Patents

Literature

33results about How to "Stable Peel Strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite polyethylene (PE) powder thermally sprayed anticorrosion coating for petroleum and natural gas pipe

InactiveCN102052543AImprove corrosion resistanceImprove cathodic protection resistanceCorrosion preventionAnti-corrosive paintsPetroleumPolymer gel

The invention provides a PE powder thermally sprayed anticorrosion coating for a petroleum and natural gas pipe, which is a blended interface anticorrosion coating formed on the inner or outer wall of the petroleum and natural gas pipe by thermally spraying low-temperature setting epoxy powder (PBE), holt melt polymer gel (AD) and modified polyethylene (PE) / propenepolymer (PP) powder on the inner or outer wall of the petroleum and natural gas pipe in turn. The anticorrosion coating has an ultrahigh stripping strength for the petroleum and natural gas pipe, overcomes the AD / PE intra-layer separation of the conventional 3PE anticorrosion technology, and improves the anticorrosion performance of the pipe; and the anticorrosion layer eliminates a cathode shielding area, improves cathode protection resistance, reduces drawbacks of 'edge turning' at a weld joint part and effectively reduces coating cost due to a one-time spraying process.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

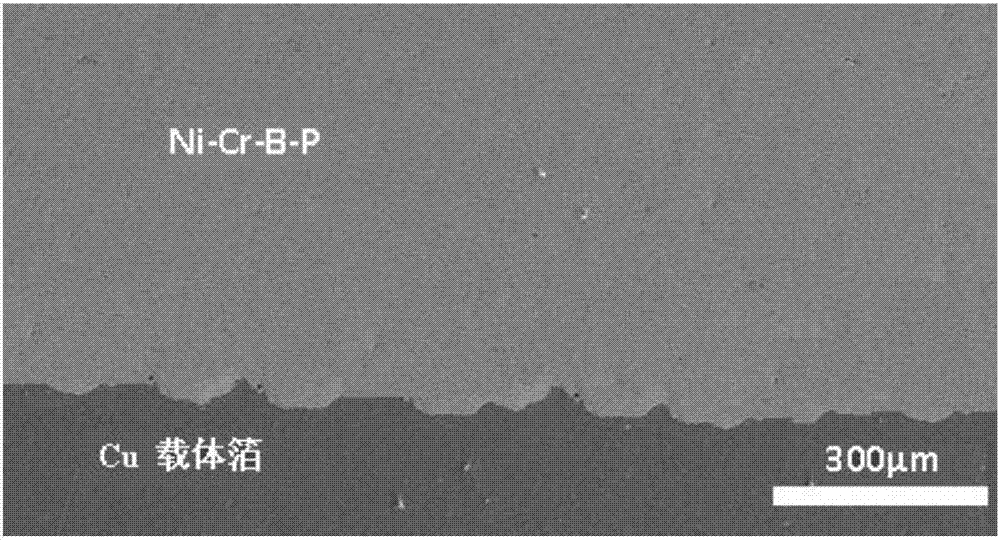

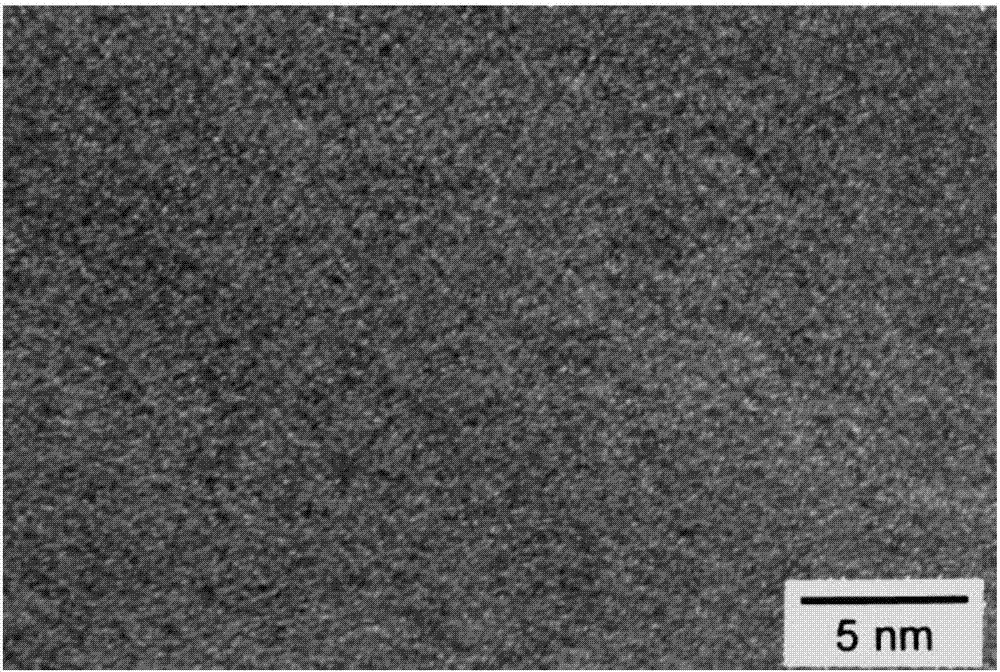

Preparation method for ultrathin copper foil Ni-Cr-B-P stripping layer

ActiveCN107475698AUniform textureStable electrodepositionLiquid/solution decomposition chemical coatingChemical platingCopper foil

The invention discloses a preparation method for an ultrathin copper foil Ni-Cr-B-P stripping layer. The preparation method comprises the following steps that a certain amount of sodium hypophosphite (NaH2PO2.H2O), sodium fluoride, sodium 2-mercaptobenzothiazole and citric acid are dissolved and mixed through distilled water; nickel sulfate NiSO4.6H2O and chromium chloride CrCl3.6H2O are added in sequence under a certain temperature and the stirring effect; the pH value is adjusted to the specified value through a 10% of NaOH solution, and dilution is conducted through water to be the specified volume; a certain concentration of KBH4 is uniformly dripped into a mixture solution to serve as a chemical plating solution; and carrier foil is chemically plated for a certain period, and after a plated part is washed through distilled water and anhydrous ethanol, the ultrathin copper foil Ni-Cr-B-P stripping layer is obtained. The stripping layer obtained through the preparation method presents a uniform single amorphous structure and has good thermal stability after hot press processing, the stripping resistance strength of the stripping layer is more stable, the process is simple, the industrialization cost is low, and the new preparation method for the ultrathin copper foil stripping layer has development prospects.

Owner:ANQING NORMAL UNIV +1

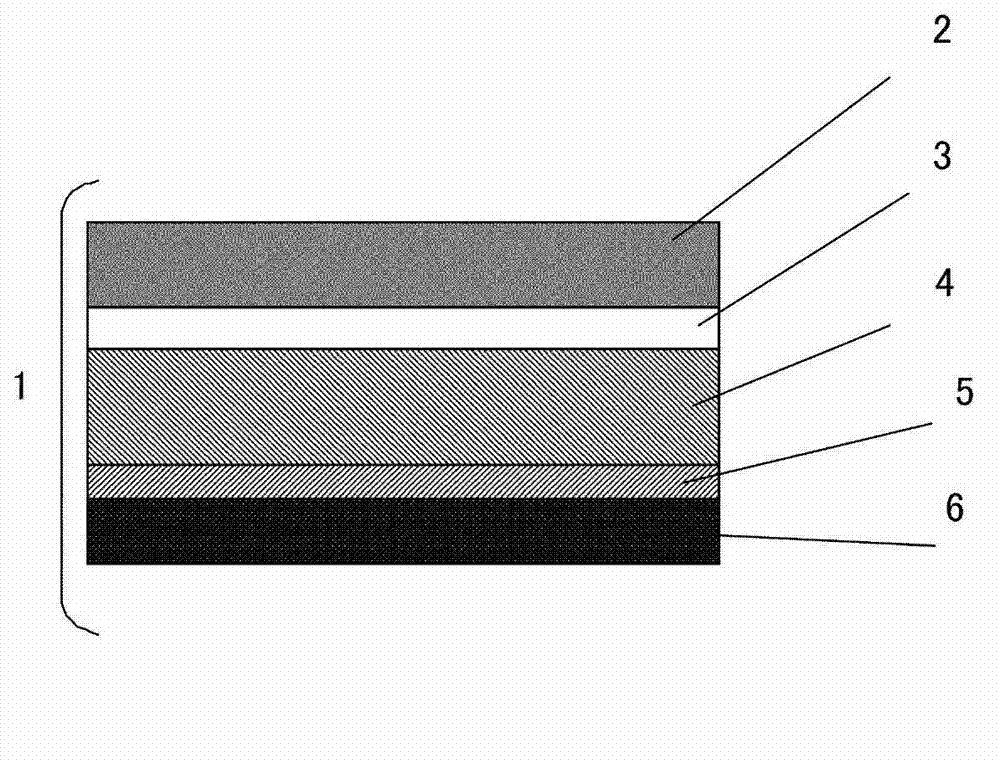

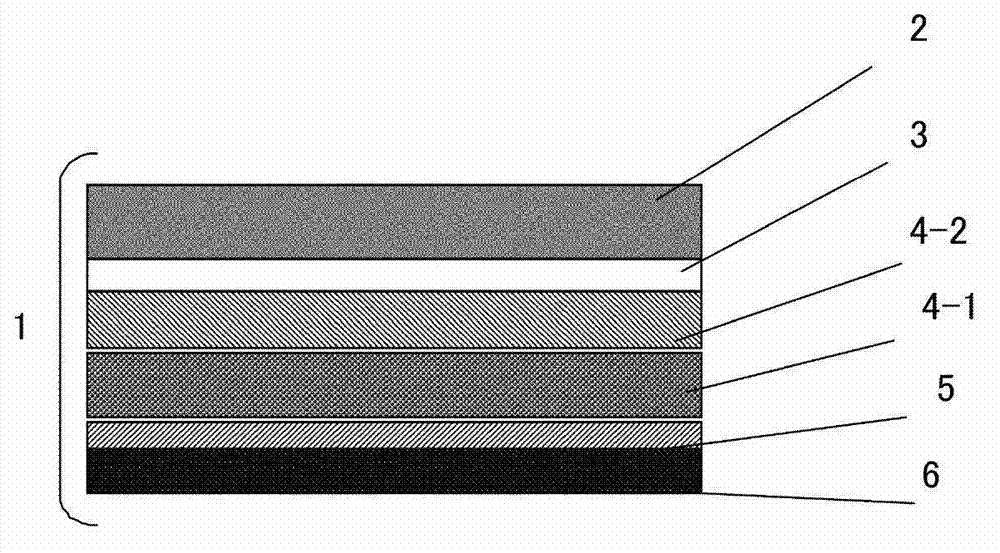

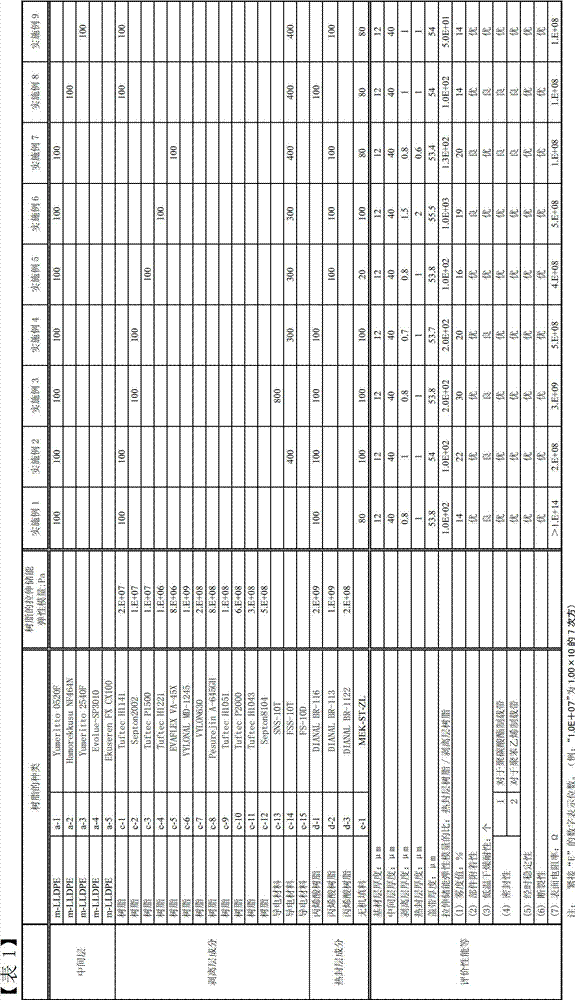

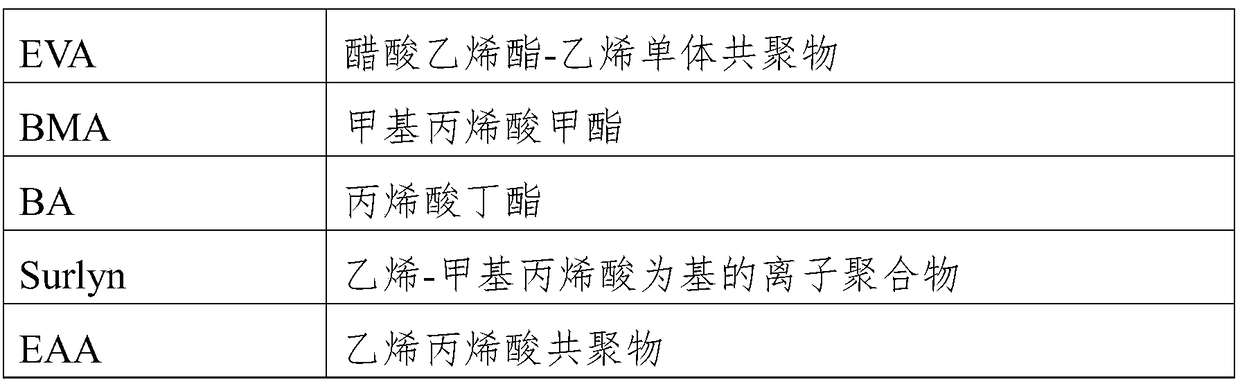

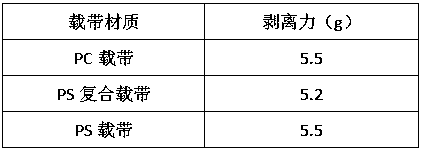

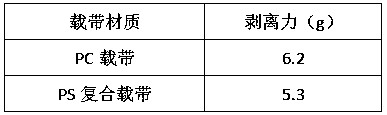

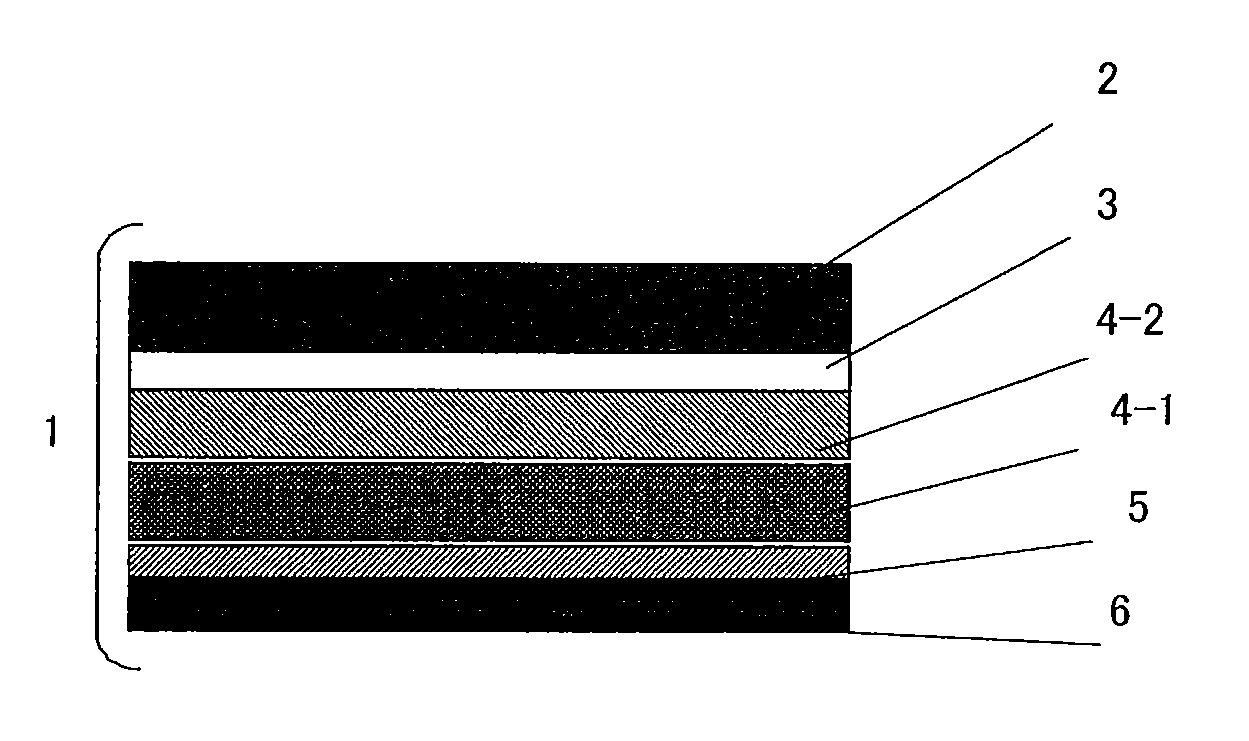

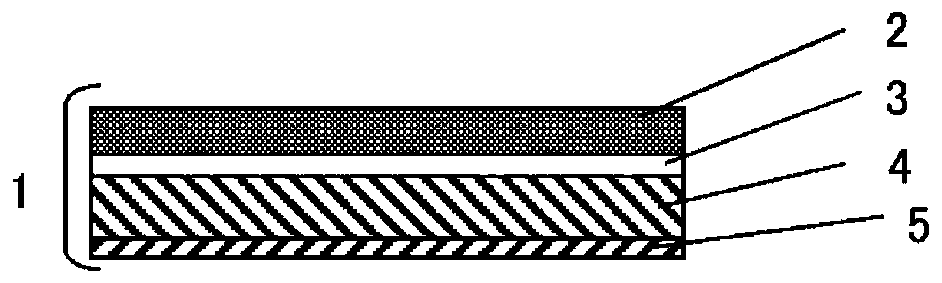

Cover tape

ActiveCN102971227AHigh transparencyInhibition of attachmentFlexible coversWrappersUltimate tensile strengthHigh velocity

Disclosed is a cover tape which comprises at least a base layer (A), an intermediate layer (B), a peeling layer (C), the primary component of which is a thermoplastic resin, and a heat seal layer (D), the primary component of which is a thermoplastic resin that can be heat sealed to a carrier tape. The tensile storage modulus (c) of the thermoplastic resin that constitutes the peeling layer (C) is within the range of 1*106 Pa to 1*108 Pa. The tensile storage modulus (d) of the thermoplastic resin that constitutes the heat seal layer (D) is within the range of 1*108 Pa to 1*10<10> Pa. The ratio of (c) and (d) satisfies 1*104>=(d) / (c)>=1*10. This kind of cover tape has the appropriate peel strength and sufficiently low fluctuation in peel strength when heat sealed to a thermoplastic resin carrier tape. Therefore, the tape will not tear even under shock caused by high-speed peeling, and adherence of electronic parts does not occur even when set aside for a long period of time of 24 to 72 hours in a high-temperature environment of 60 to 80 C.

Owner:DENKA CO LTD

Strippable multilayer-structure surface protective film and product thereof

InactiveCN101892019AStable Peel StrengthThin material handlingHeat-activated film/foil adhesivesTectorial membraneDicarboxylic acid

Owner:EI DU PONT DE NEMOURS & CO

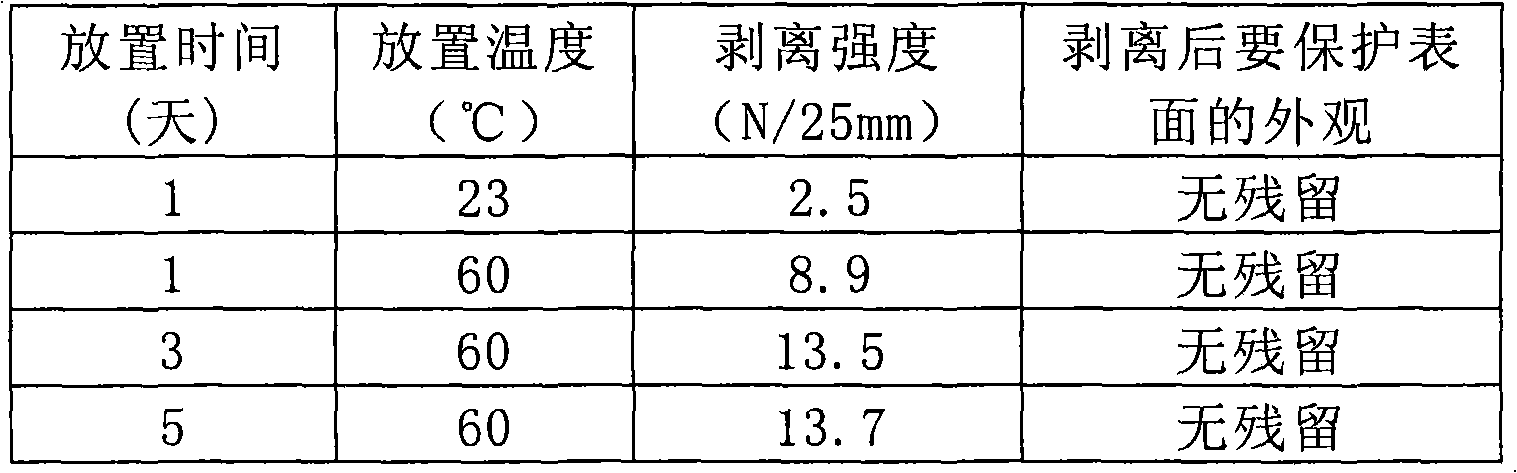

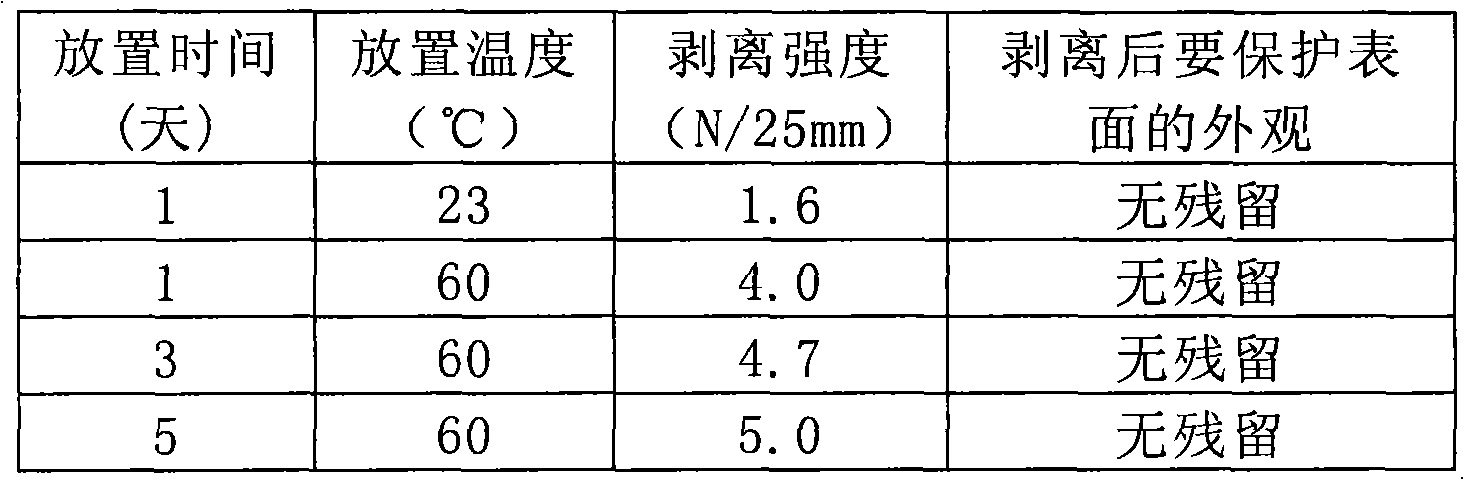

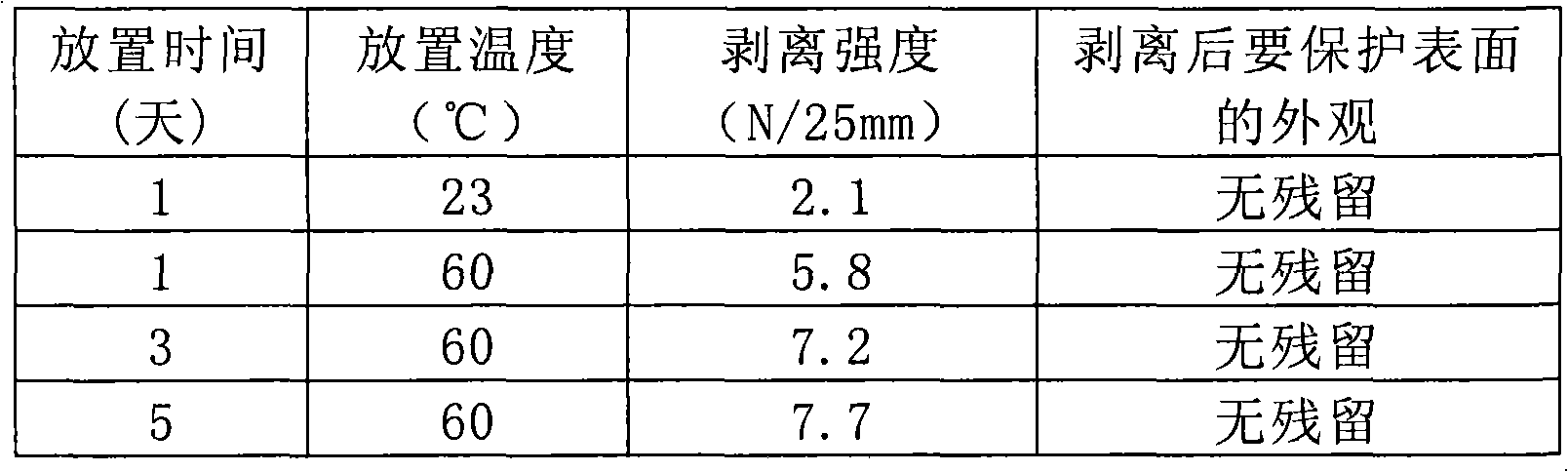

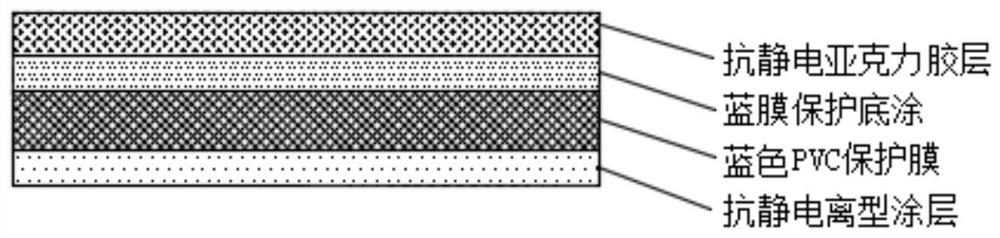

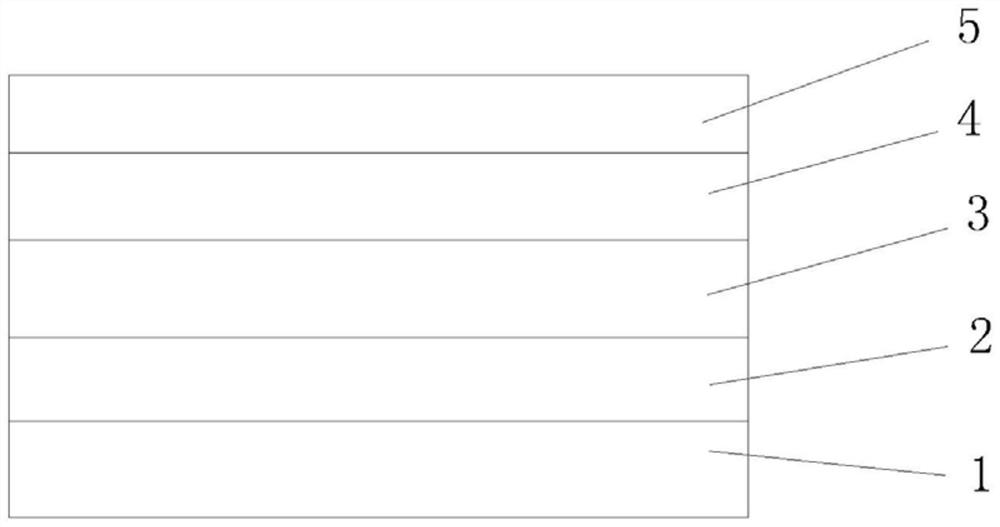

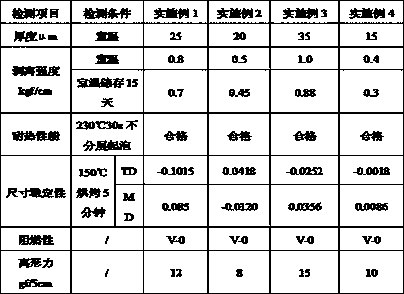

Antistatic semiconductor chip cutting protective film

PendingCN112795323AEye-catching identificationEfficient identificationFilm/foil adhesive primer layersEster polymer adhesivesPolymer scienceWafer

The invention discloses the technical field of chip cutting protection films, and particularly relates to an antistatic semiconductor chip cutting protection film. The protection film comprises an antistatic release coating, a PVC blue film, a blue film protection base coating and an antistatic acrylic adhesive layer, and has the advantages of good flexibility, high temperature resistance, easiness in wafer expansion and wafer cutting, and capability of eliminating static electricity generated by friction in wafer expansion and cutting; the arrangement of the blue film protection prime coat can prevent a plasticizer in the PVC blue film from being separated out and permeating into the adhesive layer to a certain extent, the high temperature resistance and solvent resistance of the PVC blue film are improved, the PVC blue film is not prone to shrinkage, and the antistatic acrylic adhesive layer is stable in peel strength, resistant to high temperature of 180 DEG C and antistatic. And the PVC blue film can be used for striking and effectively identifying the protective film, so the use is convenient. The total thickness of the protective film is 80 + / -2 [mu]m, the peel strength is 100 + / -20 gf / inch, no adhesive is left, the antistatic resistance value is 106-109 omega, and the release force is 20 gf / inch.

Owner:东莞市清鸿新材料科技有限公司

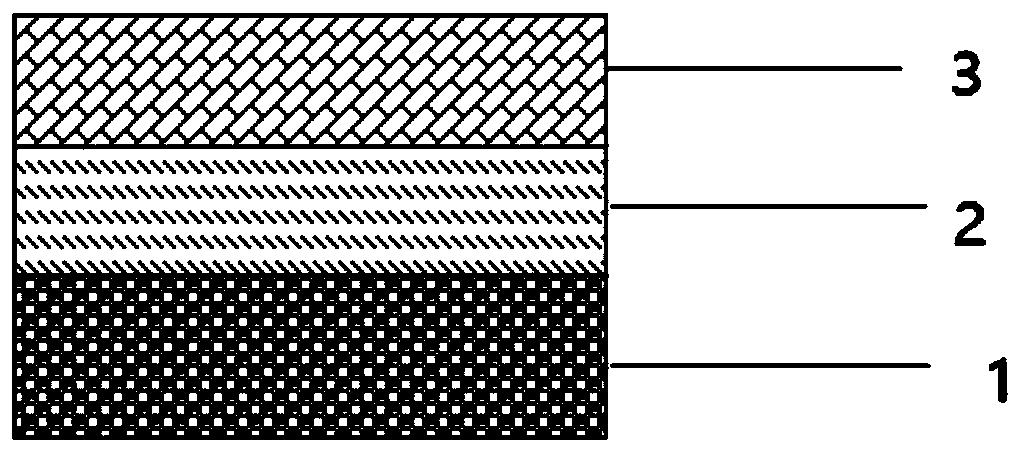

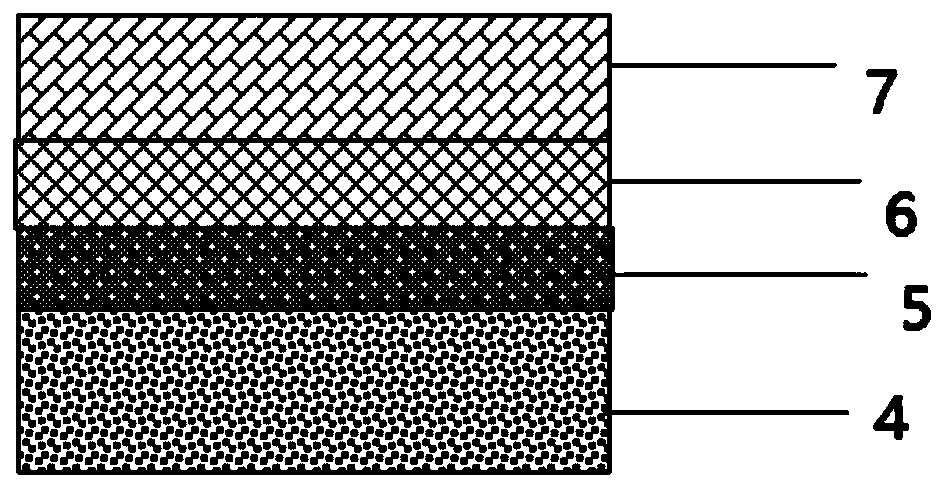

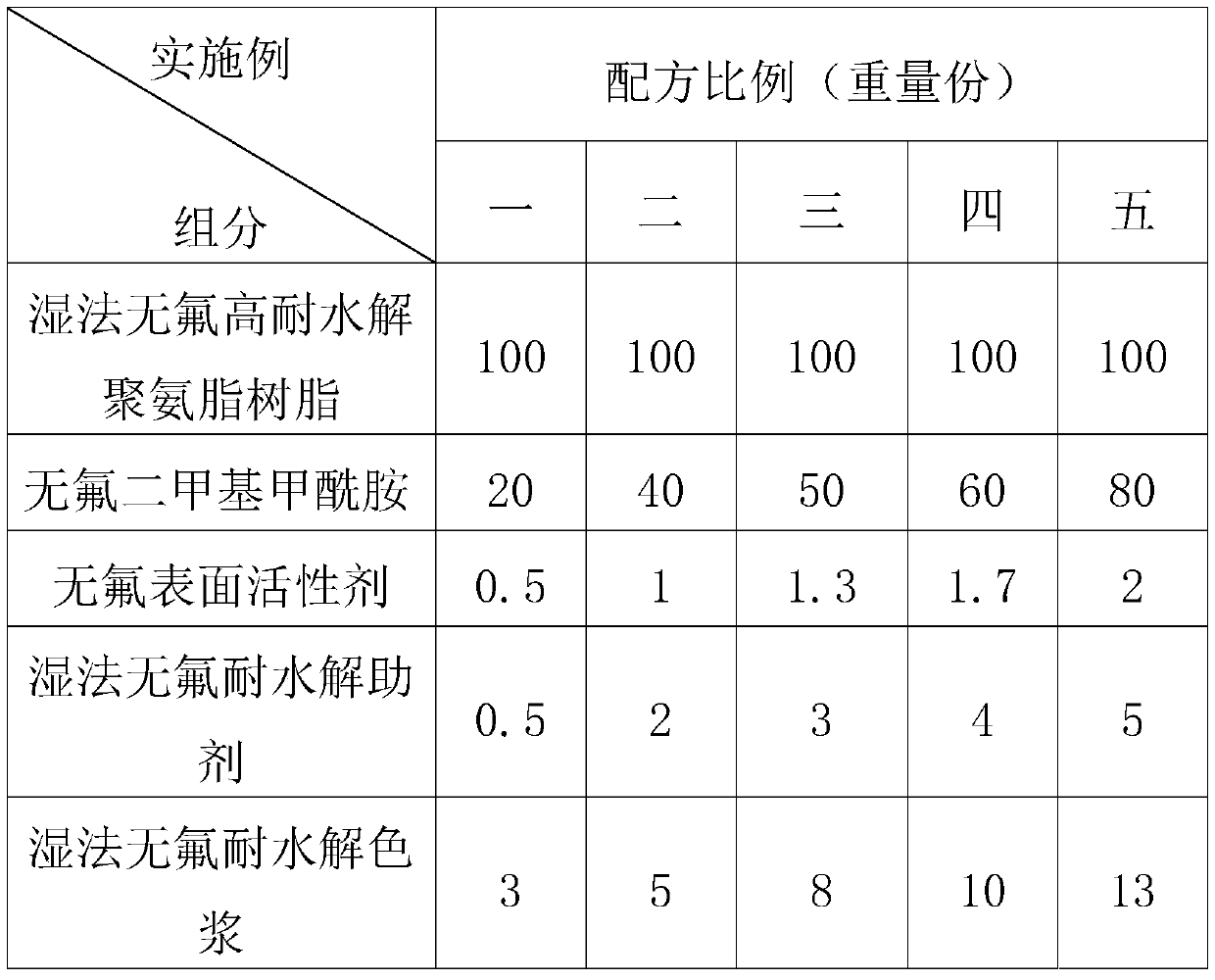

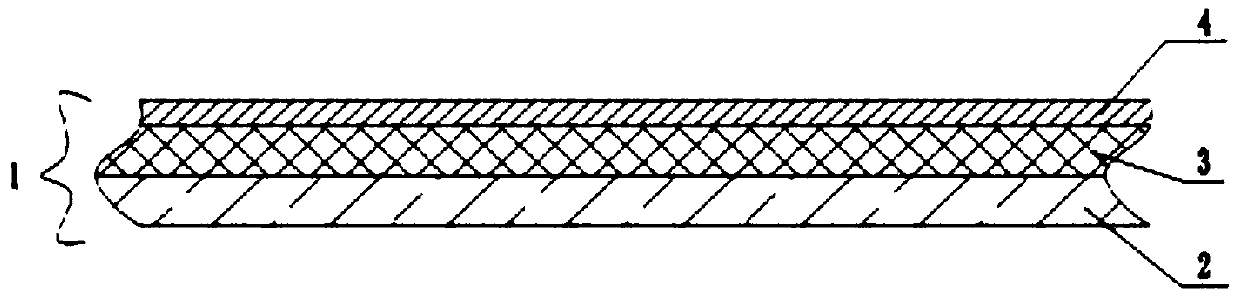

Production process of fluorine-free environment-friendly sports shoe synthetic leather

The invention discloses a production process of fluorine-free environment-friendly sports shoe synthetic leather, which specifically comprises the steps: preparing a fluorine-free wet base coating material, a fluorine-free wet base impregnation material and a dry top material according to a formula, impregnating a nonwoven fabric into the wet base impregnation material, scraping to apply the wet base coating material onto the surface of the nonwoven fabric, solidifying in a solidification tank to form a film, extruding, washing, and baking and setting to form a wet base; scraping to apply a mixed solution of the dry top material onto release paper, bonding the wet base through a fluorine-free adhesive, and separating the release paper a finished product. The environmental damage due to theuse of conventional fluorine hydrolysis-resistant resin is eliminated, the synthetic leather produced herein is soft to touch, and has excellent elasticity, high peeling strength and high hydrolysisresistance.

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

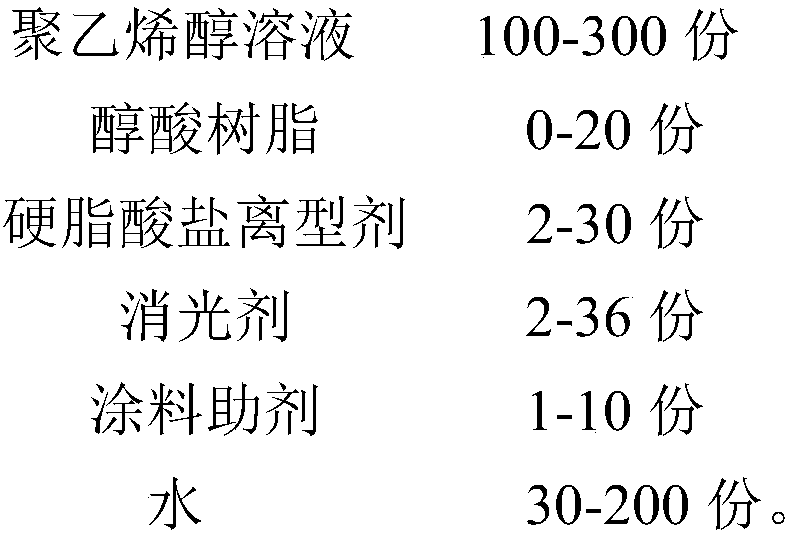

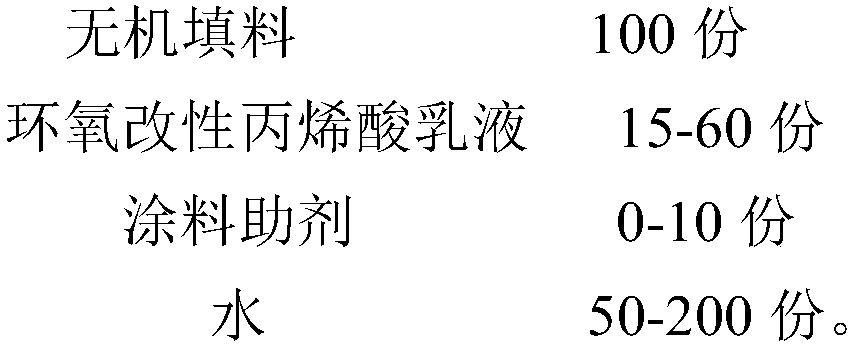

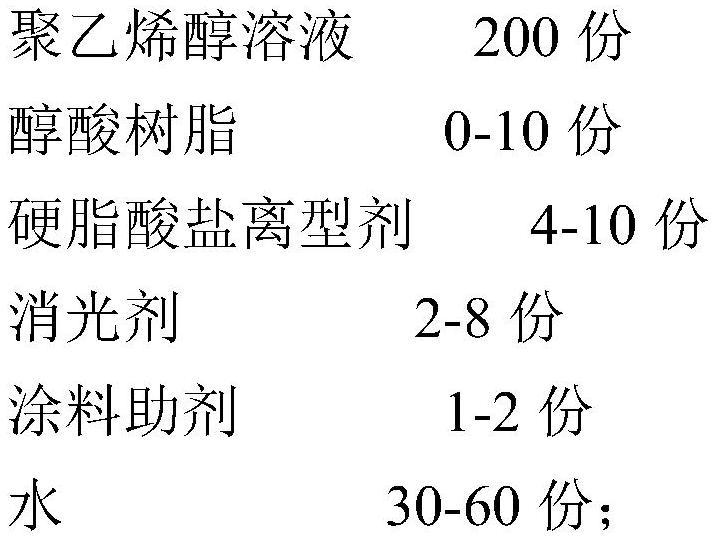

Release paper taking stearate as release agent

ActiveCN109098032AWith high temperature resistance of 210 ℃Less coatingNon-fibrous pulp additionCoatings with pigmentsPolyvinyl alcoholPulp and paper industry

The invention discloses release paper taking stearate as a release agent. The release paper includes base paper, an anti-permeation primer layer and a release layer which are sequentially composited,and the release layer takes the stearate as the release agent and takes polyvinyl alcohol resistant to high temperature as a resin. The release layer comprises, by weight parts, 100-300 parts of polyvinyl alcohol solution, 0-20 parts of alkyd resin, 2-30 parts of stearate release agent, 2-36 parts of matting agent, 1-10 parts of coating aid and 30-200 parts of water. The release paper is characterized by resisting high temperature, can be applied to a process of production of PU, PVC and PU / PVC composite artificial leather at the same time, the coating amount is low, the release paper is not curled, and the peeling strength can be adjusted for different artificial leather resins.

Owner:浙江池河科技有限公司

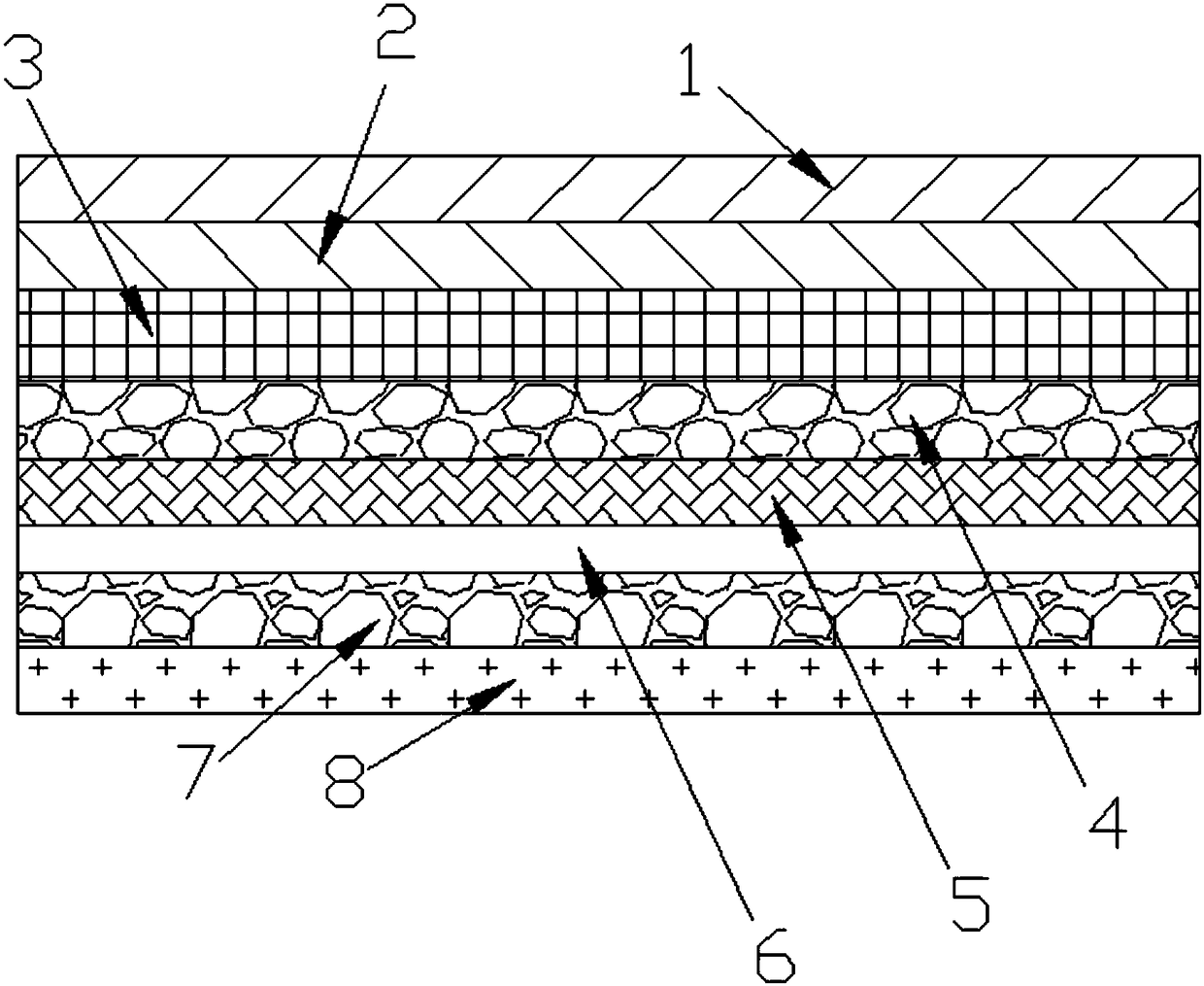

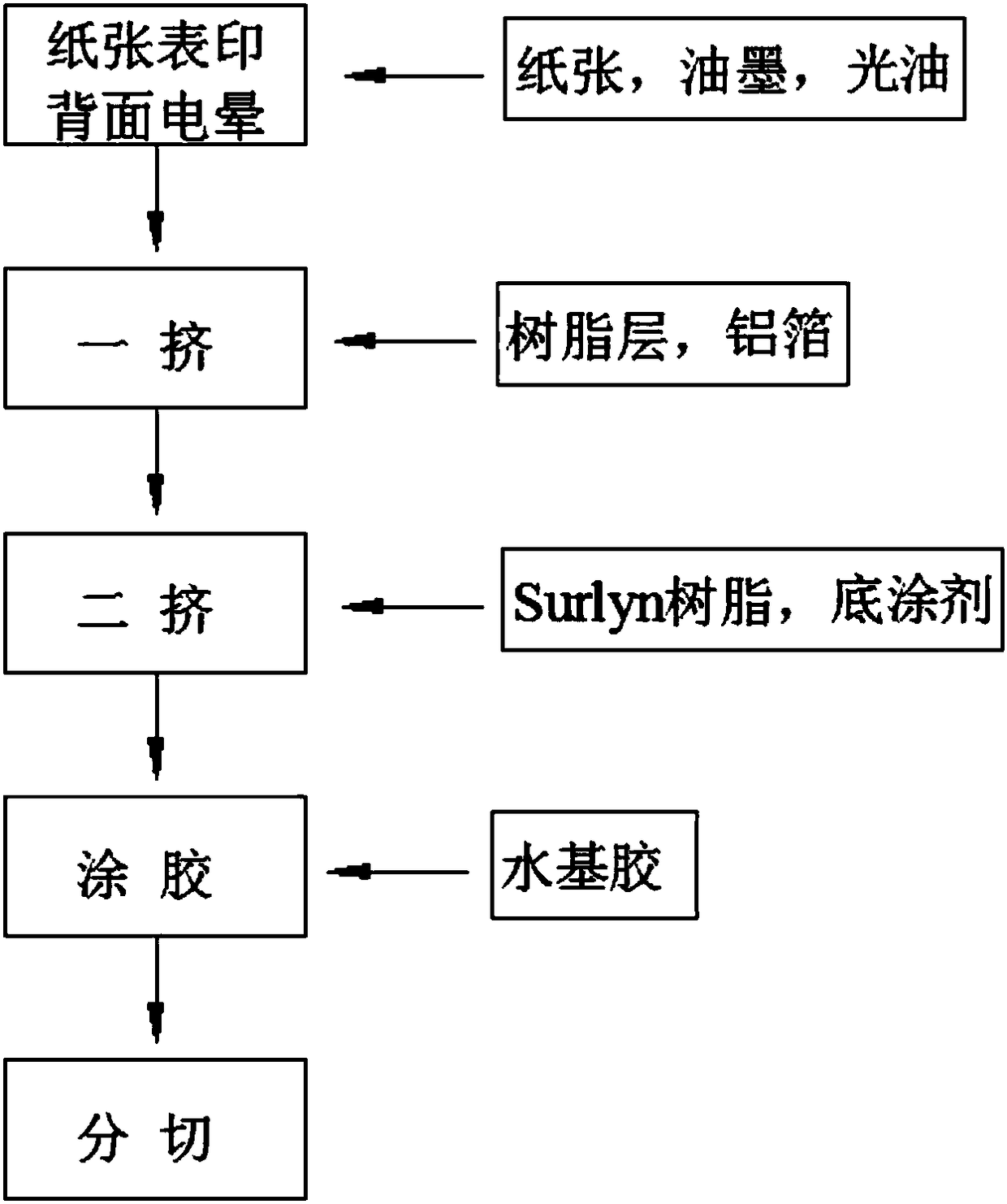

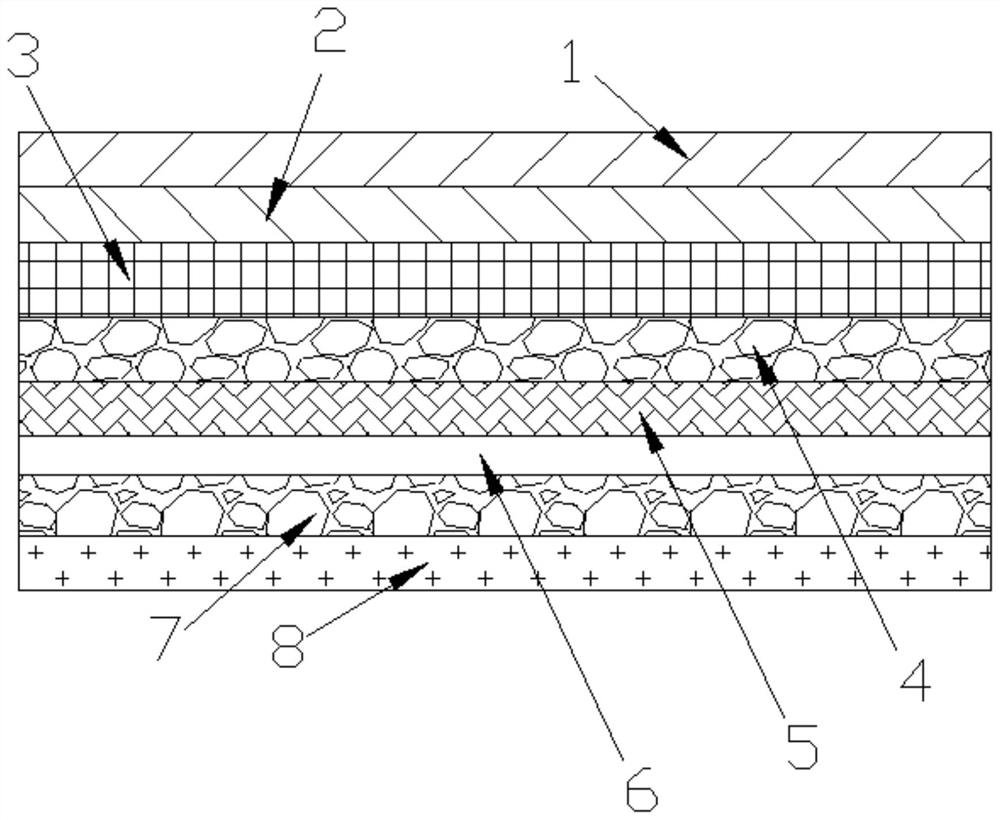

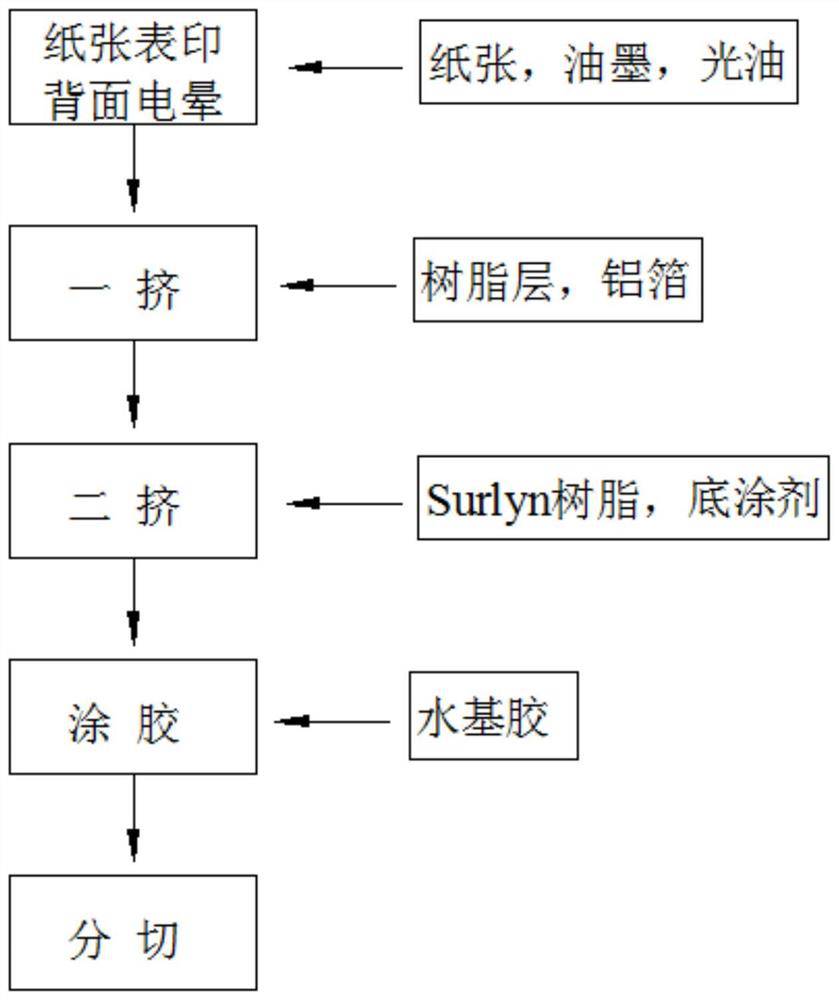

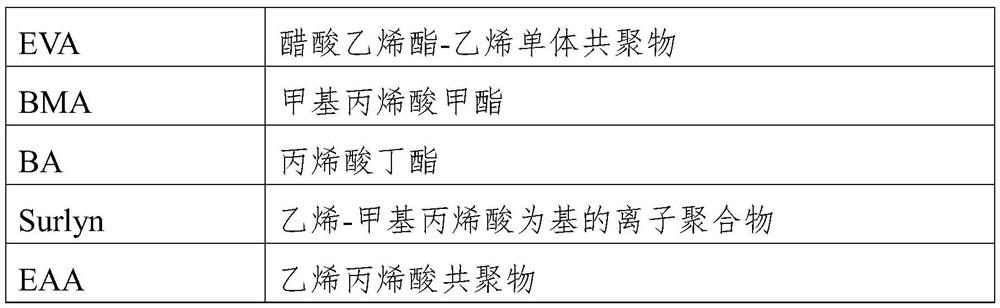

Stably and cleanly stripped glued medical instrument packaging material and preparation method thereof

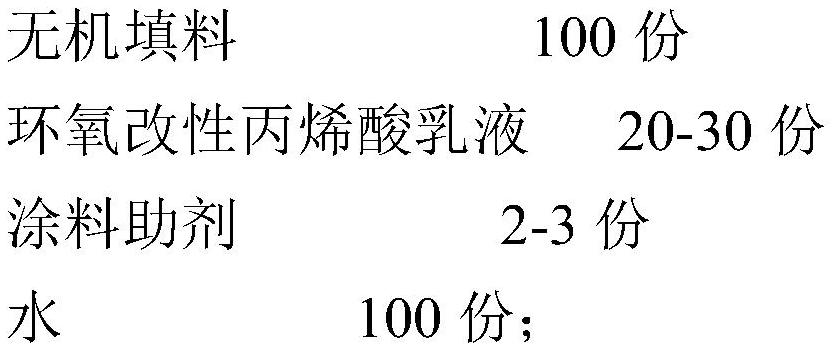

ActiveCN108441129AExtended shelf lifeStable and clean peelingFlexible coversWrappersWater basedEthylene Oxide Sterilization

The invention discloses a stably and cleanly stripped glued medical instrument packaging material comprising a gloss paint protective layer, an ink-printed paper sheet layer, a barrier layer and a glue layer arranged from top to bottom; a resin layer is extruded and compounded from each of two sides of the barrier layer; and main resin of the glue layer is a water-based adhesive. The invention further discloses a preparation method of the stably and cleanly stripped glued medical instrument packaging material; the stably and cleanly stripped glued medical instrument packaging material is suitable for a pressure steam and ethylene oxide sterilization way, the storage period of a sterilized product is long, and the product quality and clinic application safety are guaranteed; the stably andcleanly stripped glued medical instrument packaging material is excellent in barrier property and capable of reducing the occurrence rate of loss such as rustiness of metal goods and prolonging the service life of the goods; and the stably and cleanly stripped glued medical instrument packaging material has stable and easy stripping and sealing effects after being sterilized, so that the labor intensity of nursing staffs is relieved.

Owner:BEMIS FLEXIBLE PACKAGING SUZHOU

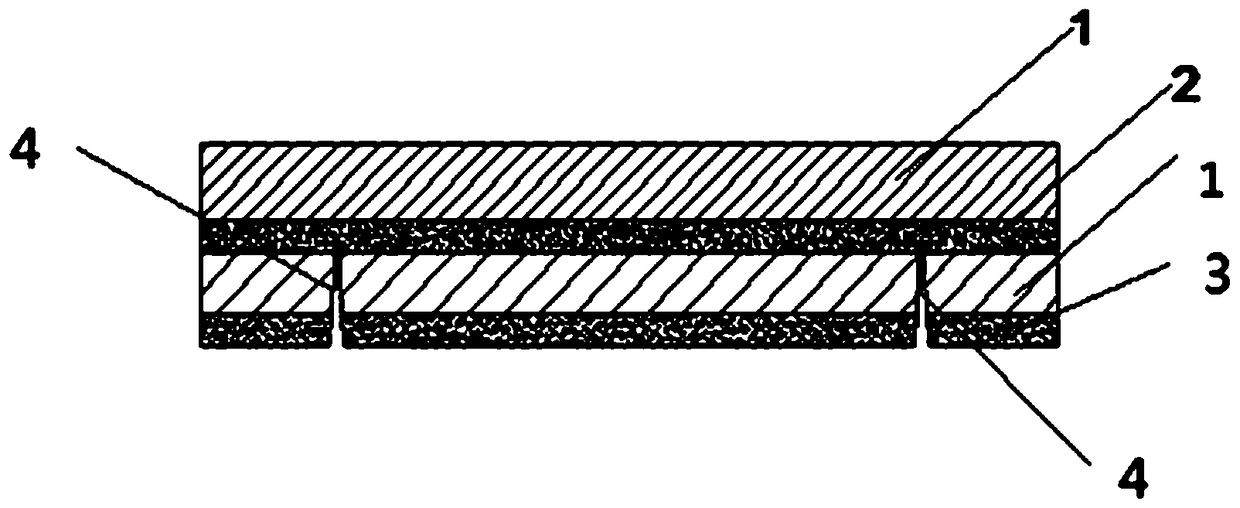

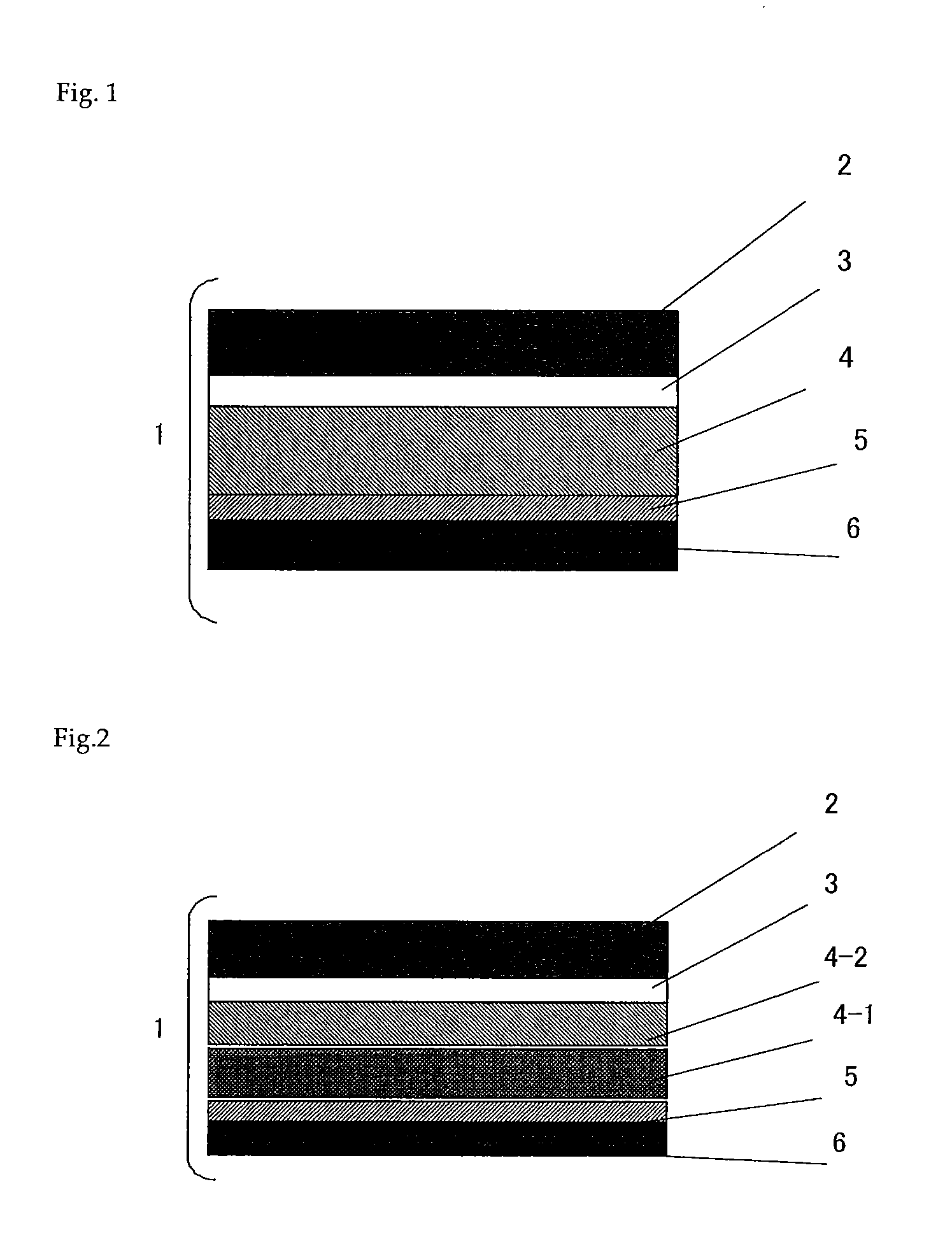

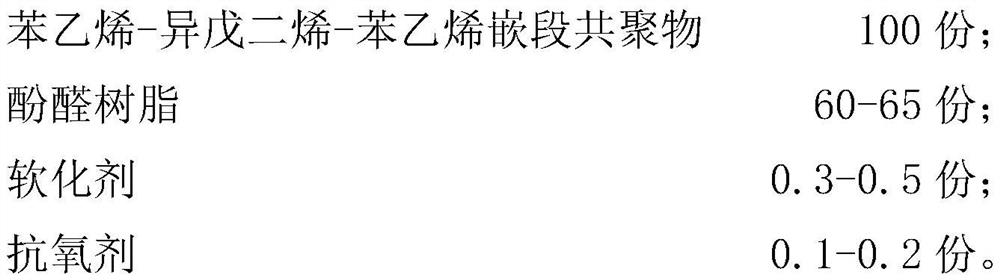

Cover strip structure

PendingCN108584148AControl Peel StrengthStable Peel StrengthPackagingEngineeringUltimate tensile strength

The invention discloses cover strip structure. The cover strip structure comprises two substrate film layers; the two substrate film layers are connected as a whole through a first adhesive layer; a second adhesive layer is arranged on the surface, without the first adhesive layer, of the first substrate film layer; two symmetric incisions are arranged on the second adhesive layer in the length direction; and the depths of the incisions extend from the second adhesive layer into the substrate film layer connected with the second adhesive layer. The cover strip structure achieves stable and uniform stripping strength.

Owner:广州市中载电子科技有限公司

Cover tape

ActiveUS20130089746A1Stable peel strengthExcellent transparencyFlexible coversWrappersChemistryPrimary component

Disclosed is a cover tape which comprises at least a base layer (A), an intermediate layer (B), a peeling layer (C), the primary component of which is a thermoplastic resin, and a heat seal layer (D), the primary component of which is a thermoplastic resin that can be heat sealed to a carrier tape. The tensile storage modulus (c) of the thermoplastic resin that constitutes the peeling layer (C) is within the range of 1×106 Pa to 1×108 Pa. The tensile storage modulus (d) of the thermoplastic resin that constitutes the heat seal layer (D) is within the range of 1×108 Pa to 1×1010 Pa. The ratio of (c) and (d) satisfies 1×104≧(d) / (c)≧1×10. This kind of cover tape has the appropriate peel strength and sufficiently low fluctuation in peel strength when heat sealed to a thermoplastic resin carrier tape. Therefore, the tape will not tear even under shock caused by high-speed peeling, and sticking of electronic parts does not occur even when set aside for a long period of time of 24 to 72 hours in a high-temperature environment of 60 to 80° C.

Owner:DENKA CO LTD

Metal foil laminated polyimide resin substrate

ActiveUS8624125B2Excellent adherence and adhesivenessImprove adhesionActive material electrodesPrinted circuit manufacturePolymer scienceMetal foil

The present invention relates to a metal foil laminated polyimide resin substrate whereina metal foil is directly laminated on one side or both sides of a polyimide resin substrate; andthe surface of the metal foil to be bonded to the polyimide resin substrate has a surface roughness (Rzjis) of 3.0 μm or less; a surface area ratio (B) of 1.25 to 2.50, in which the surface area ratio (B) is calculated as a ratio [A / 6550] of a surface area of a two-dimensional region with a surface area of 6550 μm2 which is determined by a laser method (three-dimensional area: A μm2) to the area of the two-dimensional region; and a chromium content per unit area of the two-dimensional region of 2.0 mg / m2 or more.

Owner:UBE CORP

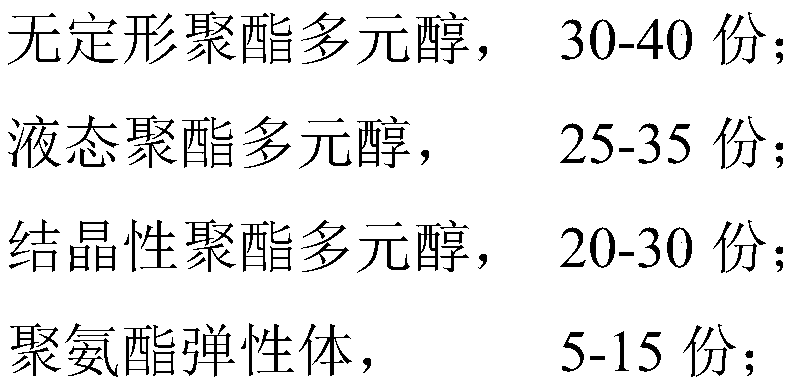

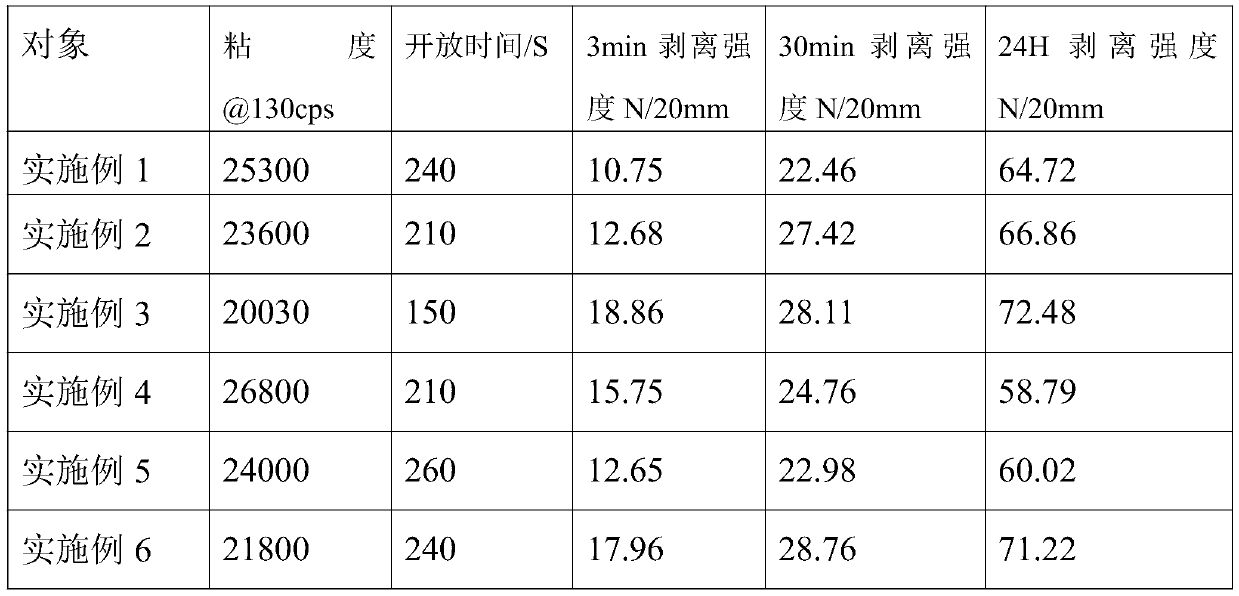

Adhesive for woodworking flat pasting

InactiveCN110484189AFast curingStable Peel StrengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventIsocyanate

The invention relates to an adhesive for woodworking flat pasting. The adhesive is prepared from the following components in parts by weight: 30 to 40 parts of amorphous polyester polyol; 25 to 35 parts of liquid polyester polyol; 20 to 30 parts of crystalline polyester polyol; 5-10 parts of a polyurethane elastomer; MDI which is added according to the isocyanate number molar ratio that NCO / OH isequal to 1.6-2.0; 0.1 to 0.3 part of an antioxidant; 0.1 to 0.5 part of a catalyst; and 0.5 to 3 parts of a silane coupling agent. The adhesive disclosed by the invention has the advantages of higherviscosity, easiness in woodworking flat sticking, zero solvent discharge in the curing process, high curing speed, no edge shrinkage phenomenon, high and stable peel strength after curing and good heat resistance.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Aqueous polyurethane resin for pressure-sensitive adhesive and preparation method thereof

ActiveCN104448219AImprove water resistanceStable Peel StrengthPolyureas/polyurethane adhesivesPolyesterEthylene diamine

The invention discloses aqueous polyurethane resin for a pressure-sensitive adhesive and a preparation method thereof. The preparation method comprises the following steps of carrying out pressure reduction dehydration on hydroxyl-terminated polyester polyol, carrying out cooling, adding diisocyanate into a reactor, carrying out a reaction process at a temperature of 70-90 DEG C for 110-120min, adding a dimethylolpropionic acid solution into the reaction product, carrying out a reaction process for 110-120min, cooling the reaction product to 50-55 DEG C, adding triethylamine into the reaction product for neutralization, carrying out full stirring for 8-10min, stopping stirring, fast pouring deionized water into the reactor, starting stirring and emulsification devices, carrying out emulsification for 8-10min, adding an ethanediamine solution into the emulsion, sequentially carrying out emulsification for 8-10min, stopping emulsification, sequentially carrying out stirring for 90-120min, carrying out filtration and discharging the product. The aqueous polyurethane resin has 180 degree peel strength of 30-300g / 25mm. Through coating machine-based coating, a plurality of the pressure-sensitive adhesive products with excellent performances are obtained and can be widely used for all industries. The preparation method is simple and easy.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

CCK release paper and preparation method thereof

PendingCN112878090AImprove water and oil repellencyImprove high temperature resistanceWater-repelling agents additionPulp beating methodsChemical pulpPaper sheet

The invention provides a preparation method of CCK release paper. The method comprises the following process steps: respectively subjecting coniferous wood chemical pulp and broadleaf wood chemical pulp to pulping, pulp mixing, auxiliary material adding, wet paper making with pulp, pre-drying, coating in a machine, post-drying, calendaring, finishing and the like so as to obtain the CCK release paper. According to the invention, the raw paper is subjected to in-machine coating treatment, so that the waterproof and oil-proof performance and the high-temperature resistance of the CCK release paper are effectively improved, and the tensile strength, the surface smoothness, the covering property and the heat insulation property of the paper are further improved after the coating. The product prepared by the method provided by the invention has the characteristics of good barrier property, high smoothness, high internal binding force, stable peel strength, environmental friendliness and the like, is directly coated with silicon and does not need to be coated in release processing, has the characteristics of cost reduction and environmental protection, and is a typical product replacing plastic. The invention also provides the CCK release paper.

Owner:YUEYANG FOREST & PAPER CO LTD

Waterborne polyurethane dispersion and single-component waterborne adhesive with same for PVC (polyvinyl chloride) calendered coatings

The invention relates to a waterborne polyurethane dispersion and a single-component waterborne adhesive with the same for PVC (polyvinyl chloride) calendered coatings. The single-component waterborneadhesive has good softness and high adhesive strength and comprises the waterborne polyurethane dispersion, a waterborne leveling agent, a waterborne wetting agent, a waterborne defoaming agent, a pHregulator, and a thickener. The invention also relates to a roller application technique which employs the single-component waterborne adhesive for calendered coatings. The single-component waterborne adhesive for PVC calendered coatings disclosed herein may be combined with PVC paste and textile base, with scraping and rolling processes involved; a prepared PVC calendered coating has very high initial viscosity, post-stabilizing peel strength, plasticizer resistance, and jungle resistance, and is widely applicable to packaging bags, raincoats, tablecloths, curtains and the like.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Novel printable mobile phone rear cover inner explosion-proof membrane and preparation method thereof

ActiveCN113025227AImproves substrate adhesion propertiesImprove degumming problemNon-macromolecular adhesive additivesEster polymer adhesivesUltraviolet lightsUv absorber

The invention discloses a novel printable mobile phone rear cover inner explosion-proof film which sequentially comprises a PE protective film layer, a printable layer, a PET base material layer, an optical adhesive layer and a release film layer from bottom to top; the optical adhesive layer contains an epoxy curing agent, an ultraviolet absorber and a coupling agent; the ultraviolet light absorber is selected from one or more of an ultraviolet light absorber UV-P, an ultraviolet light absorber UV-234, an ultraviolet light absorber UV-329 and an ultraviolet light absorber UV-531, and the coupling agent is selected from one or more of a silane coupling agent KH-550, a silane coupling agent KH-560, a silane coupling agent KH-570 and a silane coupling agent KH-580. The explosion-proof film has high peel strength to mobile phone rear cover glass, the peel strength can reach 2000 gf / in or above, the explosion-proof film still has stable peel strength under the environments of high temperature, low temperature, 65 / 95, salt mist, QUV and the like, and no adhesive residue phenomenon is generated; the silane coupling agent is added into the optical adhesive layer, so that the base material adhesive force performance of the optical adhesive is greatly improved, and the degumming problem of the explosion-proof membrane is solved.

Owner:浙江日久新材料科技有限公司

Epoxy adhesive and application thereof

InactiveCN110452652AReduce release forceStable Peel StrengthNon-macromolecular adhesive additivesFilm/foil adhesivesHigh energyEther

The invention discloses an epoxy adhesive and an application thereof. The purpose of the invention is to solve the problems of high energy consumption, long cycle, high etching liquid processing costand incompatibility with the environmental protection requirement in the production process of existing FPC lamp strips. The epoxy adhesive includes a polyurethane, a polyphenylene ether, an epoxy resin, a curing agent, a flame retardant, a filler and a solvent. A technology for preparing a PET cover film from the epoxy adhesive concretely comprises the following steps: uniformly coating one sideof an electric insulating film with the epoxy adhesive, allowing the electric insulating film coated with the adhesive to go through a drying oven in order to remove a solvent and dry the electric insulating film, performing rolling re-laminating the electric insulating film with a semi-cured adhesive layer to a release material, and finally aging the obtained product to obtain the PET cover film.The epoxy adhesive prepared in the invention and the PET cover film using the adhesive have a low release force and a stable peeling strength, can be used for preparing non-etched LED circuit boards,have a low production cost, and are green and environmentally friendly.

Owner:西安航天三沃化学有限公司

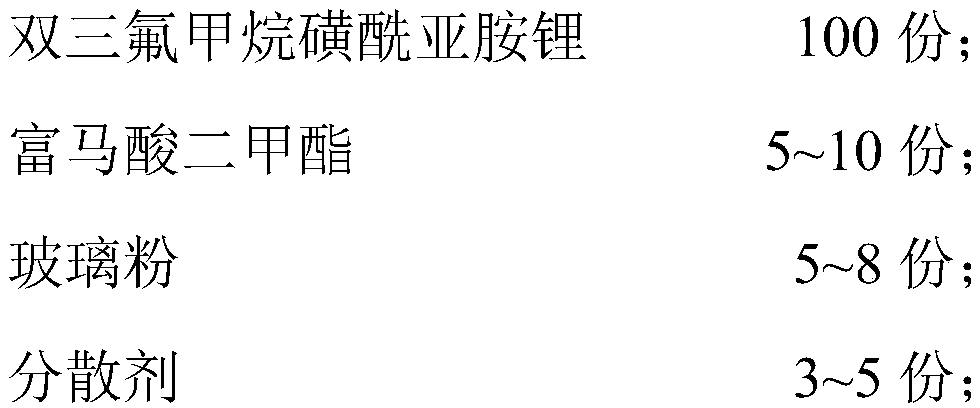

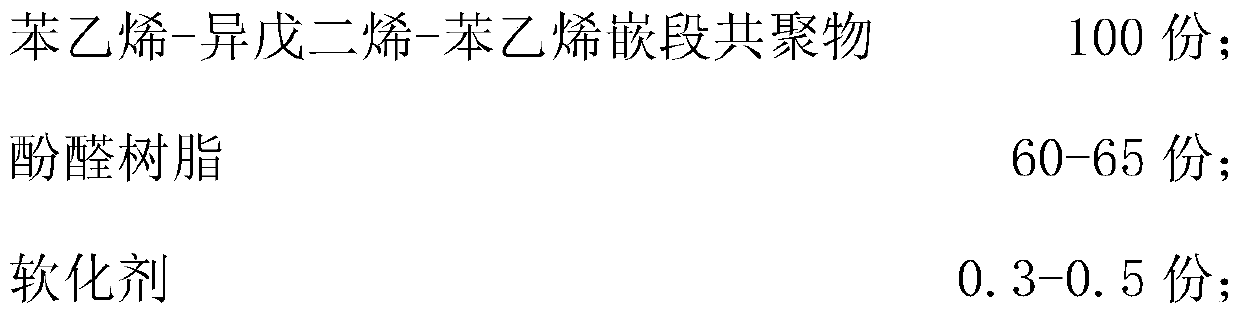

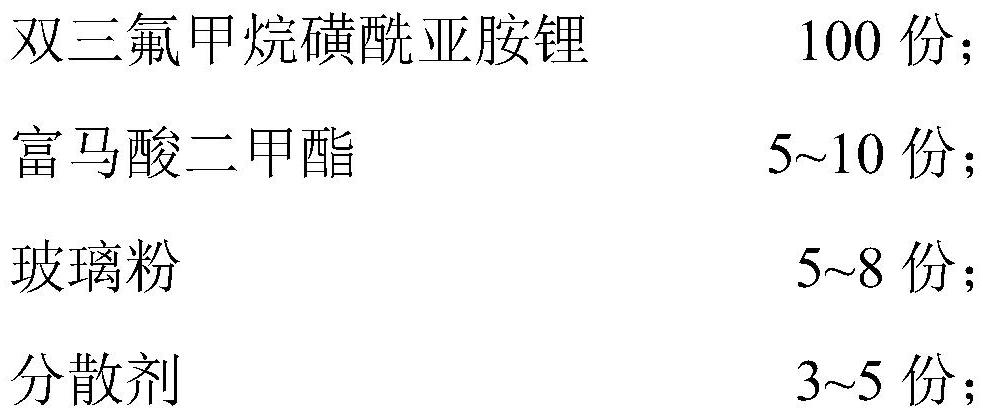

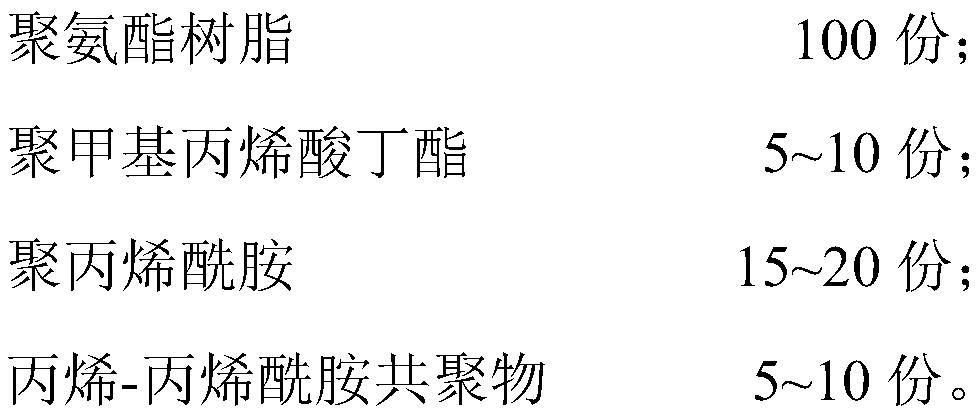

Antistatic protective film with stable viscosity

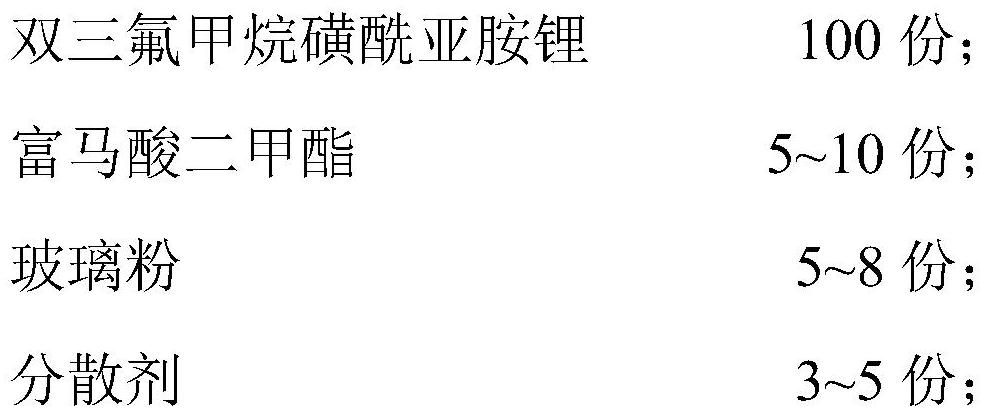

ActiveCN109401656AHigh bonding strengthImprove cohesionFilm/foil adhesivesPolyureas/polyurethane adhesivesTectorial membraneLithium

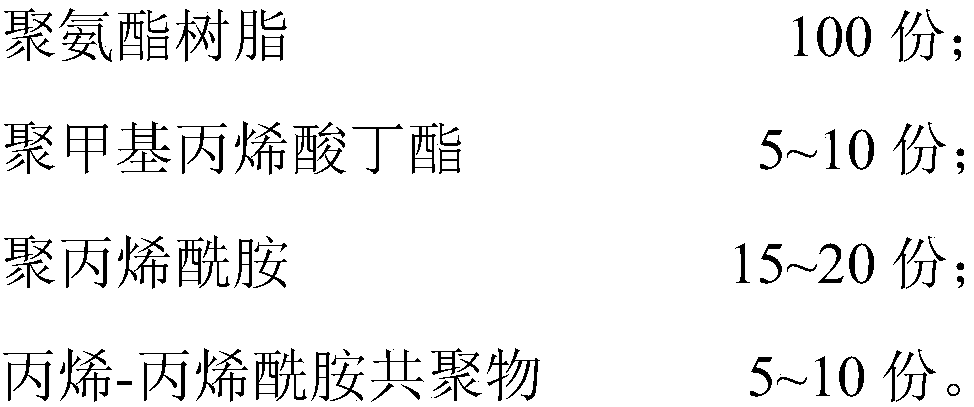

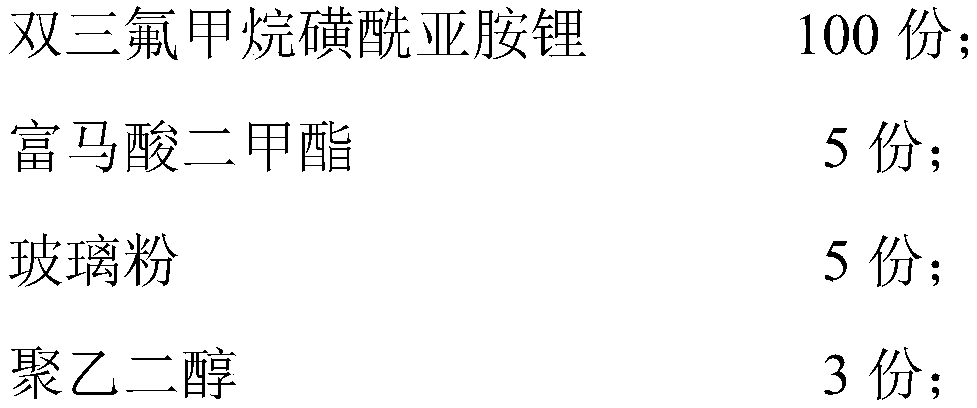

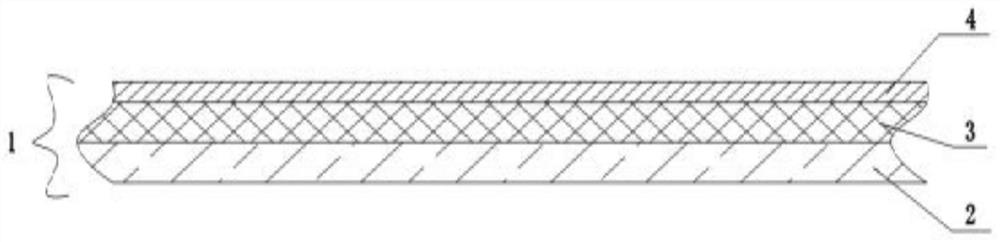

The invention discloses an antistatic protective film with stable viscosity. The antistatic protective film comprises a PET base material layer, antistatic layers arranged on the upper surface and thelower surface of the PET base material layer, and adhesive layers arranged on the outer surfaces of the antistatic layers; each antistatic layer is prepared from the following components in parts byweight: 100 parts of lithium bisimide, 5-10 parts of dimethyl fumarate, 5-8 parts of glass powder and 3-5 parts of a dispersant; and each adhesive layer is prepared from the following components in parts by weight: 100 parts of polyurethane resin, 5-10 parts of poly-n-butyl methacrylate, 15-20 parts of polyacrylamide and 5-10 parts of a propylene-acrylamide copolymer. Compared with the prior art,the protective film provided by the invention has the stable viscosity and good antistatic performance simultaneously, and can be used for packaging of electronic components.

Owner:东莞市卓华高分子材料有限公司

A kind of release paper with stearate as release agent

ActiveCN109098032BWith high temperature resistance of 210 ℃Less coatingNon-fibrous pulp additionCoatings with pigmentsPolymer sciencePolyvinyl alcohol

Owner:浙江池河科技有限公司

A kind of waterborne polyurethane resin for pressure-sensitive adhesive and preparation method thereof

ActiveCN104448219BImprove water resistanceStable Peel StrengthPolyureas/polyurethane adhesivesPolyesterPolyol

The invention discloses aqueous polyurethane resin for a pressure-sensitive adhesive and a preparation method thereof. The preparation method comprises the following steps of carrying out pressure reduction dehydration on hydroxyl-terminated polyester polyol, carrying out cooling, adding diisocyanate into a reactor, carrying out a reaction process at a temperature of 70-90 DEG C for 110-120min, adding a dimethylolpropionic acid solution into the reaction product, carrying out a reaction process for 110-120min, cooling the reaction product to 50-55 DEG C, adding triethylamine into the reaction product for neutralization, carrying out full stirring for 8-10min, stopping stirring, fast pouring deionized water into the reactor, starting stirring and emulsification devices, carrying out emulsification for 8-10min, adding an ethanediamine solution into the emulsion, sequentially carrying out emulsification for 8-10min, stopping emulsification, sequentially carrying out stirring for 90-120min, carrying out filtration and discharging the product. The aqueous polyurethane resin has 180 degree peel strength of 30-300g / 25mm. Through coating machine-based coating, a plurality of the pressure-sensitive adhesive products with excellent performances are obtained and can be widely used for all industries. The preparation method is simple and easy.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

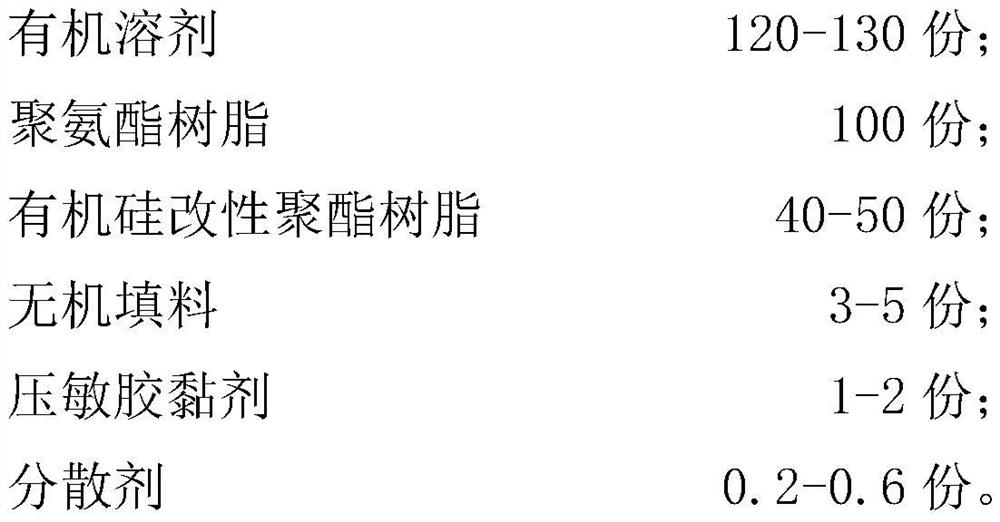

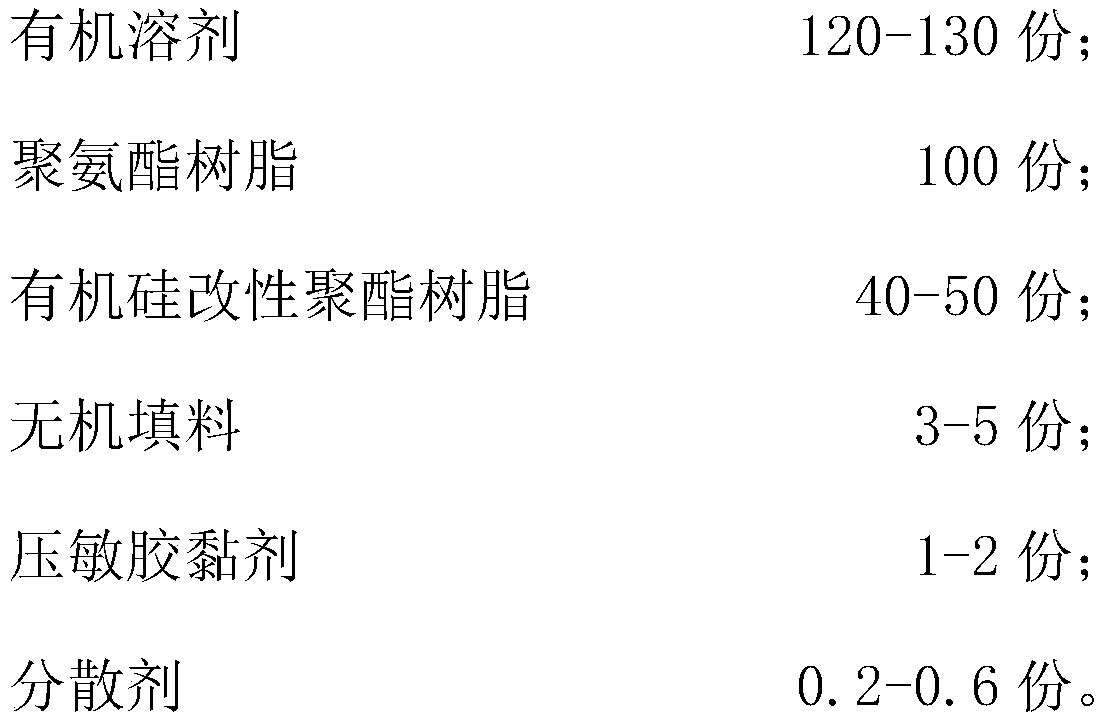

Protective film for various roughness surfaces

ActiveCN110951408BImprove stabilityGood adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceOrganosolv

The invention discloses a protective film for surfaces with various roughnesses, which comprises a base material layer and an adhesive layer arranged on the base material layer, wherein the adhesive layer comprises the following components by weight: polyurethane 100 parts of resin; 40-50 parts of silicone modified polyester resin; 3-5 parts of inorganic filler; 120-130 parts of organic solvent; 1-2 parts of pressure-sensitive adhesive; 0.2-0.6 parts of dispersant. By improving the formulation of the adhesive layer, the viscosity stability of the adhesive layer is improved, so that the adhesive layer has stable and excellent adhesiveness on surfaces with different roughnesses.

Owner:SUZHOU TAILUN ELECTRONIC MATERIALS CO LTD

Protective film for surfaces with various roughness

ActiveCN110951408AImprove stabilityGood adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceOrganic solvent

The invention discloses a protective film for surfaces with various roughness degrees. The protective film comprises a base material layer and an adhesive layer arranged on the base material layer, and the adhesive layer comprises the following components in parts by weight: 100 parts of polyurethane resin, 40 to 50 parts of organic silicon modified polyester resin, 3-5 parts of an inorganic filler, 120 to 130 parts of an organic solvent, 1-2 parts of a pressure-sensitive adhesive, and 0.2-0.6 part of dispersing agent. By improving the formula of the adhesive layer, the viscosity stability ofthe adhesive layer is improved, so that the adhesive layer has stable and excellent viscosity on surfaces with different roughness.

Owner:SUZHOU TAILUN ELECTRONIC MATERIALS CO LTD

Antistatic protective film with stable tack

ActiveCN109401656BHigh bonding strengthImprove cohesionFilm/foil adhesivesPolyureas/polyurethane adhesivesImidePolymer science

The invention discloses an antistatic protective film with stable viscosity. The antistatic protective film comprises a PET base material layer, antistatic layers arranged on the upper surface and thelower surface of the PET base material layer, and adhesive layers arranged on the outer surfaces of the antistatic layers; each antistatic layer is prepared from the following components in parts byweight: 100 parts of lithium bisimide, 5-10 parts of dimethyl fumarate, 5-8 parts of glass powder and 3-5 parts of a dispersant; and each adhesive layer is prepared from the following components in parts by weight: 100 parts of polyurethane resin, 5-10 parts of poly-n-butyl methacrylate, 15-20 parts of polyacrylamide and 5-10 parts of a propylene-acrylamide copolymer. Compared with the prior art,the protective film provided by the invention has the stable viscosity and good antistatic performance simultaneously, and can be used for packaging of electronic components.

Owner:东莞市卓华高分子材料有限公司

Stable and clean peelable glue-coated medical device packaging material and preparation method

ActiveCN108441129BExtended shelf lifeStable and clean peelingFlexible coversWrappersEthylene Oxide SterilizationAdhesive glue

The invention discloses a glue-coated medical device packaging material that can be peeled off stably and cleanly. The main resin of the resin layer and the glue layer is a water-based adhesive. The invention also discloses its preparation method; the invention is suitable for pressure steam and ethylene oxide sterilization methods, and the sterilized items have a long shelf life, which ensures product quality and safety for clinical application; excellent barrier performance, reduces metal The incidence of rust and other losses of similar items can be reduced, and the service life of the items can be extended; the stable and easy-peel sealing effect after sterilization reduces the labor intensity of the nursing staff.

Owner:BEMIS FLEXIBLE PACKAGING SUZHOU

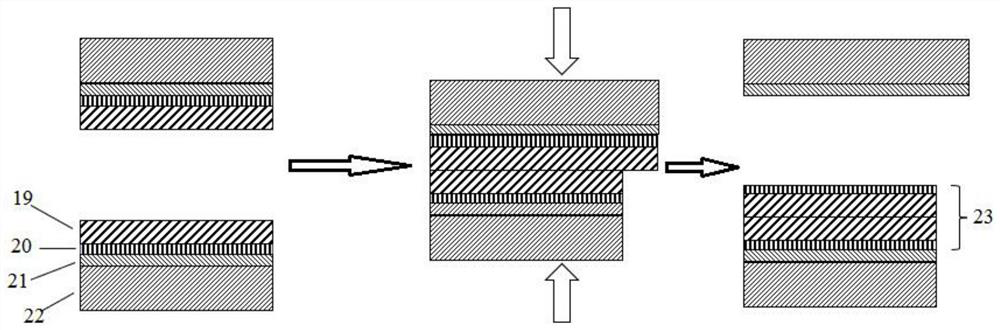

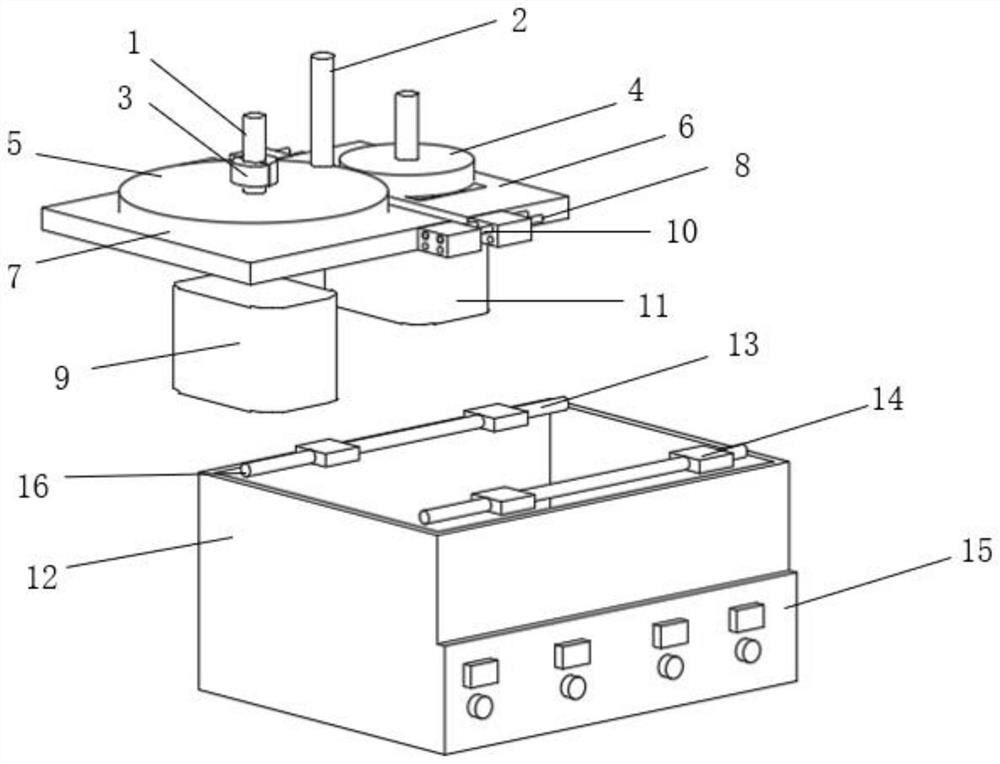

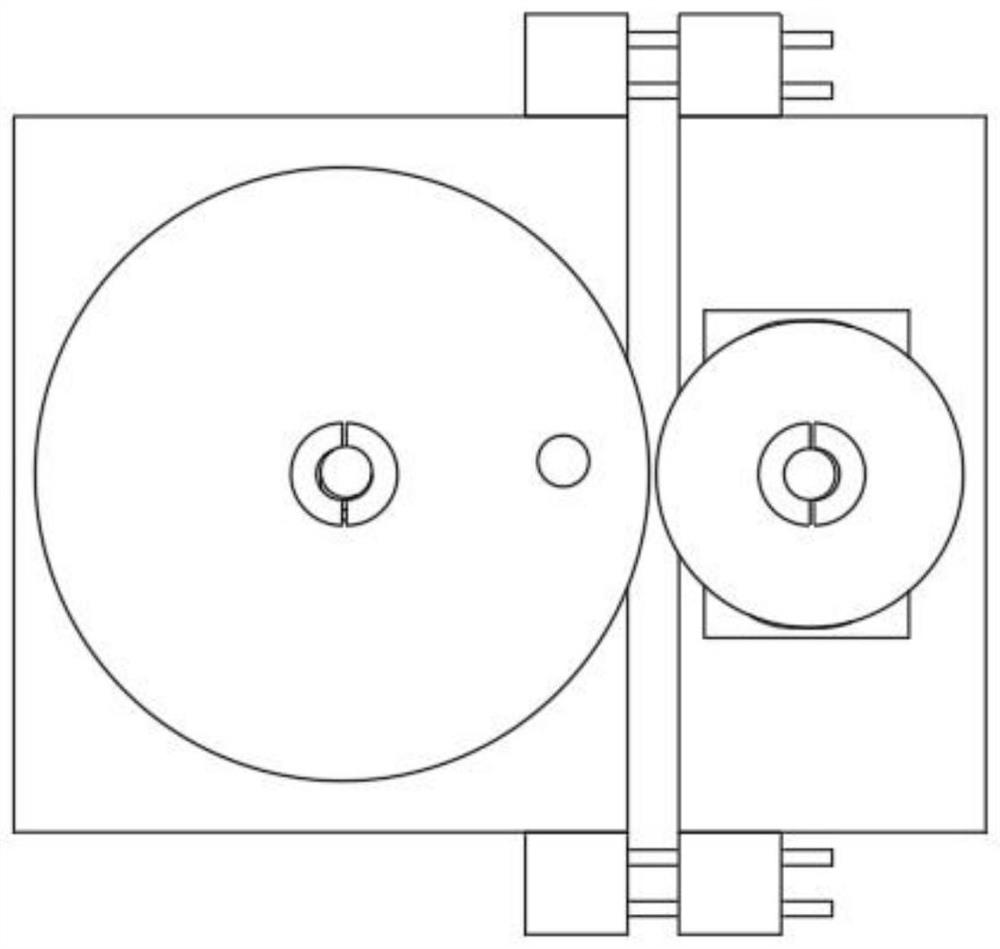

Multi-layer YBCO superconducting tape stripping device and stripping method thereof

PendingCN114388195AEasy to operateStable peelingSuperconductors/hyperconductorsSuperconductor devicesYttrium barium copper oxideEngineering

The invention discloses a multi-layer YBCO (Yttrium Barium Copper Oxide) superconducting tape stripping device and a stripping method thereof, and relates to the field of high-current-carrying superconducting tape preparation. Superconducting tapes which are welded together in a face-to-face manner are continuously stripped through the stripping device, and a superconducting long tape with multiple layers of YBCO is prepared; the problem that the manual stripping radius is difficult to control is solved; the force is difficult to control in the manual stripping process; and the manual stripping speed is unstable. According to the invention, the defects of manual stripping of the multi-layer YBCO superconducting layer are ingeniously avoided, an innovative stripping device is adopted, the operation steps are simplified, the stripping is more stable, the steps are concise, and the method has important significance for preparing the multi-layer YBCO superconducting long belt.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

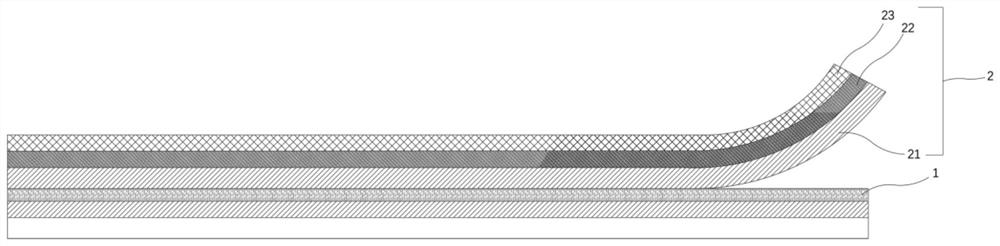

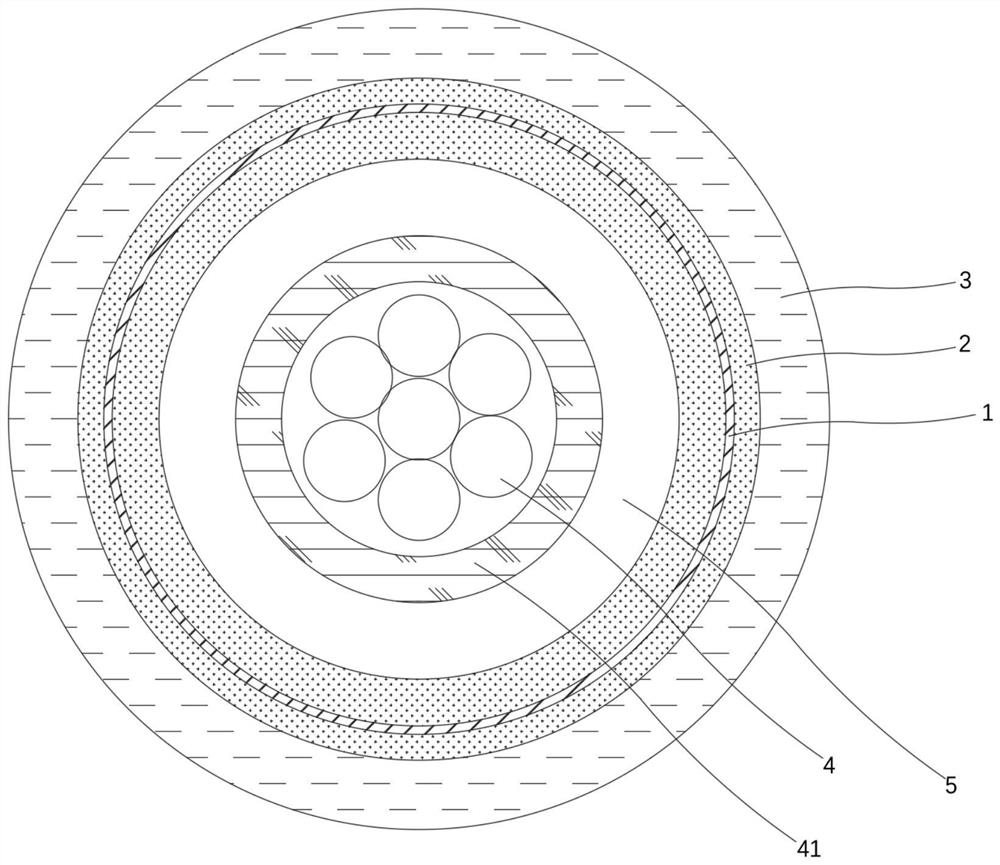

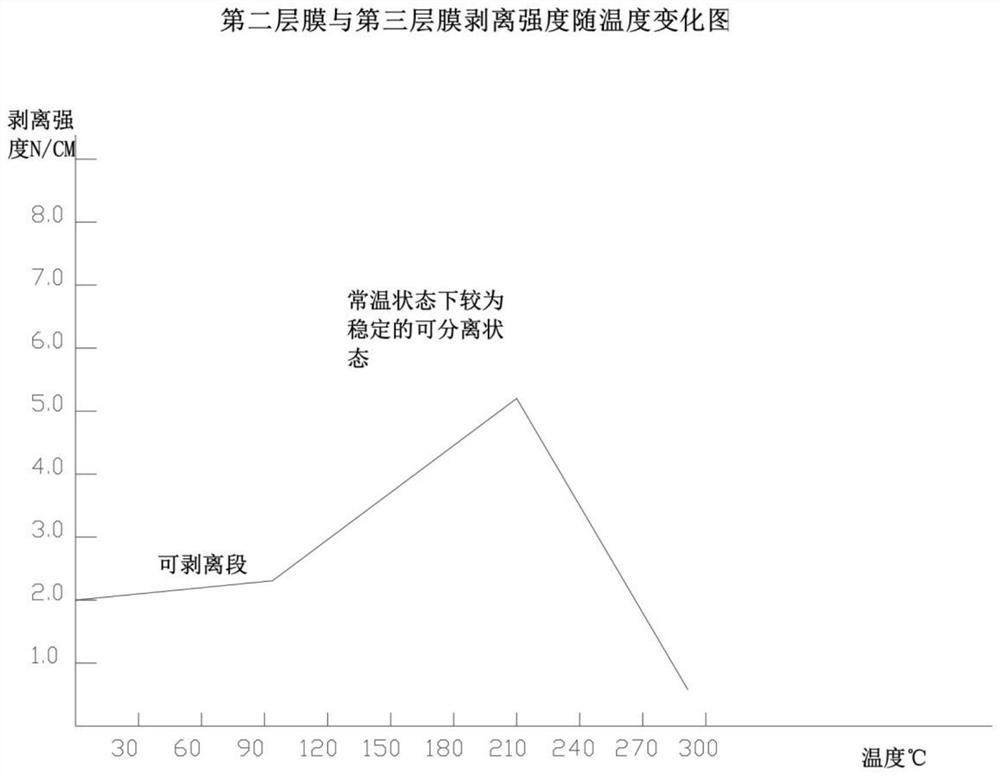

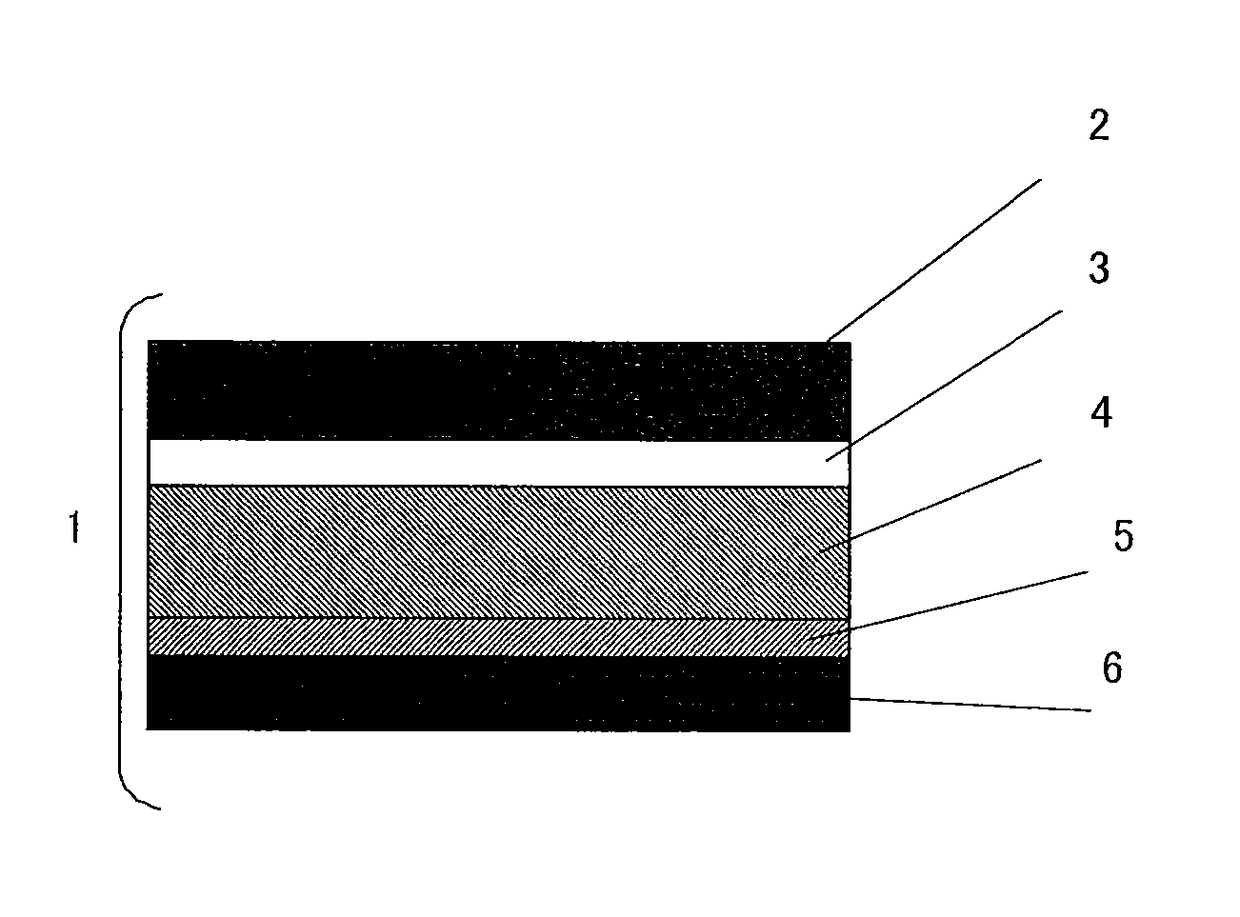

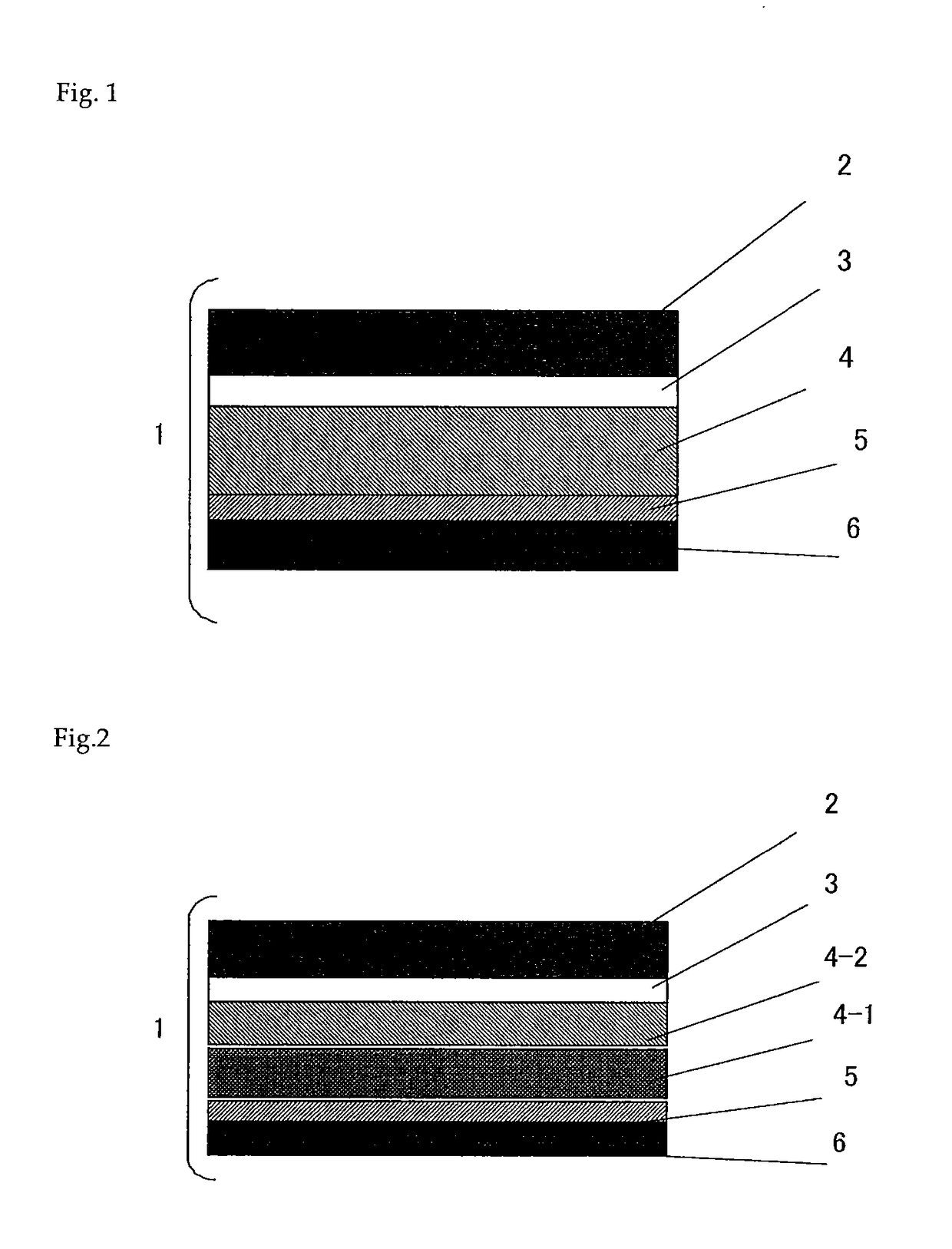

Composite armoring structure and optical fiber cable

PendingCN114296197AStable Peel StrengthFacilitate strippingActive material electrodesFibre mechanical structuresPhysical chemistryPolypropylene

The invention discloses a composite armoring structure and an optical fiber cable, and the structure comprises a steel base band, and one surface of the steel base band is provided with a composite structure. The composite structure comprises a first film layer, a second film layer and a third film layer, and the first film layer and the steel base band are bonded through electromagnetic compounding; the second-layer film is made of polyethylene; the third-layer film is made of modified polypropylene; the steel base band is made of low-carbon steel, and the thickness of the steel base band ranges from 0.1 mm to 0.3 mm; the outer surface of the steel base band is provided with a chromium-plated textured layer; the first layer of film is made of a propylene copolymer. The stripping strength of the second layer film and the third layer film is relatively stable, stripping is convenient, the third layer film and the outer sheath layer of the optical cable can be firmly bonded, and the optical cable can be used for stripping the outer sheath layer and an armored structure (without the third layer film) during installation or maintenance, so that the installation and use efficiency is improved; and the head of the optical cable can be conveniently used, and separation and connection (or installation) are facilitated.

Owner:上海网讯新材料科技股份有限公司

Cover tape

ActiveUS9662866B2Stable Peel StrengthHigh transparencyFlexible coversWrappersPolymer scienceSilicone tape

Disclosed is a cover tape which comprises at least a base layer (A), an intermediate layer (B), a peeling layer (C), the primary component of which is a thermoplastic resin, and a heat seal layer (D), the primary component of which is a thermoplastic resin that can be heat sealed to a carrier tape. The tensile storage modulus (c) of the thermoplastic resin that constitutes the peeling layer (C) is within the range of 1×106 Pa to 1×108 Pa. The tensile storage modulus (d) of the thermoplastic resin that constitutes the heat seal layer (D) is within the range of 1×108 Pa to 1×1010 Pa. The ratio of (c) and (d) satisfies 1×104≧(d) / (c)≧1×10. This kind of cover tape has the appropriate peel strength and sufficiently low fluctuation in peel strength when heat sealed to a thermoplastic resin carrier tape. Therefore, the tape will not tear even under shock caused by high-speed peeling, and sticking of electronic parts does not occur even when set aside for a long period of time of 24 to 72 hours in a high-temperature environment of 60 to 80° C.

Owner:DENKA CO LTD

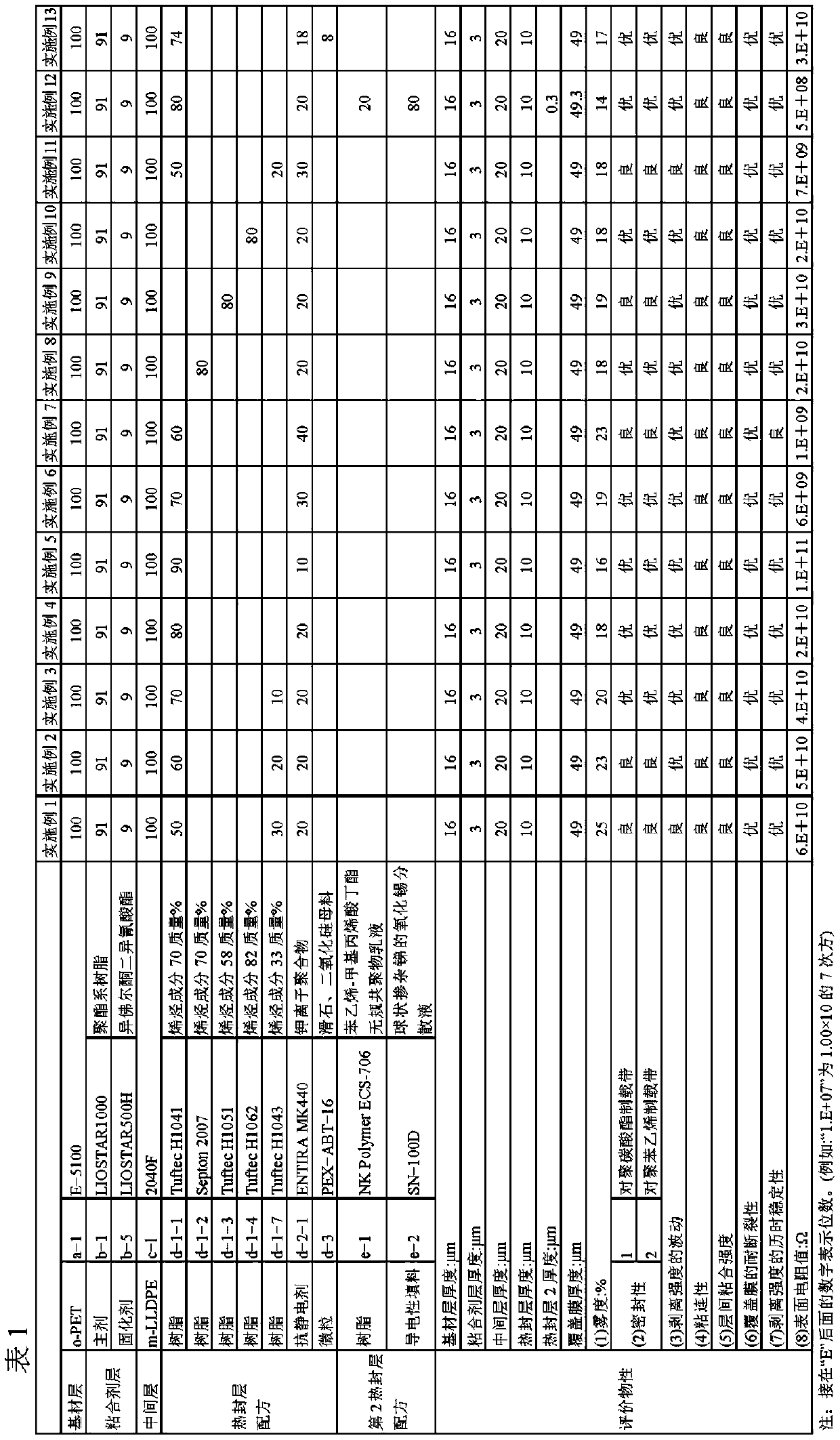

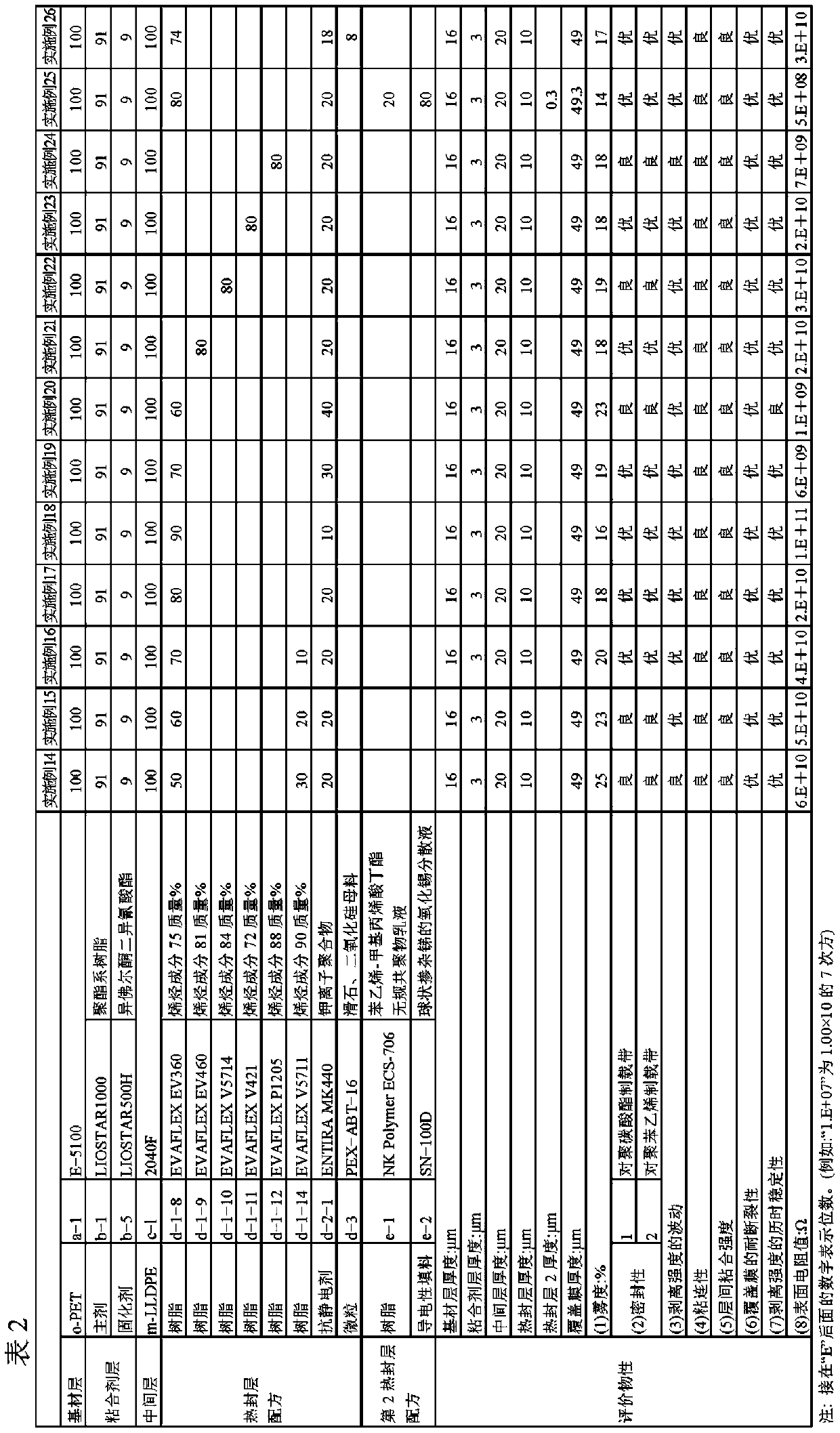

Cover film and electronic component package using same

ActiveCN106604816BStable Peel StrengthHigh transparencyFlexible coversWrappersPolymer sciencePotassium ions

The present invention provides a cover film which is stable in peel strength continuously within a predetermined value range when the cover film is peeled off, excellent in transparency, and less prone to "film breakage" during high-speed peeling. To provide a cover film comprising at least (A) a substrate layer and (B) an adhesive layer, (C) an intermediate layer and (D) a heat-sealing layer having a heat-sealable resin, (B) a The main agent is polyester resin, 50% by mass or more of the curing agent is isophorone diisocyanate, and (D) the heat sealing layer contains: 50-90% by mass of (d-1) olefin-based resin and 10-40% by mass % (d-2) a potassium ion polymer with antistatic properties, the (d-1) olefin-based resin comprises: an olefin-styrene block copolymer containing 58-82 mass % of an olefin component and an olefin-styrene block copolymer containing 75- Any one or more of ethylene-vinyl acetate copolymers containing 88% by mass of olefin content.

Owner:DENKA CO LTD

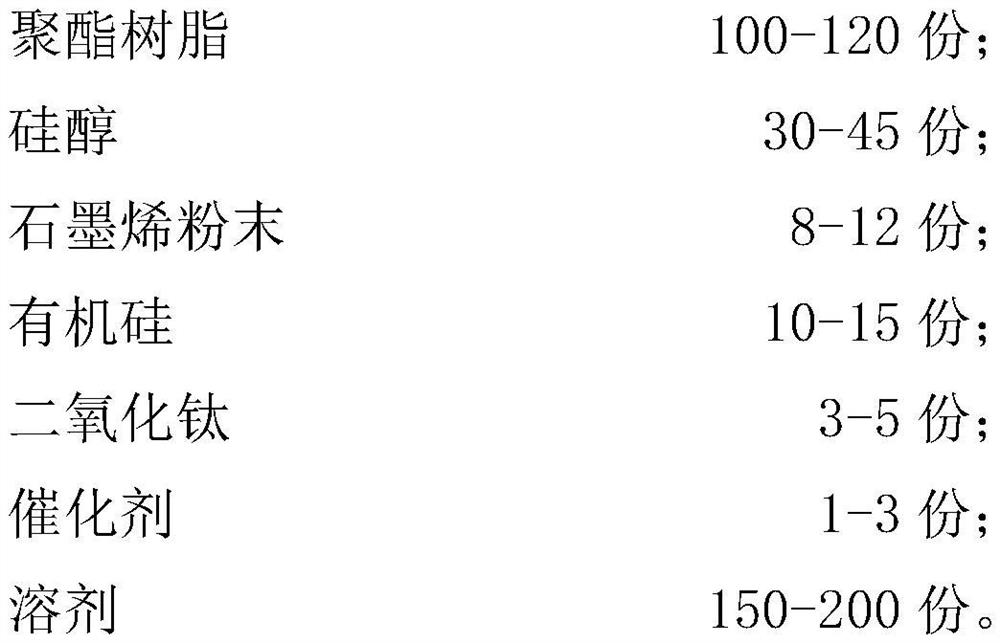

Self-repairing protective film and preparation method thereof

InactiveCN112852322AHigh tensile strengthImprove toughnessFilm/foil adhesivesPolyurea/polyurethane coatingsPolymer scienceUltraviolet lights

The invention relates to a self-repairing protective film which sequentially comprises a PET film layer and a release film layer, the face, making contact with the release film, of the PET film layer is coated with an adhesive layer, and the other face of the PET film layer is coated with a self-repairing layer. The self-repairing layer is prepared from the following raw materials in parts by weight: 10 to 20 parts of an ultraviolet light absorber UV-0, 30 to 50 parts of polypropylene glycol, 30 to 50 parts of dicyclohexyl methane diisocyanate, 2 to 6 parts of butanediol and 0.5 to 1.5 parts of an organic tin compound. The preparation method of the self-repairing protective film comprises the following steps: (1) weighing the raw materials of the self-repairing layer according to the required weight, mixing together, and uniformly stirring to obtain slurry; and (2) coating the PET film with the mixed slurry, and heating the PET film at 60-120 DEG C for 1-3 minutes for curing; and (3) coating the adhesive layer on the other side of the PET film and covering the release film.

Owner:HUNAN SHANGXIN NEW MATERIAL TECH CO LTD

Waterborne polyurethane dispersion and one-component waterborne adhesive for pvc calendered coating including it

The invention relates to a water-based polyurethane dispersion and a one-component water-based adhesive for PVC calendering coating including the water-based polyurethane dispersion. The adhesive balances soft feel and bond strength. The water-based adhesive is composed of the following components: water-based polyurethane dispersion, water-based leveling agent, water-based wetting agent, water-based defoamer, pH regulator, and thickener. The invention also relates to a roll coating process used for the one-component water-based adhesive for the calendering coating. The one-component water-based adhesive for PVC calendering coating disclosed by the present invention can be used for compounding PVC paste and textile substrates, including scraping and roller coating processes, and the prepared PVC calendering coating has very high initial bonding strength. Peel strength after stabilization, resistance to plasticizers and high jungle resistance, can be widely used in packaging bags, raincoats, tablecloths, curtains, etc.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com