CCK release paper and preparation method thereof

A release paper and pulp technology, applied in pulp beating methods, papermaking, paper and other directions, can solve the problems of papermaking environmental pollution, difficult to decompose, difficult to degrade, etc., and achieve the effects of environmental protection, high smoothness and high internal binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

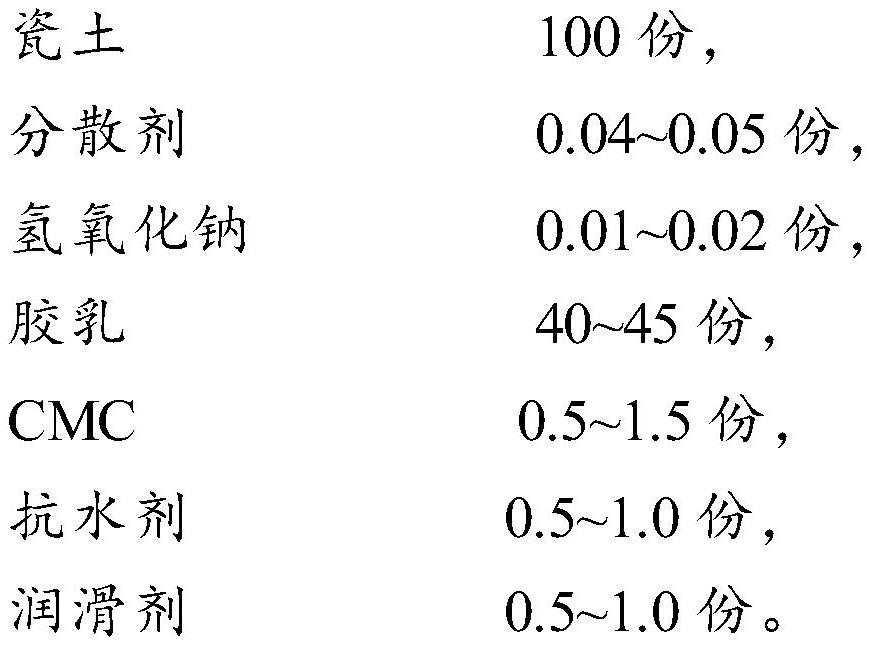

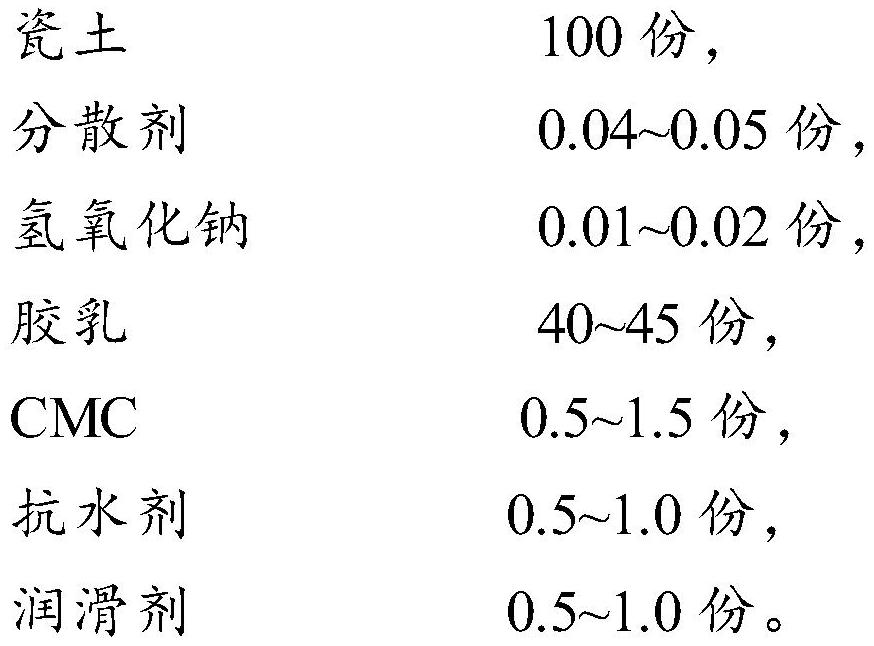

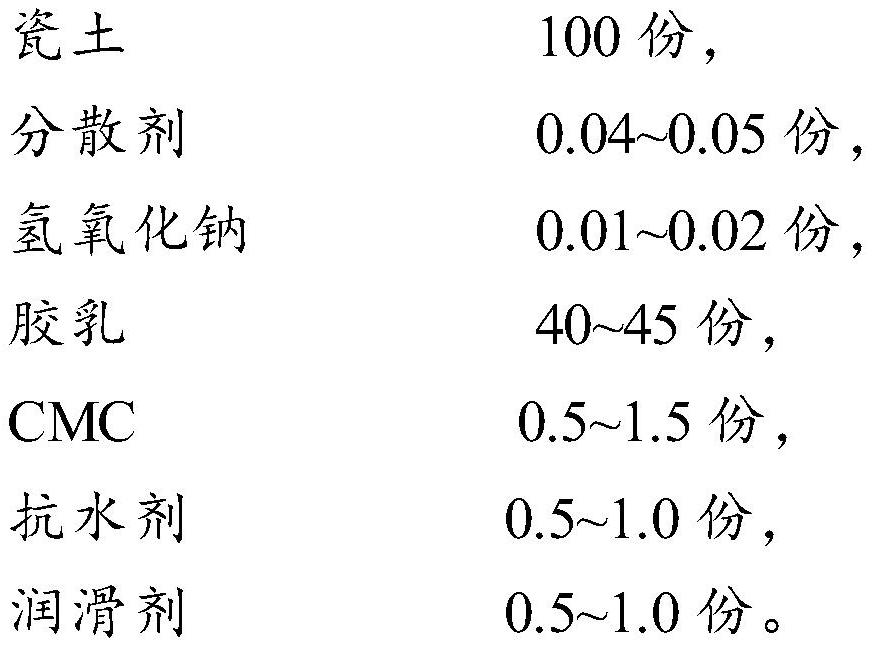

[0021] The invention provides a kind of preparation method of CCK release paper, comprising:

[0022] The chemical pulp of coniferous wood and the chemical pulp of hardwood are beaten respectively, and then the pulp is blended and auxiliary materials are added to obtain pulp;

[0023] The pulp is subjected to wet papermaking, pre-drying, coating, post-drying and calendering to obtain CCK release paper.

[0024] In the present invention, the softwood chemical pulp can be purchased from the market, for example, the softwood chemical pulp provided by Silverstar, Pacific, Laha or Botnia can be used.

[0025] In the present invention, the hardwood chemical pulp can be purchased from the market, for example, the hardwood chemical pulp provided by Guri, Symbo, Alpine, Little Bird or Fenya can be used.

[0026] In the present invention, the mass ratio of the softwood chemical pulp to the hardwood chemical pulp is preferably (25-35): (65-75), more preferably (28-32): (68-72), most pre...

Embodiment 1

[0069] After beating, the Pacific coniferous wood kraft pulp (300ml) and Senbo broadleaf kraft pulp (320ml) with freeness meeting the requirements are mixed according to the ratio of 30wt%: 70wt%; The weight ratio of the amount of slurry) is light calcium carbonate filler, which is sent to the first-stage four-stage conical slag remover by the slurry pump for purification and slag removal, and then enters the degassing tank for degassing treatment; after that, it enters the pressure screen for screening treatment (Cation PAM dosage 0.5kg / t paper (dry pulp), cationic starch 10kg / t paper (dry pulp), sizing agent alkyl ketene dimer 2.5kg / t paper (dry pulp) Sieve inlet, modified diatomite 2.5kg / t paper (absolutely dry pulp) is added to the pressure sieve outlet); then sent to the headbox for online, adjust the online flow, and control the weight of the paper at 68g / m 2 After the wet paper leaves the wire section, it enters the press section for five-roller and three-nip composite ...

Embodiment 2

[0072] Silver star coniferous wood kraft pulp (310ml) and parrot broadleaf wood kraft pulp (320ml) with freeness meeting requirements after beating are mixed according to the ratio of 30wt%: 70wt%; The weight ratio of the amount of slurry) is light calcium carbonate filler, which is sent to the first-stage four-stage conical slag remover by the slurry pump for purification and slag removal, and then enters the degassing tank for degassing treatment; after that, it enters the pressure screen for screening treatment (Cation PAM dosage 0.5kg / t paper (dry pulp), cationic starch 10kg / t paper (dry pulp), sizing agent alkyl ketene dimer 2.5kg / t paper (dry pulp) Sieve inlet, modified diatomite 2.5kg / t paper (absolutely dry pulp) is added to the pressure sieve outlet); then sent to the headbox for online, adjust the online flow, and control the weight of the paper at 77g / m 2 After the wet paper leaves the wire section, it enters the press section for five-roller and three-nip composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| free rate | aaaaa | aaaaa |

| free rate | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com