Protective film for various roughness surfaces

A protective film and roughness technology, applied in the direction of film/flaky adhesives, non-polymer adhesive additives, adhesive types, etc., can solve problems such as unstable viscosity, achieve stable peel strength, improve The effect of stability and excellent adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

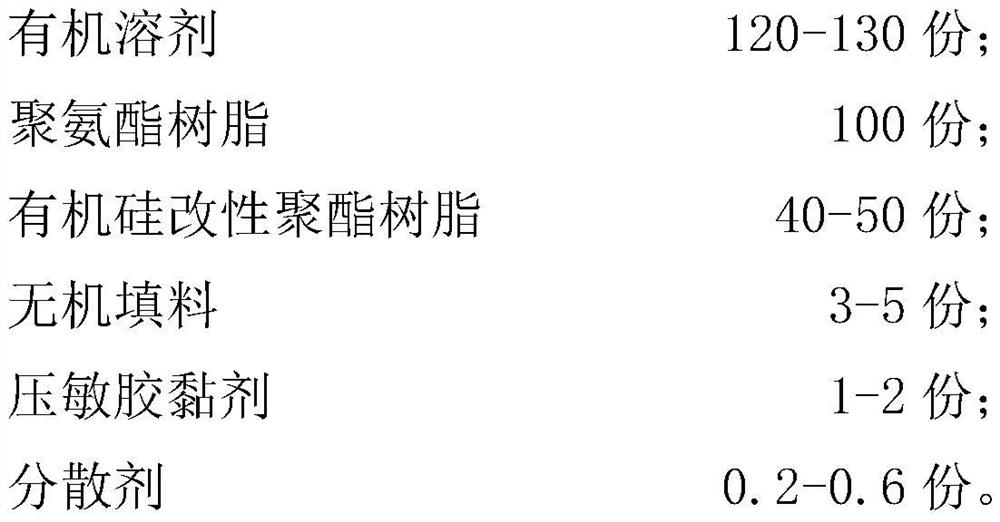

[0021] A protective film for surfaces with various roughnesses in this embodiment includes a substrate layer and an adhesive layer disposed on the substrate layer, wherein the adhesive layer includes the following components by weight:

[0022]

[0023] Wherein, the inorganic filler is attapulgite powder, and the organic solvent is acetone.

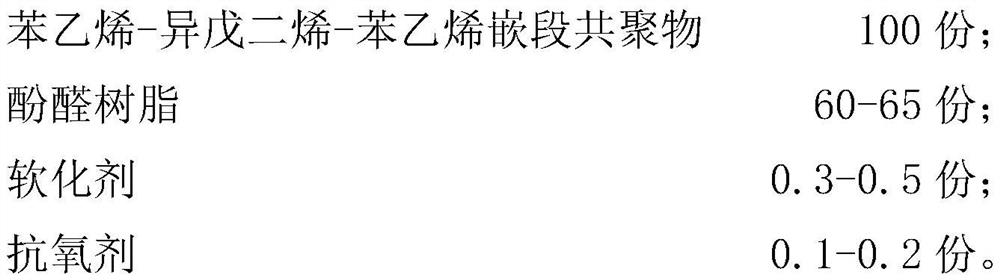

[0024] Wherein, the pressure-sensitive adhesive comprises the following components in parts by weight:

[0025]

[0026] Wherein, the softener is polystyrene, and the antioxidant is diphenylamine.

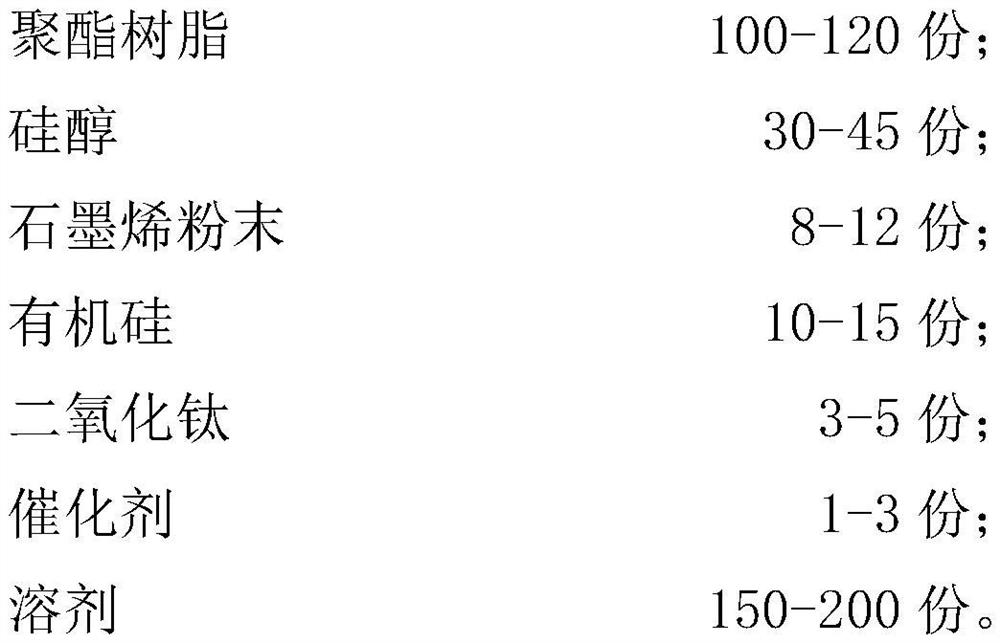

[0027] Wherein, the silicone modified polyester resin comprises the following components in parts by weight:

[0028]

[0029] Wherein, the preparation of the organosilicon-modified polyester resin comprises the following steps: uniformly mix organosilicon, polyester resin, silanol and catalyst, heat up to 150° C., add graphene powder and titanium dioxide, and stir at 600 r / min for 1.2 h, cooling down to normal temperature, adding a...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment is that the inorganic filler is superfine calcium carbonate, and the rest are the same as the first embodiment.

Embodiment 3

[0035] The difference between this embodiment and the first embodiment is that the organic solvent is methyl acetate, and the rest are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com