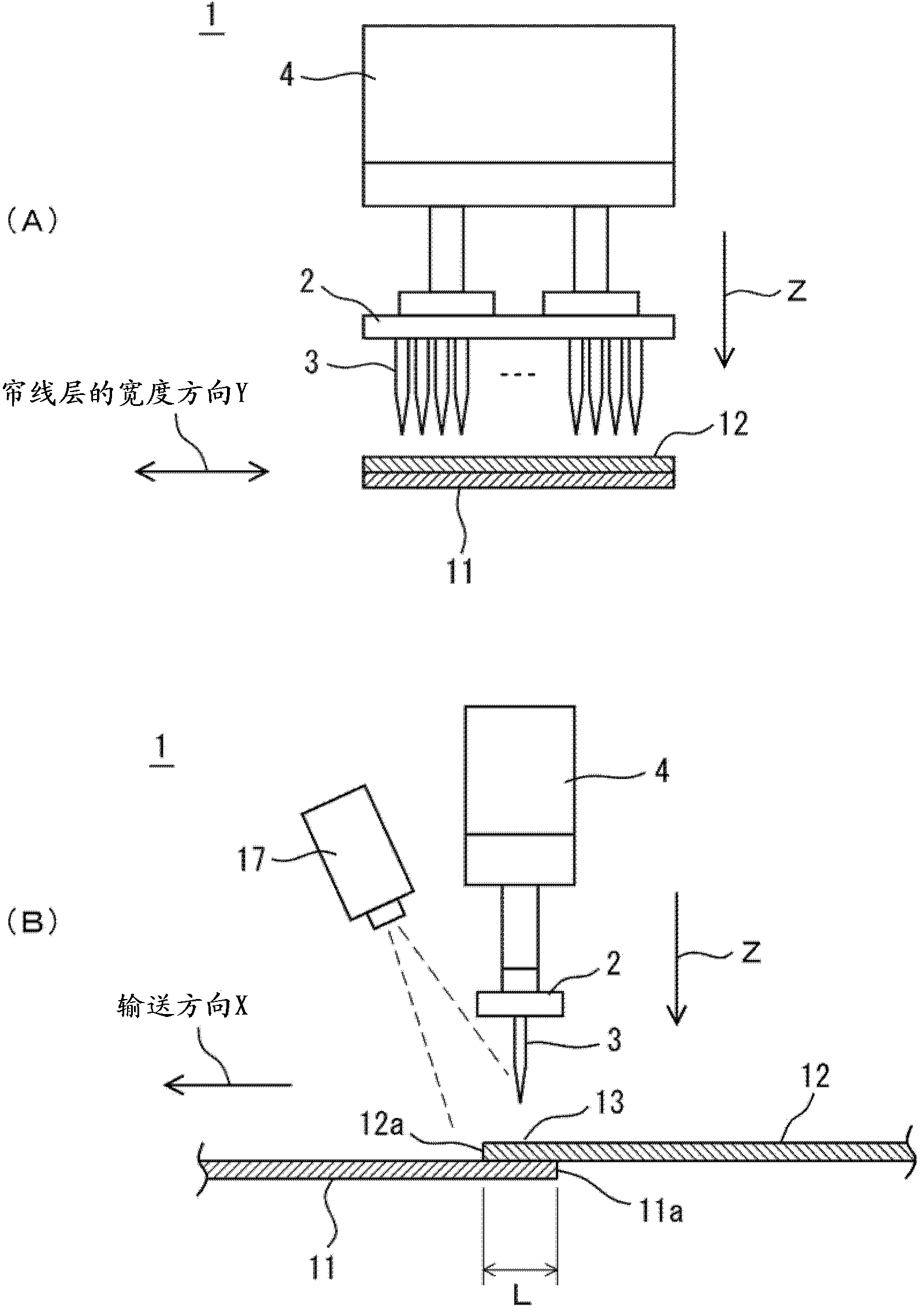

[0061] figure 1 It is a figure which shows the 1st Embodiment of the joining apparatus of the cord layer for tires concerning this invention, figure 1 (A) is a brief side view, figure 1 (B) is a brief front view.

[0062] The joining apparatus 1 is an apparatus for manufacturing a long carcass cord or the like by repeatedly overlapping and joining edge portions of two cord layers.

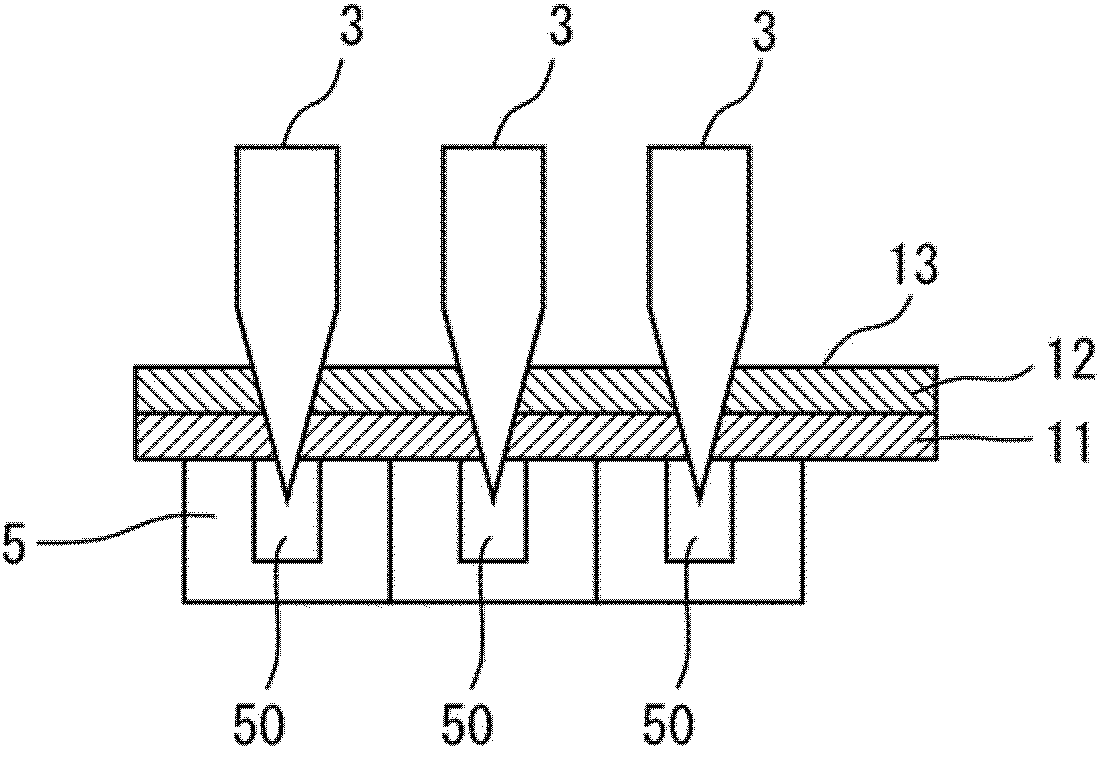

[0063] like figure 1 As shown, the joining device 1 is equipped with: an elevating member 2 provided with a plurality of acicular protrusions 3; an actuator 4 as a driving unit of the elevating member; And the belt conveyor (not shown) which forms the overlapping part 13. in addition, figure 1 Also shown in FIG. 2 is a position sensor 17 that detects the position of the cord layers 11 , 12 conveyed in the conveying direction X by means of a belt conveyor.

[0064] The elevating member 2 is arranged above the overlapping portio...

no. 2 approach

[0084] (1) Structure of the joining device for tire cord layers

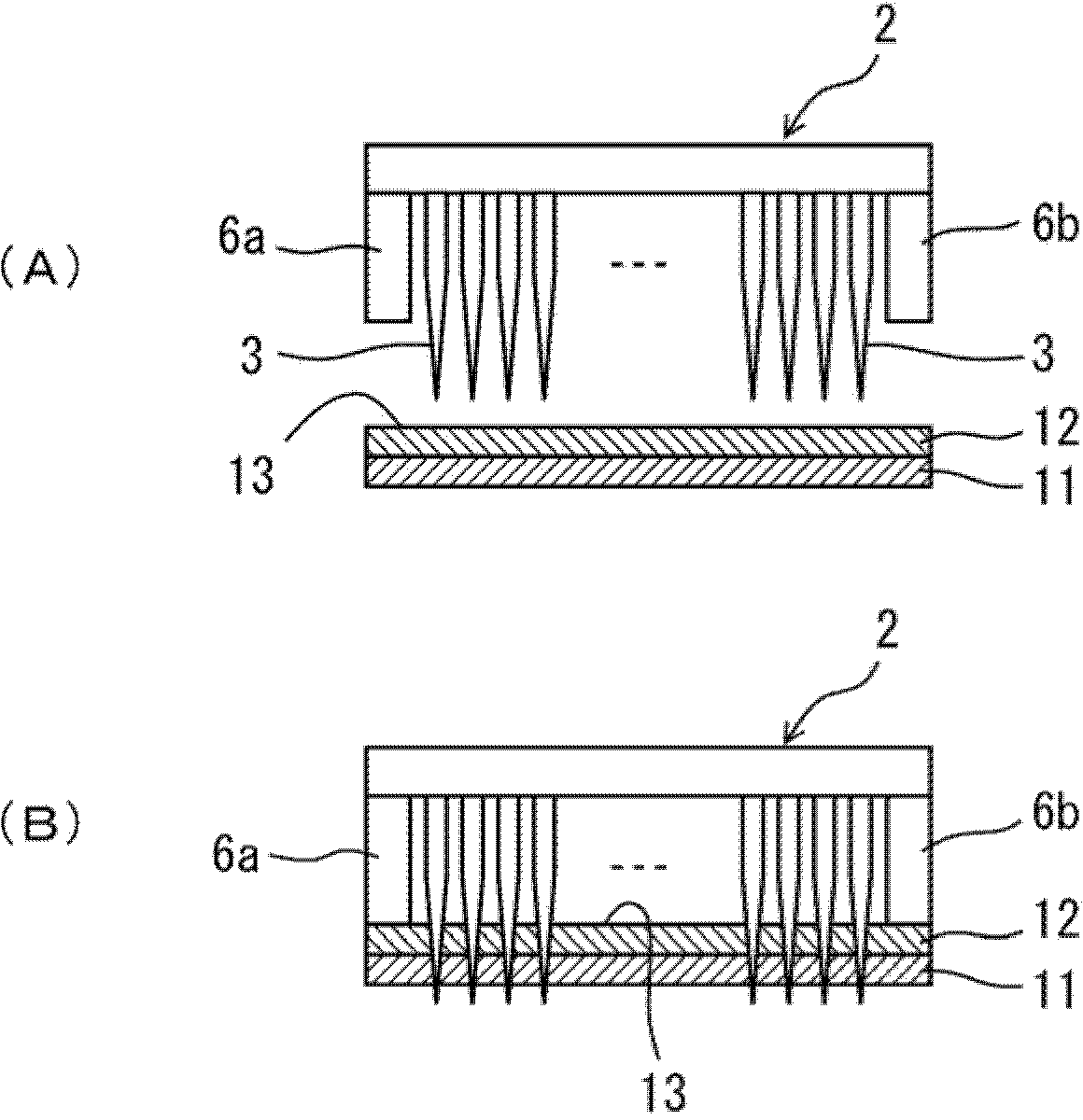

[0085] Figure 5 It is an enlarged front view of main parts showing a second embodiment of the tire cord ply joining device.

[0086] In the joining device 21 of the second embodiment, the shape of the tip of the needle-like protrusion 23 provided on the elevating member 2 is a flat surface, and a laser scanning sensor 28 for detecting minute unevenness on the surface of the upper cord layer 12 is provided, Other than that, the rest is the same as the joining device 1 of the first embodiment, and only the parts different from the first embodiment will be described below.

[0087] like Figure 5 As shown, the tip portion 23a of the acicular protrusion 23 in this embodiment is formed as a flat surface with a diameter of 0.3 mm to 0.5 mm.

[0088] The laser scanning sensor 28 is installed near the lifting member, and detects the position of the cords 15 constituting the cord layer 12 by detecting minute unevenne...

Embodiment

[0099] Next, the state of joining was evaluated by joining edge portions of two cord layers having different overlapping amounts to perform tensile evaluation.

[0100] 1. Test body

[0101] Use two cord layers with a size of 525mm×1450mm×0.95mm (thickness) (the number of cords is 1450), and as shown in Table 1, use less than 3mm (1 to 2 cords), 3mm or more (3 or more cords) overlapping amount was joined to prepare a test body. In addition, as a test body of less than 3 mm, a test body obtained by cutting and joining two edges was prepared.

[0102] 2. Joining method

[0103] As the joining method, the joining method based on the first embodiment (Example), the joining method based on the conventional lap joint method (Comparative Example 1), and the joining method based on the zipper joint method (Comparative Example 2) were used.

[0104] 3. Evaluation method

[0105] Assuming that expansion occurs, each test body is stretched using a tensile shear machine (shear force: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com