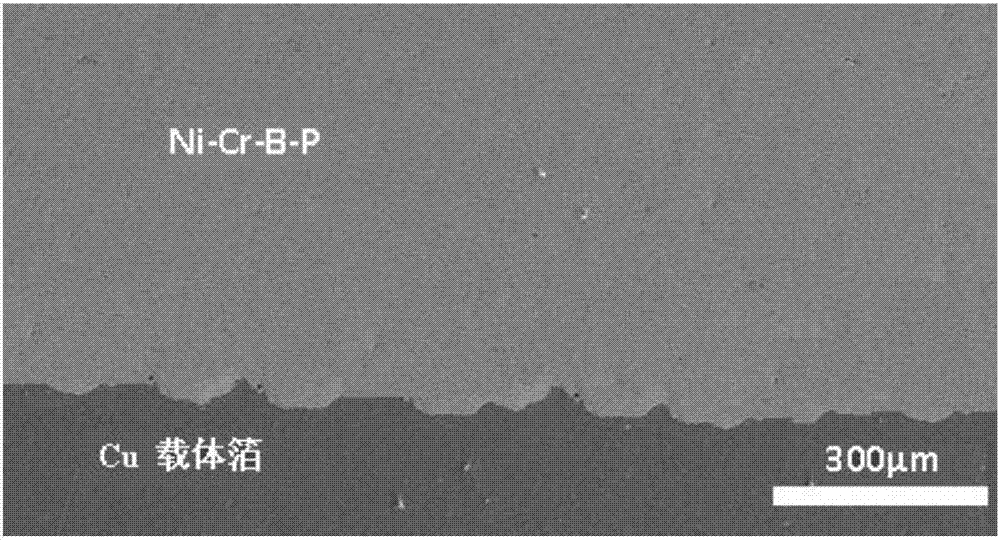

Preparation method for ultrathin copper foil Ni-Cr-B-P stripping layer

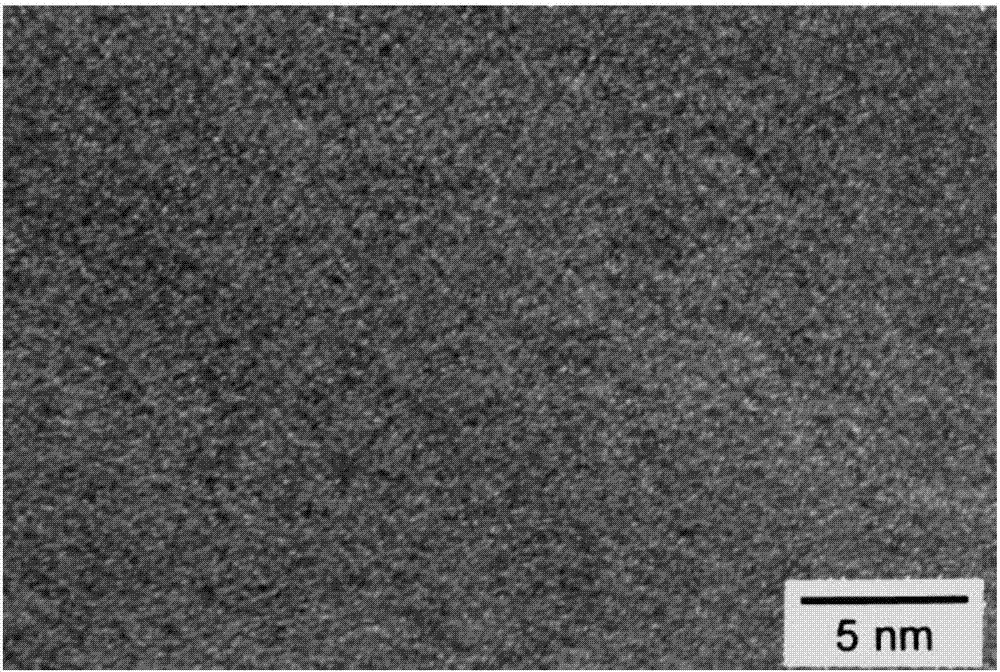

A technology of ultra-thin copper foil and peeling layer, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., can solve the problem of difficulty in achieving the anti-peeling strength of ultra-thin copper foil, increased economic cost, and complicated process and other problems, to achieve the effect of firm joint, stable anti-peeling strength and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments.

[0026] The carrier foil is subjected to alkaline degreasing, pickling, ultrasonic washing, drying, put into the plating tank, and a certain amount of sodium hypophosphite (NaH 2 PO 2 ·H 2 O) (mass concentration 40g / L), sodium fluoride (mass concentration 3.5g / L), mercaptobenzothiazole sodium (mass concentration 0.5g / L) and citric acid (mass concentration 12g / L) were dissolved and mixed with distilled water respectively , add nickel sulfate NiSO 4 ·6H 2 O (mass concentration 13g / L), CrCl 3 ·6H 2 O (mass concentration 20g / L), adjust the pH value to 4.5 with 10% NaOH solution, dilute to the specified volume with water, and finally get 200mL mixed solution, mix 54g / L KBH 4 100mL of the solution was evenly dropped into the mixed solution within 15 minutes as an electroless plating solution, and the plating was carried out for 25 minutes. After the plated parts were washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com