Device and method for drying marine underwater motor

A technology for underwater motors and drying equipment, which is applied in the field of ocean engineering, can solve the problems that have not found the same or similar literature reports, delay the construction period of offshore operations, and inconvenient transportation, so as to shorten the maintenance period, eliminate transportation costs, and reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

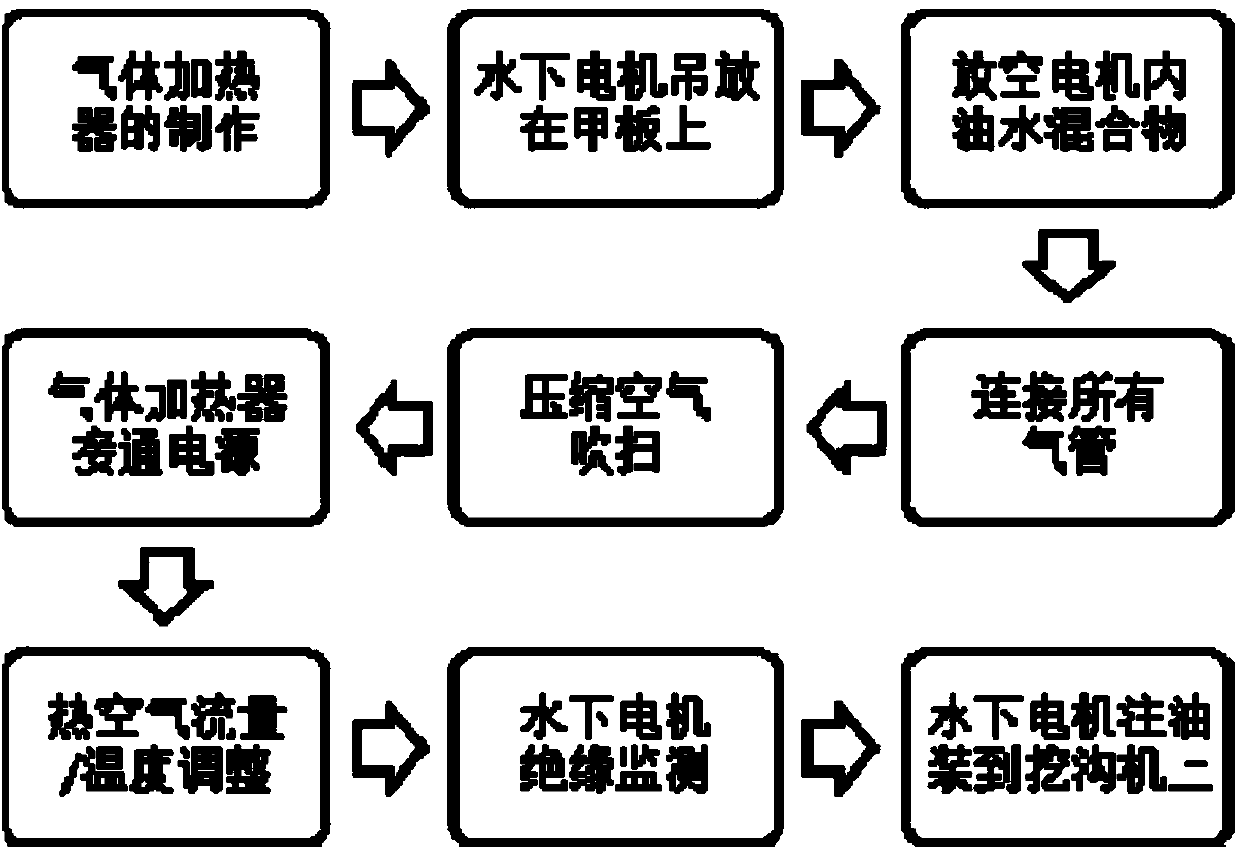

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited to the following embodiments.

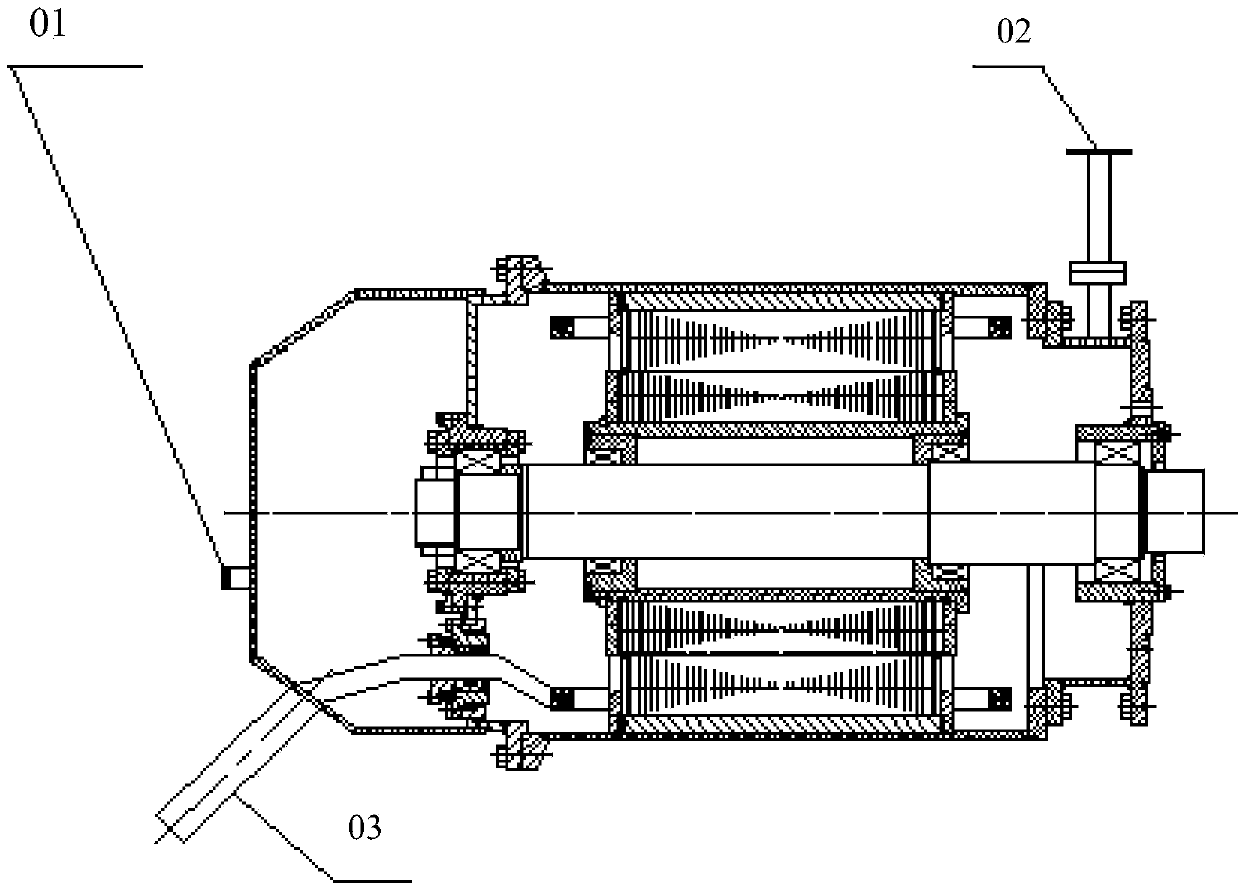

[0024] The drying equipment of the offshore underwater motor is installed on the deck of the offshore working mother ship, the offshore working mother ship is provided with a compressed air storage tank, and the underwater motor is provided with a compensator interface 02 and a motor chamber oil filling exhaust port 01 (See figure 1 ).

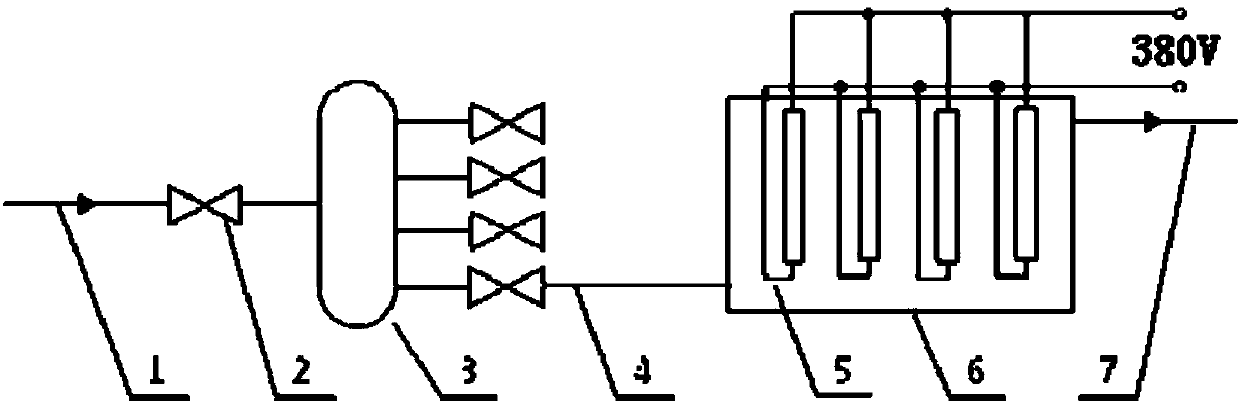

[0025] See figure 2 , the figure shows that the drying equipment for underwater motors in the sea includes a main gas pipe 1, a gas distribution tank 3, a gas distribution pipe 4, a gas heater 6 and a hot gas pipe 7. The main air pipe 1 adopts a rubber hose with a working pressure of 1.6MPa or more and 1-1 / 2", one end of the main air pipe 1 is connected to the output end of the air storage tank of the offshore working mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com