Cover tape

一种盖带、热塑性树脂的技术,应用在挠性覆盖物、包装物品类型、特殊包装物件等方向,能够解决盖带透明度降低等问题,达到透明度优良、稳定剥离强度、抑制飞出的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

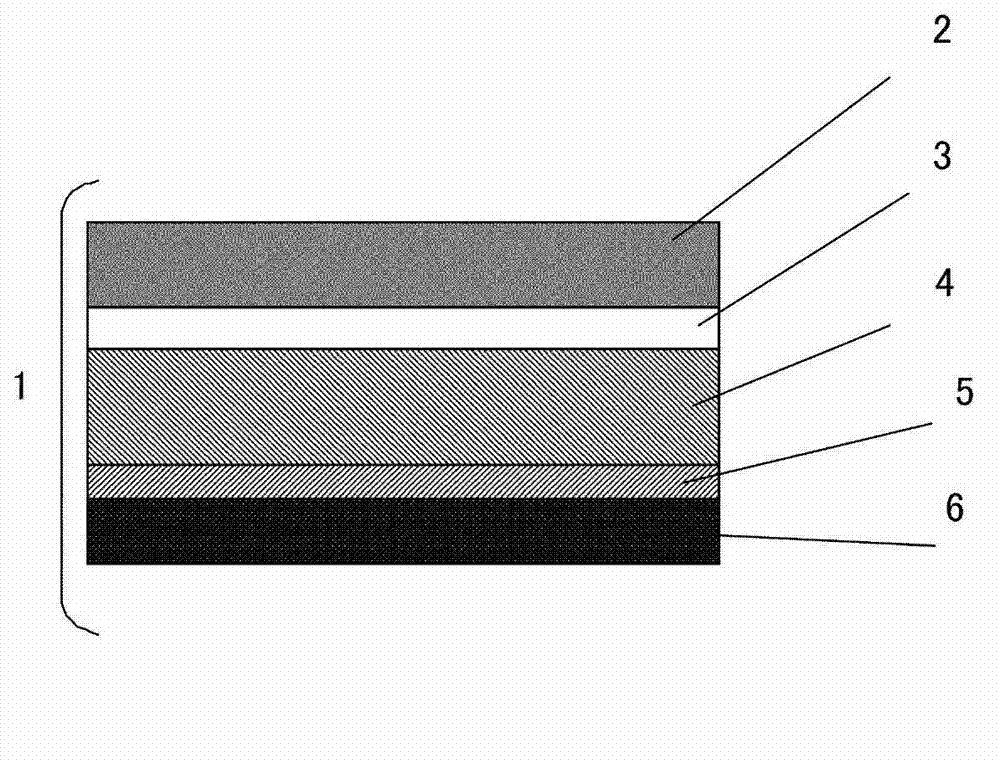

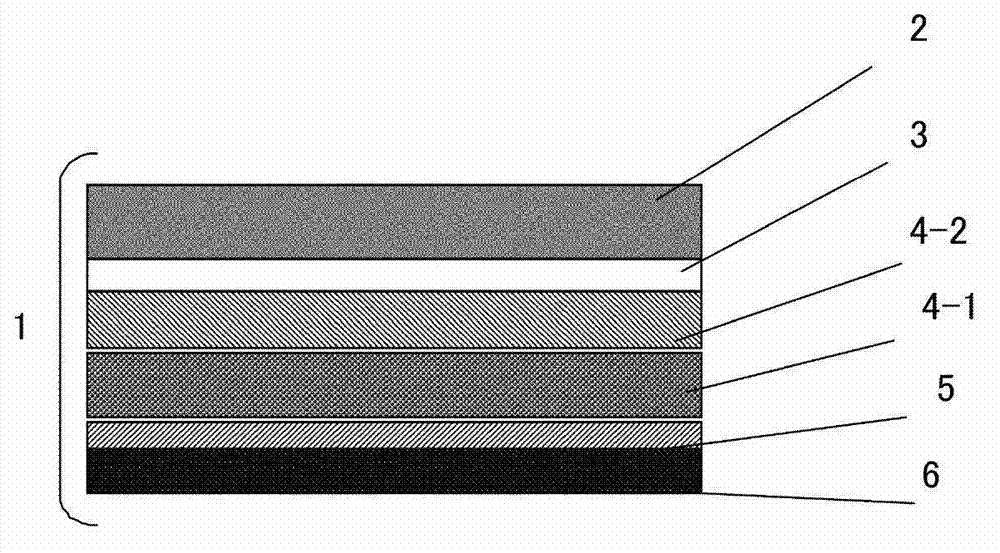

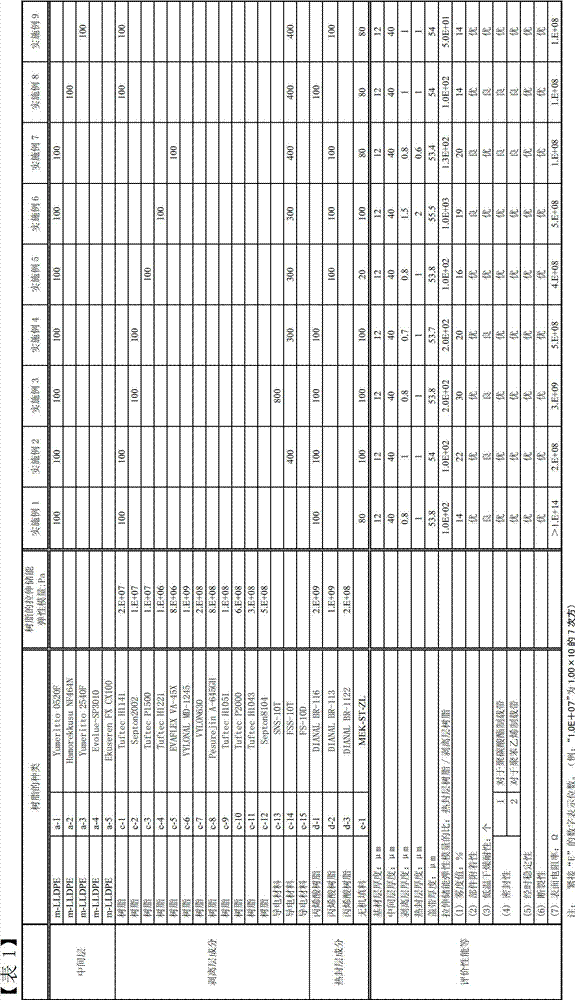

[0106] [(a-1)m-LLDPE] polymerized by a metallocene catalyst was used as the raw resin, and the resin raw material was stirred at 200°C using a single-screw extruder with a diameter of 40mm, and passed through a T-die at a rate of 20m per minute. Extrude at a linear speed to obtain an interlayer film with a thickness of 40 m. On the surface of a biaxially stretched polyester film with a thickness of 12 μm, a polyester-based primer was coated by gravure printing, and the above-mentioned intermediate layer film [(a-1)m-LLDPE] was pasted to obtain a biaxially stretched polyester film. A laminated film formed of an axially stretched polyester layer and an m-LLDPE layer. Next, after corona treatment was performed on the m-LLDPE surface of the film, [(c-1) resin] dissolved in cyclohexane was applied to the corona-treated surface by gravure printing, so that This became a peeling layer with a dry thickness of 0.8 µm. Furthermore, as a heat seal layer, a random copolymer of butyl met...

Embodiment 2)

[0108] As shown in Table 1, the (c-14) conductive material was mixed into the peeling layer, and 400 parts by mass was mixed with respect to 100 parts by mass of the resin. Except for the mixing ratio and composition shown in Table 1, it was the same as Example 1, and a cover was produced. bring.

Embodiment 3~9、 comparative example 2~10

[0110] A cover tape was produced in the same manner as in Example 1, except that materials such as resins shown in Table 1 and Table 2 were used to form the intermediate layer, release layer, and heat-sealing layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com