Novel printable mobile phone rear cover inner explosion-proof membrane and preparation method thereof

A mobile phone back cover and anti-explosion film technology, applied in the direction of adhesive type, film/sheet release liner, film/sheet adhesive, etc., to improve adhesion performance, improve degumming problems, and avoid adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

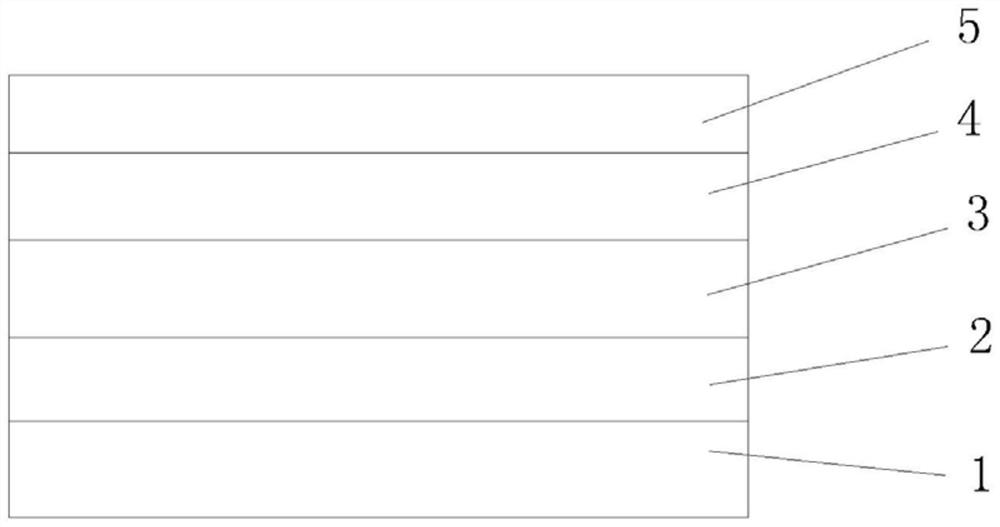

[0025] refer to figure 1 , a new type of explosion-proof film in the back cover of the mobile phone that can be printed in the present invention, which successively includes a PE protective film layer 1, a printable layer 2, a PET substrate layer 3, an optical adhesive layer 4 and a release film layer 5 from bottom to top. The thickness range of the printable layer 2 is 1-3um, the thickness of the PE protective film layer 1 is 25um, the thickness of the PET substrate layer 3 is 25um, and the thickness of the optical adhesive layer 4 is 10um. The thickness of the release film layer 5 is 75um.

[0026] The preparation method of the explosion-proof film in the novel printable mobile phone back cover is as follows:

[0027] a. Using 1000 parts of acrylate adhesive as raw material, add 1 part by weight of UV absorber UV-531, 1 part by weight of epoxy curing agent, 0.1 part by weight of silane coupling agent KH-550, 200 parts by weight of Ethyl acetate, mixed and stirred for 30 mi...

Embodiment 2

[0034] refer to figure 1 , a new type of explosion-proof film in the back cover of the mobile phone that can be printed in the present invention, which successively includes a PE protective film layer 1, a printable layer 2, a PET substrate layer 3, an optical adhesive layer 4 and a release film layer 5 from bottom to top. The thickness range of the printable layer 2 is 1-3um, the thickness of the PE protective film layer 1 is 50um, the thickness of the PET substrate layer 3 is 100um, and the thickness of the optical adhesive layer 4 is 30um. The thickness of the release film layer 5 is 175um.

[0035] The preparation method of the explosion-proof film in the novel printable mobile phone back cover is as follows:

[0036] a. Using 1000 parts of acrylate adhesive as raw material, add 1 part by weight of UV absorber UV-329, 10 parts by weight of epoxy curing agent, 5 parts by weight of silane coupling agent KH-550, 1000 parts by weight of Ethyl acetate, mixed and stirred for 3...

Embodiment 3

[0043] refer to figure 1 , a new type of explosion-proof film in the back cover of the mobile phone that can be printed in the present invention, which successively includes a PE protective film layer 1, a printable layer 2, a PET substrate layer 3, an optical adhesive layer 4 and a release film layer 5 from bottom to top. The thickness range of the printable layer 2 is 1-3um, the thickness of the PE protective film layer 1 is 40um, the thickness of the PET substrate layer 3 is 75um, and the thickness of the optical adhesive layer 4 is 20um. The thickness of the release film layer 5 is 125um.

[0044] The preparation method of the explosion-proof film in the novel printable mobile phone back cover is as follows:

[0045]a. Using 1000 parts of acrylate adhesive as raw material, add 2 parts by weight of ultraviolet absorber UV-329, 5 parts by weight of epoxy curing agent, 3 parts by weight of silane coupling agent KH-550, 500 parts by weight of Ethyl acetate, mixed and stirred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com