Automatic peeling device for elongated peeled goods and peeling method

A peeling machine and material technology, which is applied in the fields of vegetable or fruit peeling, application, food science, etc., can solve problems such as incompatibility, and achieve the effect of simple structure, space-saving location, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

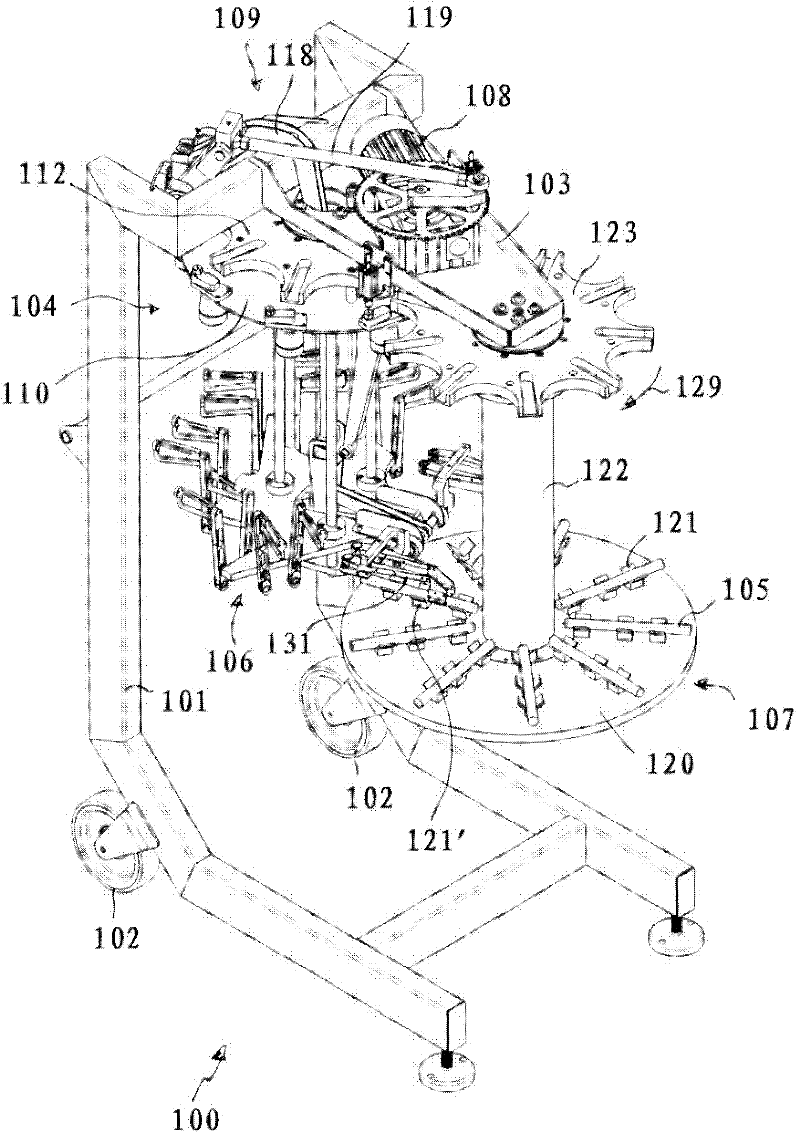

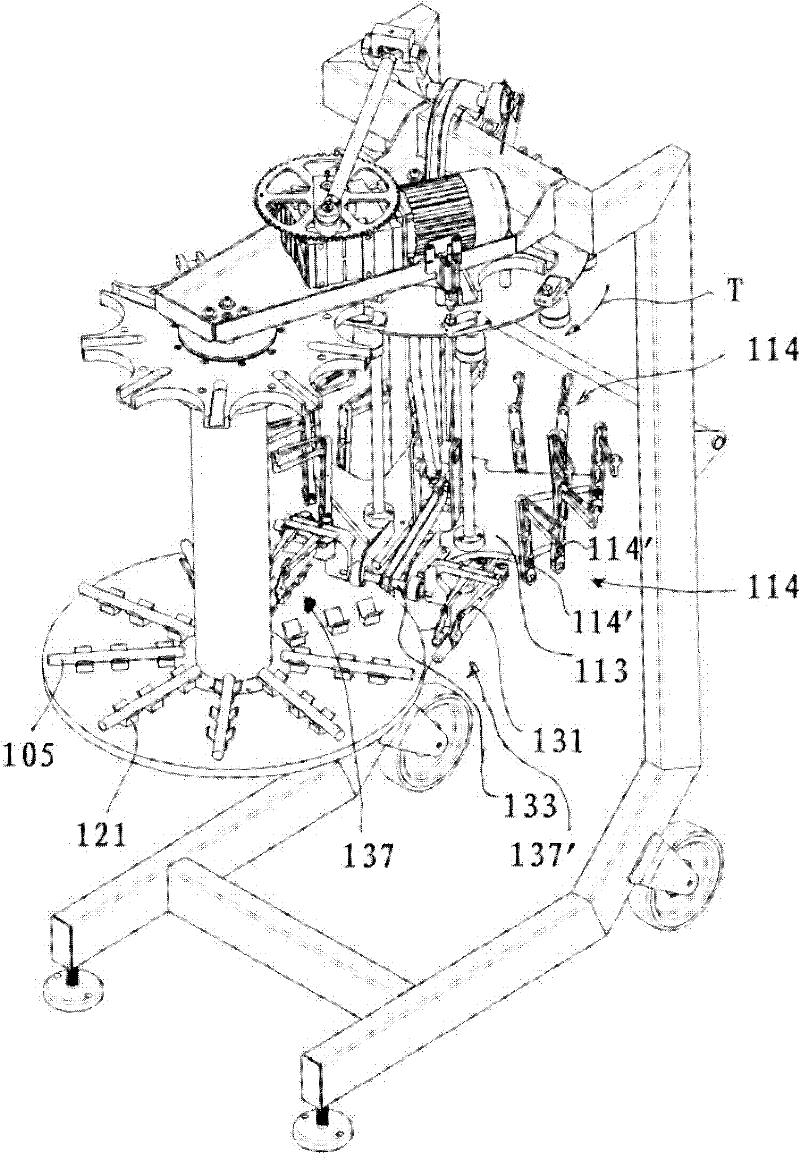

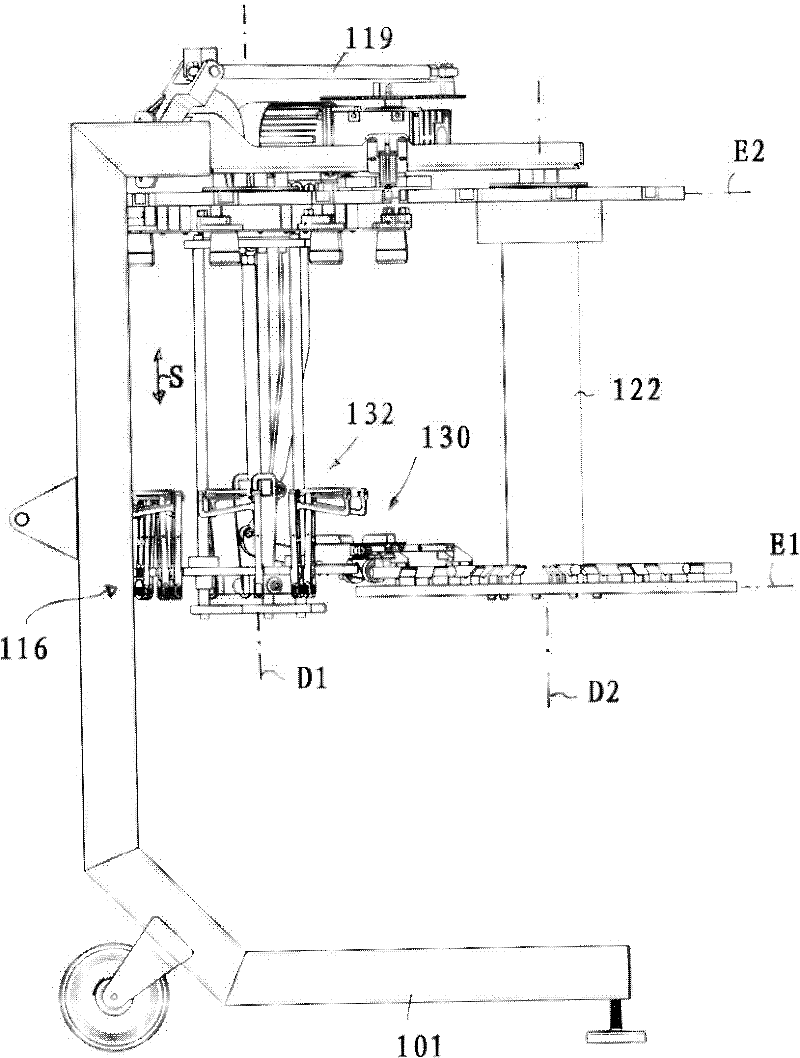

[0032] The automatic peeler according to the invention is preferably used for peeling rod-shaped peeling products designed as asparagus stalks. The automatic peeler can be placed anywhere in a space-saving manner. Only the electrical connection for the drive is required for operation.

[0033] exist Figures 1 to 8 An automatic peeler 100 is described in Figures 9 to 13 The automatic peeler shown can preferably have a cleaning device.

[0034] The automatic peeler 100 has an L-shaped stand with rollers 102 so that the automatic peeler 100 can be positioned at a desired place.

[0035] In the area above the support 101, the support plate 103 stretches out in the horizontal direction, and a clamping device 104 is arranged at this support plate place for keeping the peeled material 105 in an upright position; the cutting device 106 is used for peeling the material 105 peels in a cutting direction S extending along the peeled material 105; the infeed / discharge device 107 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com