Paper surface degumming device capable of being separated wholly

A degumming device, integrated technology, applied in non-electric variable control, instrument, control/regulation system, etc., can solve the problems of paper waste, paper damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

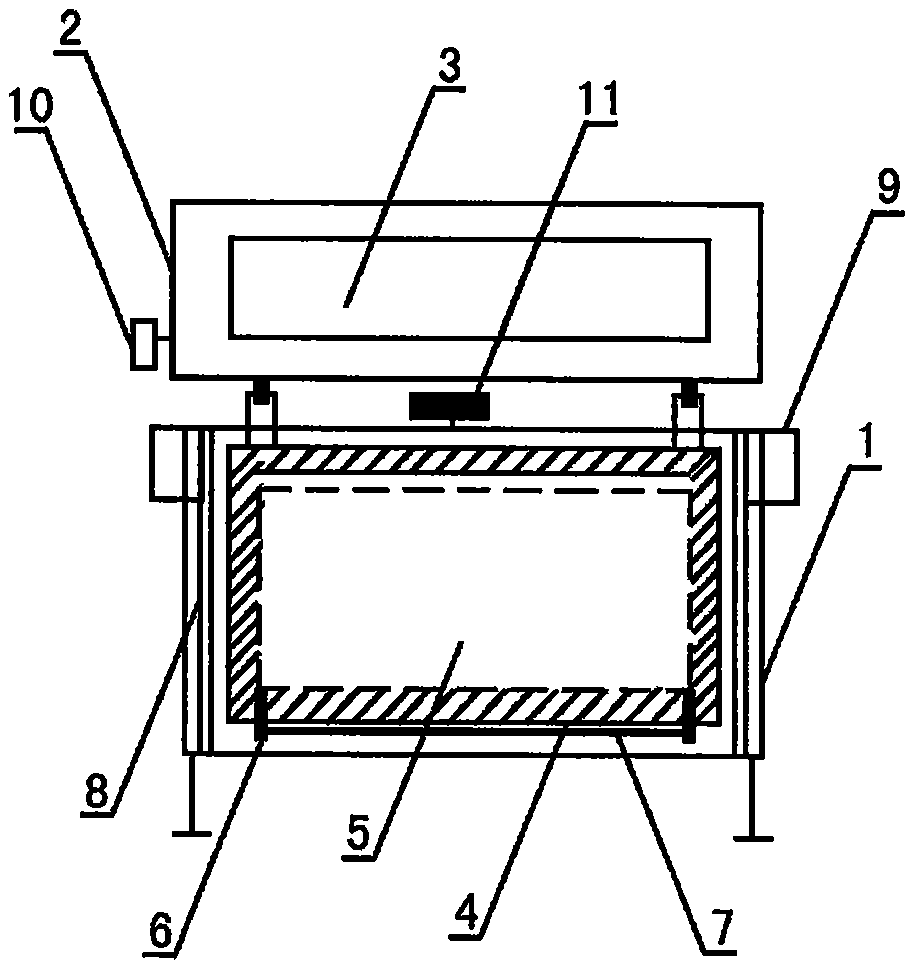

[0012] Embodiment: as shown in the accompanying drawing. The paper surface degumming device that can be separated as a whole includes a body (1), a cover device (2) is arranged on the upper part of the body (1), and a heating sheet (3) is arranged on the inner surface, and the cover body is connected with the degumming structure including a temperature control base (4), the storage area (5), the positioning slider (6), the rail shifting device (7), the humidification component (8) is located on both sides of the body (1) and connected with the corresponding water storage device (9) respectively. The required degumming paper surface is positioned, and the corresponding temperature is adjusted according to the temperature characteristics of the latex, and then the overall separation is carried out.

[0013] The paper surface degumming device can be separated as a whole, and the prompt device (10) is provided on the left side of the cover device (2), and the prompt information is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com