Patents

Literature

62results about How to "Free shipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

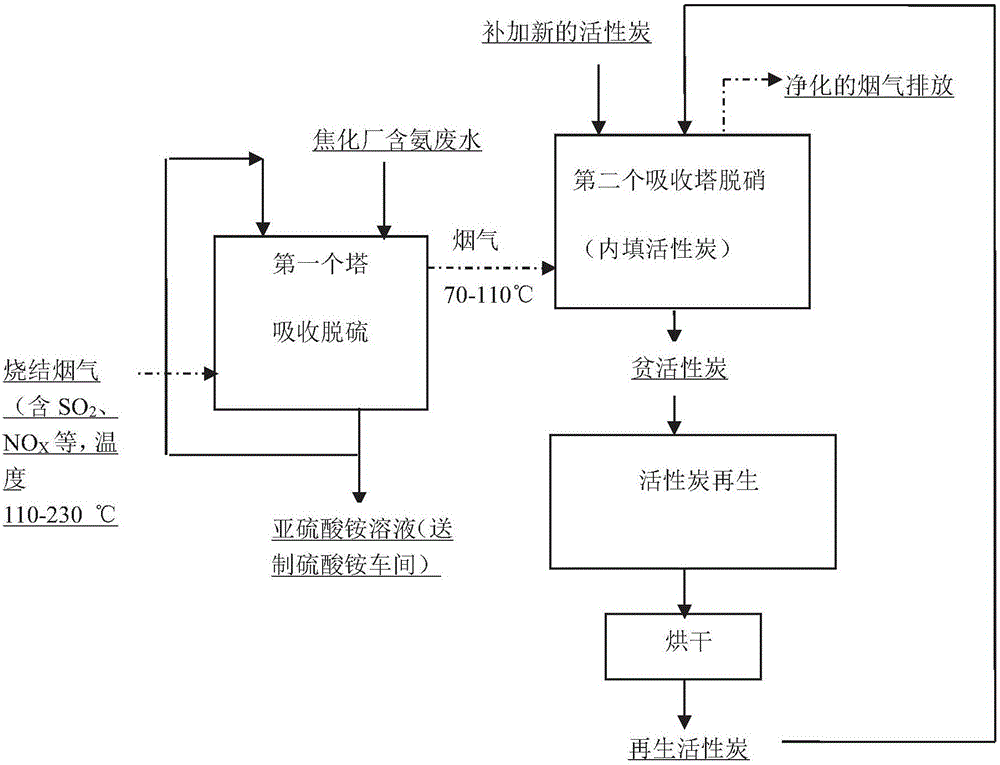

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

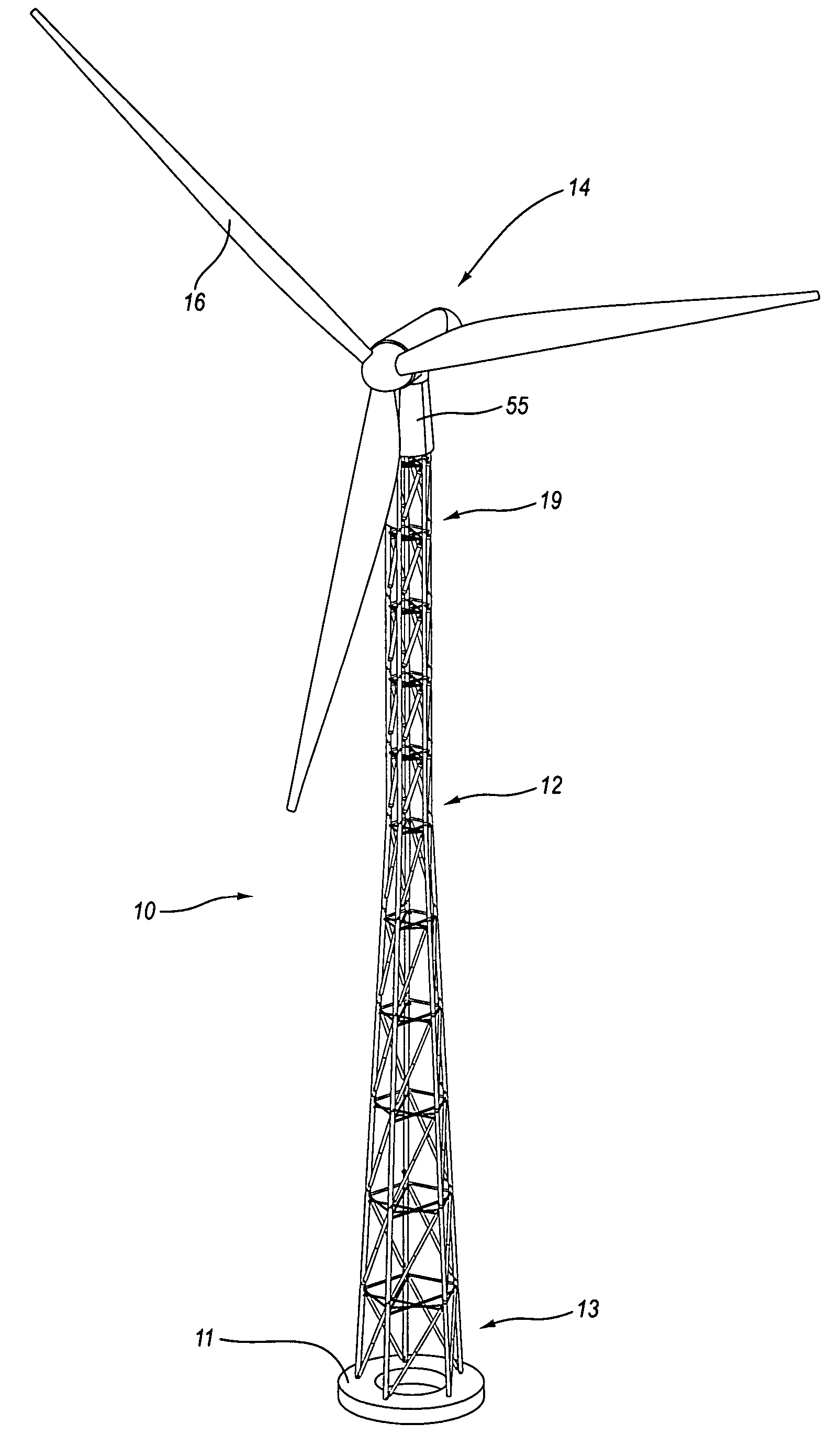

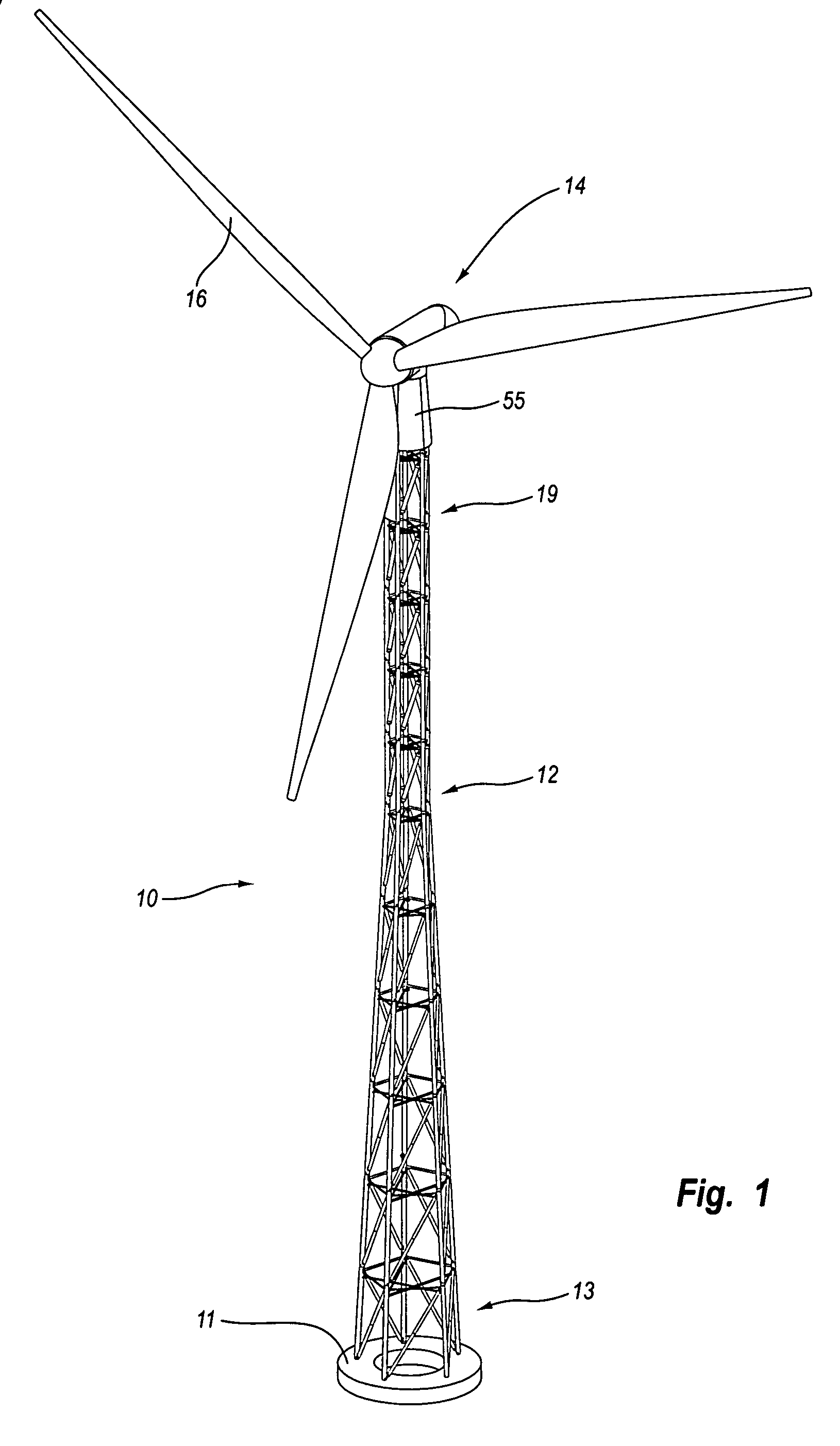

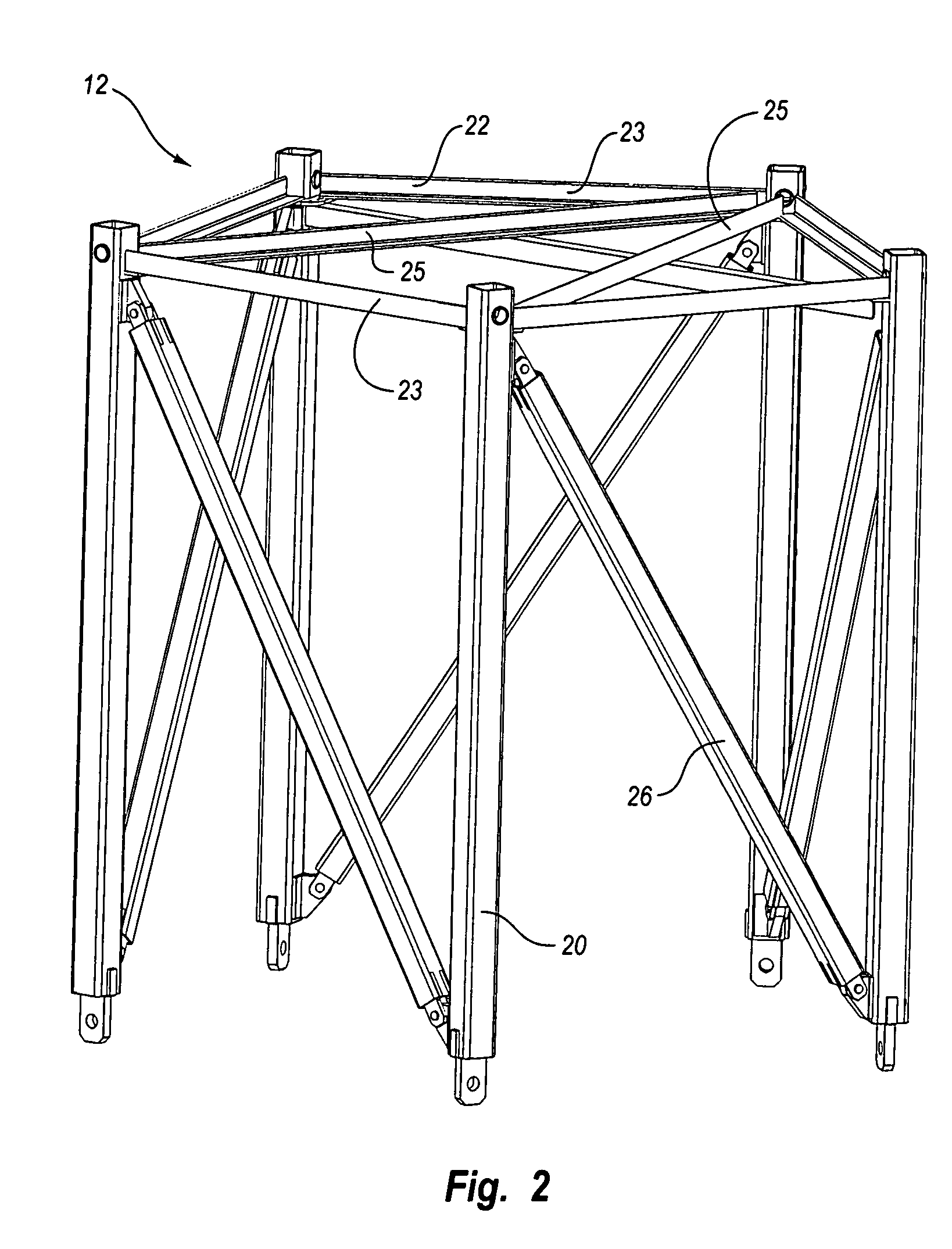

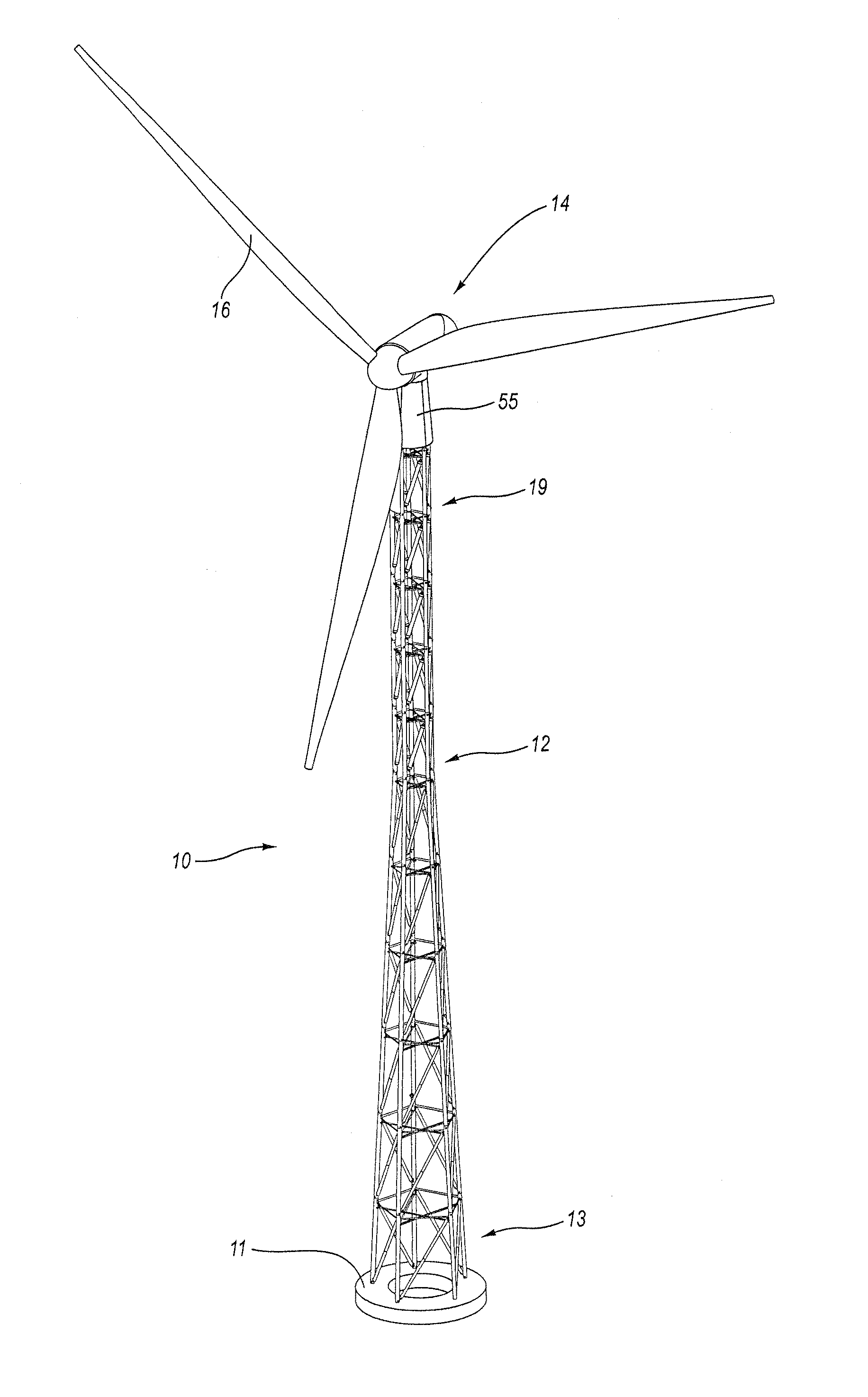

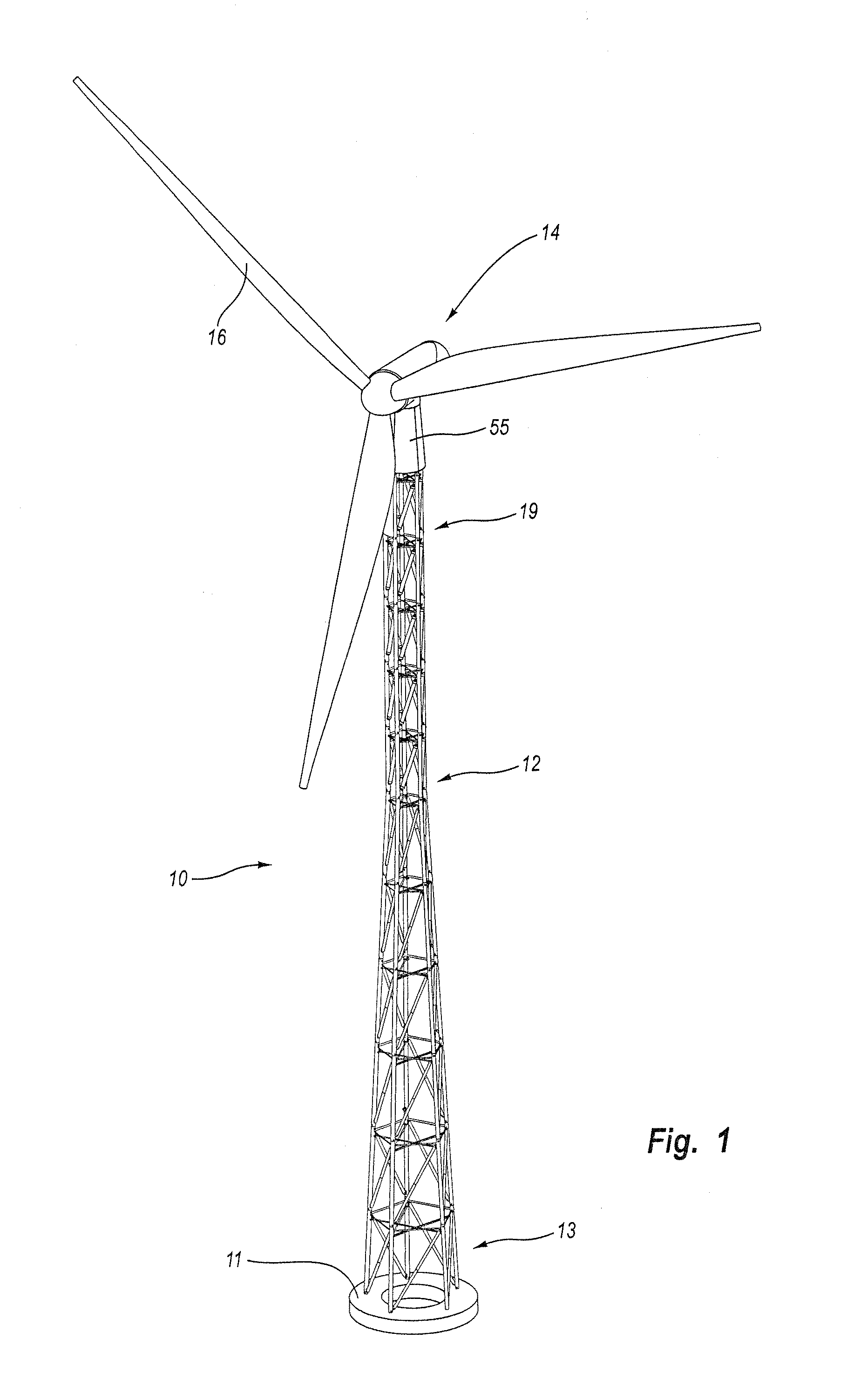

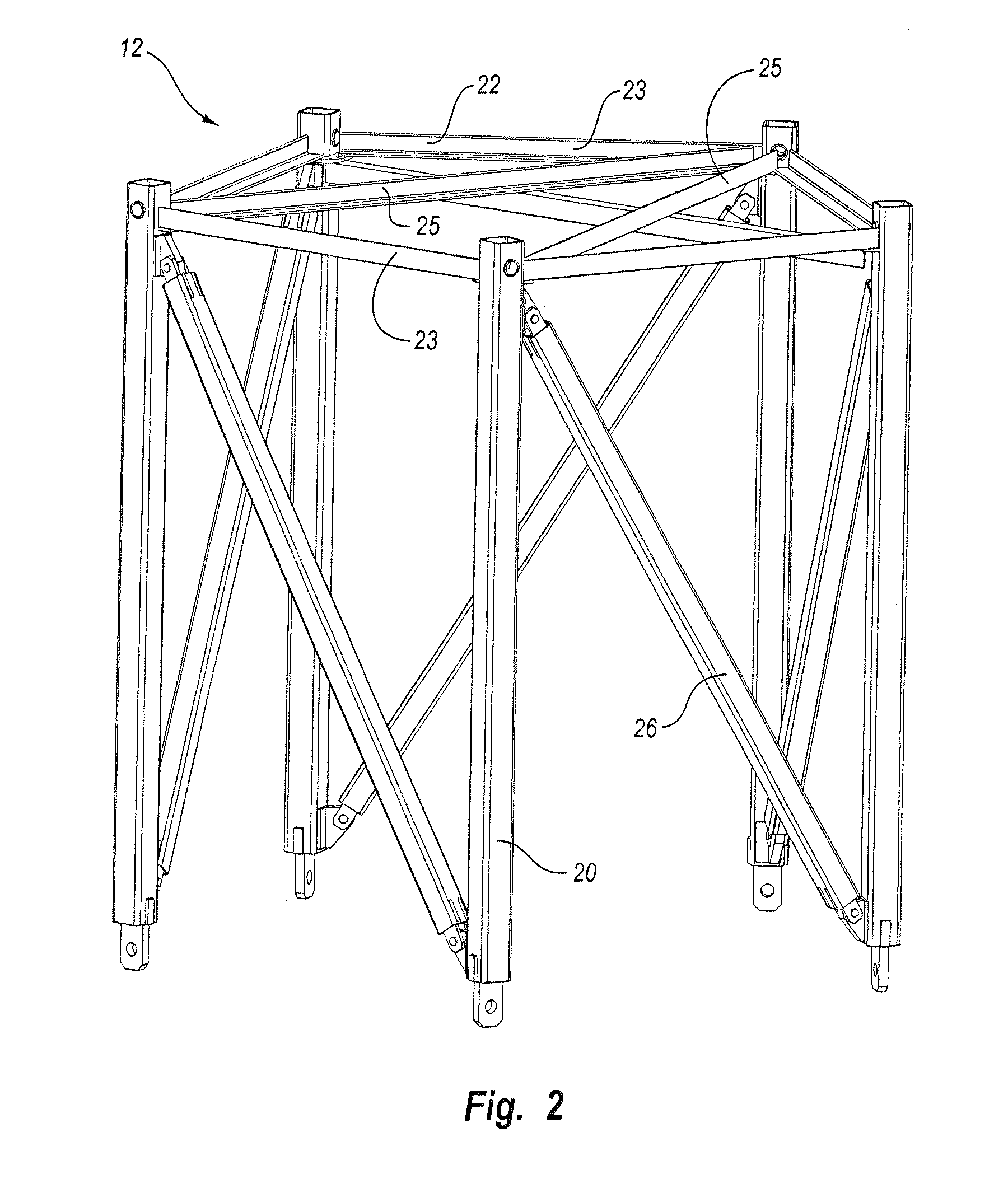

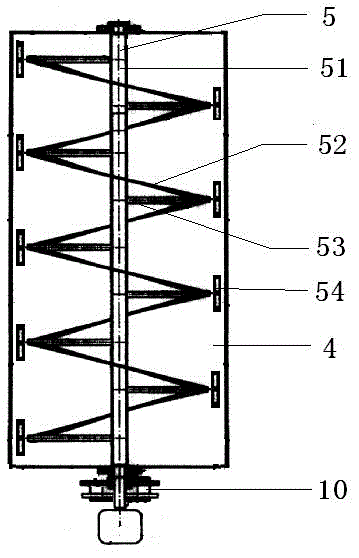

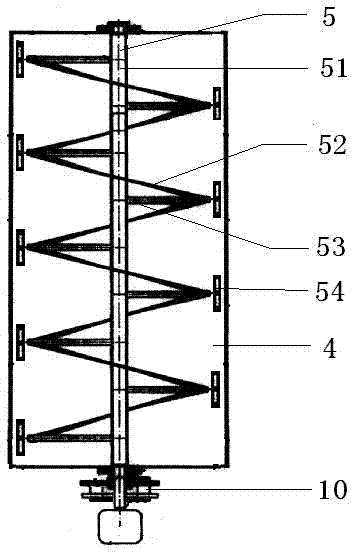

Structural tower

InactiveUS20060277843A1Reduce energy costsGenerate efficientlyCollapsable antennas meansEngine manufactureHigh elevationDiagonal

A structural tower having a space frame construction for high elevation and heavy load applications is disclosed, with particular application directed to wind turbines. The structural tower includes damping or non-damping struts in the longitudinal, diagonal or horizontal members of the space frame. One or more damping struts in the structural tower damp resonant vibrations or vibrations generated by non-periodic wind gusts or sustained high wind speeds. The various longitudinal and diagonal members of the structural tower may be secured by pins, bolts, flanges or welds at corresponding longitudinal or diagonal joints of the space frame.

Owner:LIVINGSTON TRACY +1

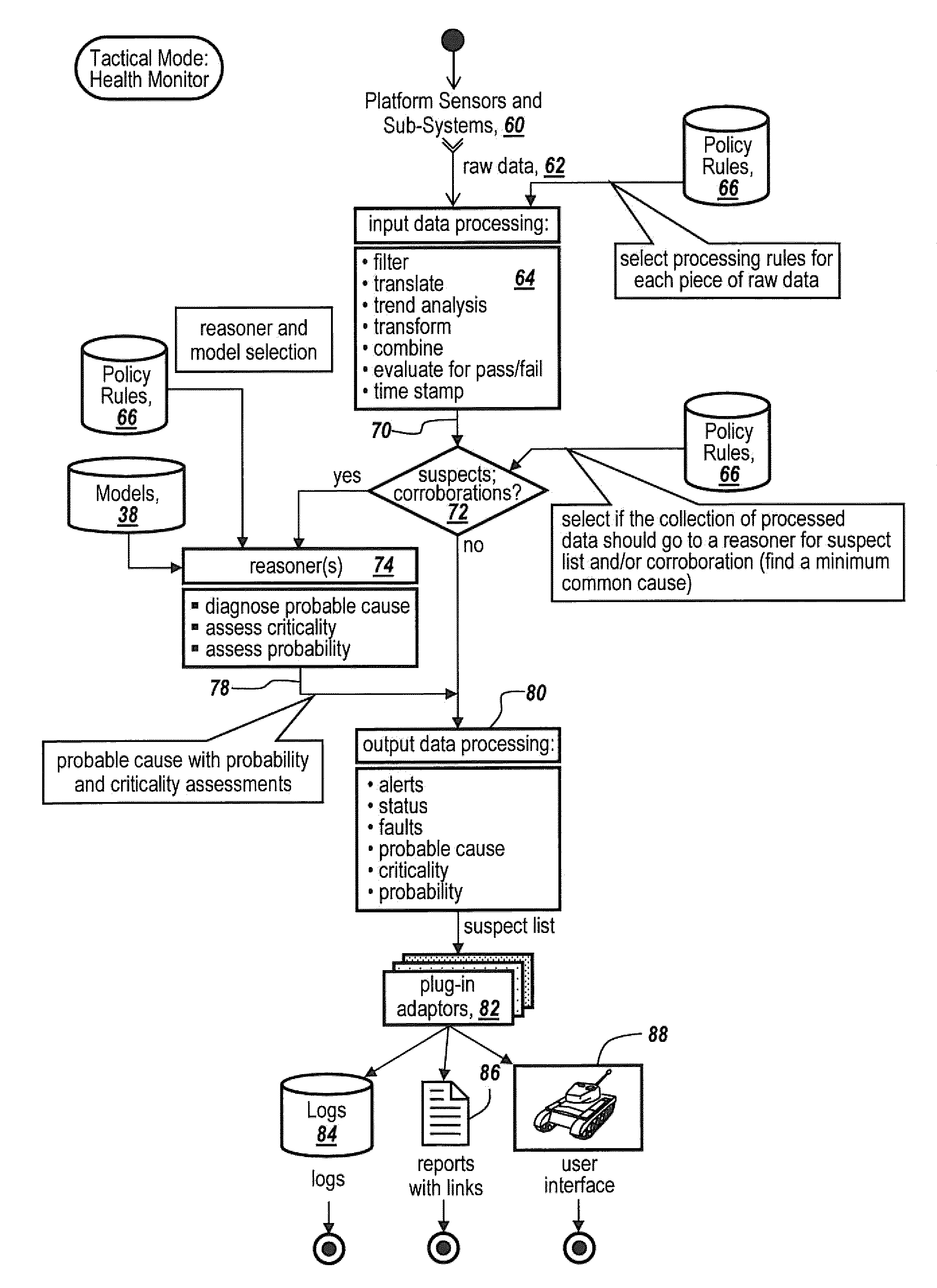

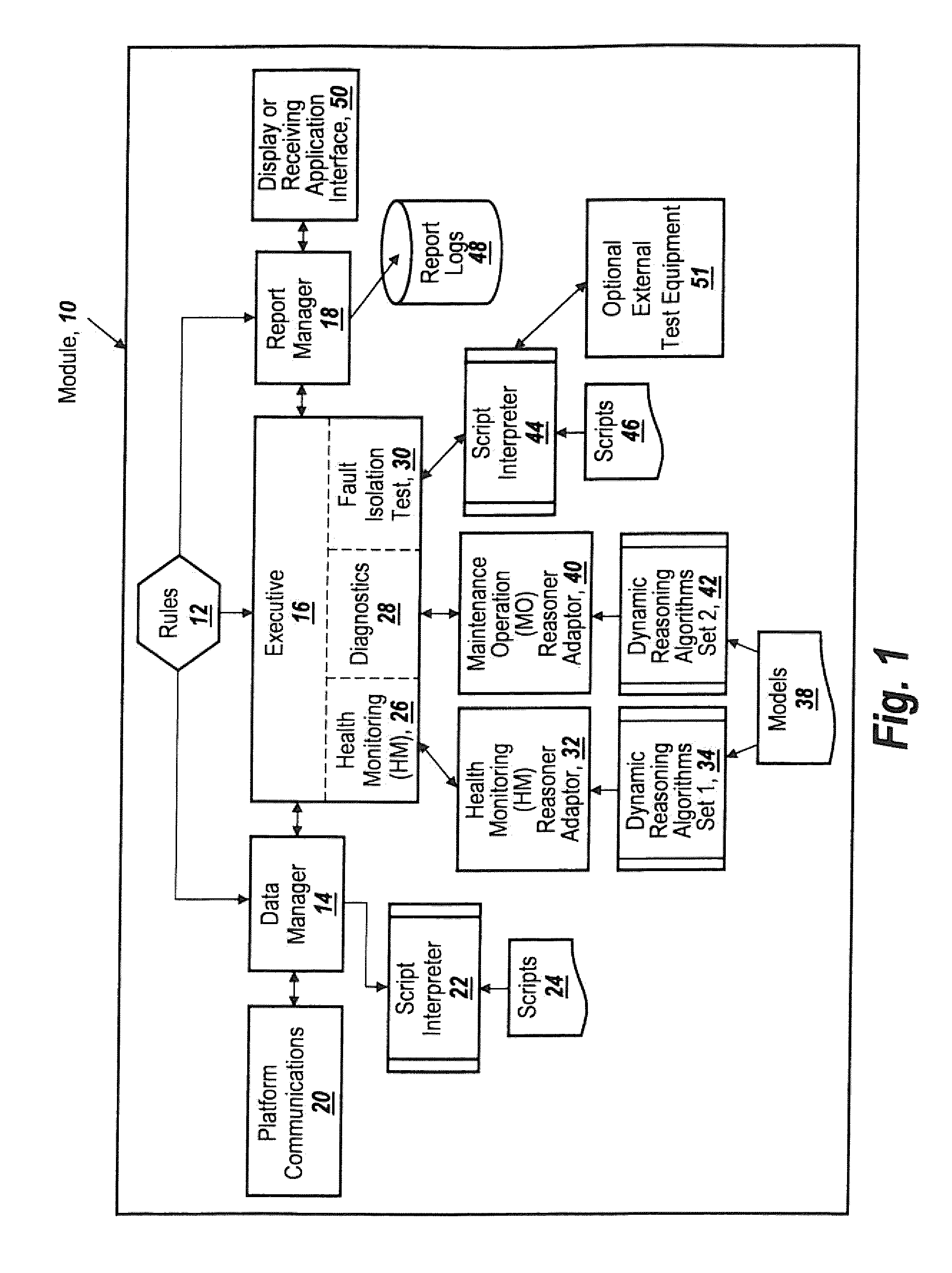

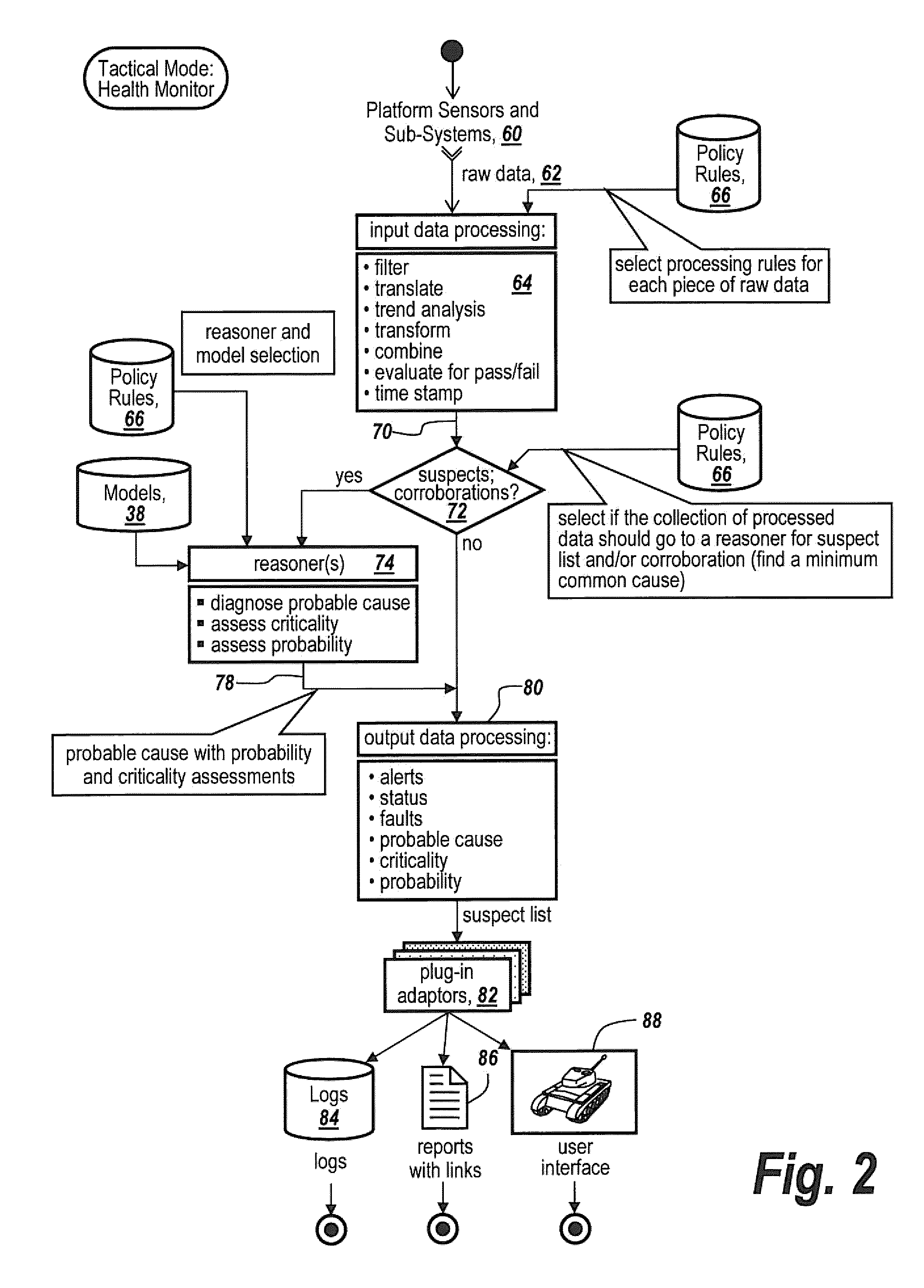

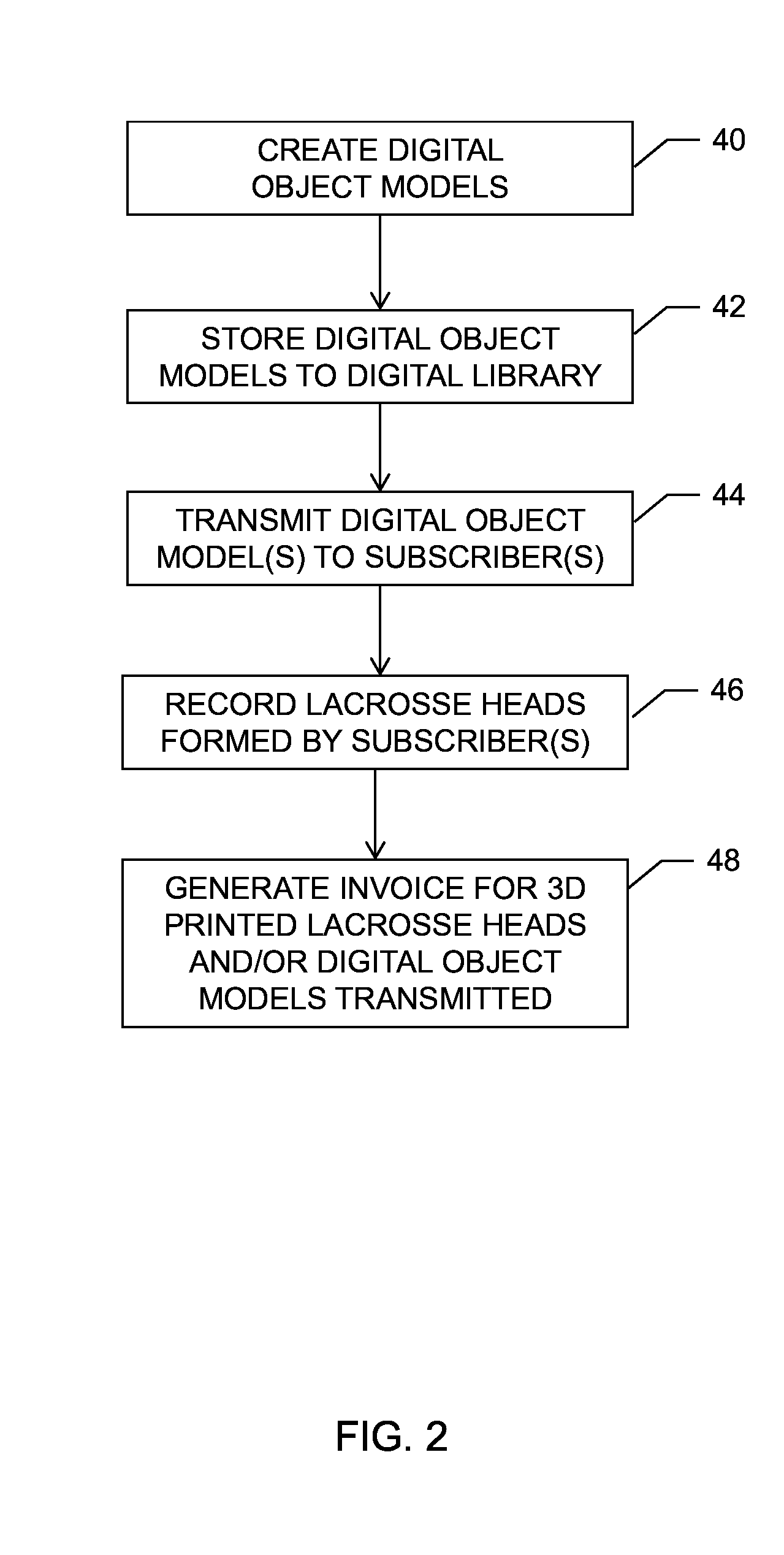

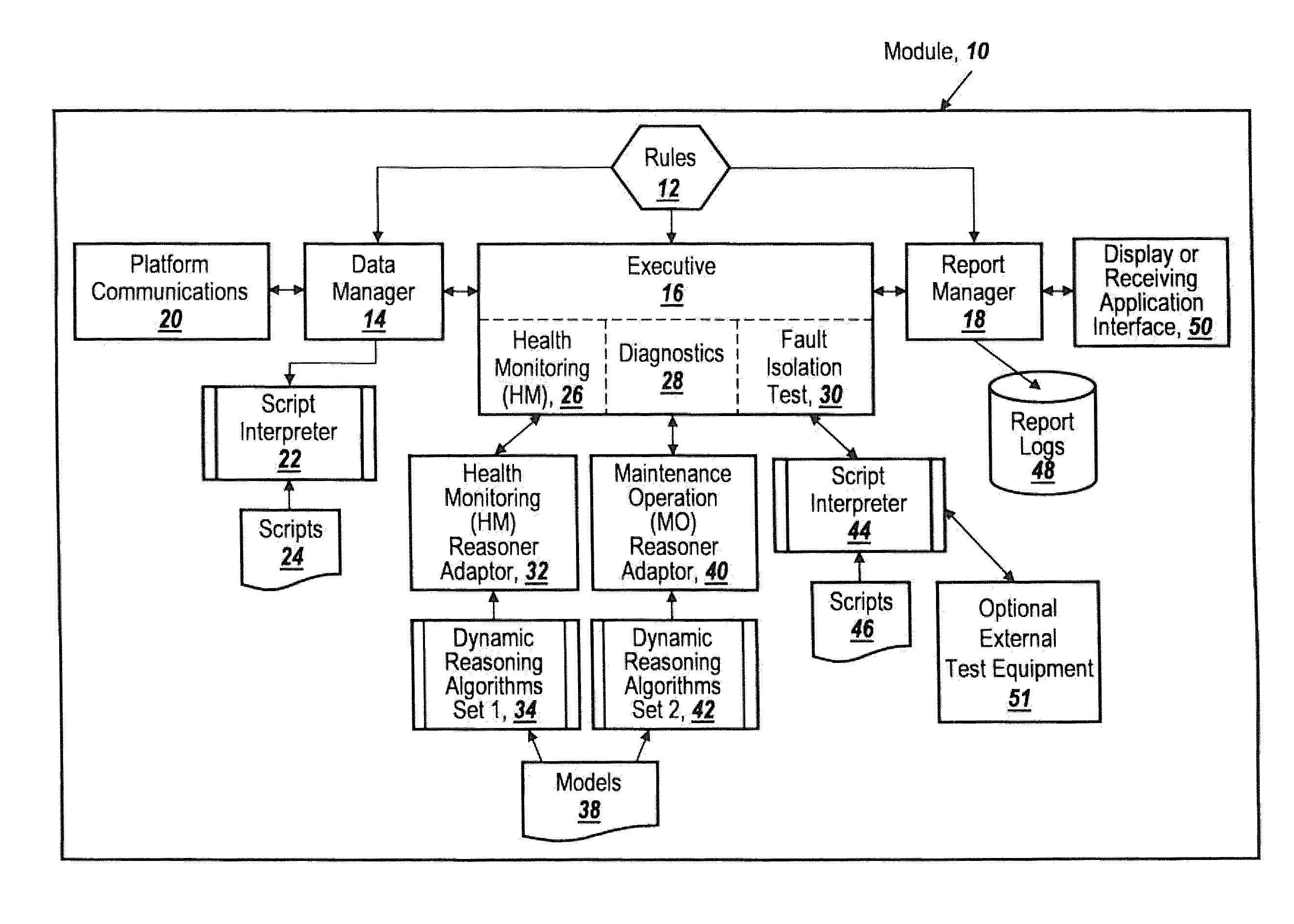

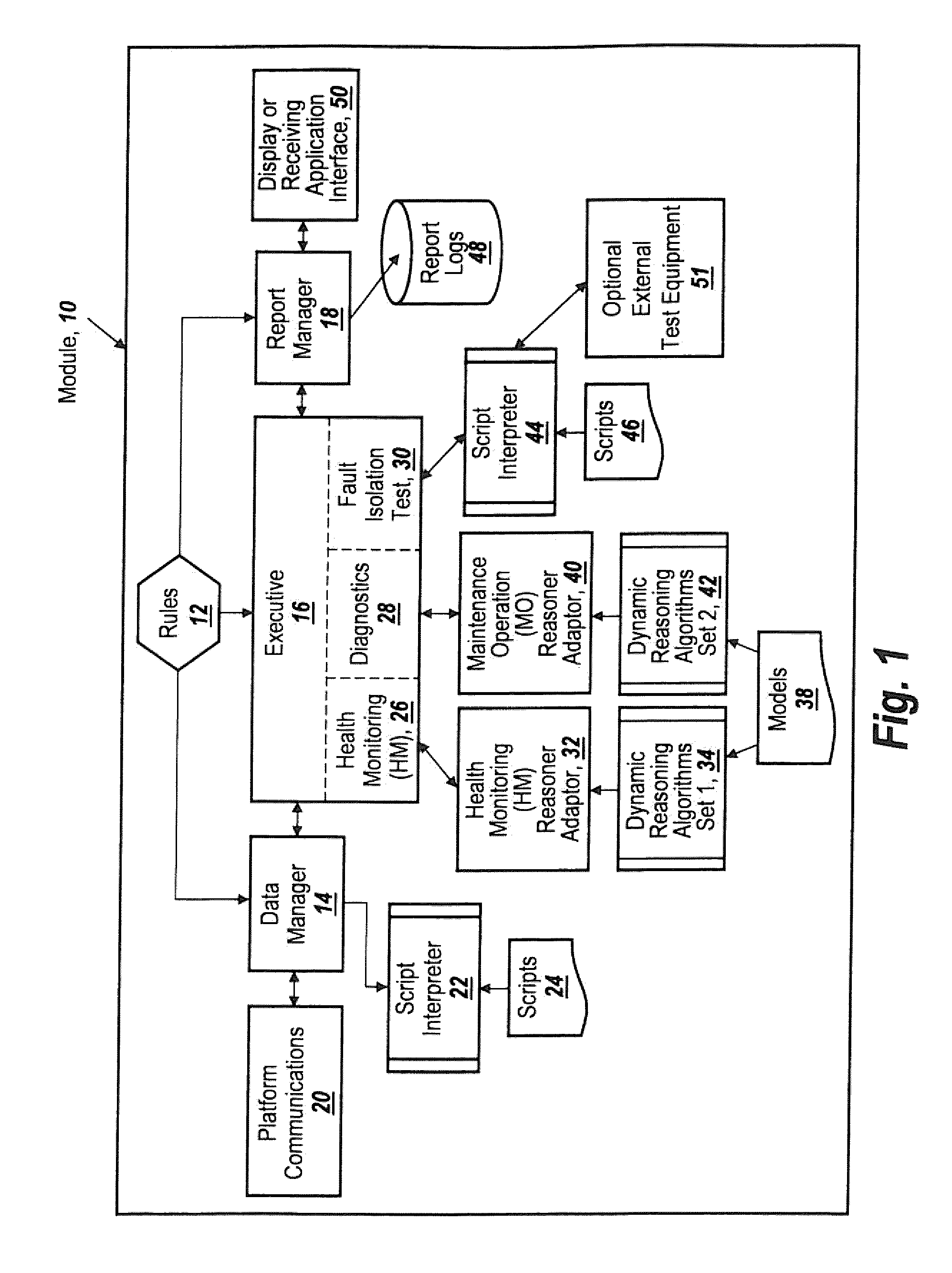

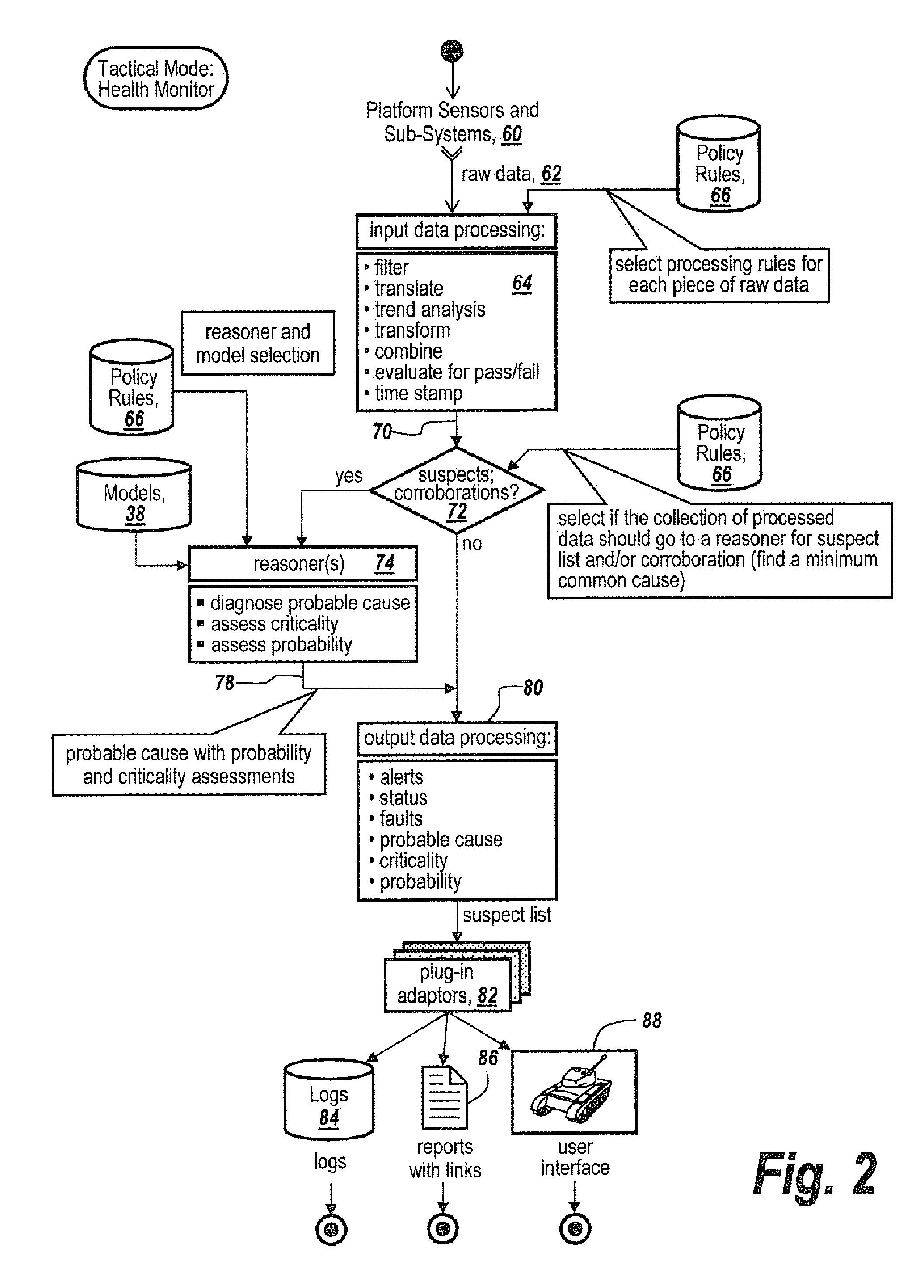

Prognostic diagnostic capability tracking system

ActiveUS20100083056A1Reduce unnecessaryFree shippingFault responseTesting/monitoring control systemsOn boardLine-replaceable unit

A universal on-board system is provided for automatic fault detection and on-the-spot repair instructions that includes a module adapted to be coupled to a wide variety of platforms and Line Replaceable Units.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

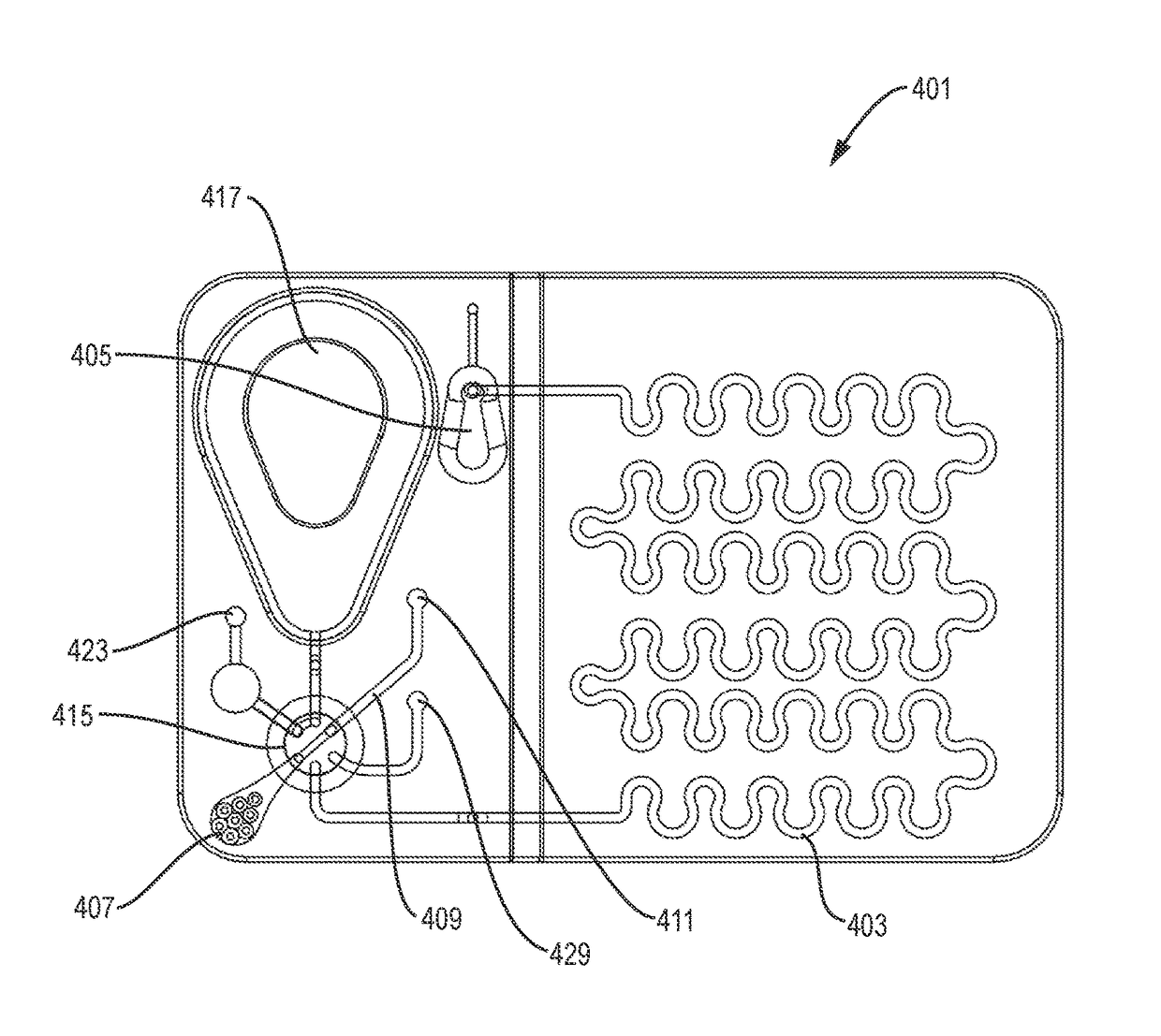

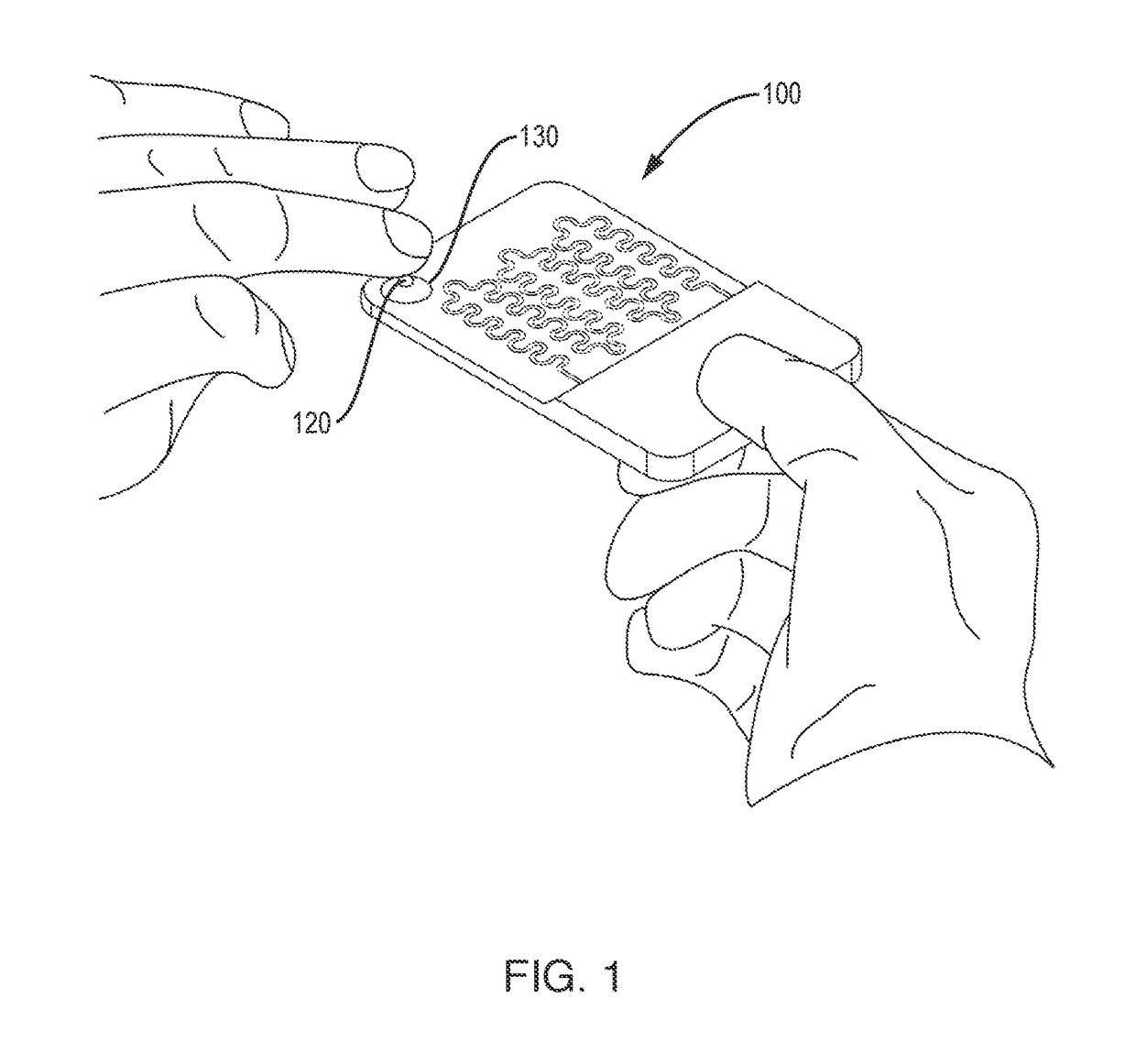

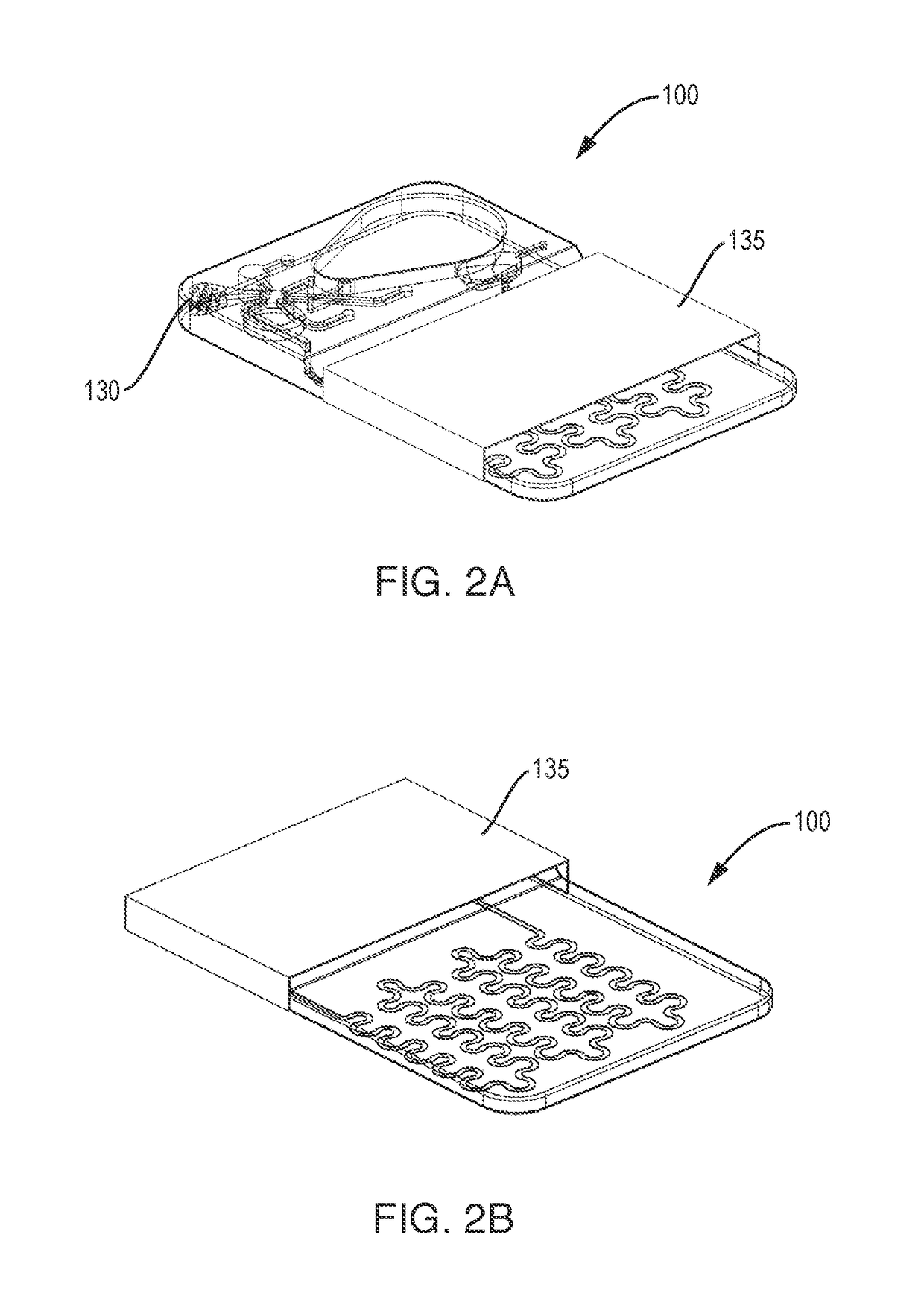

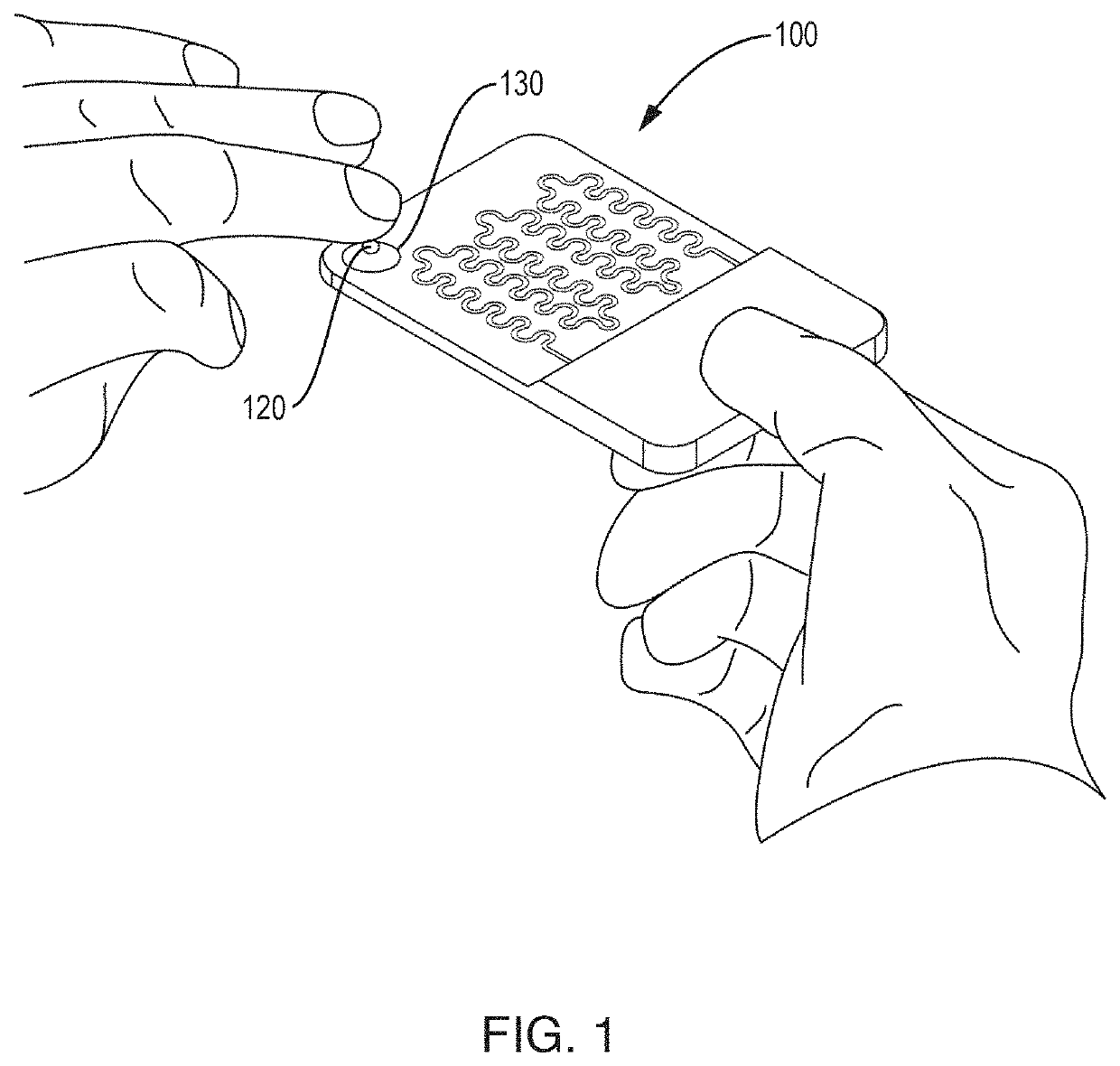

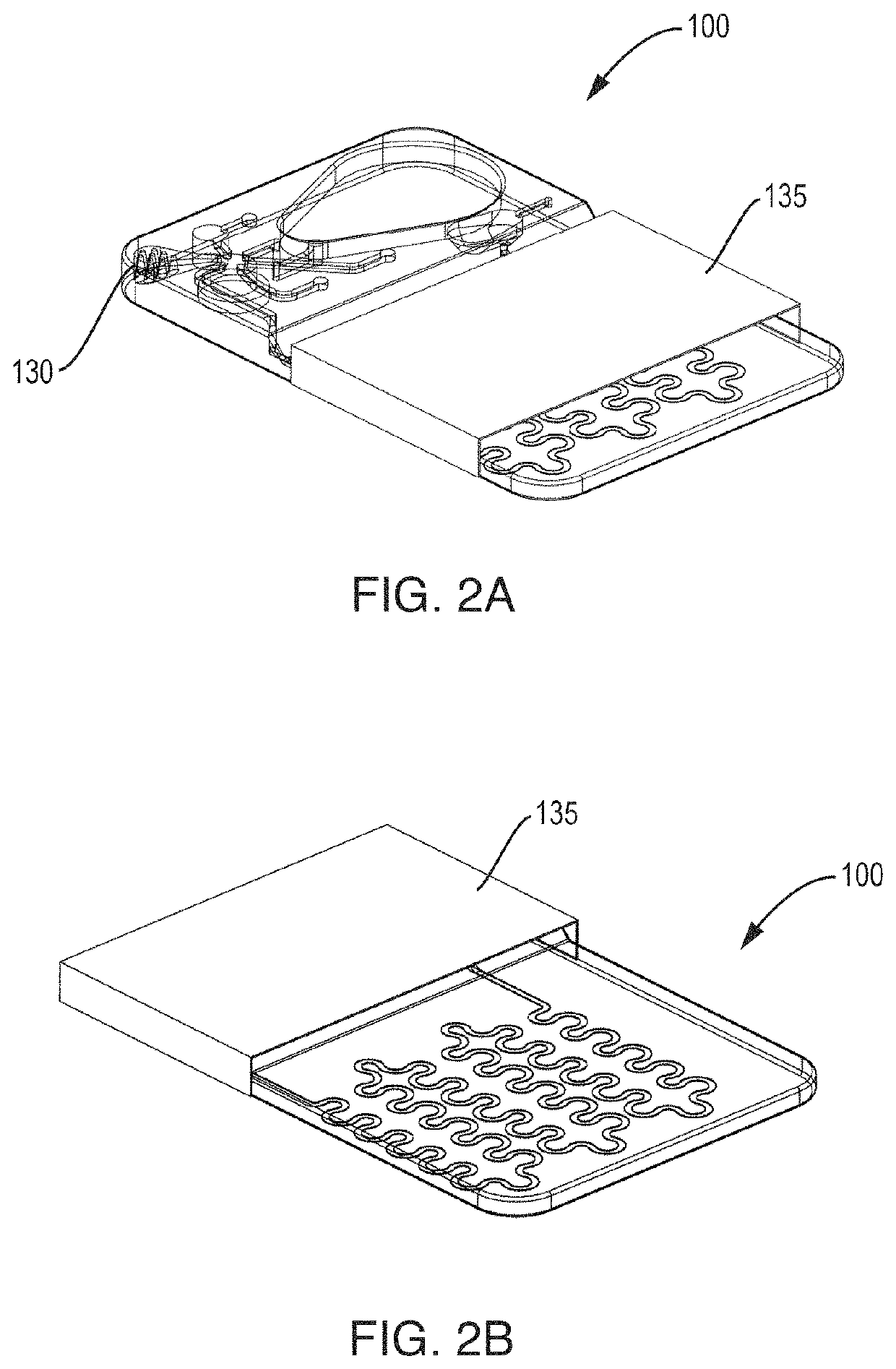

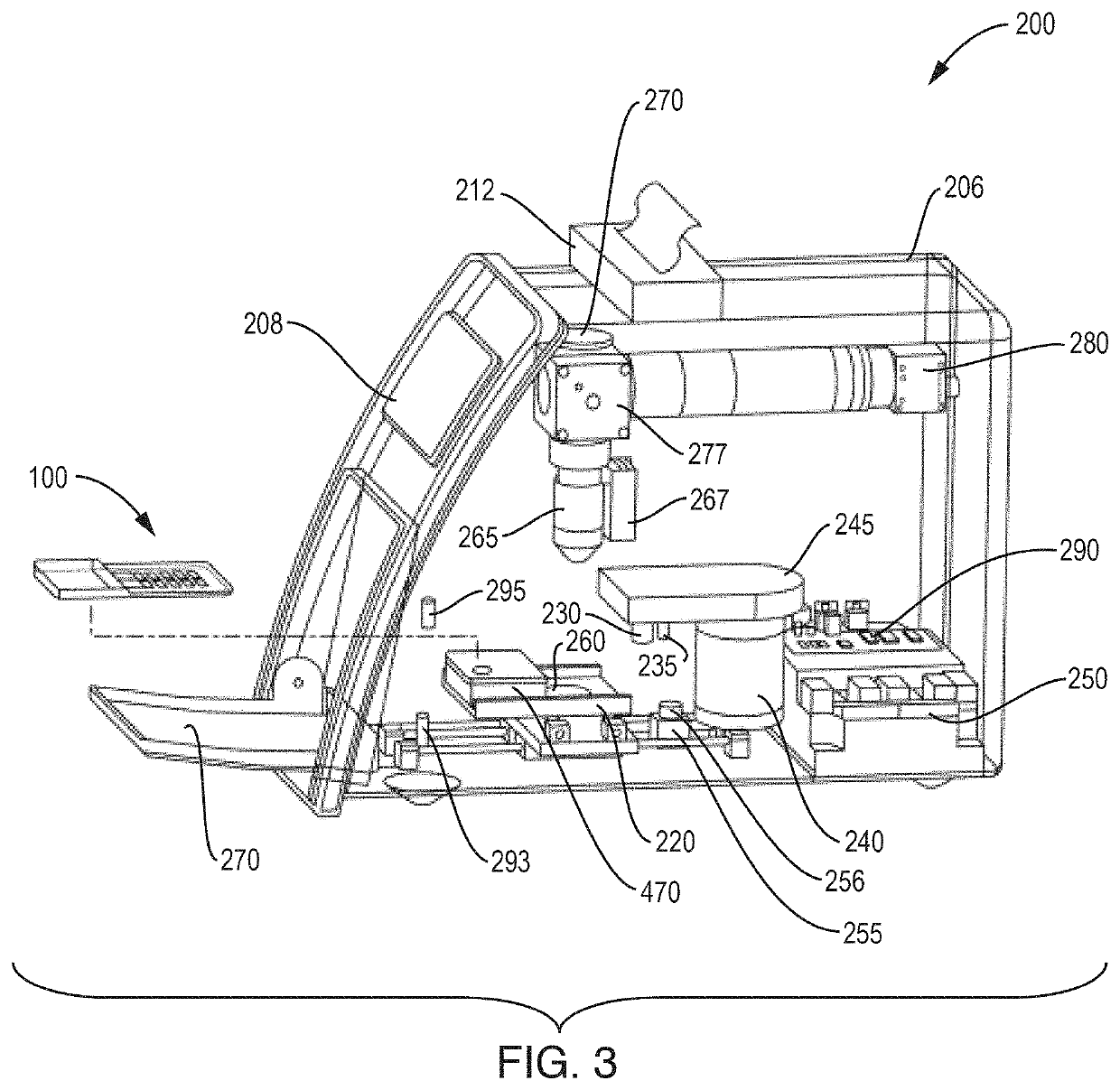

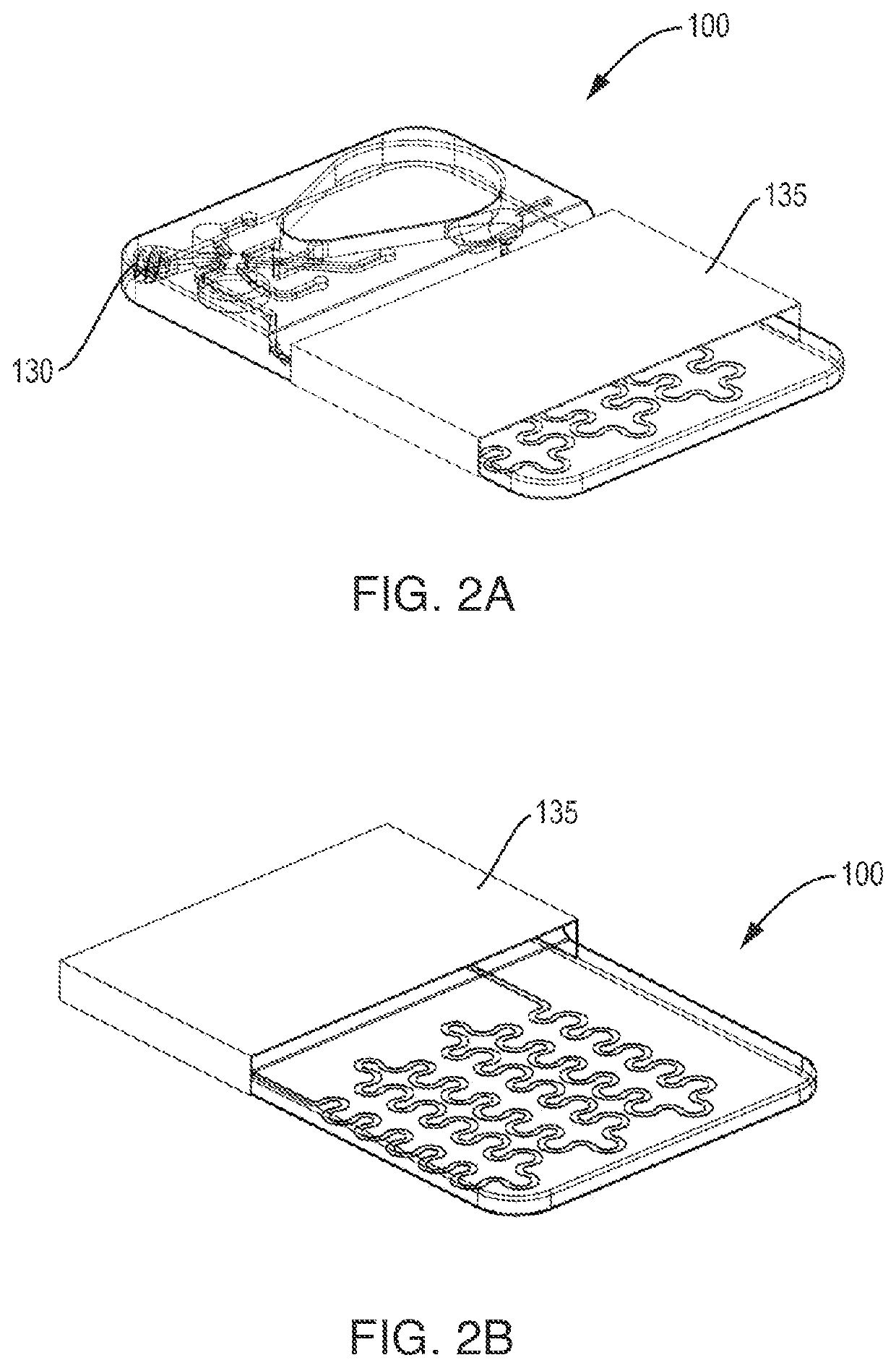

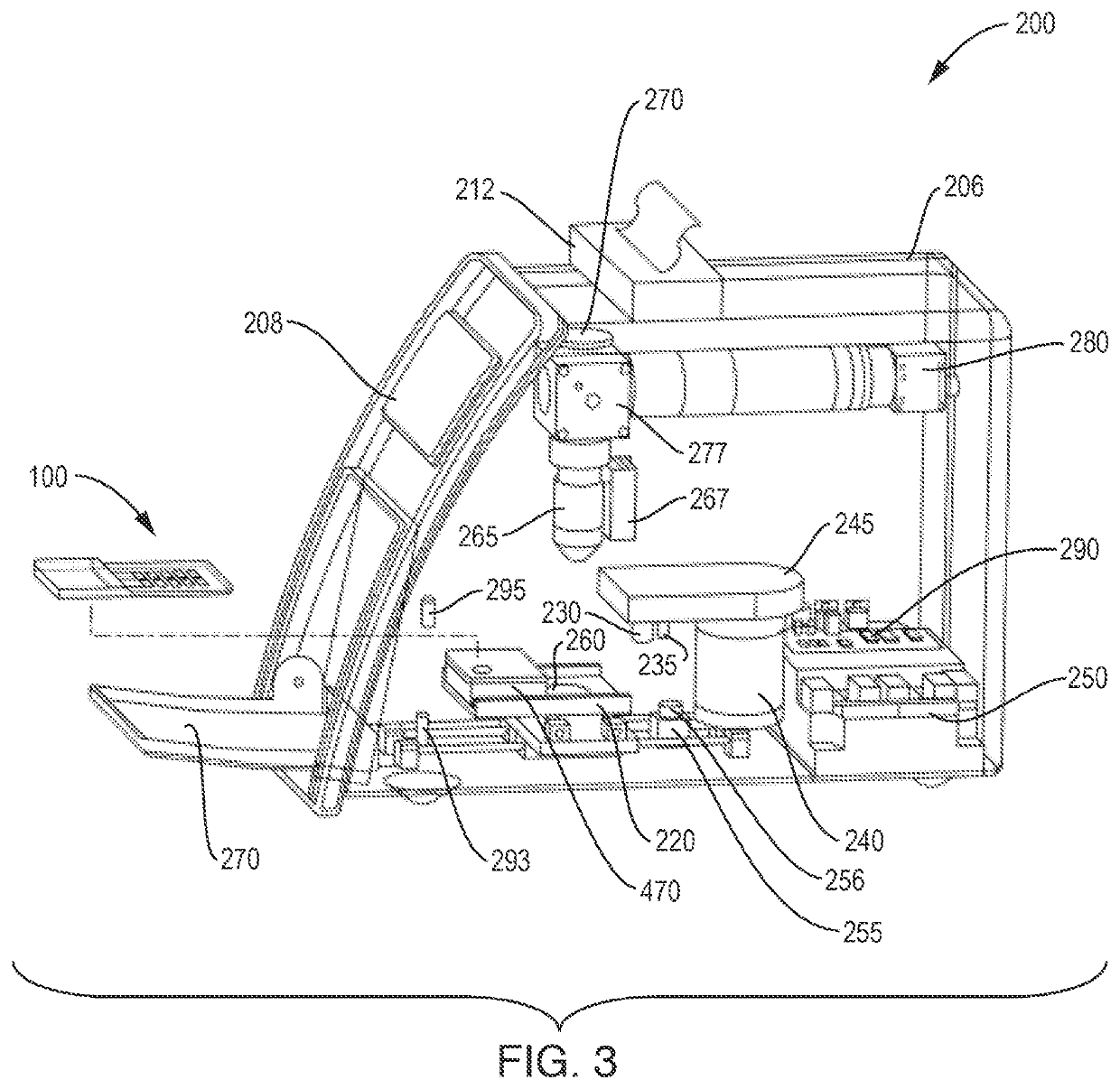

Automated microscopic cell analysis

ActiveUS9767343B1High quantitative accuracySample preparation is improvedWithdrawing sample devicesPreparing sample for investigationCellular componentCell analyzer

This disclosure describes single-use test cartridges, cell analyzer apparatus, and methods for automatically performing microscopic cell analysis tasks, such as counting blood cells in biological samples. A small unmeasured quantity of a biological sample such as whole blood is placed in the disposable test cartridge which is then inserted into the cell analyzer. The analyzer isolates a precise volume of the biological sample, mixes it with self-contained reagents and transfers the entire volume to an imaging chamber. The geometry of the imaging chamber is chosen to maintain the uniformity of the mixture, and to prevent cells from crowding or clumping, when it is transferred into the imaging chamber. Images of essentially all of the cellular components within the imaging chamber are analyzed to obtain counts per unit volume. The devices, apparatus and methods described may be used to analyze a small quantity of whole blood to obtain counts per unit volume of red blood cells, white blood cells, including sub-groups of white cells, platelets and measurements related to these bodies.

Owner:MEDICA CORP

Structural tower

InactiveUS20100226785A1Reduce energy costsGenerate efficientlyEngine manufactureEngine fuctionsHigh elevationDiagonal

Owner:GE WIND ENERGY

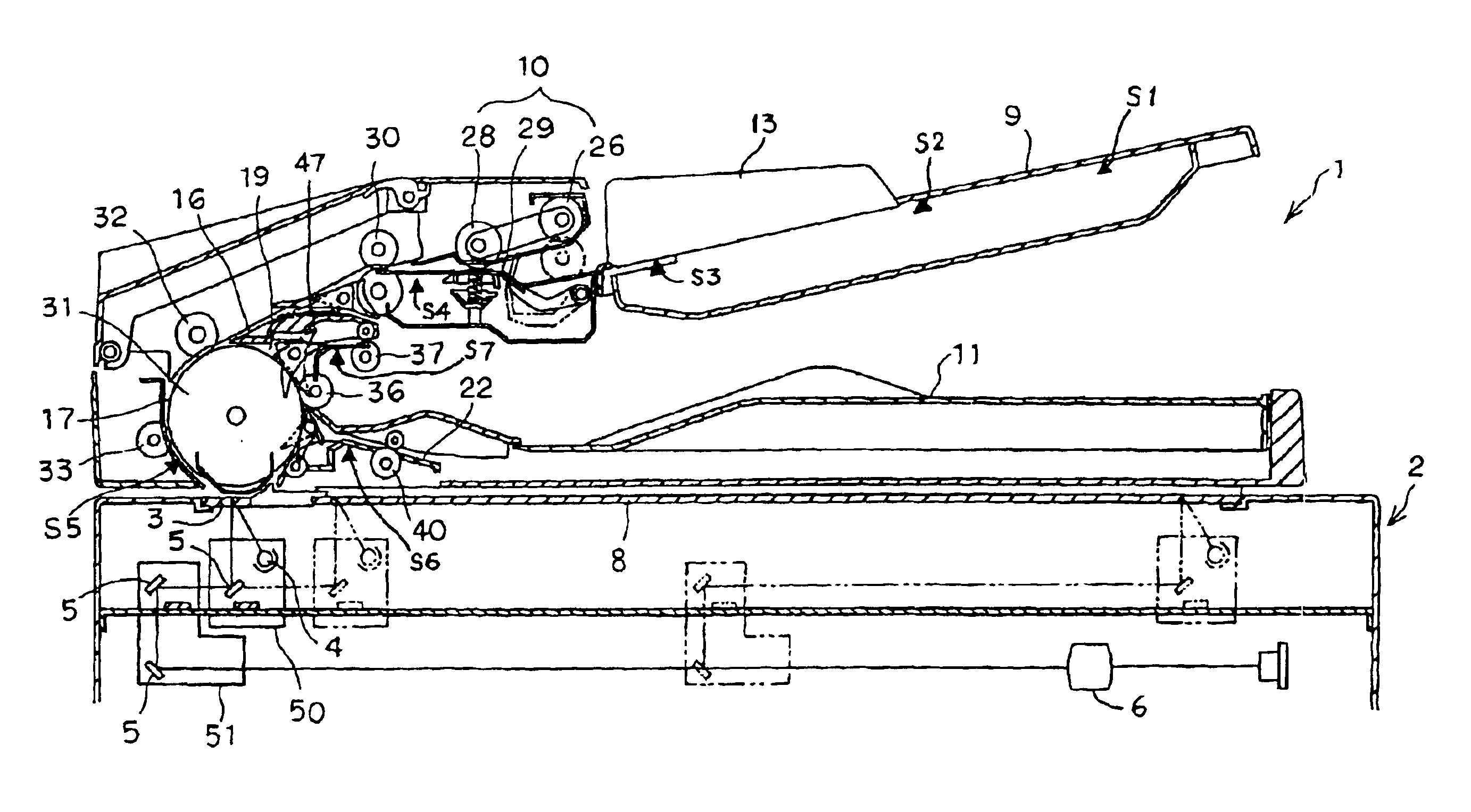

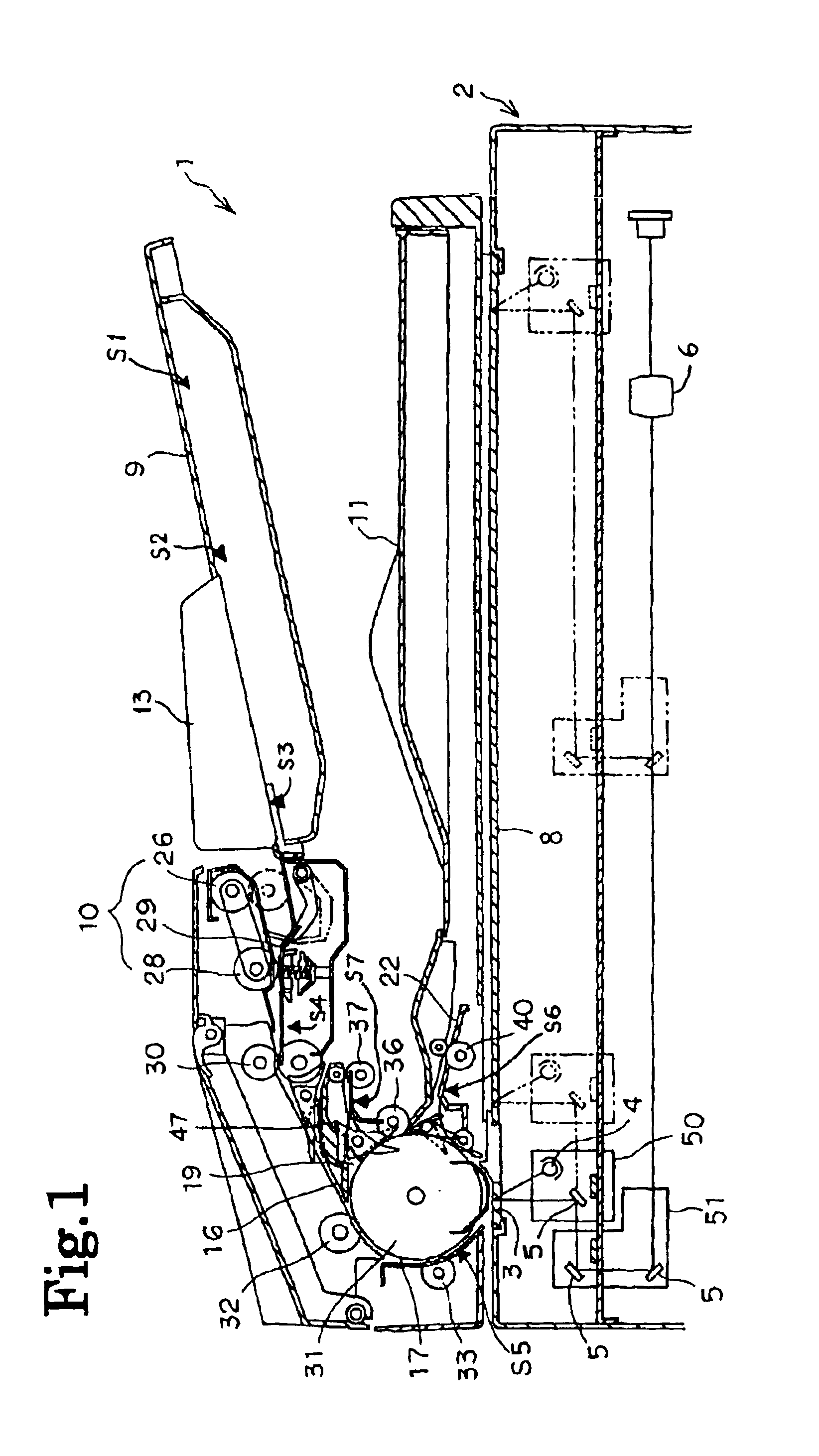

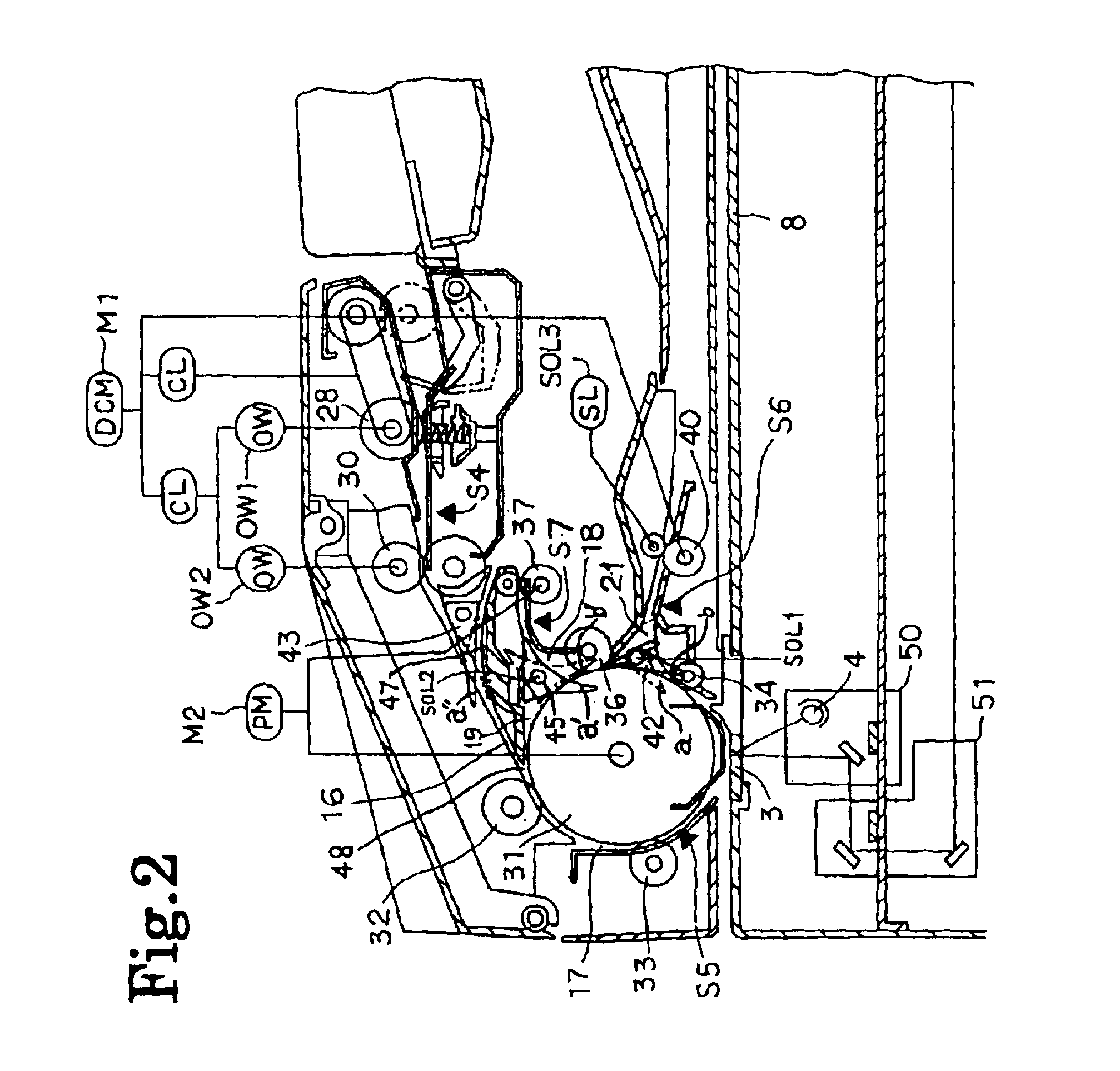

Image reading apparatus, image reading method and document feeder apparatus

InactiveUS6859637B2Improve transport efficiencyEliminate damageElectrographic process apparatusPropulsive elementsPaper documentDocument preparation

An image reading apparatus includes a transport path for guiding an original from an original tray to a reading position; a transport device for transporting the original toward a downstream side in a forward direction or toward an upstream side in a reverse direction; a reading device for reading the original at the reading position; a determining device for determining whether the original has a black and white image or color image; and a retreat path disposed at an upstream side of the reading position for retreating at least a part of the original from the transport path. After the determining device determines the original, the original is transported in the reverse direction to retreat it to the retreat path. Then, the original is transported to the reading position, so that the reading device reads the original in a reading mode according to a result of the determination.

Owner:NISCA KK

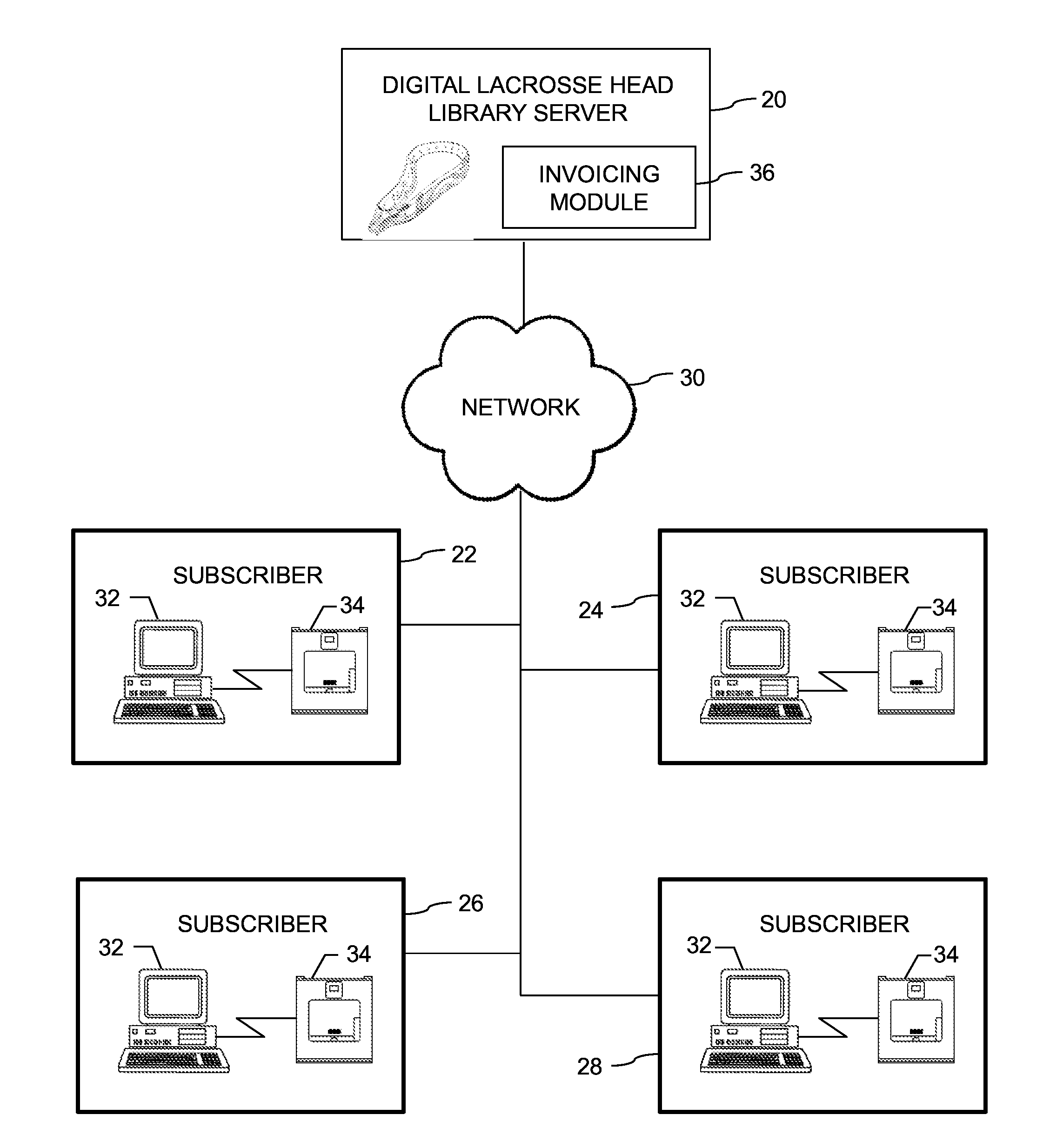

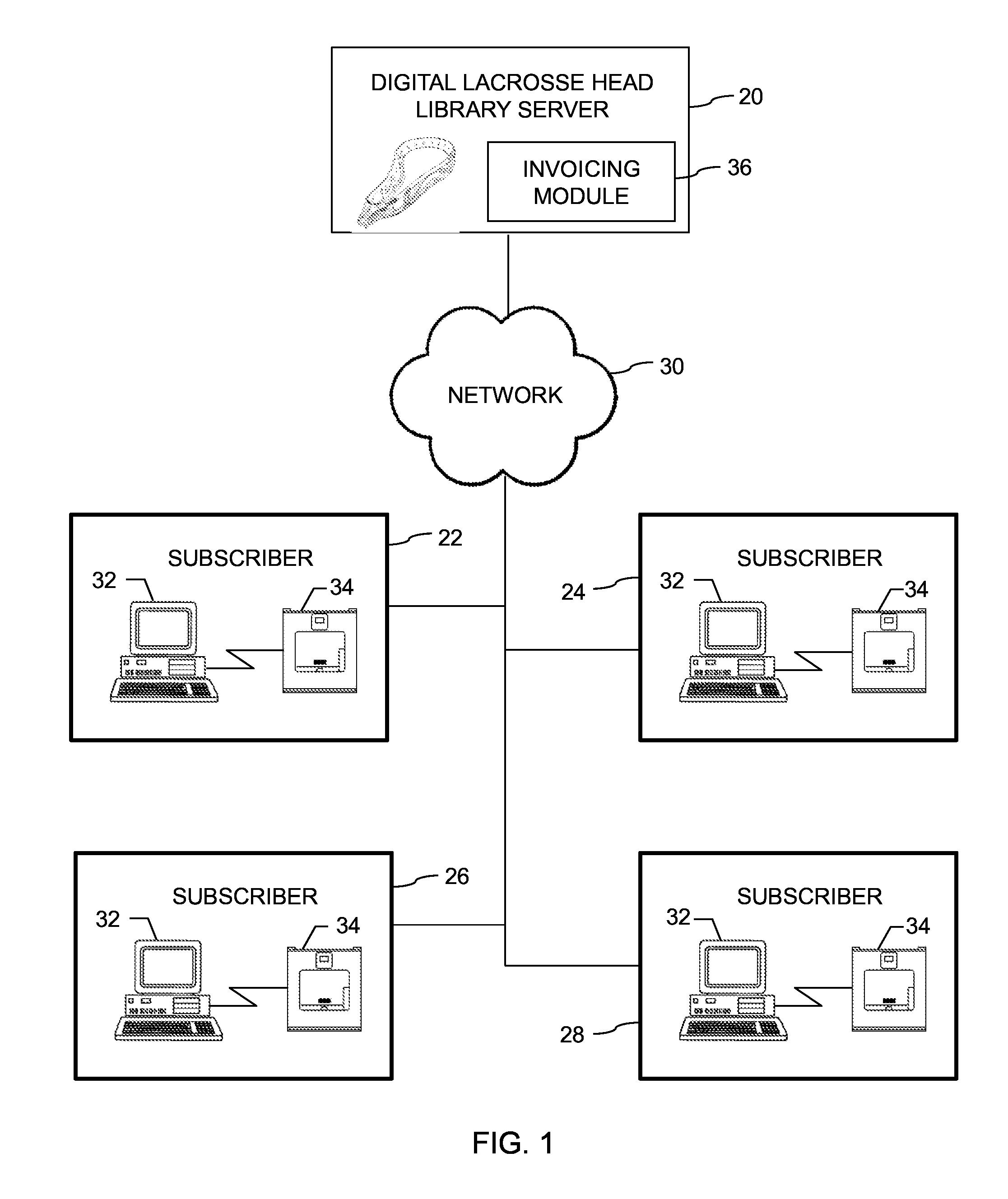

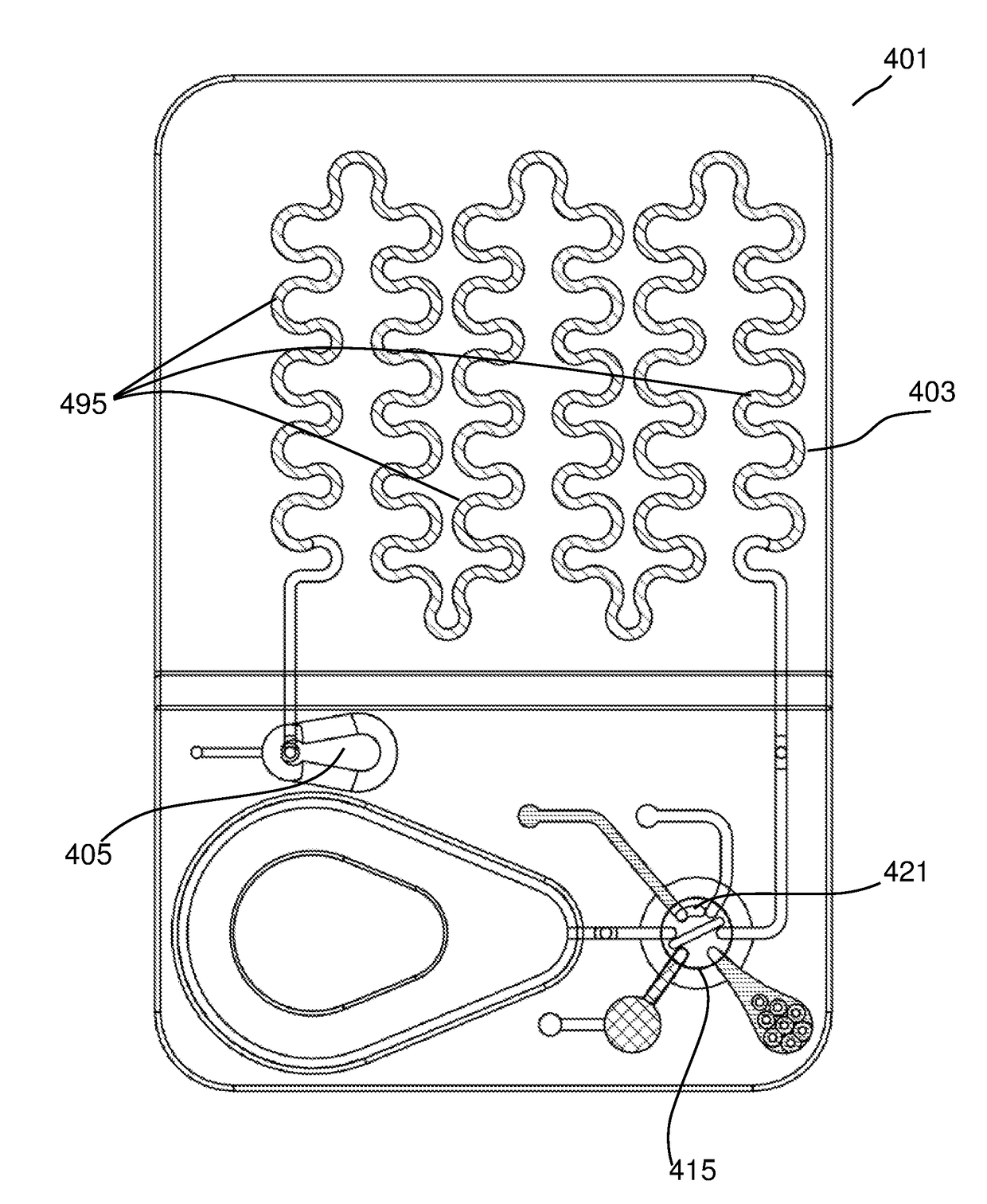

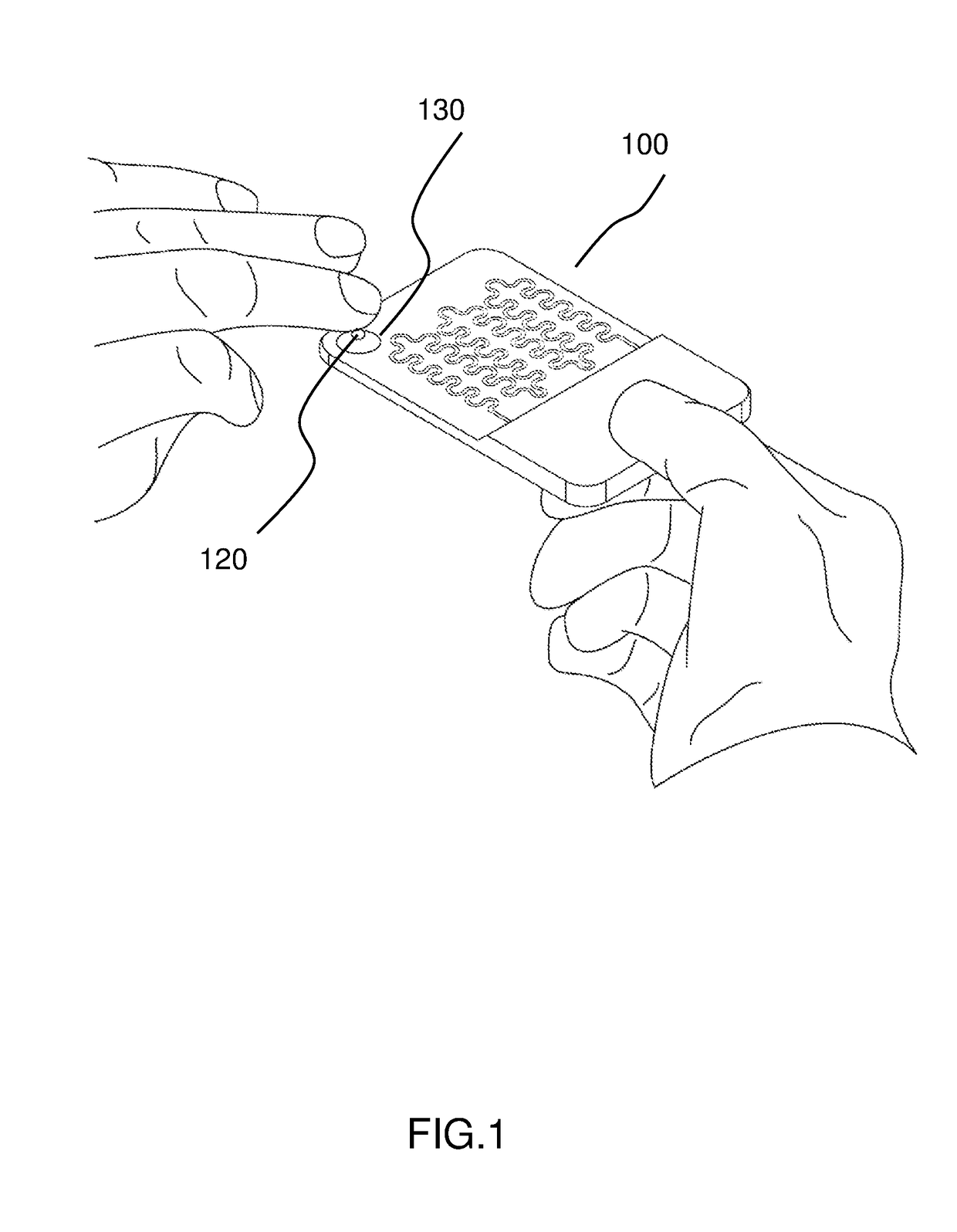

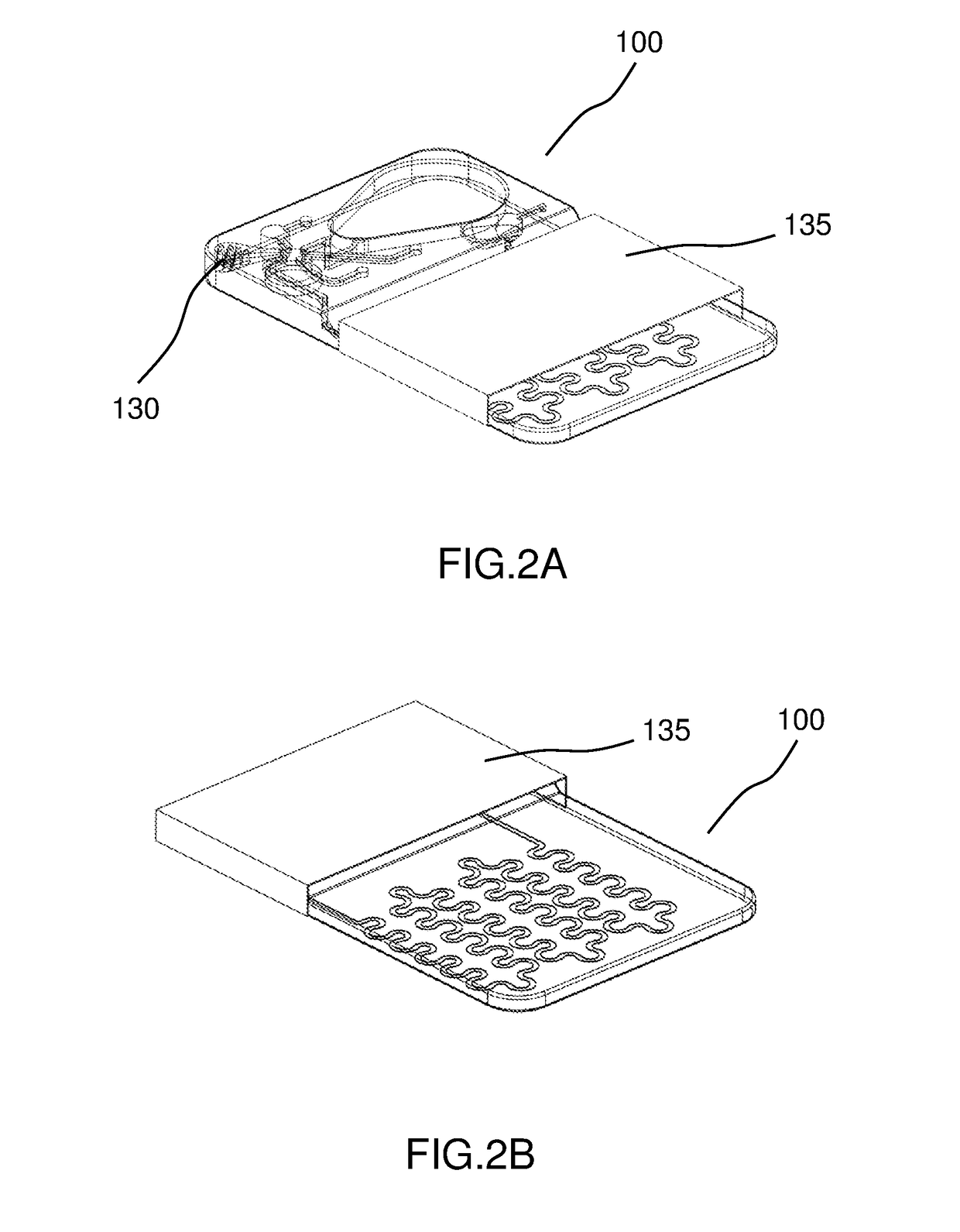

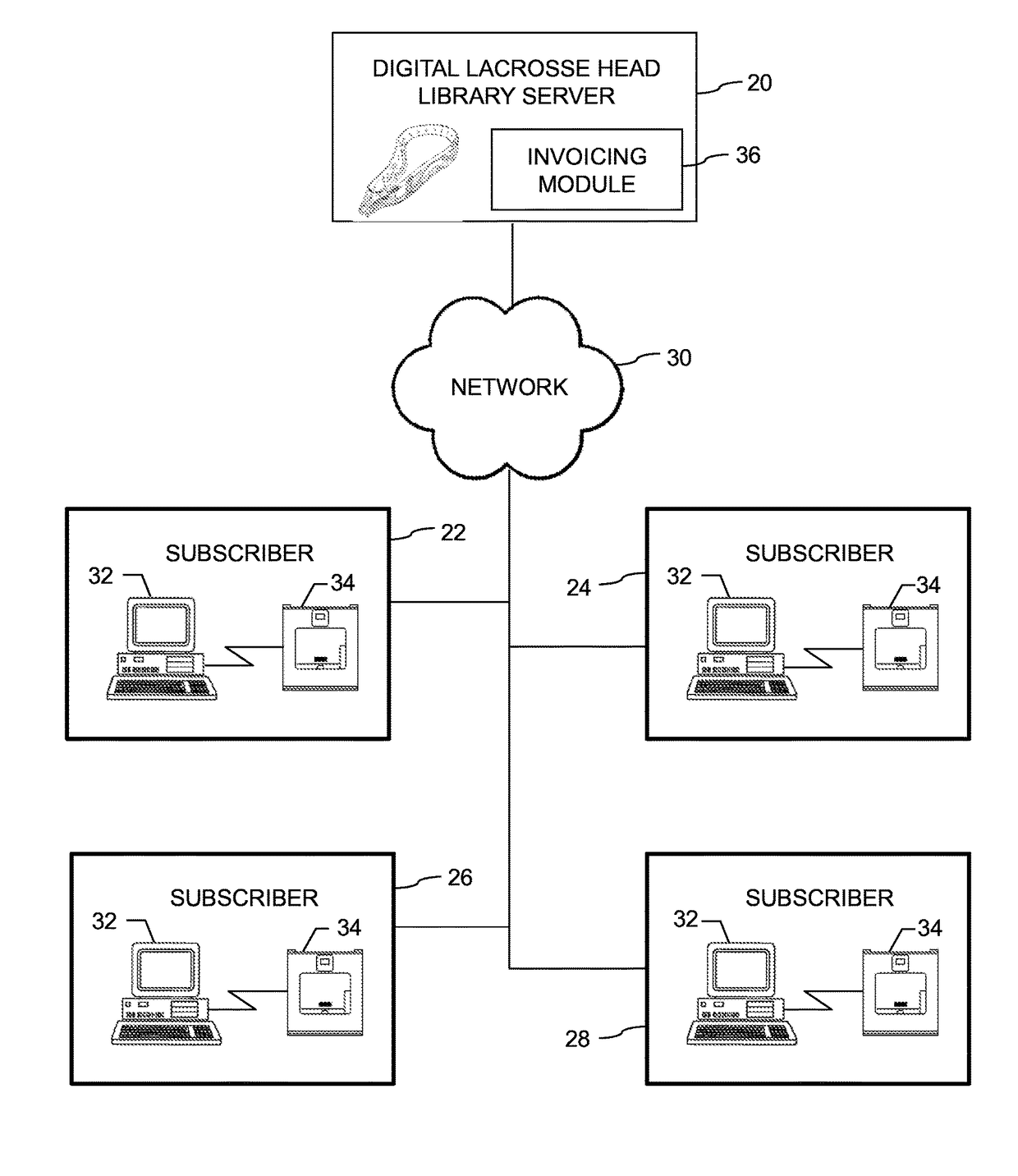

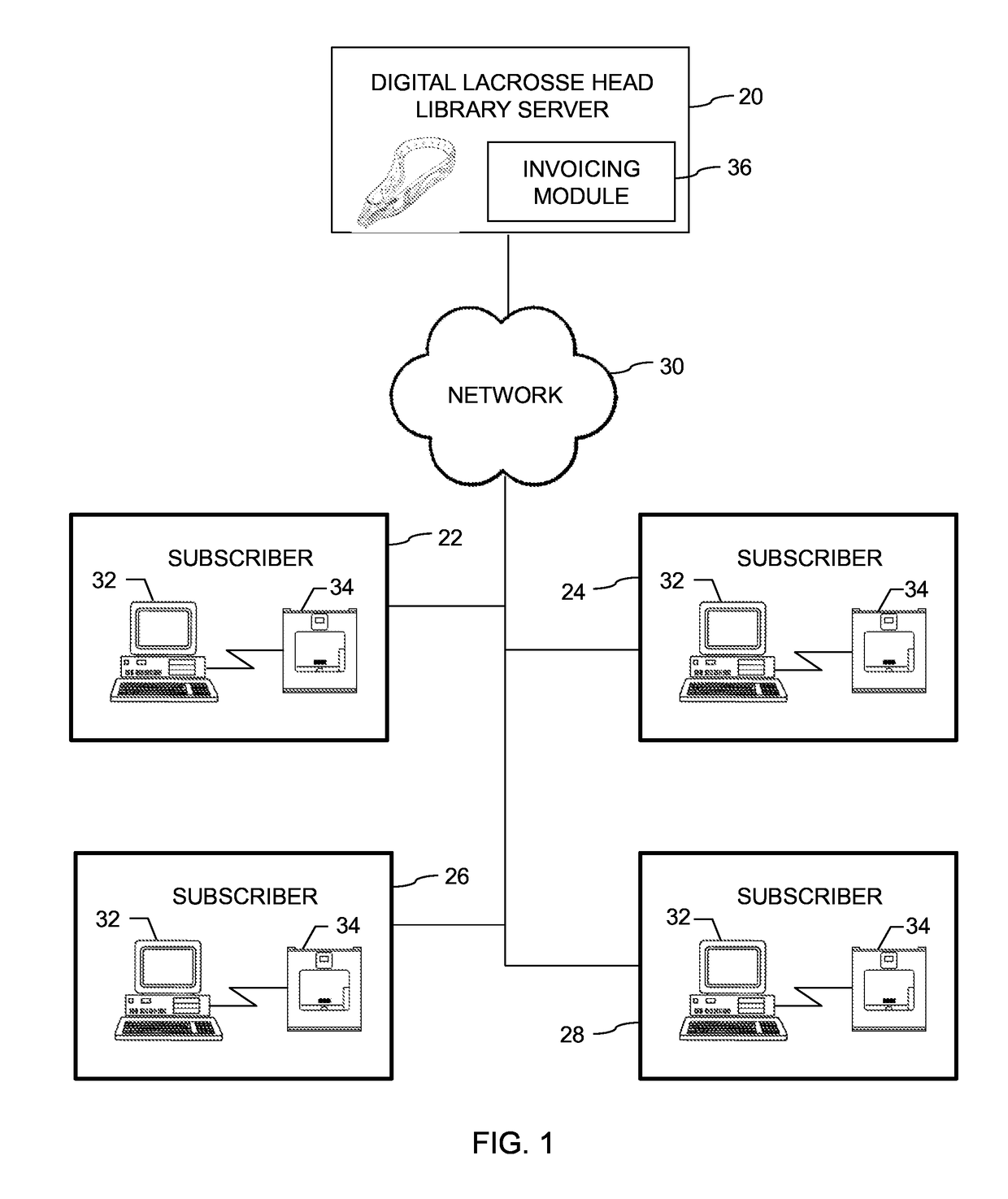

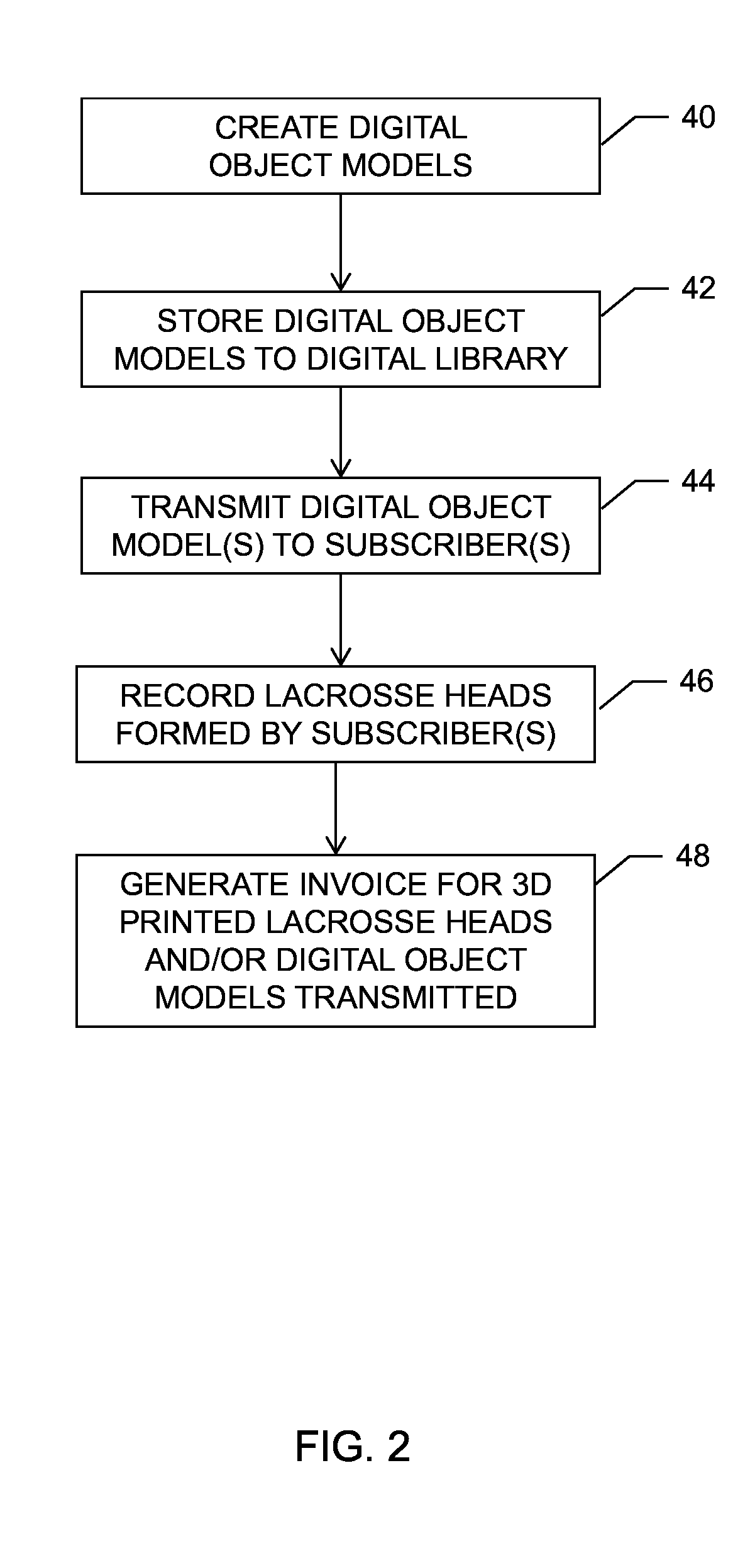

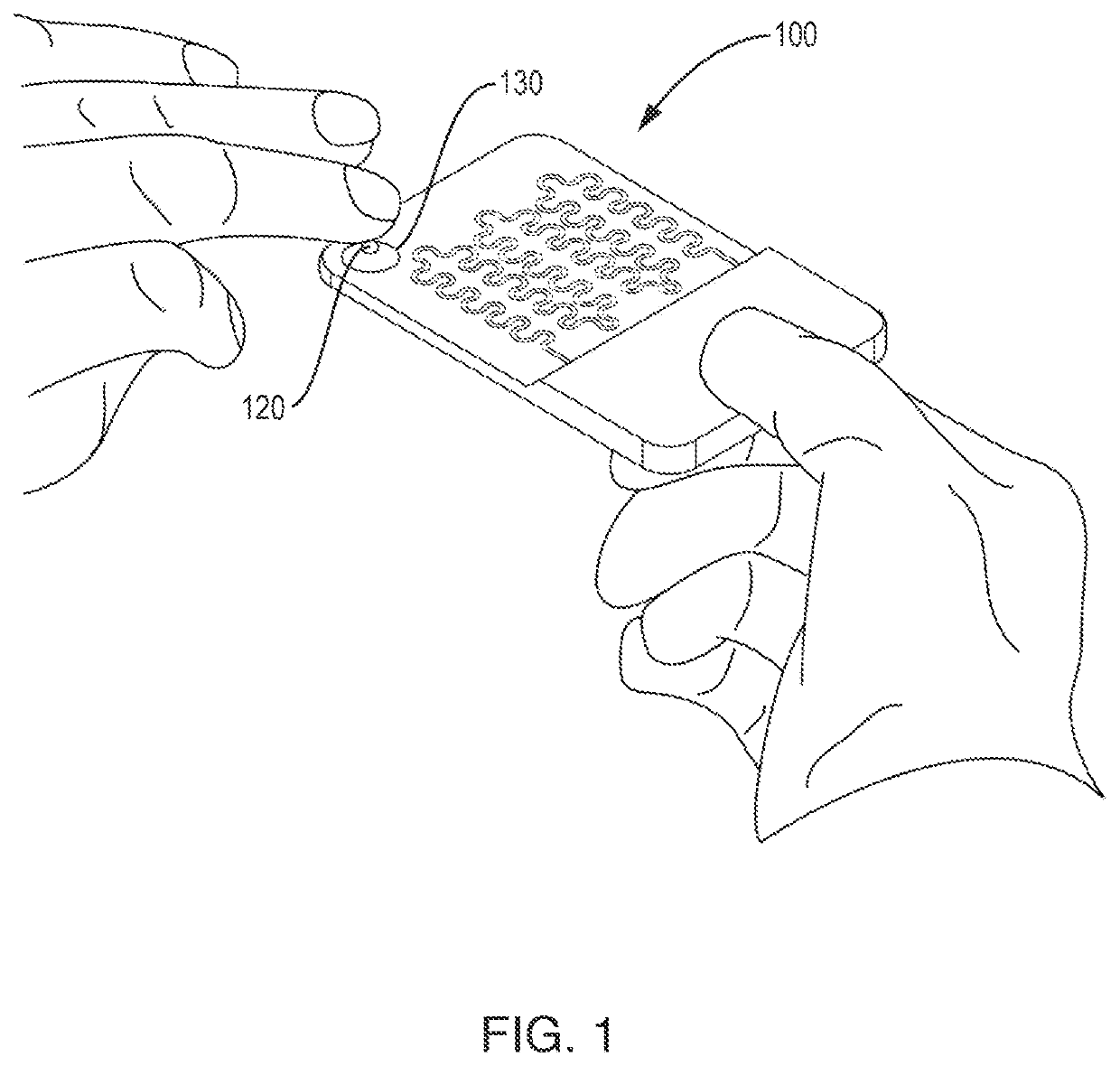

Systems and methods for 3D printing of lacrosse heads

ActiveUS20150165692A1Reduce manufacturing costEasy to customizeAdditive manufacturing apparatusBall sportsPersonalizationComputer graphics (images)

Methods for the individualized design and manufacture of lacrosse heads using point of sale additive fabrication. In one aspect, a subscription-based method includes digitizing a plurality of lacrosse heads having different three-dimensional attributes, storing the resulting digital object data into a digital lacrosse head library, transmitting the digital lacrosse head library to a subscriber, recording the number of lacrosse heads formed by the subscriber using additive fabrication, and generating an invoice based on the number of formed lacrosse heads. In another aspect, a method includes displaying images of lacrosse heads on a user interface, enabling the user-specified selection of discrete components of a lacrosse head, enabling the user specification combination of the discrete components, superimposing the user-specified combination to form a digital object representation of a lacrosse head, forming a tangible three-dimensional lacrosse head by additive fabrication, and transferring the tangible three-dimensional lacrosse head to the consumer.

Owner:WARRIOR SPORTS INC

Prognostic diagnostic capability tracking system

InactiveUS8001423B2Reduce unnecessaryFree shippingError detection/correctionTesting/monitoring control systemsOn boardLine-replaceable unit

A universal on-board system is provided for automatic fault detection and on-the-spot repair instructions that includes a module adapted to be coupled to a wide variety of platforms and Line Replaceable Units.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Automated microscopic cell analysis

ActiveUS20170326549A1Easy to operateAvoid cross contaminationWithdrawing sample devicesPreparing sample for investigationCellular componentWhite blood cell

This disclosure describes single-use test cartridges, cell analyzer apparatus, and methods for automatically performing microscopic cell analysis tasks, such as counting blood cells in biological samples. A small unmeasured quantity of a biological sample such as whole blood is placed in the disposable test cartridge which is then inserted into the cell analyzer. The analyzer isolates a precise volume of the biological sample, mixes it with self-contained reagents and transfers the entire volume to an imaging chamber. The geometry of the imaging chamber is chosen to maintain the uniformity of the mixture, and to prevent cells from crowding or clumping, when it is transferred into the imaging chamber. Images of essentially all of the cellular components within the imaging chamber are analyzed to obtain counts per unit volume. The devices, apparatus and methods described may be used to analyze a small quantity of whole blood to obtain counts per unit volume of red blood cells, white blood cells, including sub-groups of white cells, platelets and measurements related to these bodies.

Owner:MEDICA CORP

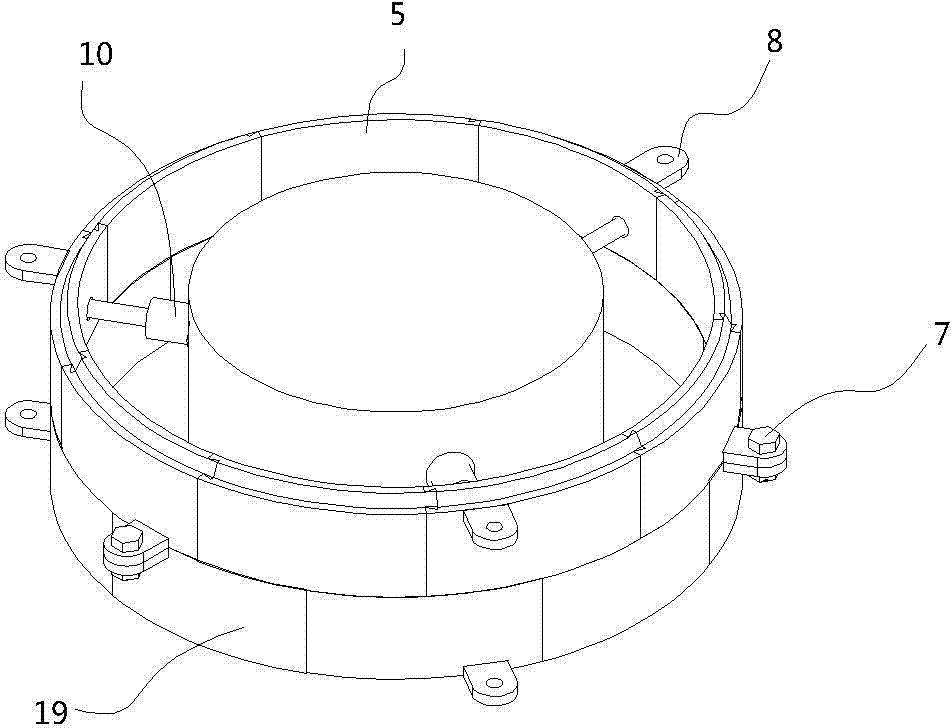

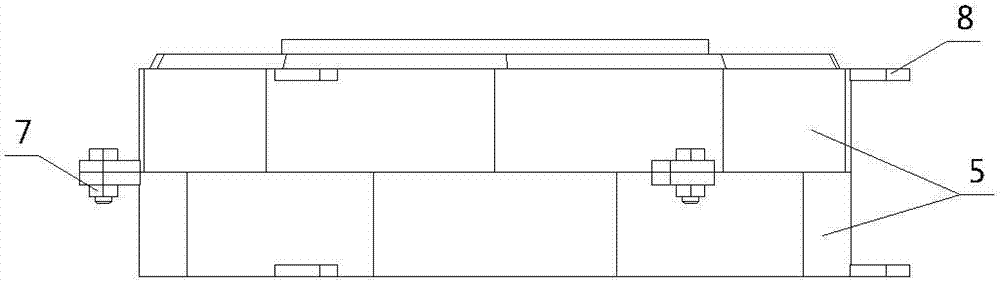

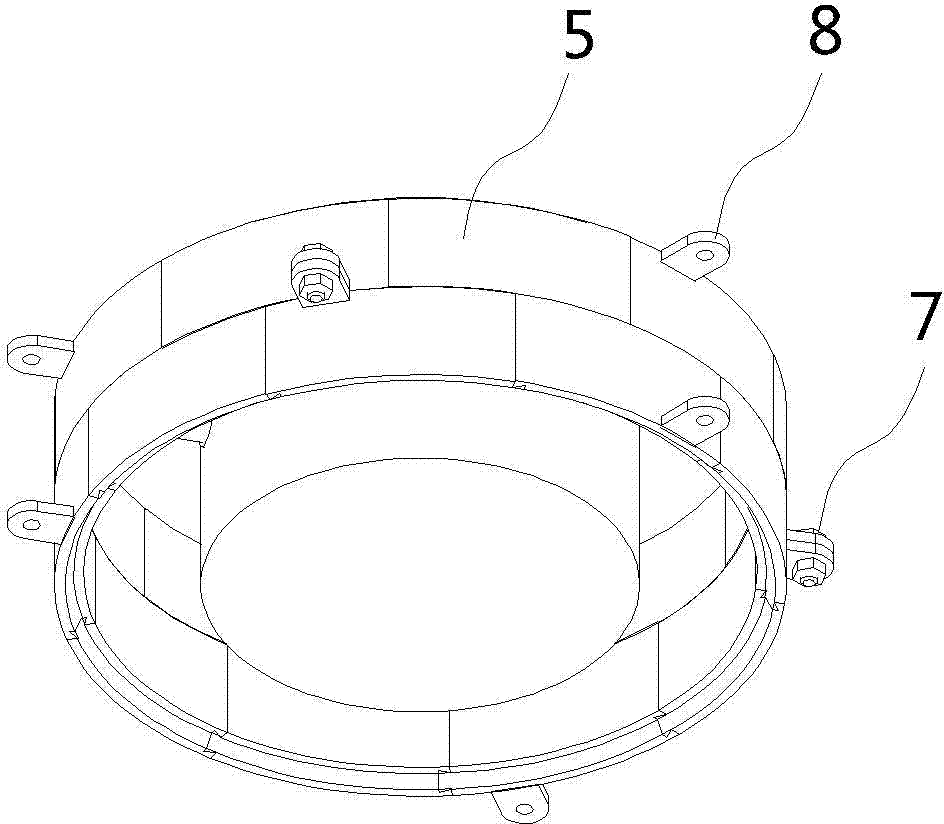

Bridge pier cofferdam reinforcing structure and constructing method thereof

ActiveCN104234064ALow consignment technical requirementsReduce difficultyFoundation engineeringEngineeringUtilization rate

The invention discloses a bridge pier cofferdam reinforcing structure. The bridge pier cofferdam reinforcing structure comprises cofferdams (19), wherein each cofferdam (19) is defined by a plurality of steel sheets (5) of an arc-shaped structure in a connected mode or defined by a plurality of steel sheets (5) of an arc-shaped structure and a plurality of steel sheets (20) of a cuboid structure in a connected mode. The bridge pier cofferdam reinforcing structure is convenient to disassemble and assemble and flexible to convey, after one cofferdam is reinforced and disassembled, the cofferdam can be directly hauled to another construction site for use, and therefore the equipment utilization rate is increased.

Owner:HEBEI ROAD & BRIDGE GROUP

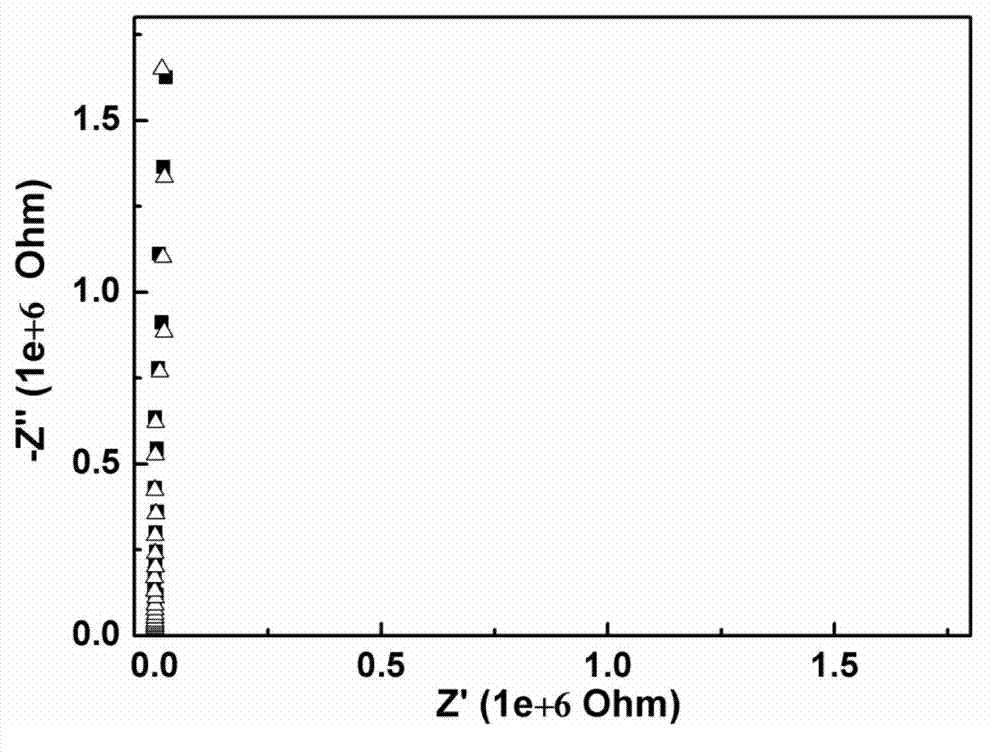

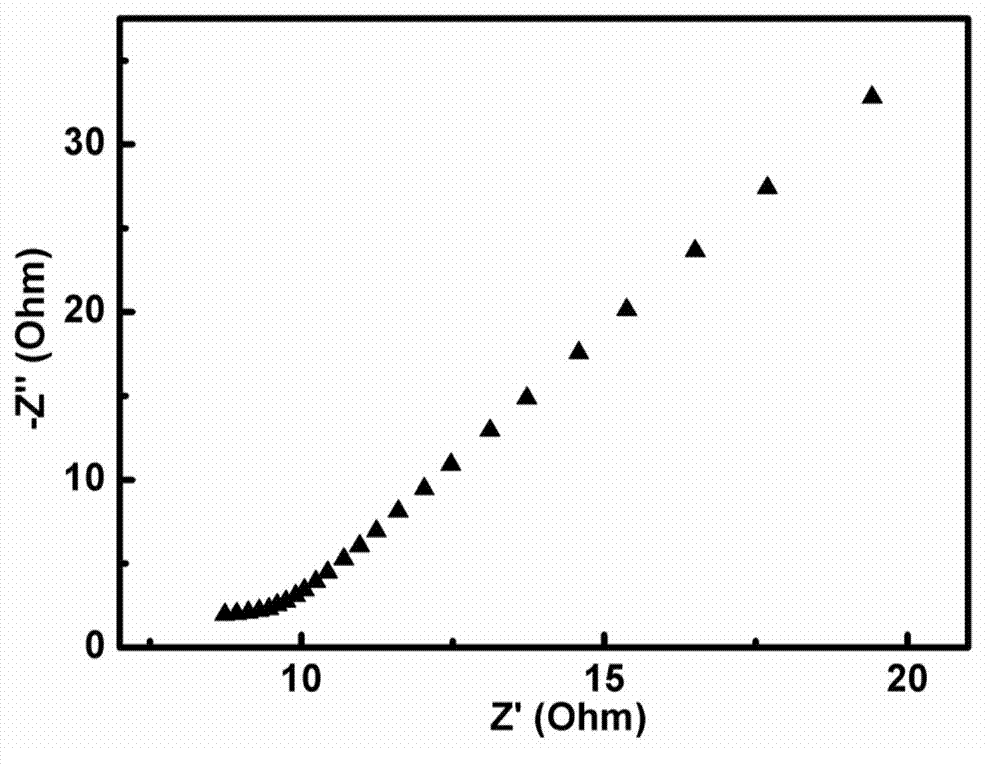

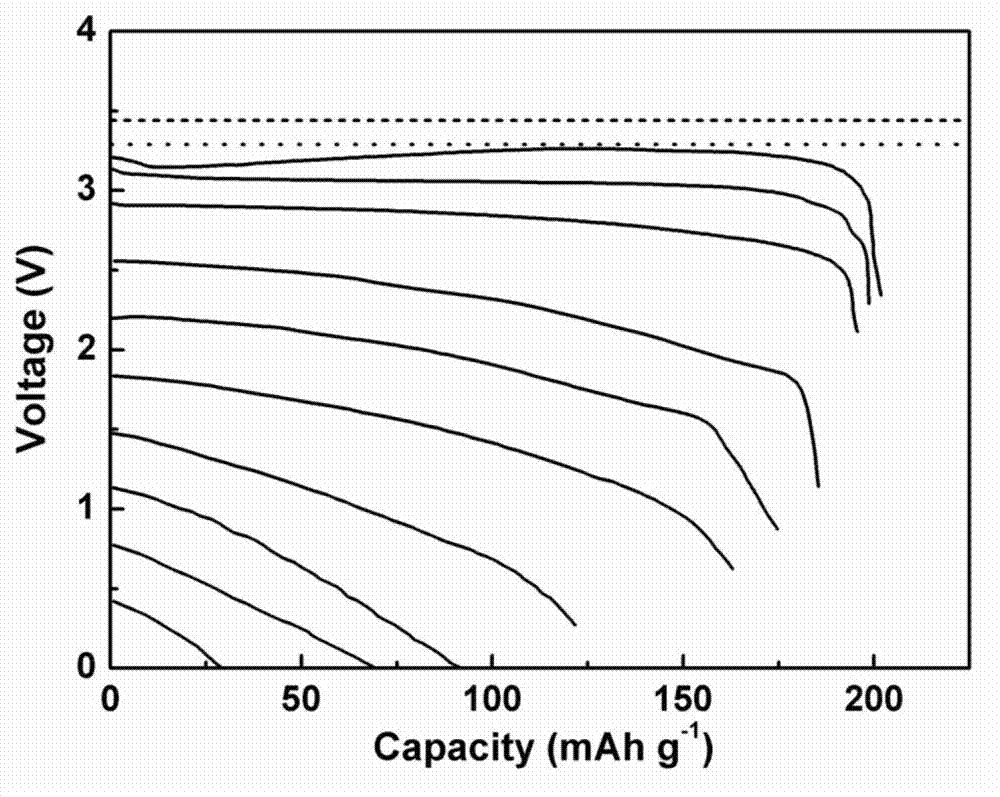

Dual-phase electrolyte and lithium-silver battery

InactiveCN103117424AImprove conductivityLower impedanceFuel and secondary cellsHigh energyPolypropylene

The invention relates to a dual-phase electrolyte and a lithium-silver battery, belonging to the technical field of chemical power supplies. The dual-phase electrolyte comprises a water solution electrolyte and a hydrophobic organic electrolyte, wherein an organic polymer film of polypropylene, polyethylene or a mixture of polypropylene and polyethylene is arranged between the two phases of the electrolytes as a diaphragm; and the water solution electrolyte comprises a lithium salt and water, the hydrophobic organic electrolyte comprises a lithium salt, propene carbonate, dimethyl carbonate, diethyl carbonate or a mixture thereof, and lithium ions in the electrolytes are 0.5-1mol / L. The battery comprises the dual-phase electrolyte, a silver oxide positive pole arranged in the alkaline water solution electrolyte, a lithium negative pole arranged in the hydrophobic organic electrolyte and a conducting wire. The hydrophobic organic electrolyte in the dual-phase electrolyte has the advantages of high electric conductivity, low diaphragm impedance and good hydrophobicity, flexibility and chemical stability; and the battery has the advantages of steady discharge voltage, high energy density and high power density.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Systems and methods for 3D printing of lacrosse heads

ActiveUS9892214B2Easy to customizeFree shippingAdditive manufacturing apparatusComputer aided designPersonalizationComputer graphics (images)

Methods for the individualized design and manufacture of lacrosse heads using point of sale additive fabrication. In one aspect, a subscription-based method includes digitizing a plurality of lacrosse heads having different three-dimensional attributes, storing the resulting digital object data into a digital lacrosse head library, transmitting the digital lacrosse head library to a subscriber, recording the number of lacrosse heads formed by the subscriber using additive fabrication, and generating an invoice based on the number of formed lacrosse heads. In another aspect, a method includes displaying images of lacrosse heads on a user interface, enabling the user-specified selection of discrete components of a lacrosse head, enabling the user specification combination of the discrete components, superimposing the user-specified combination to form a digital object representation of a lacrosse head, forming a tangible three-dimensional lacrosse head by additive fabrication, and transferring the tangible three-dimensional lacrosse head to the consumer.

Owner:WARRIOR SPORTS INC

Automated microscopic cell analysis

ActiveUS10625259B1High quantitative accuracySample preparation is improvedWithdrawing sample devicesPreparing sample for investigationCellular componentHematological test

This disclosure describes single-use test cartridges, cell analyzer apparatus, and methods for automatically performing microscopic cell analysis tasks, such as counting and analyzing blood cells in biological samples. A small measured quantity of a biological sample, such as whole blood, is placed in a mixing bowl on the disposable test cartridge after being inserted into the cell analyzer. The analyzer also deposits a known amount of diluent / stain in the mixing bowl and mixes it with the blood. The analyzer takes a measured amount of the mixture and dispenses in a sample cup on the cartridge in fluid communication with an imaging chamber. The geometry of the imaging chamber is chosen to maintain the uniformity of the mixture, and to prevent cells from crowding or clumping as it is transferred into the imaging chamber by the analyzer. Images of all of the cellular components within the imaging chamber are counted and analyzed to obtain a complete blood count.

Owner:MEDICA CORP

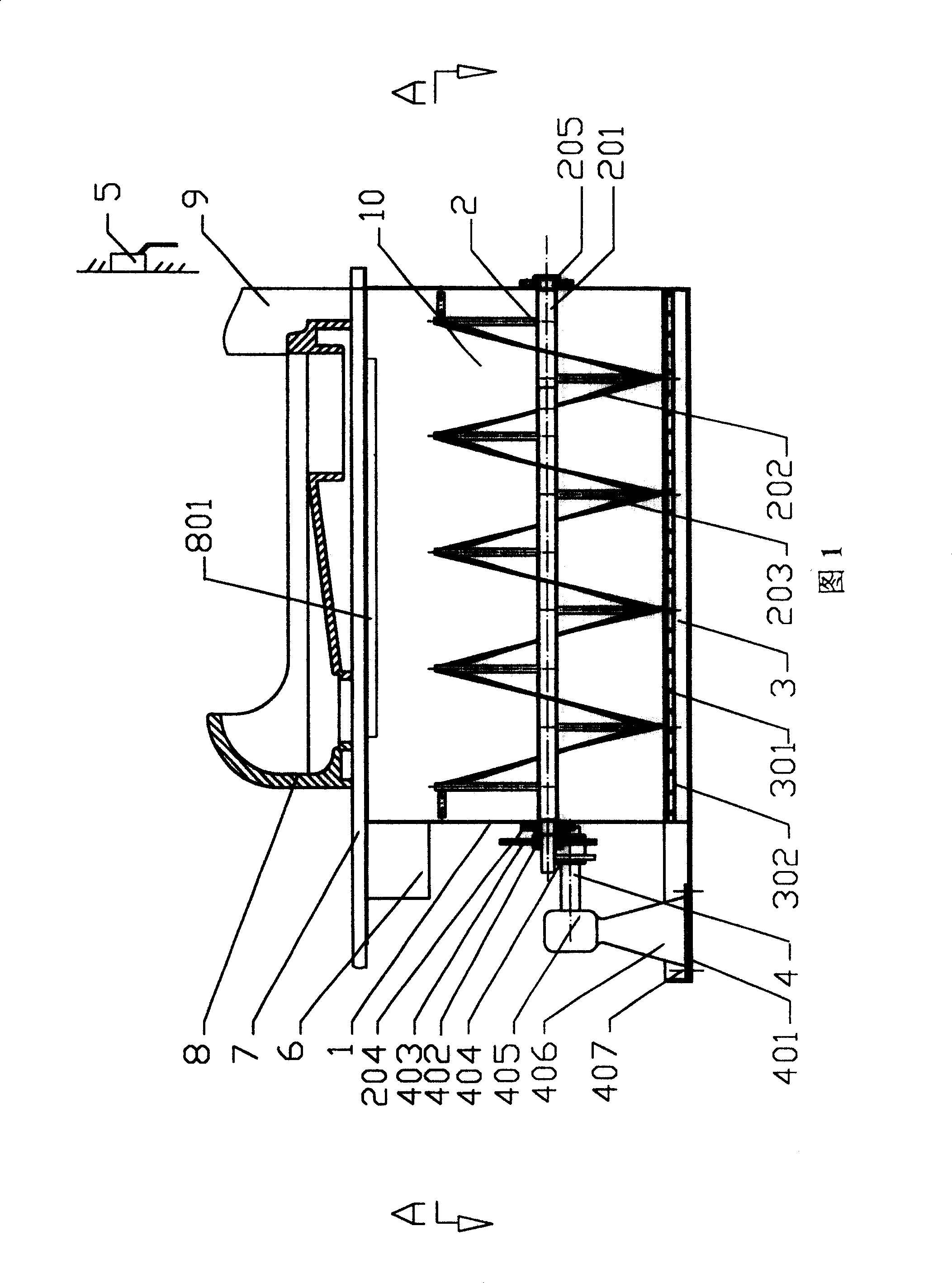

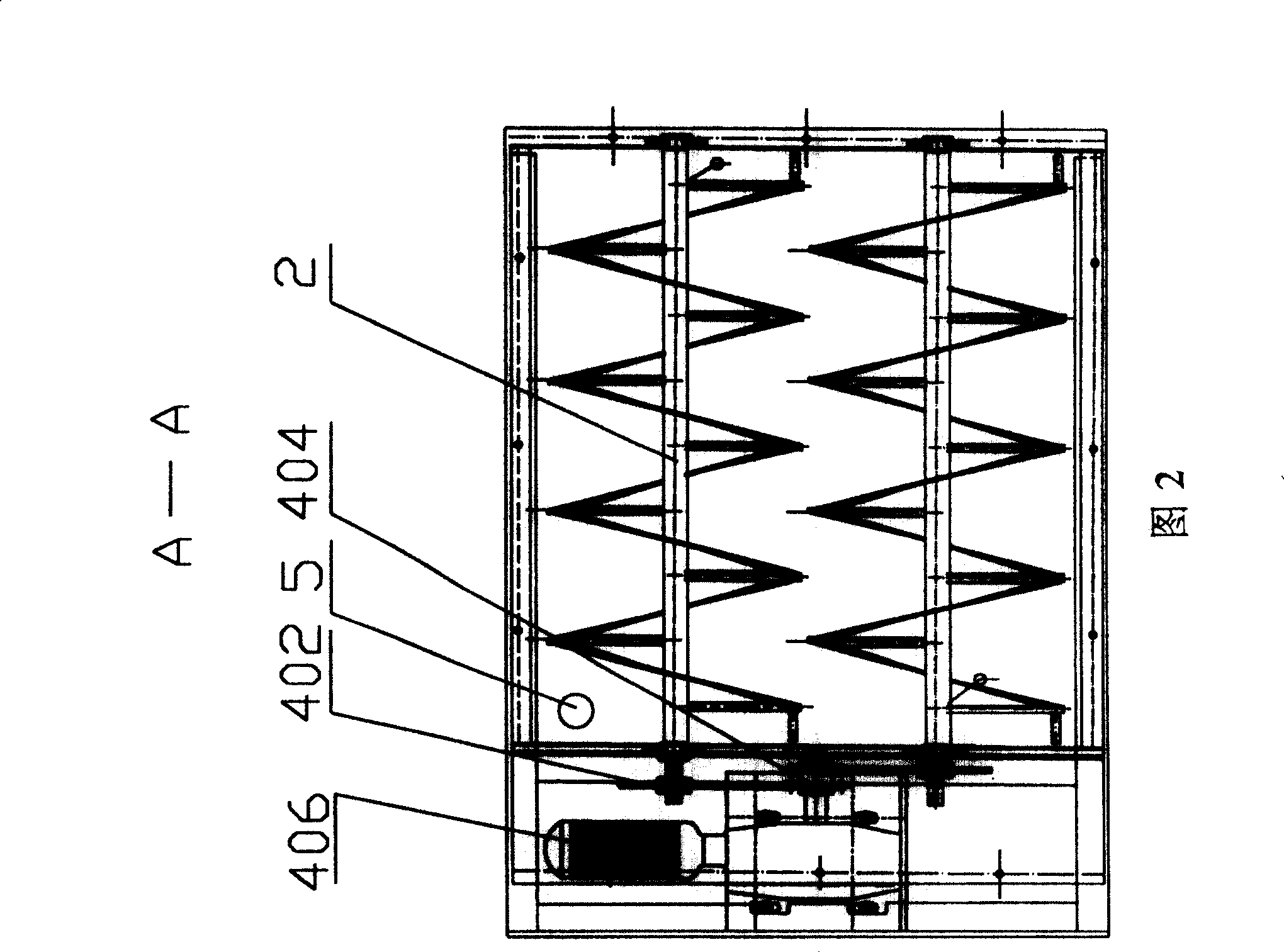

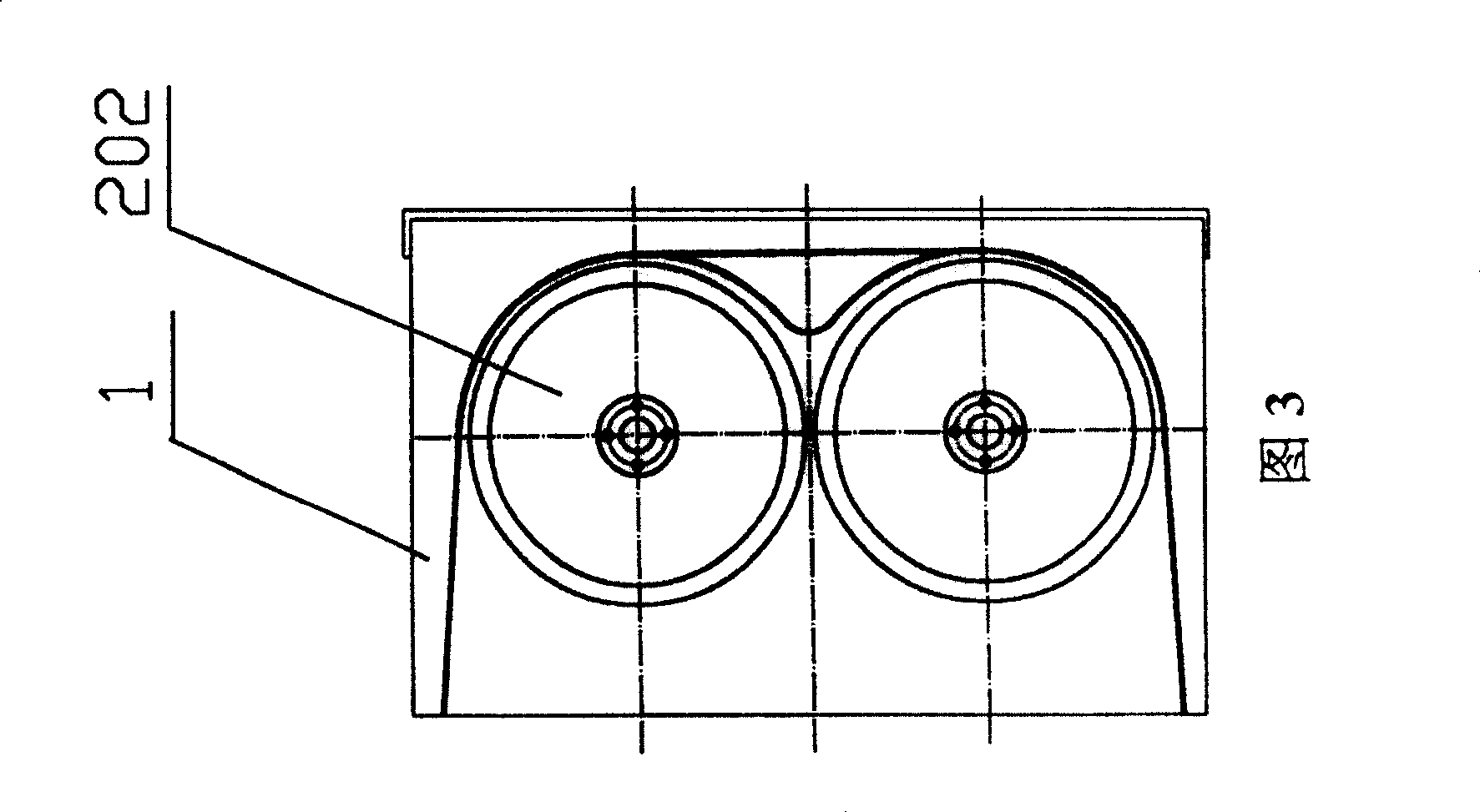

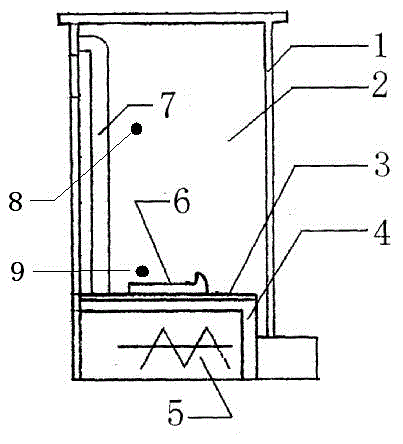

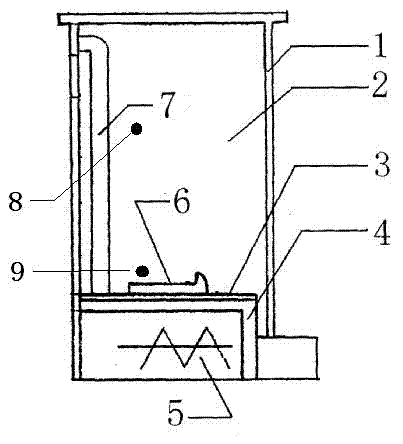

Microbial degradation environment protection toilet apparatus

ActiveCN100460611CFree shippingNo pollution in the processSludge processingLavatory sanitoryLitterProduct gas

The present invention relates to microbiological degradable environment-protecting lavatory equipment. It includes squatting closet, exhaust pipe, exhaust fan, fermentation tank, mechanical driving device and electric control device, in which the fermentation tank interior is equipped with a stirrer. Said invention also provides the connecting mode of the above-mentioned all portions and the working principle of said lavatory equipment.

Owner:生态洁环保科技股份有限公司

Bio-toilet not easy to accumulate dirt

InactiveCN102912842AFree shippingClearance NoneLavatory sanitoryBiological sludge treatmentMicroorganismProcess engineering

The invention provides a bio-toilet not easy to accumulate dirt. The bio-toilet comprises a squatting pan, a fermentation tank, a mechanical transmission unit and an electric control unit. The squatting pan is arranged on a squatting board, a movable blocking board is hinged to the lower portion of the squatting pan, the electric control unit is arranged under the squatting board, and the fermentation tank is arranged under the squatting board and corresponds to the squatting pan. Microorganisms and carriers are arranged in the fermentation tank, a heating unit is arranged at the outer bottom of the fermentation tank, and the mechanical transmission unit is mounted at the outer end of the fermentation tank and connected with a stirrer in the fermentation tank which is U-shaped. The stirrer is in a stirring cage structure and comprises a stirring cage shaft and a spiral stirring cage connected on the stirring cage shaft. The stirring cage is connected with the stirring cage shaft through stirring rods, one end of the stirring cage shaft is connected with the mechanical transmission unit, and scraper boards parallel with the stirring cage shaft are arranged at the top of the stirring cage.

Owner:生态洁环保科技股份有限公司

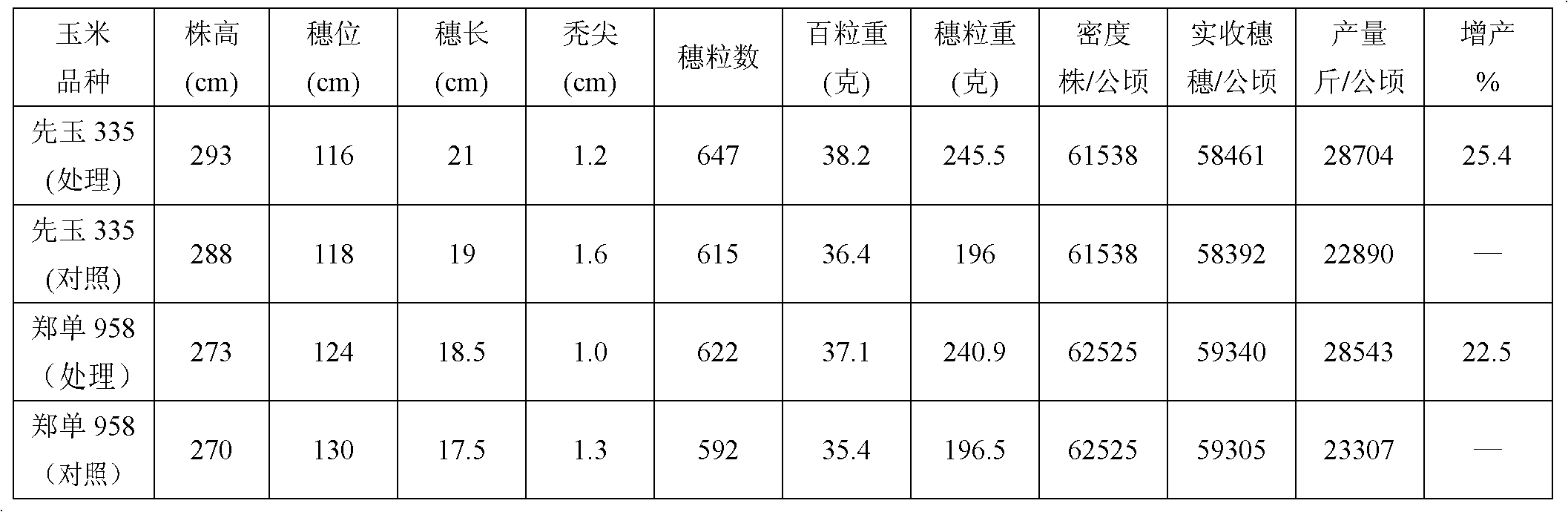

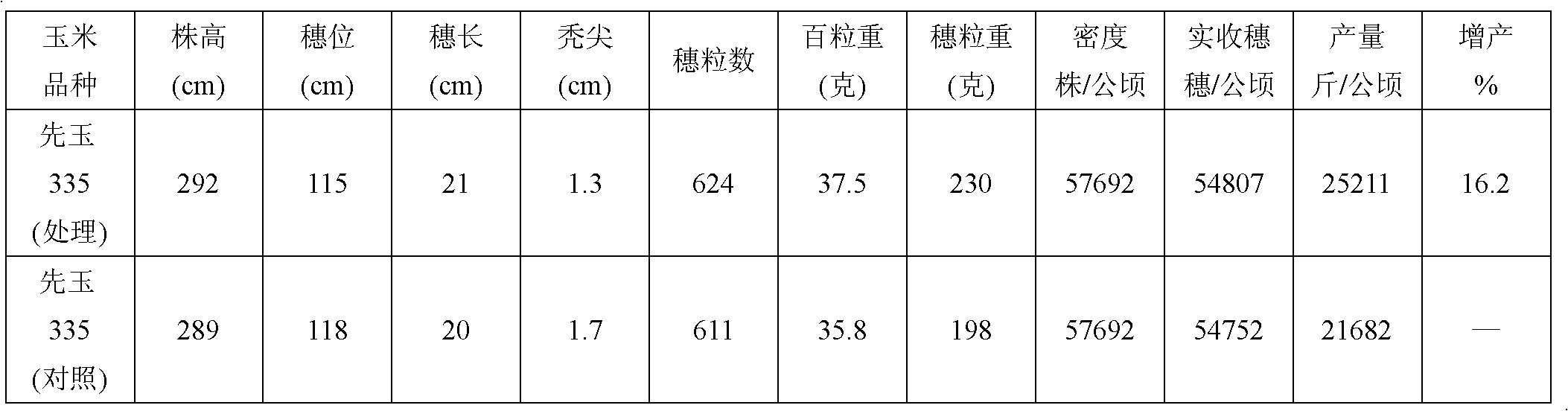

Synergist for photosynthesis of plant cell nutrition

InactiveCN102320888AEssential elements needed for metabolismIncrease productionFertilizer mixturesPlant cellPotassium

The invention relates to a synergist for photosynthesis of plant cell nutrition, which belongs to a crop fertilizer. The synergist comprises the following raw materials by weight-to-volume ratio: 18-22g of plant photosynthesis synergist, 18-22g of foliar fertilizer Nong Dafeng and 18-22g of Glamorous potassium. The invention has the advantages that the formula is novel, the basic essential factors required by the cell metabolism can be satisfied, and the crop output is increased.

Owner:许君

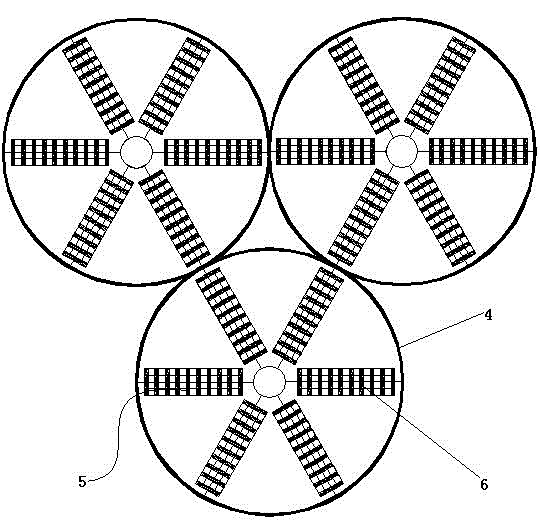

Automatic control classified transport system of columnar materials

ActiveCN104828539AFree shippingRealize full angle transformationConveyor partsHardware structureTransport system

The invention relates to an automatic control classified transport system of columnar materials. The system comprises a plurality of rotating plates that are connected by arc chain conveyor belts; and at least one arc chain conveyor belt is arranged at the rotating plate. The system is characterized in that a plurality of arc chain sheets are arranged at each arc chain conveyor belt. At least one inlet and / or at least one outlet that are / is formed by the arc chain conveyor belt are / is formed at the edge of each rotating plate; and the inlet and the outlet can be in butt joint with the two arc chain conveyor belts at the inside and outside of the rotating plate directly. According to the invention, on the basis of combination of the rotating plates and the arc chain conveyor belts, free transport of columnar materials can be realized at the hardware structure. During the transport process, omnidirectional transformation of operation directions of materials, material autorotation, material weight measurement identification, material radian and taper measurement identification, and movement responses of material entrance and exit to the rotating plates can be realized.

Owner:SUZHOU INST OF INDAL TECH

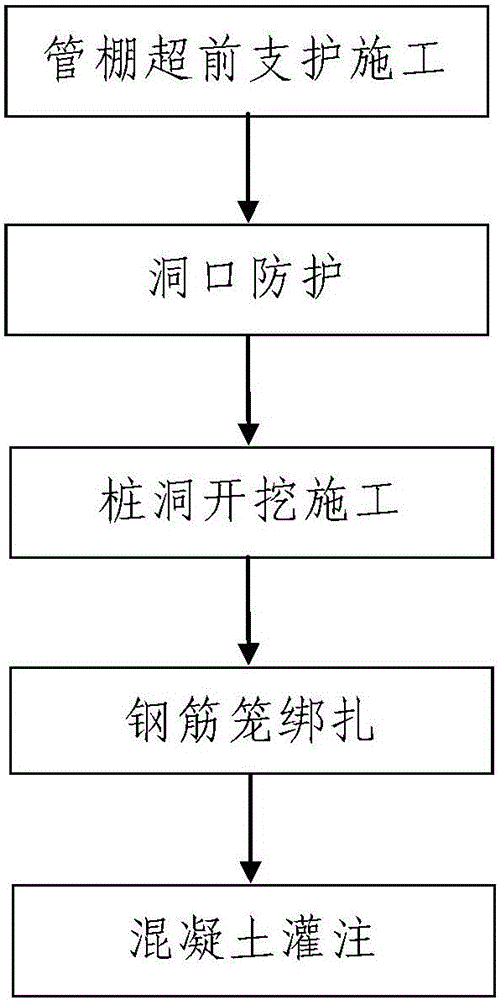

Construction process for superlarge-section and large-dip-angle tunnel type pile foundation

ActiveCN105970992AThe process steps are simpleReasonable designFoundation engineeringReinforced concreteRebar

The invention discloses a construction process for a supperlarge-section and large-dip-angle tunnel type pile foundation. The pile foundation to be constructed is a reinforced concrete pile. A pile hole of the reinforced concrete pile is a superlarge-section large-dip-angle tunnel hole. In construction of the pile foundation to be constructed, the process comprises the steps of firstly, pile hole construction, i.e., 101, advanced pipe shed support construction is conducted at the top of the pile hole, 102, hole mouth protection is conducted and a hole mouth support structure is constructed at a hole mouth of the pile hole, and 103, pile hole excavation construction is conducted, a full section excavation method is adopted for the pile hole excavation with a plurality of construction segments arranged from top to bottom, and a full section support structure is adopted for supporting; and secondly, pile body construction, i.e., the pile body of the reinforced concrete pile is constructed, and the construction process comprises the two steps of reinforcing cage binding and concrete spouting. The construction process for the supperlarge-section and large-dip-angle tunnel type pile foundation is simple in step, reasonable in design, low in investment cost, simple and easy to construct, good in use effect and capable of easily and fast completing the construction process of the tunnel type pile foundation, and the construction process is easy to control.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

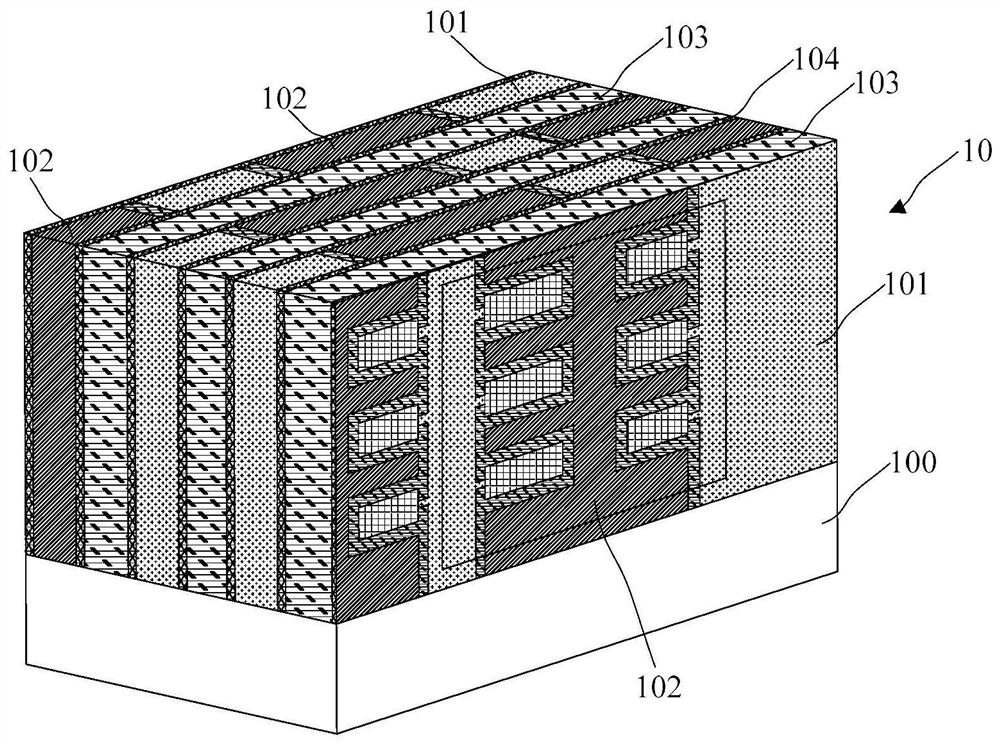

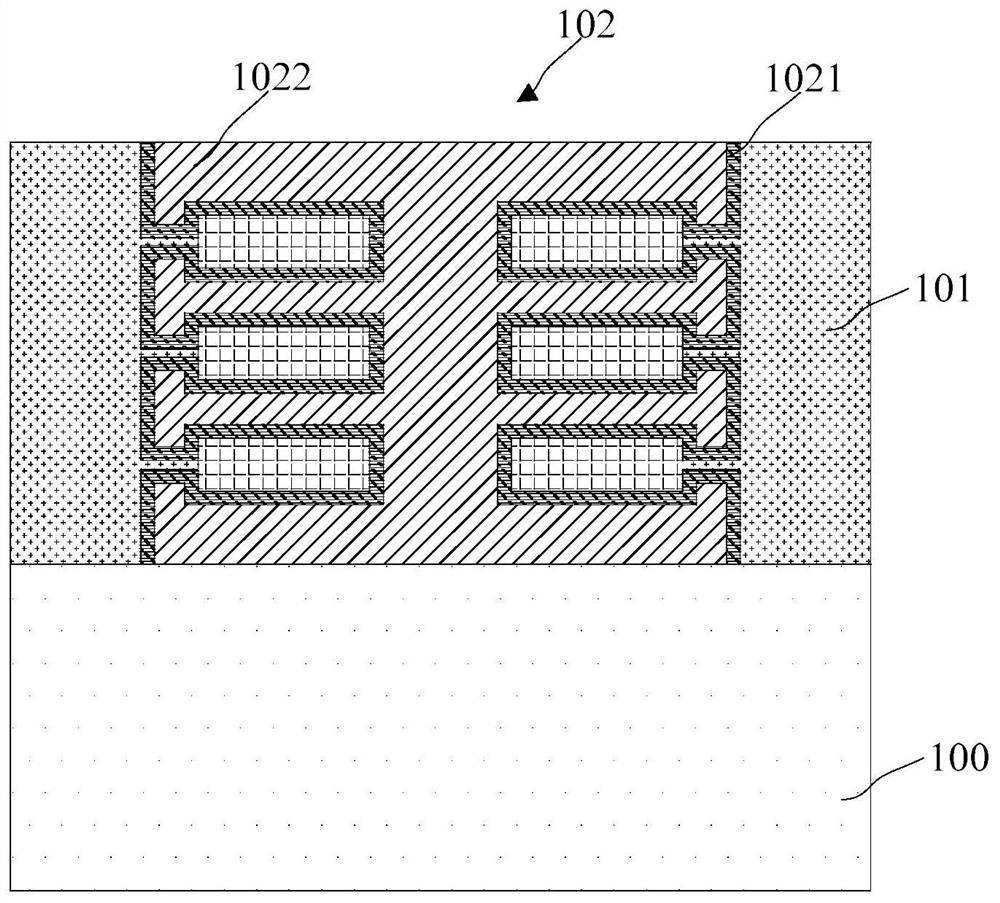

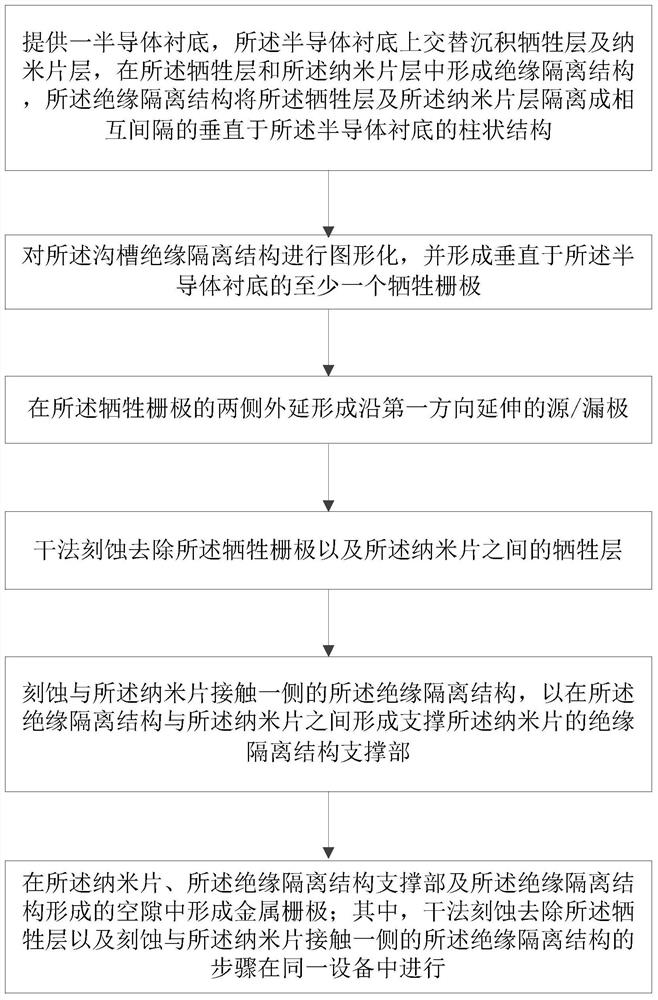

Nanosheet field effect transistor and preparation method thereof

PendingCN111755333AAvoid damageImprove stabilityNanoinformaticsSemiconductor/solid-state device manufacturingEngineeringField effect

The invention provides a nanosheet field effect transistor and a preparation method thereof, and the method comprises the steps: forming a nanosheet layer and a sacrificial layer on a semiconductor substrate, forming an insulation isolation structure in the nanosheet layer and the sacrificial layer, removing the sacrificial layer through dry etching, etching the insulation isolation structure, andforming a nanosheet supporting part; forming continuous gate insulating layers on the surfaces of the nanosheet and the nanosheet supporting part, and forming a second gate insulating layer between the gate insulating layers on the outer sides of the connecting parts, and forming a metal gate between the gate insulating layer and the second gate insulating layer. According to the invention, the sacrificial layer is removed and the insulation isolation structure is etched to form the nanosheet supporting structure in the same equipment, so the transportation or movement of the structure is avoided, and the nanosheet is prevented from being damaged due to factors such as physical vibration and the like. And the stability of the nanosheet is further improved by the gate insulating layer. Inaddition, dry etching is adopted in the method, and the damage, caused by chemical reagents, to the nanosheet is avoided.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

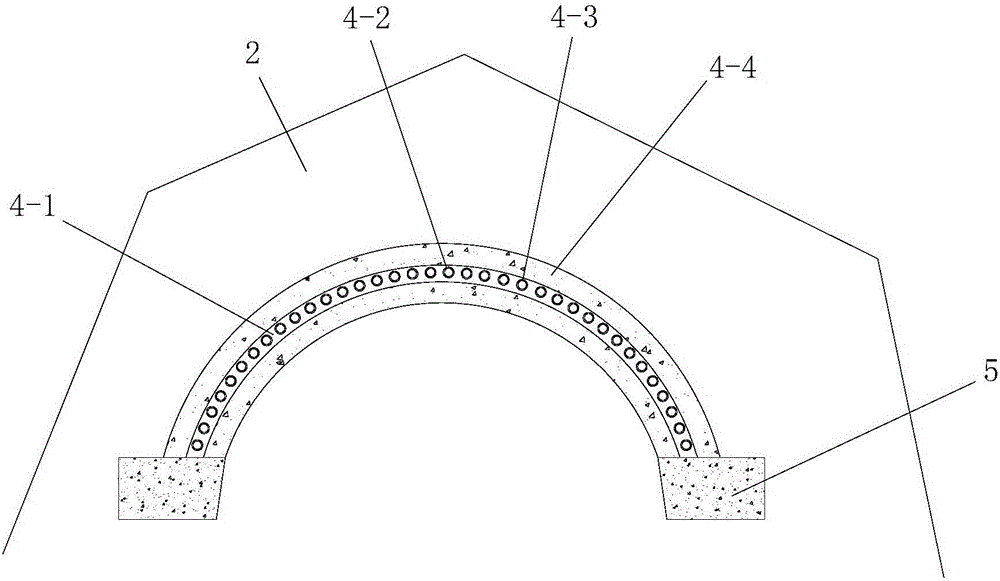

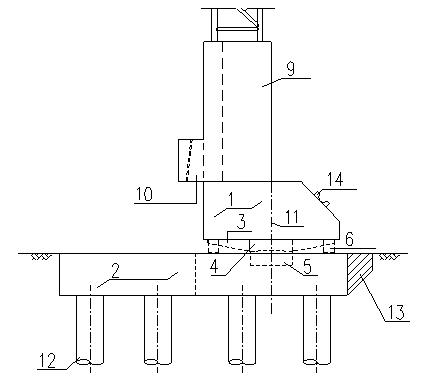

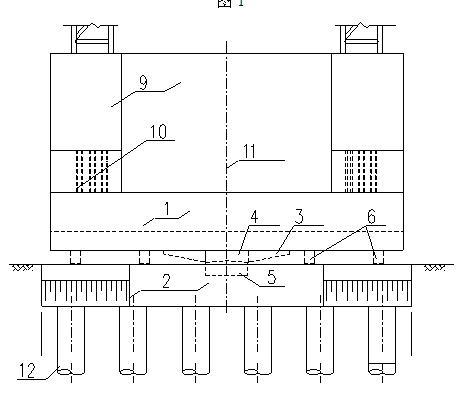

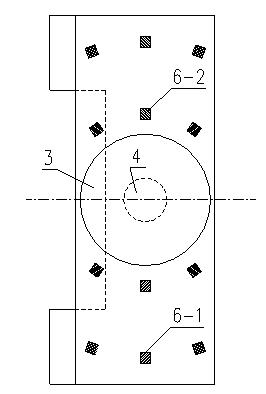

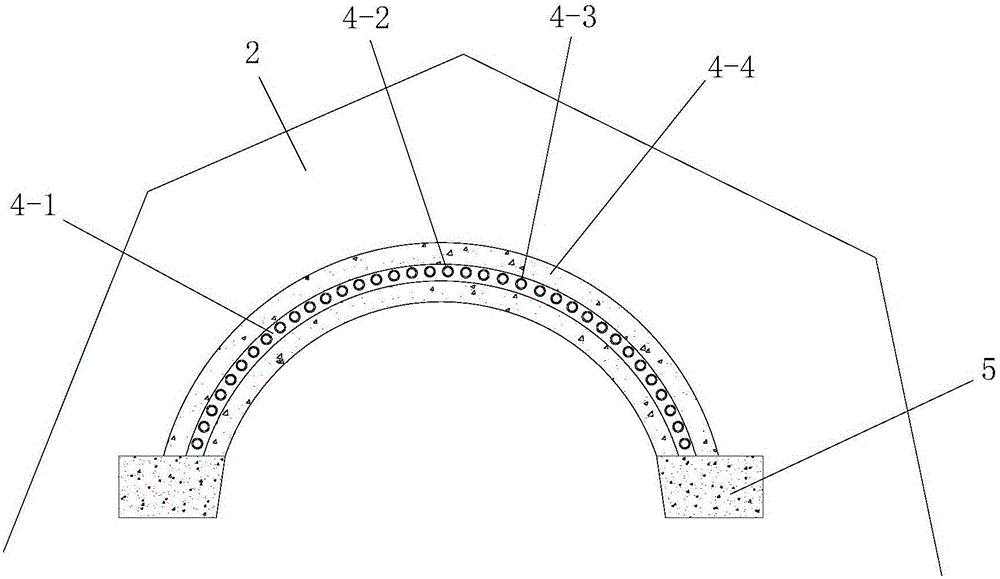

Reinforced concrete spherical hinge structure of swing bridge and manufacturing process thereof

InactiveCN102359064AOptimizing Partial ConstructionSimple processBridge structural detailsBridge erection/assemblyReinforced concreteRebar

The invention relates to a reinforced concrete spherical hinge structure of a swing bridge and a manufacturing process thereof. The reinforced concrete spherical hinge structure comprises an upper turntable used for supporting a rotating structure and a lower turntable of a basic connection body and is characterized in that an inverted conical structure formed by pouring the reinforced concrete is arranged at a lower side of the upper turntable, an upper grinding cover formed by pouring the reinforced concrete is coaxially arranged at a center of the lower end of the inverted conical structure, a lower grinding center matched with the upper grinding cover in a rotating positioning manner is arranged at an upper side of the lower turntable, and the lower grinding center is formed by pouring the reinforced concrete. The reinforced concrete spherical hinge structure of the swing bridge has the advantages of simple structure, low manufacturing cost, simple manufacturing process and convenience for installation.

Owner:中铁二十四局集团福建铁路建设有限公司

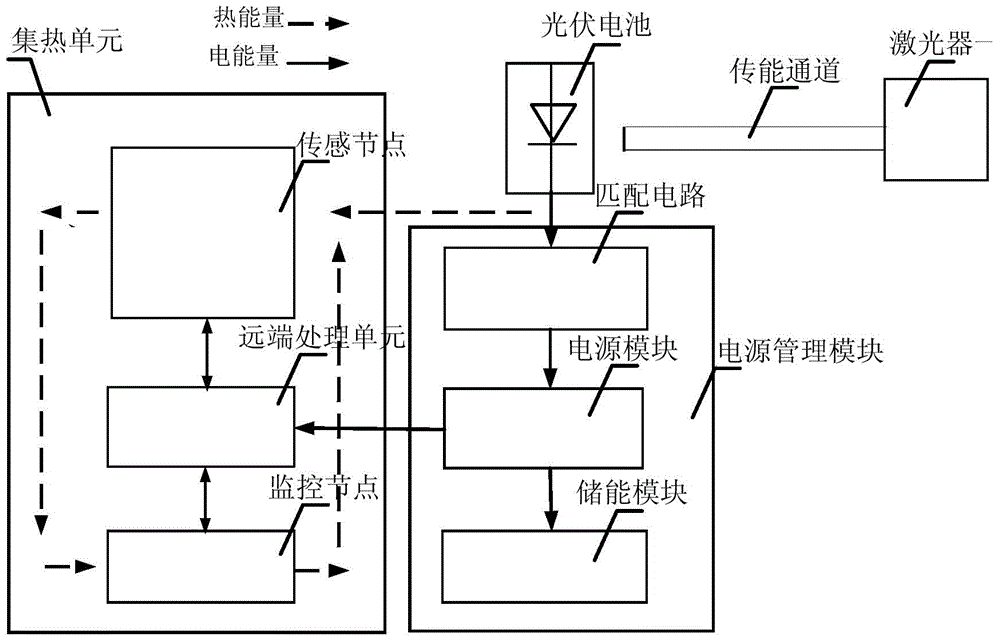

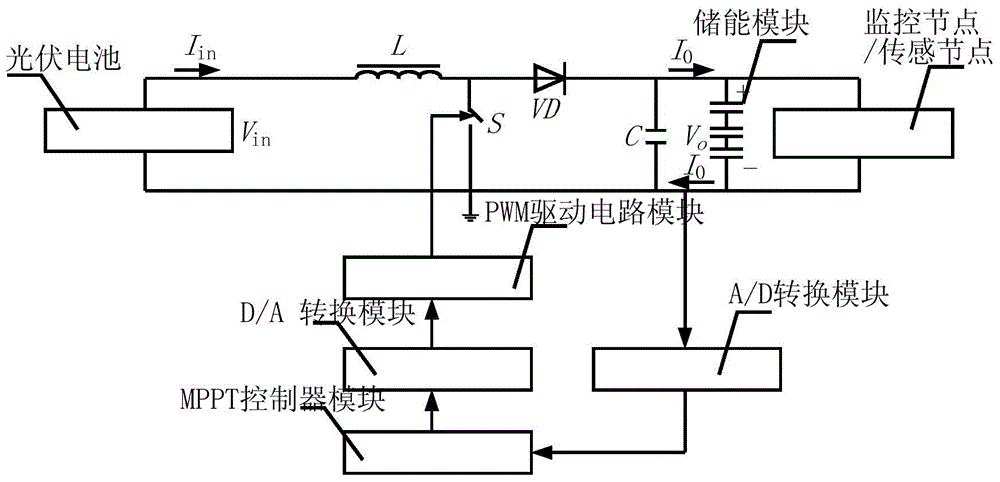

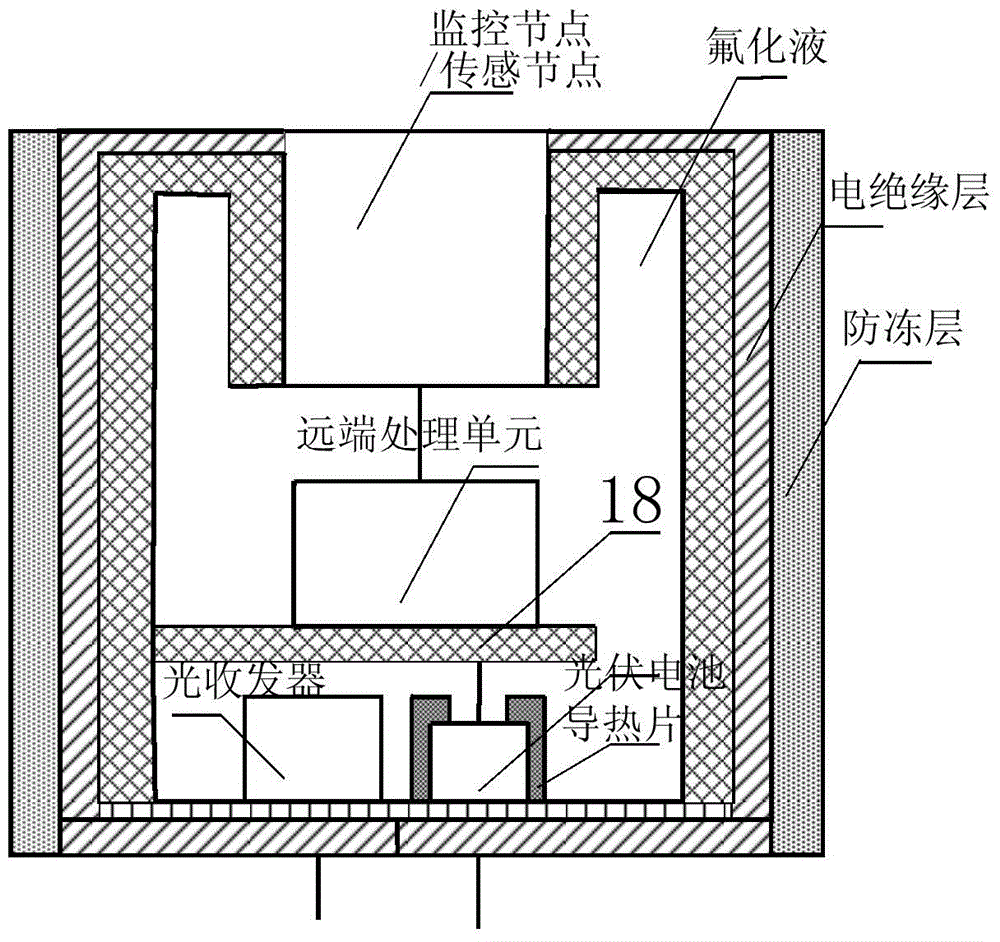

Light-heat-electricity combination device based on laser energy supply technology

ActiveCN104617864AImprove conversion efficiencyGood radiation resistancePhotovoltaicsPhotovoltaic energy generationElectricityElectromagnetic interference

The invention discloses a light-heat-electricity combination device based on the laser energy supply technology. The device comprises a generating unit, a heat collecting unit and a photoelectric conversion device. The device is characterized in that the generating unit is connected with the heat collecting unit through the photoelectric conversion device. The light-heat-electricity combination device based on the laser energy supply technology solves the problem that a power supply on a high voltage power line cannot continuously work, is low in stability and suffers from electromagnetic interference; a photovoltaic battery is high in conversion efficiency (up to be more than 40%), so that the device is relatively high in temperature characteristic, anti-radiation characteristic and relatively low in generation cost, and as a result, the device can continuously and stably work.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

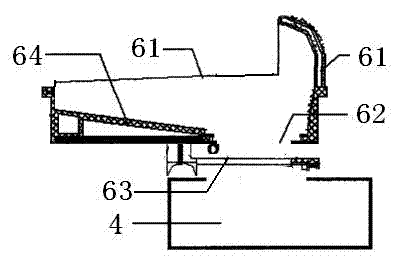

Squatting pan capable of easily keeping clean and ecological toilet comprising squatting pan

InactiveCN102920387AFree shippingNo pollution in the processBathroom coversAgainst vector-borne diseasesMechanical engineeringToilet

The invention provides a squatting pan capable of easily keeping clean and an ecological toilet comprising the squatting pan. The squatting pan capable of easily keeping clean comprises a bottom face, side walls, a manure opening and a movable baffle hinged with the lower side, and is characterized in that the height from the manure opening to the bottom face of the side wall of the far end of the manure opening is gradually raised. Further, the invention also provides the ecological toilet comprising the squatting pan.

Owner:生态洁环保科技股份有限公司

Building floor and producing method thereof

The invention discloses a building floor slab which is characterized by comprising a steel-formed ring beam and a main beam form; a stainless steel joist bracket assembly is laid on the top of the form; a ceiling block is adhered to the interior of a joist box; the ceiling block supports the top by a steel pipe; and bars are distributed on the surface of the ceiling. The joist box is 60mm multiplied by 60mm or 60mm multiplied by 80mm; the top of the joist box is welded with an embedded oar hook; the side of the joist facing light is sprayed with certain color. Deformed steel bars of 10mm to 12mm are adopted in main bedded steel bars on the surface of the ceiling, while round steels of 6mm are adopted in surface steel bars. The building floor slab has the advantages of high production efficiency, low cost, simple and convenient construction, and being environment-friendly.

Owner:冯国添

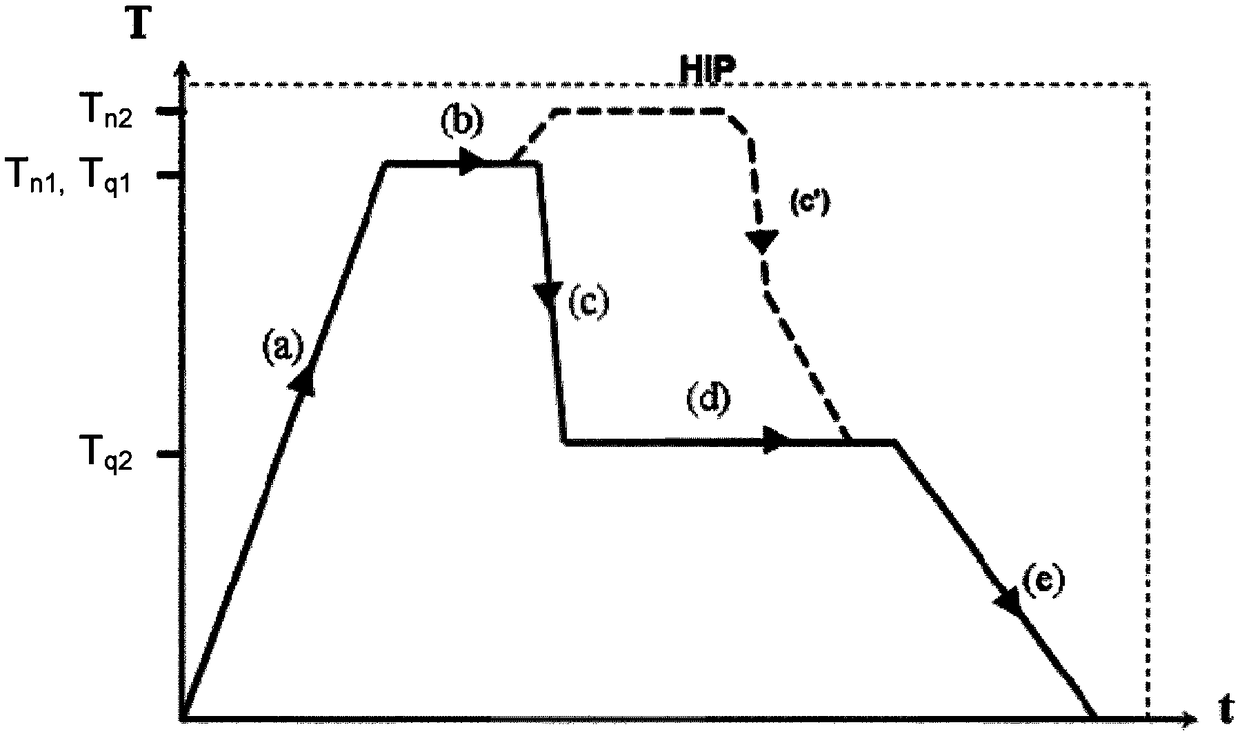

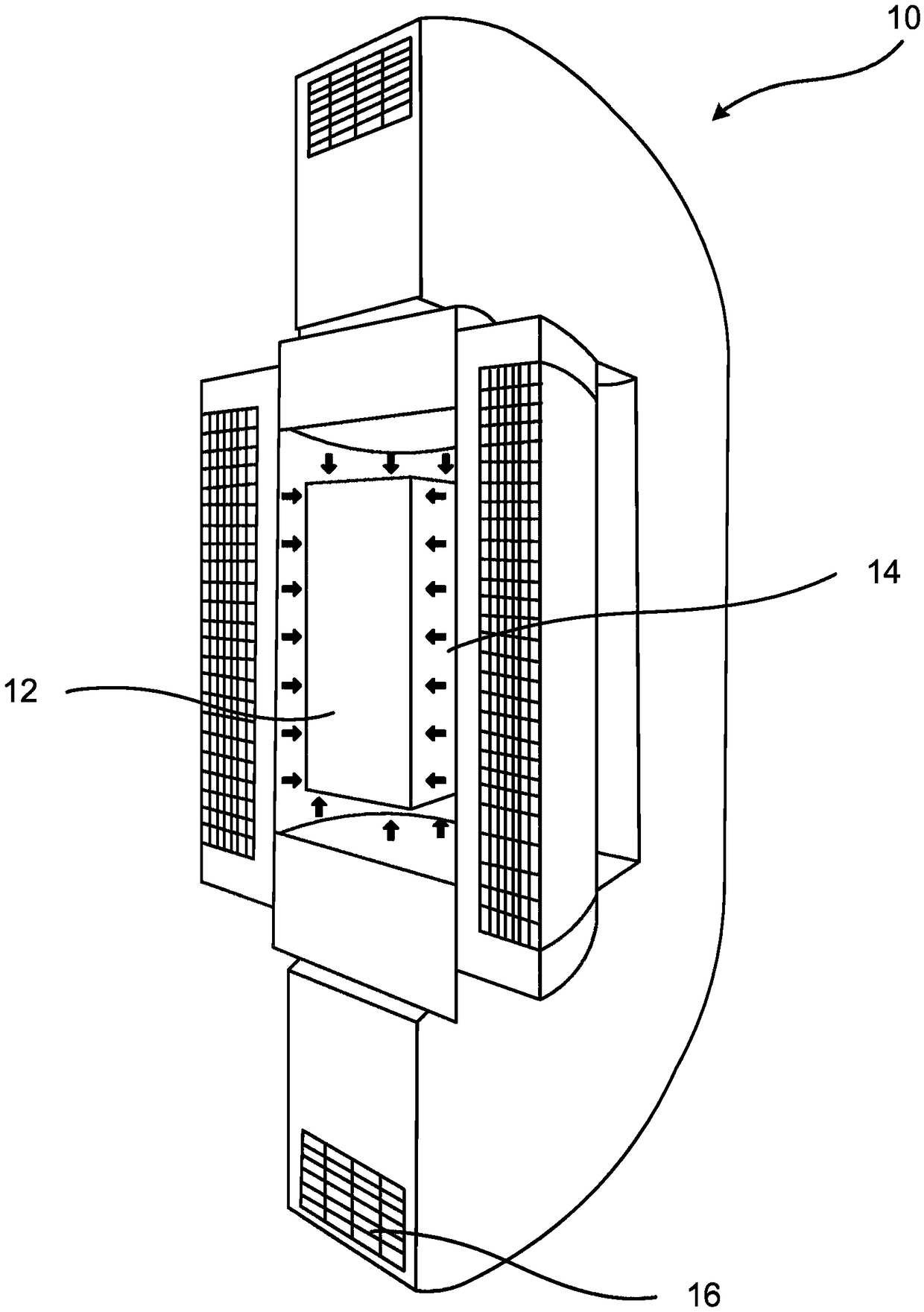

Method of treating a workpiece comprising a titanium metal and object

ActiveCN109154040AImprove mechanical propertiesFacilitated DiffusionSolid state diffusion coatingSuperimposed coating processSurface layerTitanium metal

Method of treating a workpiece (12) comprising a titanium metal, wherein a titanium metal surface layer of the workpiece is converted to titanium nitrides. The method comprises the following steps: a)heating the workpiece (12) to an initial nitriding temperature (Tn1) and b) subjecting said workpiece to one or more nitriding temperatures (Tn1, Tn2) for predetermined time(s) in a nitrogen containing gas (14) under high pressure at hot isostatic pressing (HIP) conditions for converting the titanium metal surface layer to a first layer portion consisting of titanium nitrides and a second layer portion comprising a nitrogen gradient in the titanium metal. The method further comprises c) quenching the workpiece (12) in the nitrogen containing gas (14) under high pressure at hot isostatic pressing (HIP) conditions, in order to strengthen the titanium metal below the in step b) formed first nitride layer portion.

Owner:SENTINABAY AB

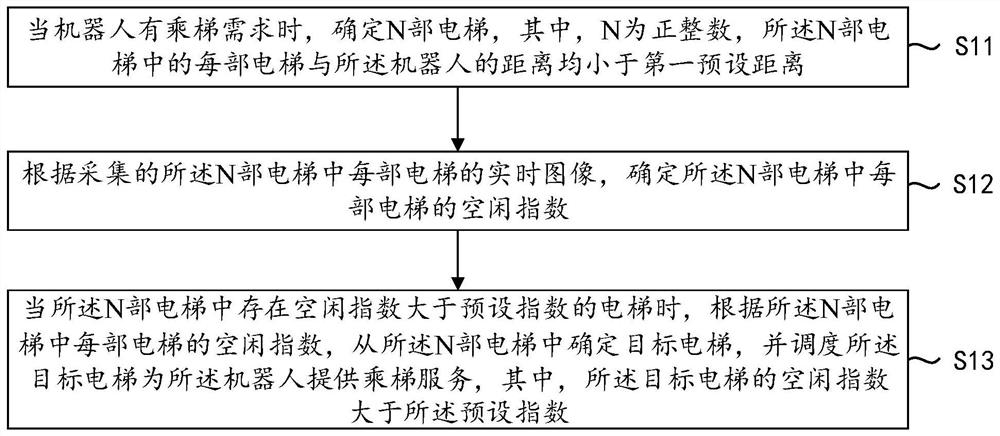

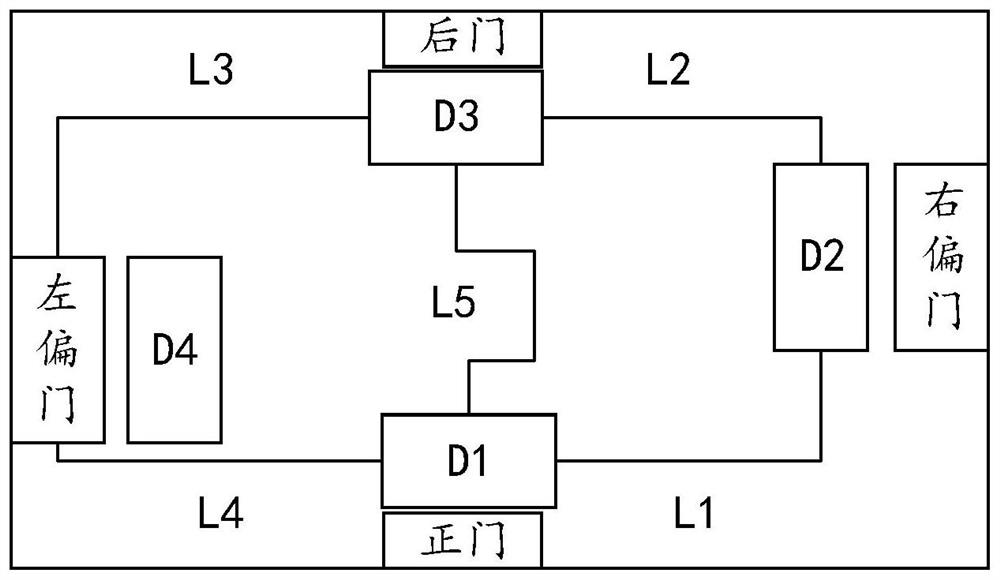

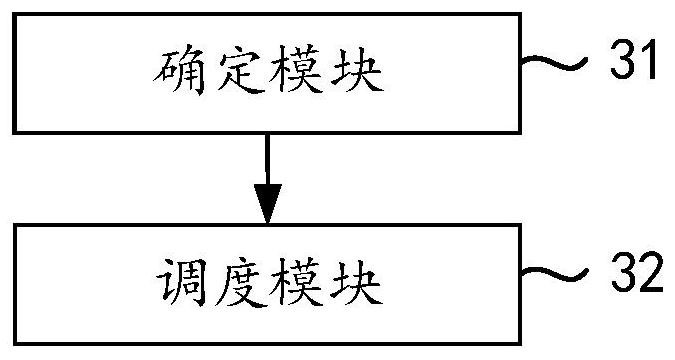

Elevator dispatching method and device, equipment and medium

ActiveCN114030958AReduce waiting timeReduce occupancyElevatorsSustainable buildingsControl engineeringControl theory

The invention discloses an elevator dispatching method and device, equipment and a medium. The method comprises the steps that when a robot has an elevator taking demand, N elevators are determined, wherein N is a positive integer, and the distance between each elevator in the N elevators and the robot is smaller than a first preset distance; according to the collected real-time image of each elevator in the N elevators, the idle index of each elevator in the N elevators is determined; when the elevators with the idle indexes larger than the preset index exist in the N elevators, a target elevator is determined from the N elevators according to the idle index of each elevator in the N elevators, and the target elevator is dispatched to provide elevator taking service for the robot, wherein the idle index of the target elevator is larger than the preset index. The idle indexes of the elevators are analyzed through the real-time images, and the idle elevators are purposefully screened out to provide elevator taking service, so that the waiting time of the robot can be greatly shortened, the occupancy rate of the elevators is reduced, the utilization rate of the elevators is increased, and the conveying amount of the elevators is reduced.

Owner:北京云迹科技股份有限公司

Automated microscopic cell analysis

ActiveUS20210039093A1Easy to operateAvoid cross contaminationWithdrawing sample devicesPreparing sample for investigationCellular componentWhole blood units

This disclosure describes single-use test cartridges, cell analyzer apparatus, and methods for automatically performing microscopic cell analysis tasks, such as counting and analyzing blood cells in biological samples. A small measured quantity of a biological sample, such as whole blood, is placed in a mixing bowl on the disposable test cartridge after being inserted into the cell analyzer. The analayzer also deposits a known amount of diluent / stain in the mixing bowl and mixes it with the blood. The analyzer takes a measured amount of the mixture and dispenses in a sample cup on the cartridge in fluid communication with an imaging chamber. The geometry of the imaging chamber is chosen to maintain the uniformity of the mixture, and to prevent cells from crowding or clumping as it is transferred into the imaging chamber by the analyzer. Images of all of the cellular components within the imaging chamber are counted and analyzed to obtain a complete blood count.

Owner:MEDICA CORP

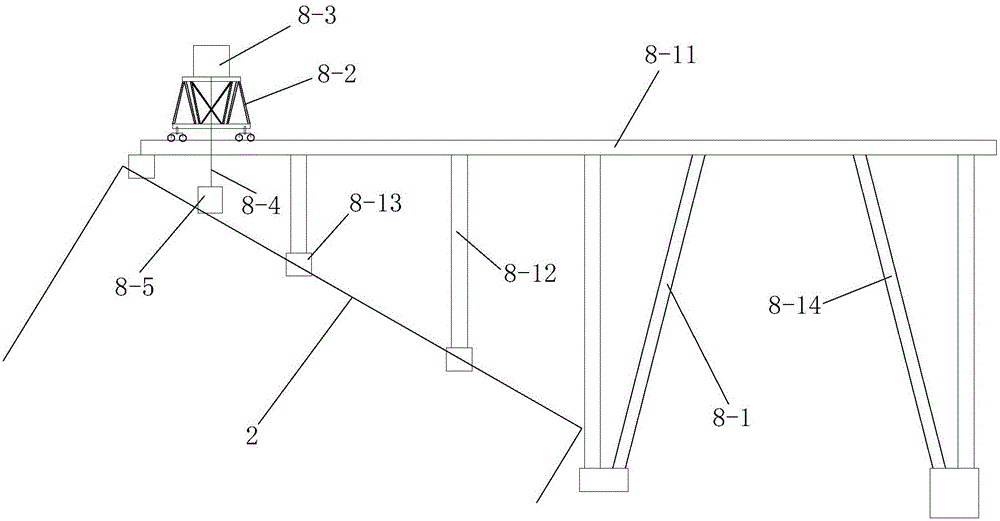

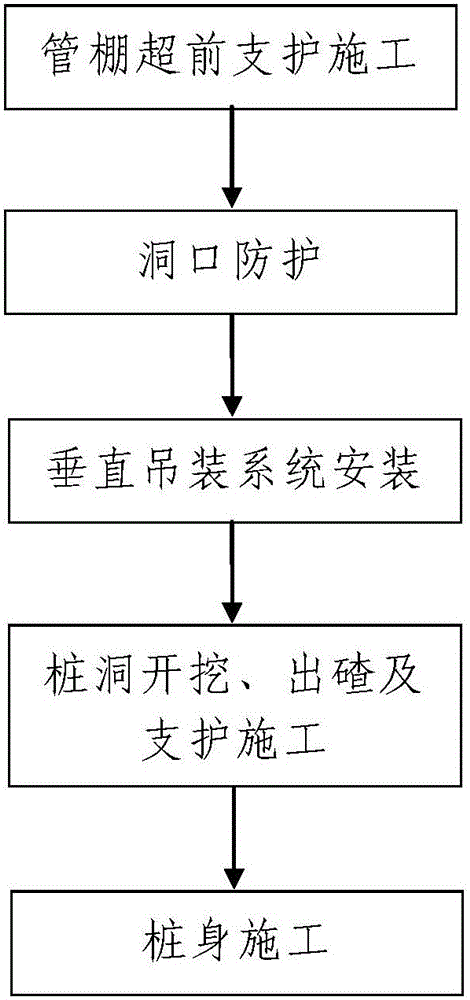

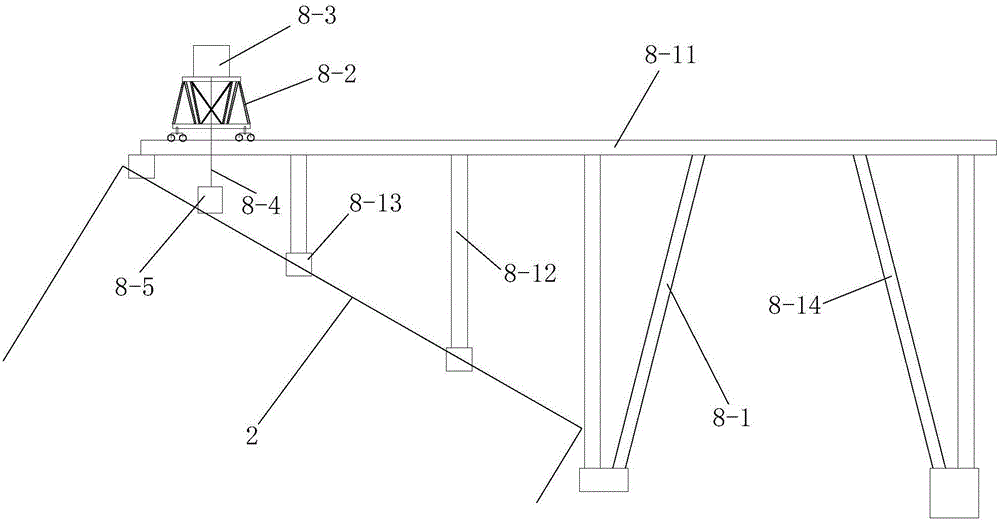

Ultralarge section inclined single-pile foundation construction process based on vertical lifting system

The invention discloses a ultralarge section inclined single-pile foundation construction process based on a vertical lifting system. A constructed ultralarge section inclined single-pile foundation is a reinforced concrete pile, and is provided with a reinforcement cage inside; the ultralarge section inclined single-pile foundation is constructed by the following steps: (1) the advance support construction is performed for a pipe roof; (2) hole opening protection: a hole opening support structure is constructed in a hole opening of a pile hole; (3) the vertical lifting system is installed; (4) the excavation, the slag discharge and the support construction are performed for the pile hole. The pile hole is excavated by multiple construction sections from top to bottom through a full-section excavation method; the slag discharge is synchronized in the excavation process; and the wall protection construction is respectively performed for pile hole sections excavated by all the construction sections; and (5) pile body construction: the reinforcement cage is bound and concrete is filled. The process is simple in steps, reasonable in design, low in investment cost, convenient for construction and excellent in use effect, can simply and quickly finish the construction process of the ultralarge section inclined single-pile foundation, and is easy to control the construction process.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

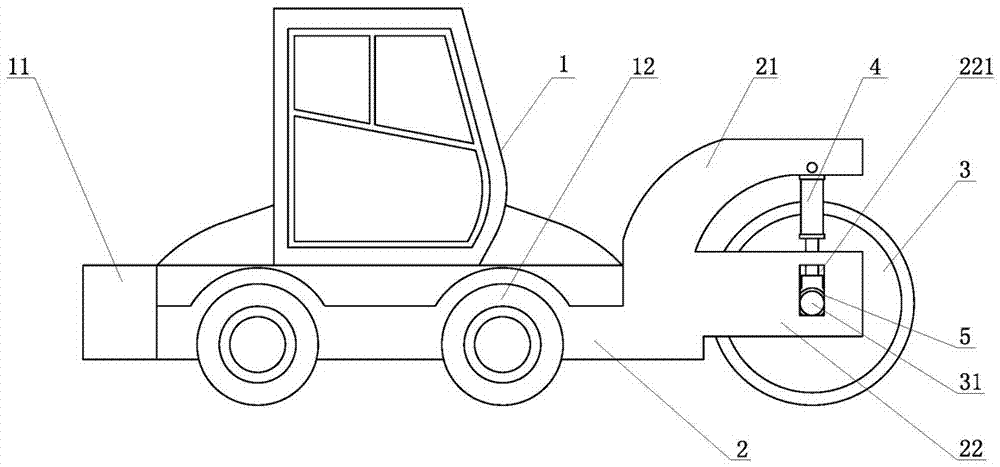

Consignment-free single steel wire road roller

PendingCN107059557AEasy to operateLifting action is stableRoads maintainenceHydraulic cylinderMechanical engineering

The invention provides a consignment-free single steel wire road roller, and belongs to the technical field of a road roller. The consignment-free single steel wire road roller comprises a roller body, the roller body is provided with a rack, the rack is provided with a pressing wheel, and the consignment-free single steel wire road roller is characterized in that the rear end of the roller body is provided with a weight box, the roller body is symmetrically provided with two roller wheels in the left and right, the front end of the roller body is provided with the rack, the rack is internally provided with the pressing wheel, the two ends of the pressing wheel are provided with fixed shafts, the rack comprises an upper support arm and a lower support arm, the lower end of the upper support arm is provided with a hydraulic cylinder, the lower end of the hydraulic cylinder is connected with the fixed shafts, and the fixed shafts are connected to the lower support arm in a slidable mode. The consignment-free single steel wire road roller has the advantages that regarding the roller, the structure of the roller body is changed, the rack is arranged at the front end of the roller body, the rack is internally provided the hydraulic cylinder, the hydraulic cylinder drives the pressing wheel to life and fall, the roller is simple in structure and convenient to operate, the pressing wheel achieves no consignment, and the transportation cost is saved.

Owner:金乡县华驰工程机械有限公司

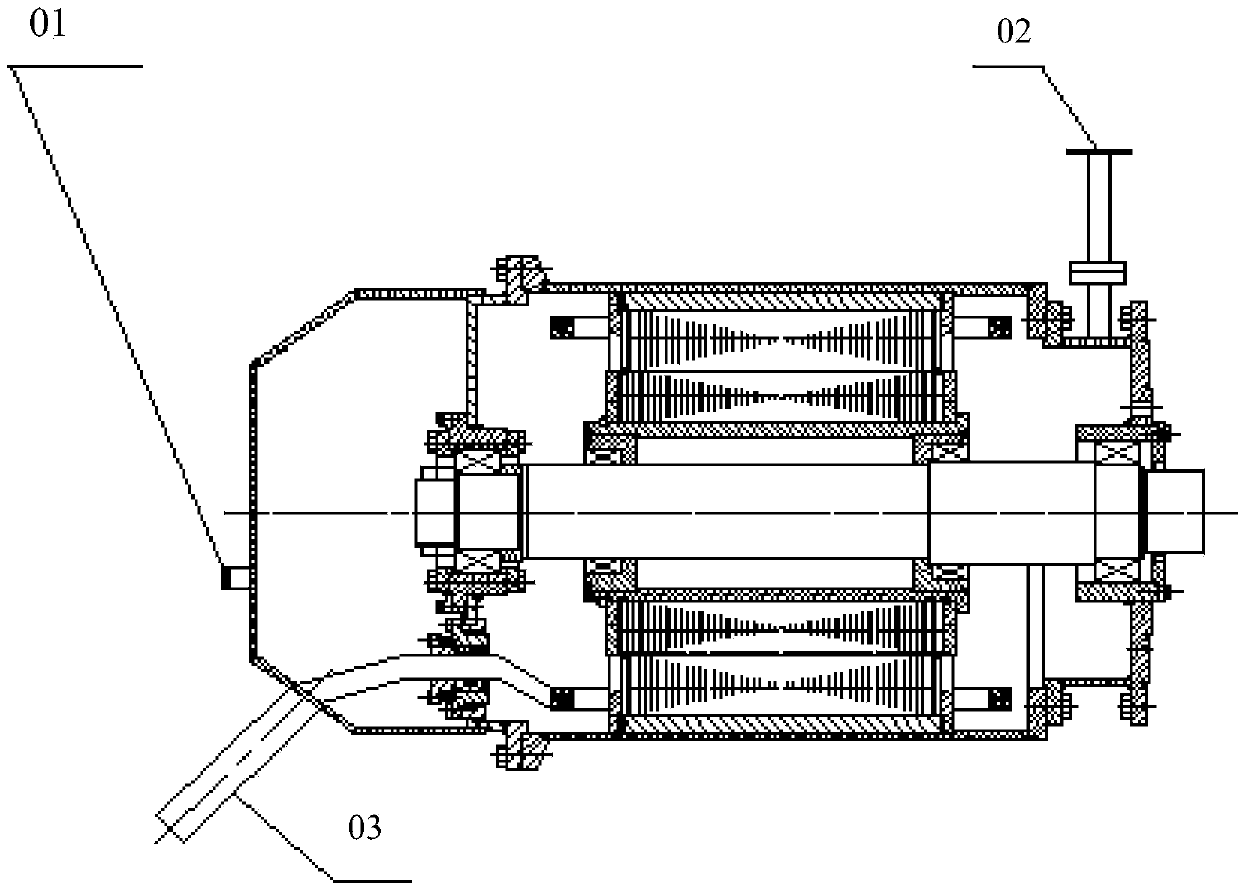

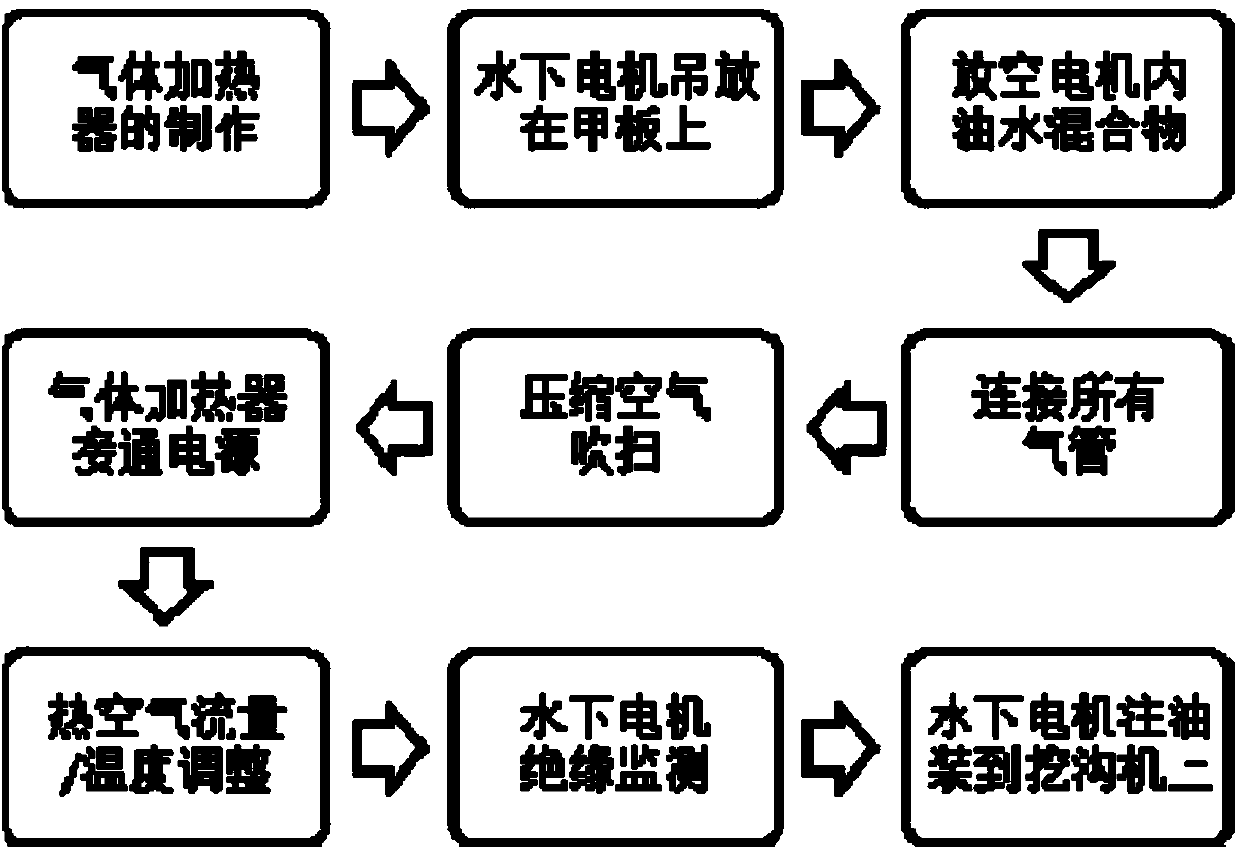

Device and method for drying marine underwater motor

ActiveCN103438668AFree shippingReduce maintenance costsDrying solid materials with heatDrying gas arrangementsWork cycleUnderwater

A device for drying a marine underwater motor is installed on a deck of a marine working mother ship provided with a gas storage tank. The underwater motor is provided with a compensator port and a motor cavity oil injection exhaust port. The device for drying the marine underwater motor comprises a main gas pipe, an auxiliary gas tank, an auxiliary gas pipe, a gas heater and a hot gas pipe. One end of the main gas pipe is connected with the output end of the gas storage tank, and the other end of the main gas pipe is connected with the input end of the gas storage tank. The auxiliary gas tank is a sealed metal structural component, and a gas flow control valve is arranged at the output end of the auxiliary gas tank. One end of the auxiliary gas pipe is connected with the output end of the auxiliary gas tank, and the other end of the auxiliary gas pipe is connected with the input end of the gas heater. The gas heater comprises a tube body and electric heating tubes which are arranged inside the tube body. One end of the hot gas pipe is connected with the output end of the gas heater, and the other end of the hot gas pipe is connected with the motor cavity oil injection exhaust port of the underwater motor. The device and method for drying the marine underwater motor have the advantages of being low in maintenance cost, short in working cycle and capable of being used for drying the underwater motor on a marine operation site.

Owner:交通运输部上海打捞局

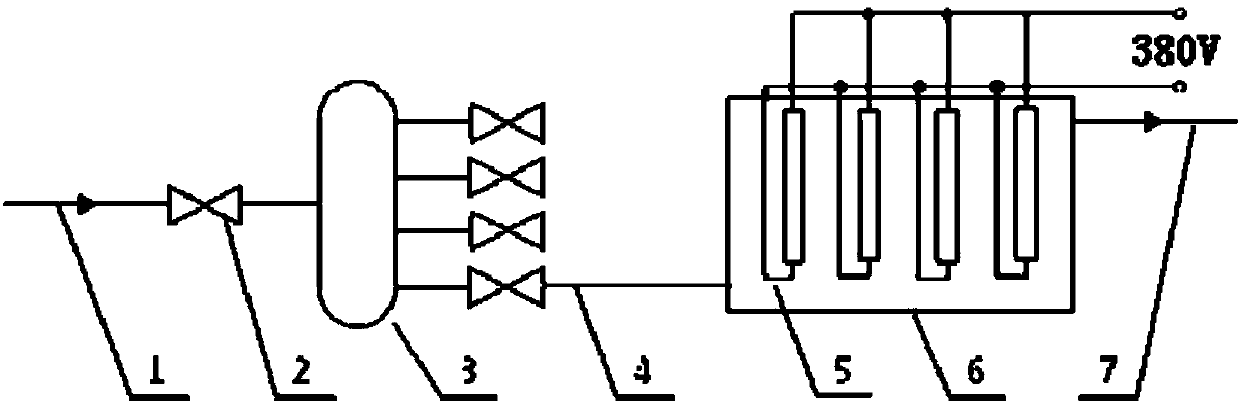

Disinfectant fluid and preparation method and device thereof

InactiveCN105165890AHigh antibacterial activityEfficient removalCellsBiocideElectrochemical responseChlorine dioxide

The invention discloses disinfectant fluid and a preparation method and device thereof. The disinfectant fluid is prepared from, by mass, 70%-85% of chlorine, 12%-20% of chlorine dioxide, 2.5%-8% of ozone and 0.5%-2% of hydrogen compound, the pH is 6.8-8, and the ORP is 800-1000 mv. The preparation method includes the steps that tap water and a 50-100 g / L electrolyte solution are input into a reactor according to the flow ratio of 3-13 to 27-37, the voltage is 45-48 V, the control current is 8-12 A, an electrochemical reaction is generated, disinfector is obtained through a positive pole, and an alkaline solution is obtained through a negative pole. The preparation device comprises a filter, an electrolyte solution tank, an electrode set, the reactor, a positive pole solution storage tank and a negative pole solution storage tank. The method is simple in process, low in cost and high in production efficiency, the prepared disinfectant fluid has high antibacterial property and is high in use efficiency, chlorinated waste is not generated, and the disinfectant fluid is mainly used for medical sterilization as well as sterilization of tableware and household utensils.

Owner:连云港龙卷风环保技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com