Waterproof connector

A connector and waterproof technology, which is applied in the field of waterproof connectors, can solve problems such as height difference, manufacturing deviation that cannot be ignored, and reliable bonding, etc., to achieve reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0060] Hereinafter, embodiments of the present invention will be described in detail using the drawings. In addition, dimensions are appropriately changed in the drawings for easy understanding.

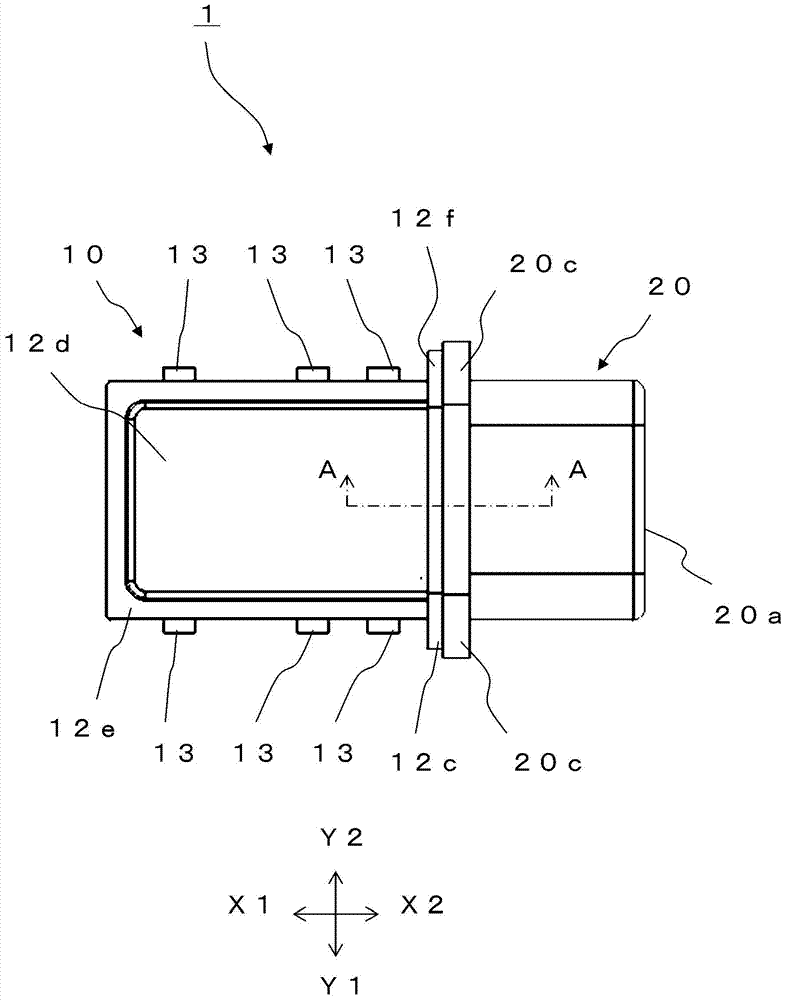

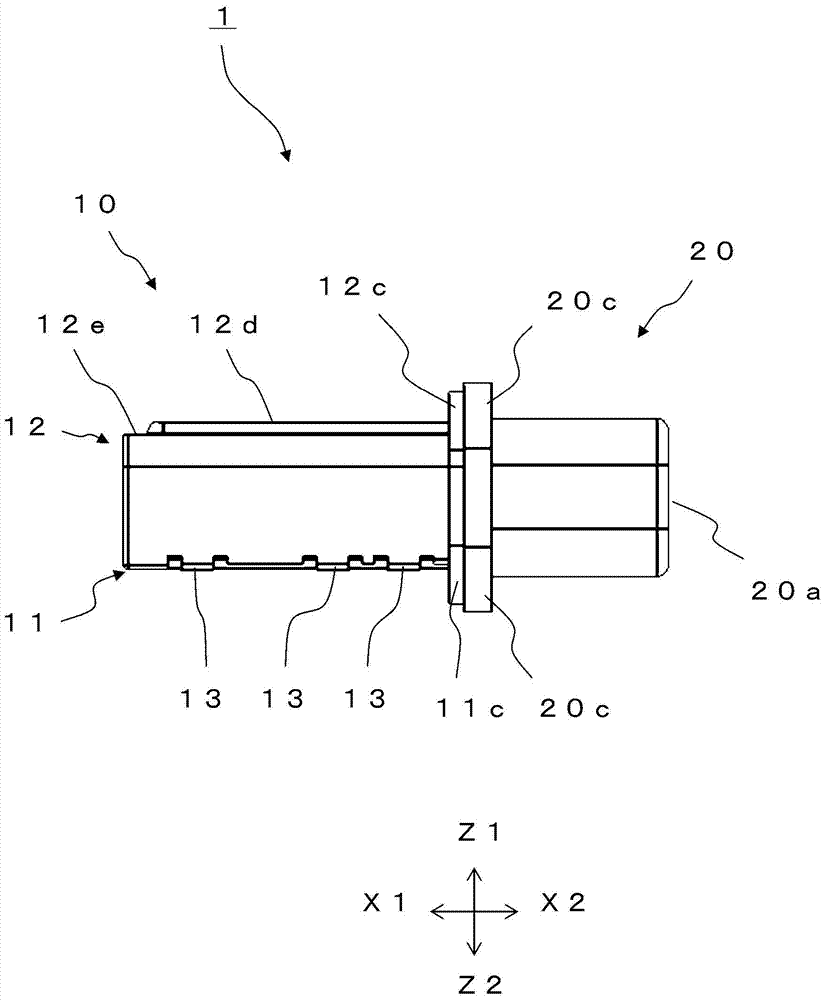

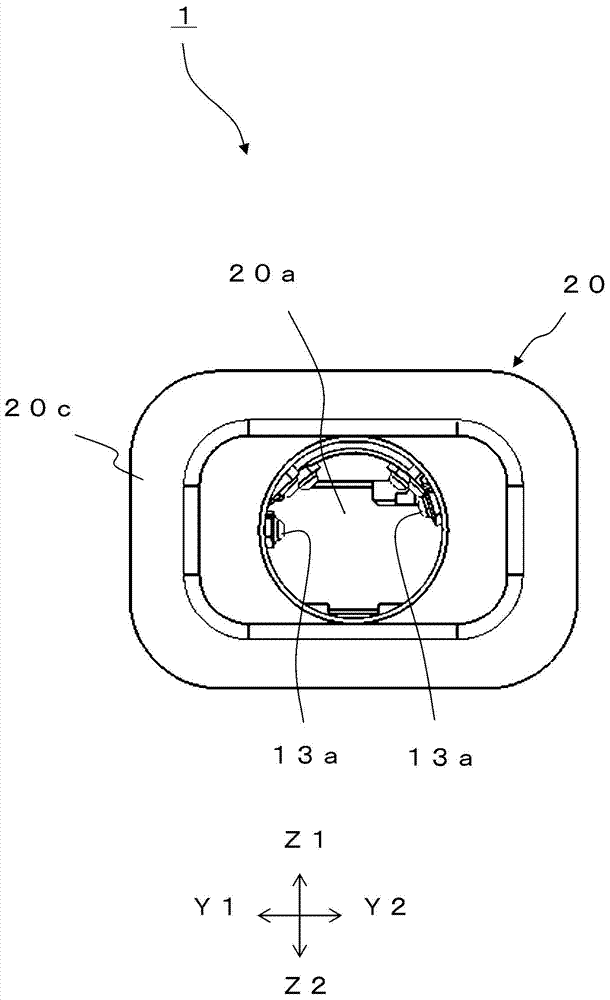

[0061] figure 1 It is a plan view showing the waterproof connector 1 according to the embodiment of the present invention. figure 2 It is a front view showing the waterproof connector 1 according to the embodiment of the present invention. image 3 It is a right side view showing the waterproof connector 1 according to the embodiment of the present invention. Figure 4 It is a perspective view showing the waterproof connector 1 according to the embodiment of the present invention. Figure 5 It is an exploded perspective view showing the waterproof connector 1 according to the embodiment of the present invention. Figure 6 It is a schematic diagram explaining the case side flange part 10c before ultrasonic welding, Figure 6 (a) is a perspective view, Figure 6 (b) is a perspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com