Production process of fluorine-free environment-friendly sports shoe synthetic leather

A production process and technology of synthetic leather, applied in footwear, textiles, papermaking, apparel, etc., can solve problems affecting human health, fluorocarbon emissions, environmental pollution, etc., and achieve excellent elasticity, strong hydrolysis resistance, and peel strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

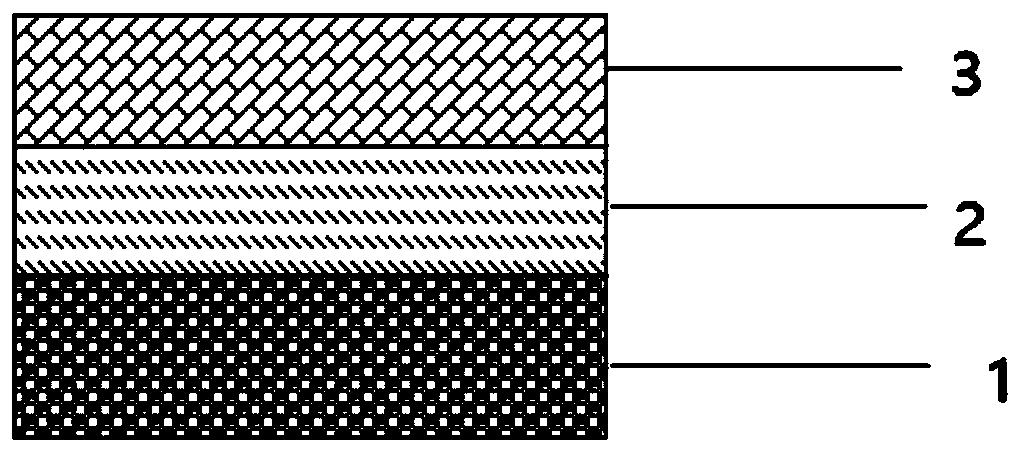

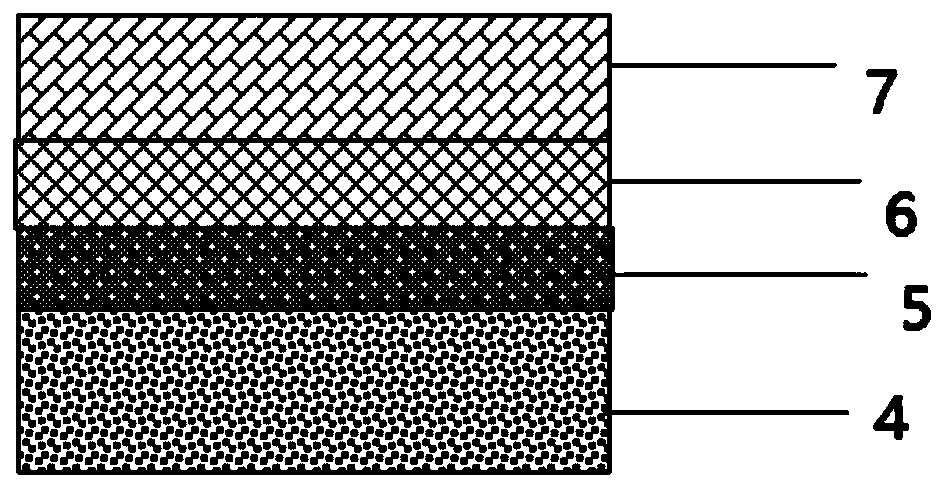

Image

Examples

Embodiment

[0039] Embodiment: A kind of fluorine-free environment-friendly sports shoe material synthetic leather production process, concrete steps are as follows:

[0040] Step 1: wet mixing preparation:

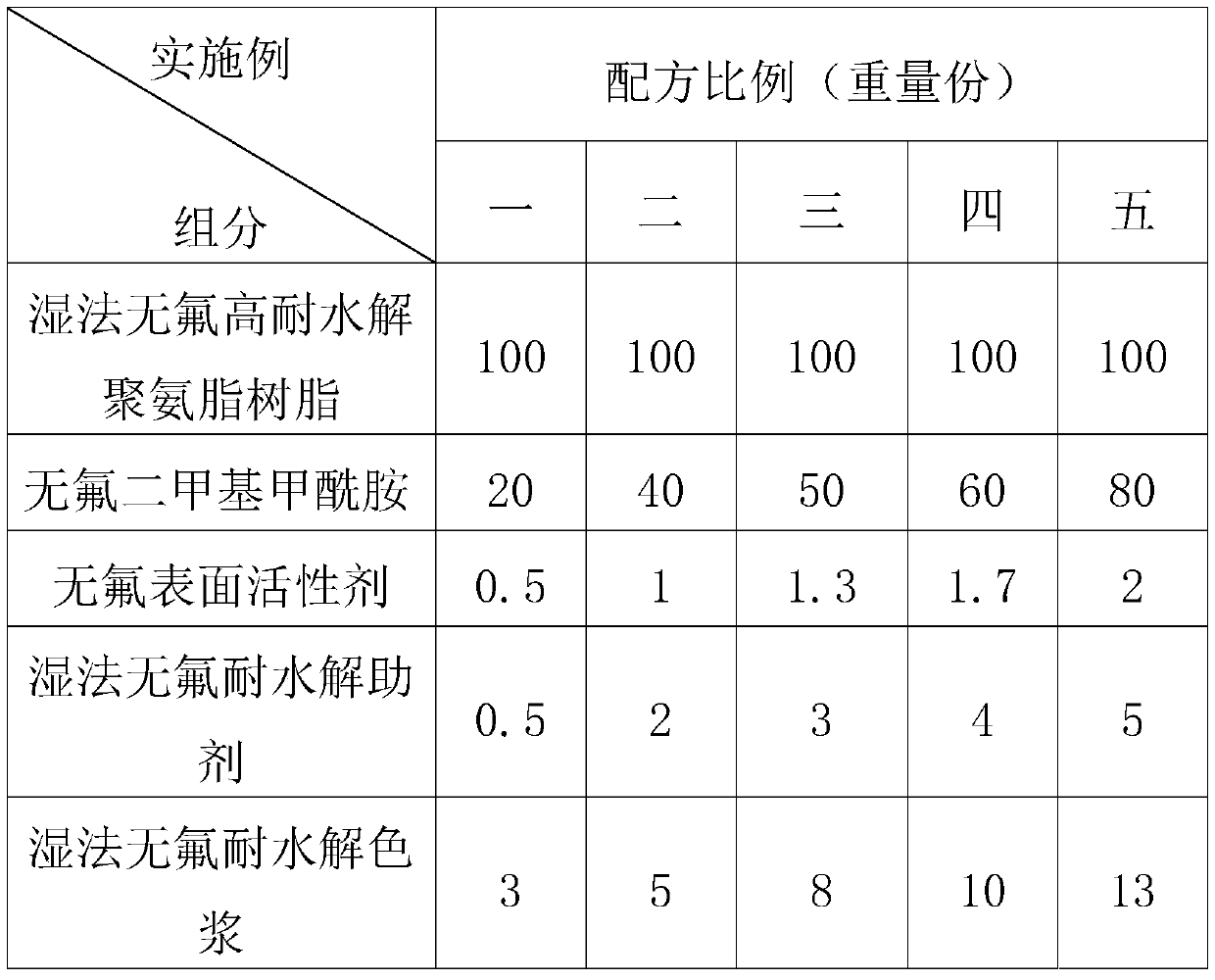

[0041] The wet method bass coating scraping material is prepared according to the following table for wet method ingredients:

[0042]

[0043] The wet method Bass impregnation material is prepared according to the following table for wet batching:

[0044]

[0045] Step 2: Wet Bass Coating Squeegee Mixing Ingredients:

[0046] a. Stir 10-15kg of fluorine-free dimethylformamide and wet-process fluorine-free hydrolysis-resistant color paste at high speed for 15-20 minutes according to the above ingredient list, filter and stand for use;

[0047] b. Add the remaining fluorine-free dimethylformamide, wet-process fluorine-free hydrolysis-resistant additive and fluorine-free surfactant into a negative-pressure vacuum reactor and mix and stir for 15-20 minutes;

[0048] c. Put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com