Consignment-free single steel wire road roller

A technology for road rollers and consignment notes, applied in the field of road rollers, can solve the problems of damage to the road surface, troublesome consignment of steel wheels, increase in transportation costs, etc., and achieve the effect of simple operation and stable center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

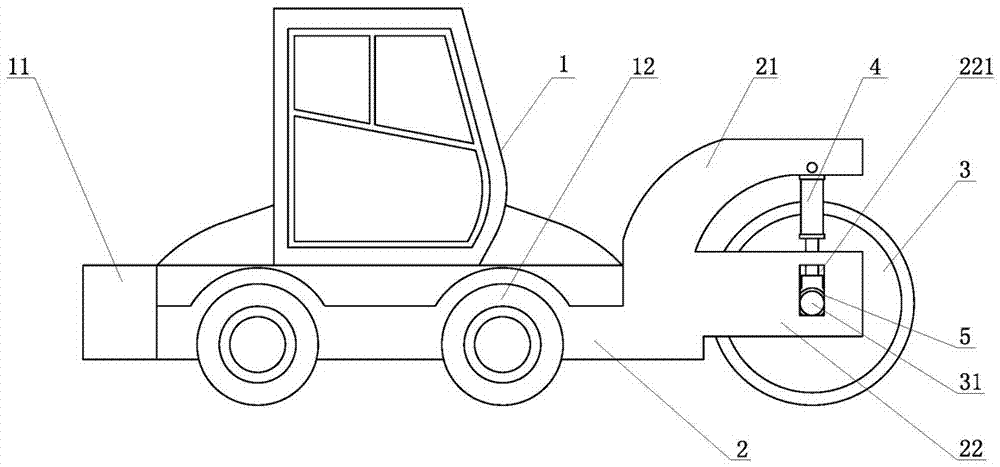

[0016] combined with figure 1 The present invention is further described in detail, so that the public can better grasp the implementation method of the present invention, the specific embodiment of the present invention is: as attached figure 1 As shown, a consignment-free single-drum road roller includes a car body 1, a frame 2 is arranged on the car body 1, and a compaction wheel 3 is arranged on the frame 2, and it is characterized in that a counterweight box is arranged at the rear end of the car body 1 11. Two wheels 12 are arranged symmetrically on the left and right sides of the car body 1. A frame 2 is fixed at the front end of the car body 1. A compacting wheel 3 is arranged inside the frame 2. A fixed shaft 31 is arranged at both ends of the compacting wheel 3. The machine The frame 2 includes an upper support arm 21 and a lower support arm 22. A hydraulic cylinder 4 is arranged at the lower end of the upper support arm 21. The lower end of the hydraulic cylinder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com