Semiconductor element mounting method and mounting substrate

An installation method and semiconductor technology, applied in semiconductor/solid-state device components, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as inability to install, time required, pollution, etc., and achieve the effect of easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Before continuing to describe the present invention, the same reference numerals are given to the same components in the drawings.

[0090] Embodiments according to the present invention will be described in detail below based on the drawings.

[0091] (first implementation)

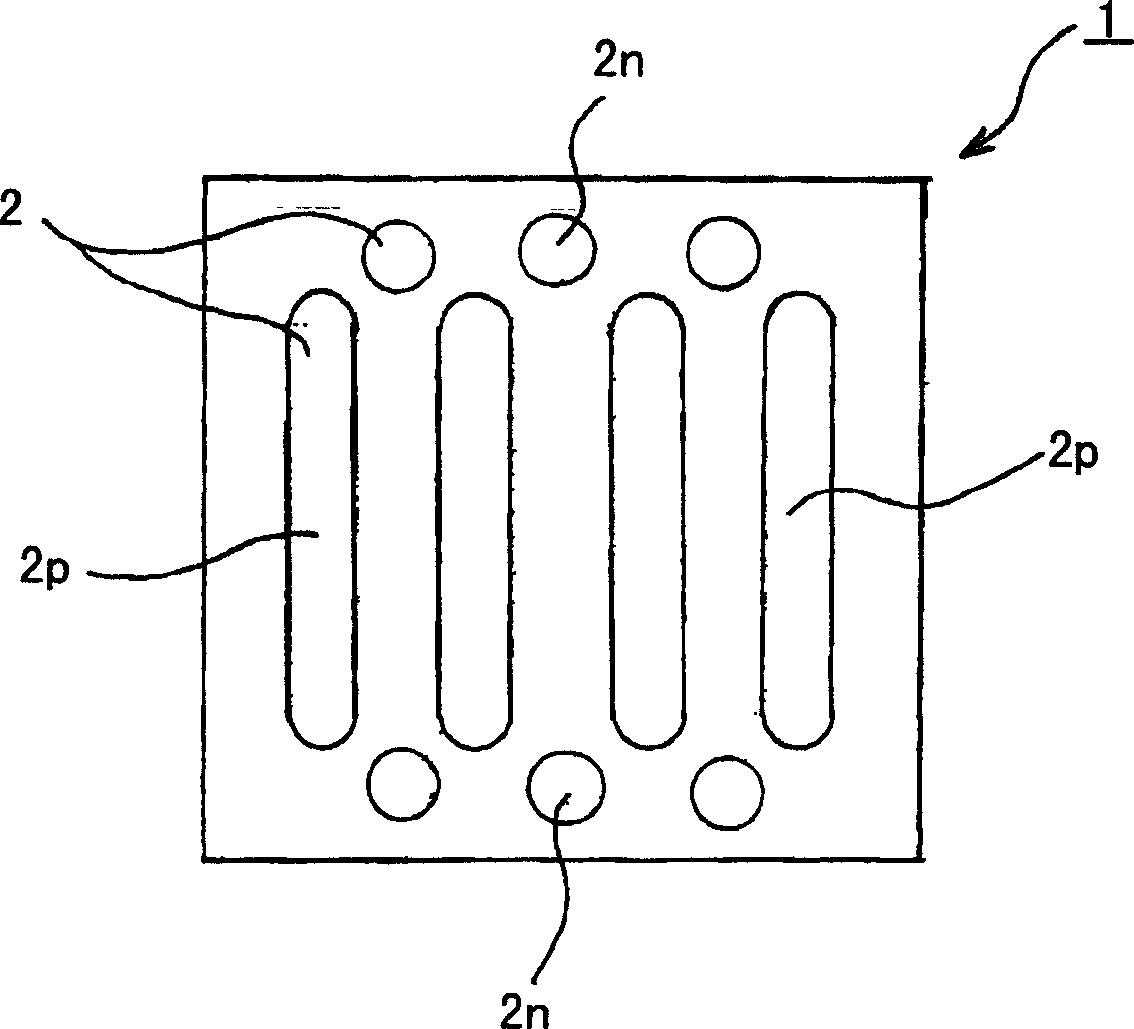

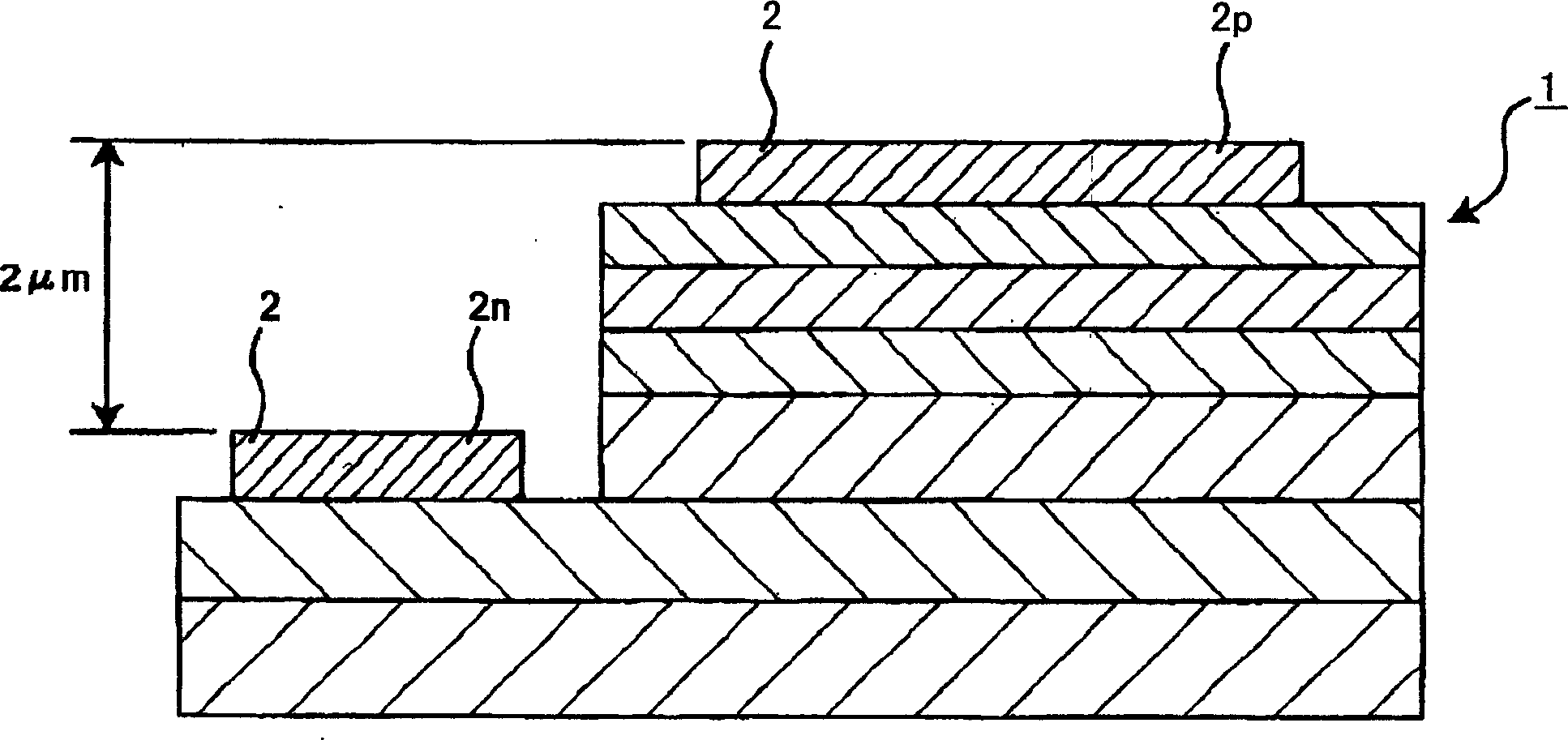

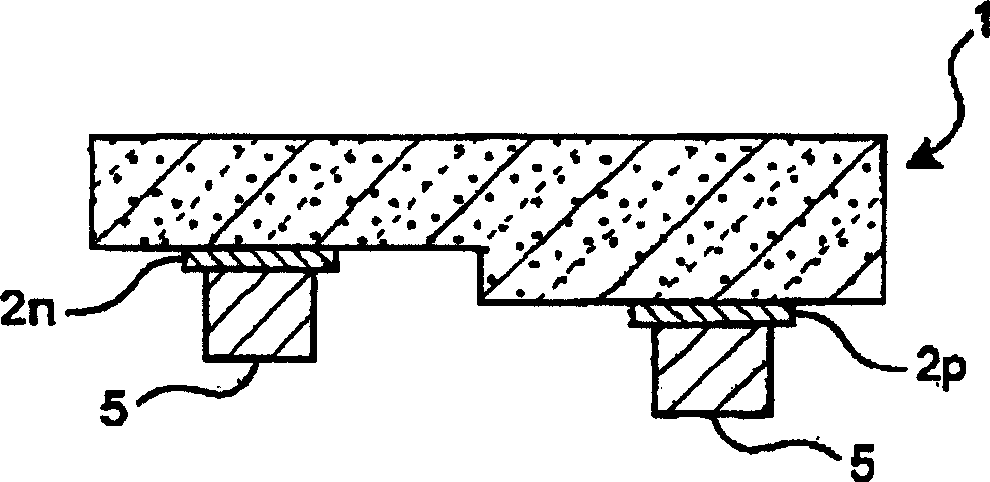

[0092] In the semiconductor element mounting method according to the first embodiment of the present invention, as an example of the above-mentioned semiconductor element, in figure 1 A schematic illustration of a planar structure in which LED chips (or LED elements) are mounted on a substrate is shown in .

[0093] Such as figure 1 As shown, an LED (Light Emitting Diode: Light Emitting Diode) chip 1 has a substantially square shape, and a plurality of pads 2 serving as an example of element electrodes are formed on the surface on the bonding side with a substrate. Each pad 2 can be divided into two types according to the characteristics of the LED chip 1: one is to form an oblong P pole pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com