Clad electrode for spark plug and method for manufacturing same

A manufacturing method and spark plug technology, which are applied in spark plug manufacturing, spark plugs, circuits, etc., can solve problems such as falling off of precious metal sheets, and achieve the effect of preventing peeling or falling off, realizing long life and reliable bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

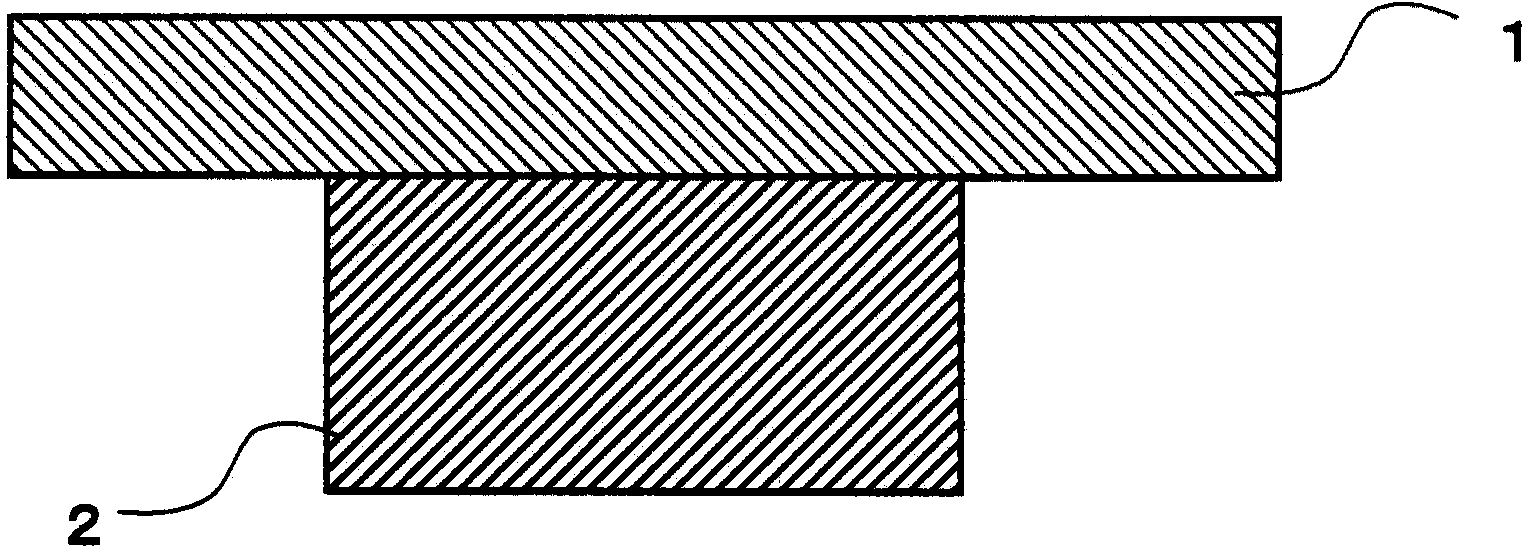

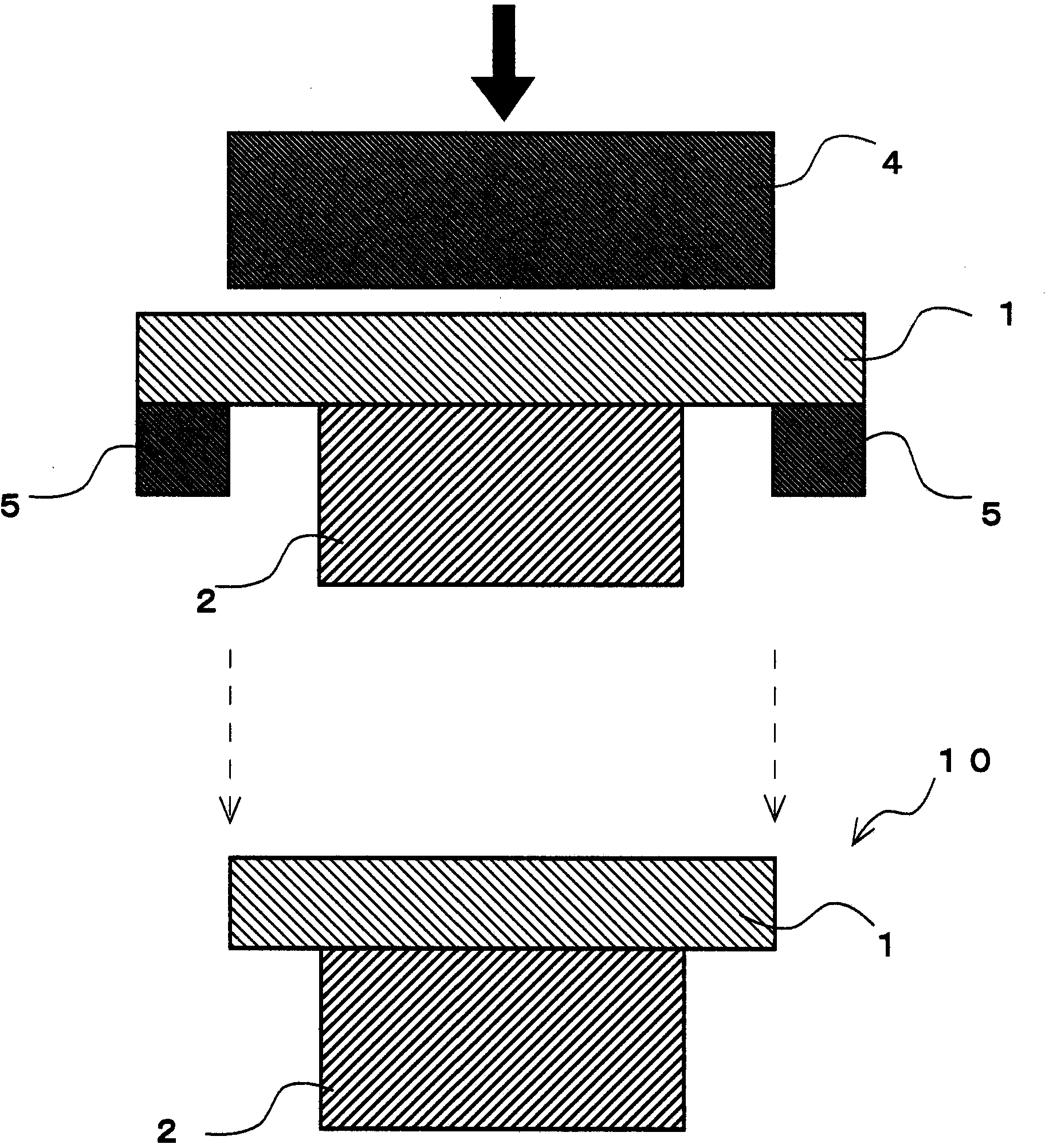

[0036] First, if Figure 1A As shown, a cylindrical noble metal sheet 2 made of a Pt-Rh20% alloy with a diameter of 1.0 mm and a thickness of 0.3 mm is placed in contact with a strip-shaped substrate 1 made of a Ni-Ir1% alloy with a thickness of 0.3 mm. , the noble metal sheet 2 is perpendicular to the substrate. When the noble metal piece 2 is brought into contact with the surface of the strip-shaped substrate 1, the noble metal piece is perpendicular to the substrate so that no gap or partial contact occurs between the contact surface of the noble metal piece and the substrate surface.

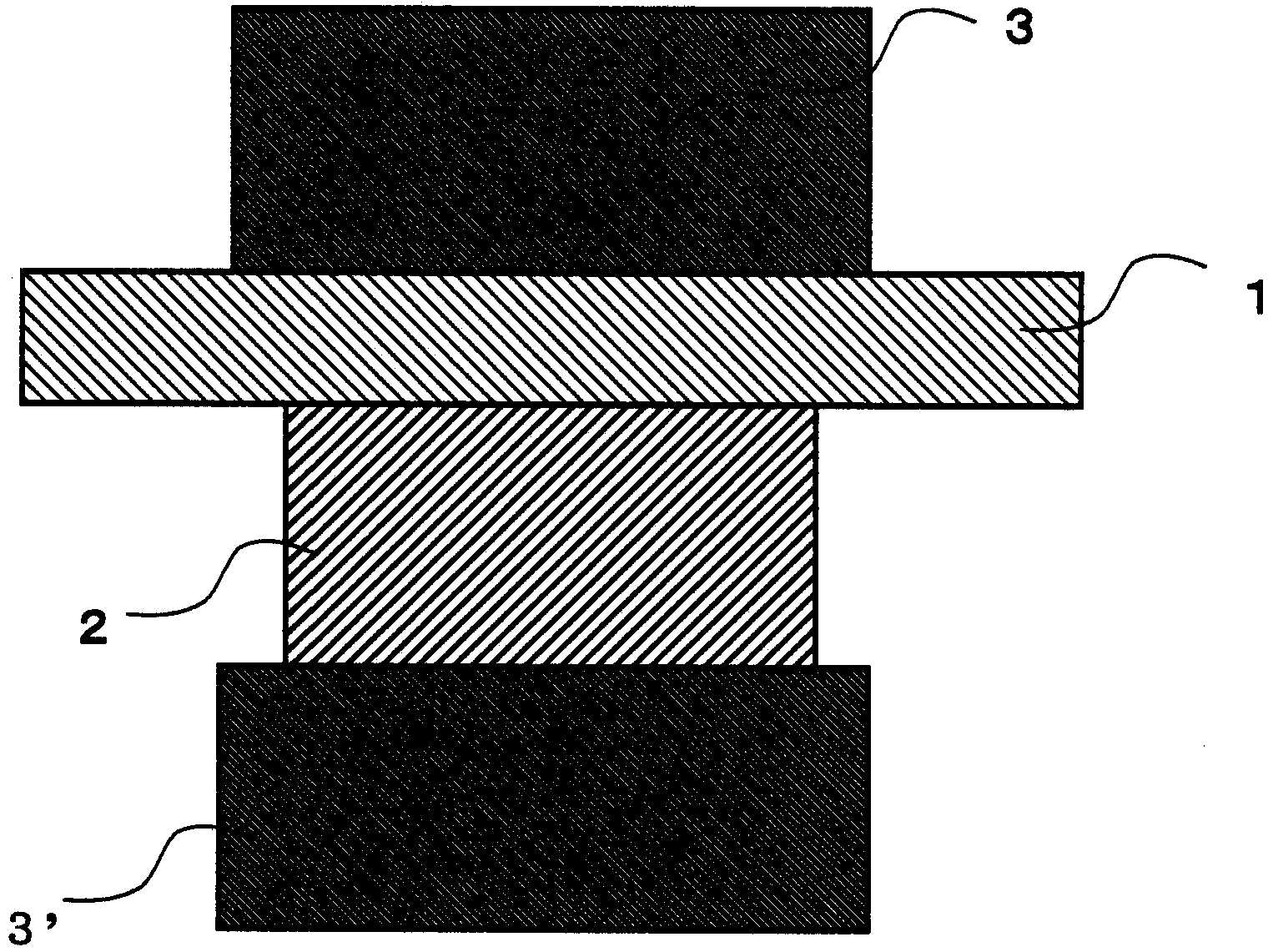

[0037] Next, if Figure 1B As shown, electrodes ( 3 , 3 ′) for resistance welding were respectively connected to the base material 1 and the precious metal sheet 2 , and resistance welding was performed under the conditions of applied pressure 7kgf, welding current 1350A, and energization time 9msec to perform preliminary joining. In the present embodiment, two types of pre-joined cladding ...

Embodiment 2

[0046] As Experiment 2, the same material as Experiment 1 was prepared, and as preliminary joining conditions, the applied pressure was the same 7kgf, compared with the resistance welding conditions of Example 1, the output was reduced to 1110A, and the energization time was 100msec. Furthermore, a clad electrode subjected to a diffusion bonding process under the same heat treatment conditions as in Example 1 (1100° C.×1 hour) was produced. The characteristics of the clad electrode of this Example 2 are the same as those of Example 1.

Embodiment 3

[0048] As Example 3, using the same combination of materials as in Example 2, setting the same pre-joining conditions as in Example 2, and manufacturing such that the subsequent heat treatment conditions were changed to the high temperature side, 1200°C x 1 hour for diffusion Join the treated clad electrode. The cross-section of the clad electrode of Example 3 was observed, and the diffusion layer was 50 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com