Dual-phase electrolyte and lithium-silver battery

An electrolyte and organic electrolyte technology, used in fuel cell type half cells and secondary battery type half cells, etc., can solve the problems of unstable chemical properties, easy corrosion, fragile diaphragm, etc., and achieve a good and stable interface, Avoid easily breakable, good hydrophobic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Propylene carbonate and dimethyl carbonate with a volume ratio of 1:1 are mixed to obtain a hydrophobic organic solvent, and lithium perchlorate is dissolved in the hydrophobic organic solvent at a concentration of 1mol / L to obtain a hydrophobic organic electrolyte ; Lithium hydroxide and lithium nitrate are dissolved in triple distilled water, the concentration of lithium hydroxide is 0.1mol / L, the concentration of lithium nitrate is 1mol / L, to obtain an aqueous electrolyte; subsequently, two diaphragms are respectively immersed in the hydrophobic It was treated for 10 days in sexual organic electrolyte and aqueous electrolyte.

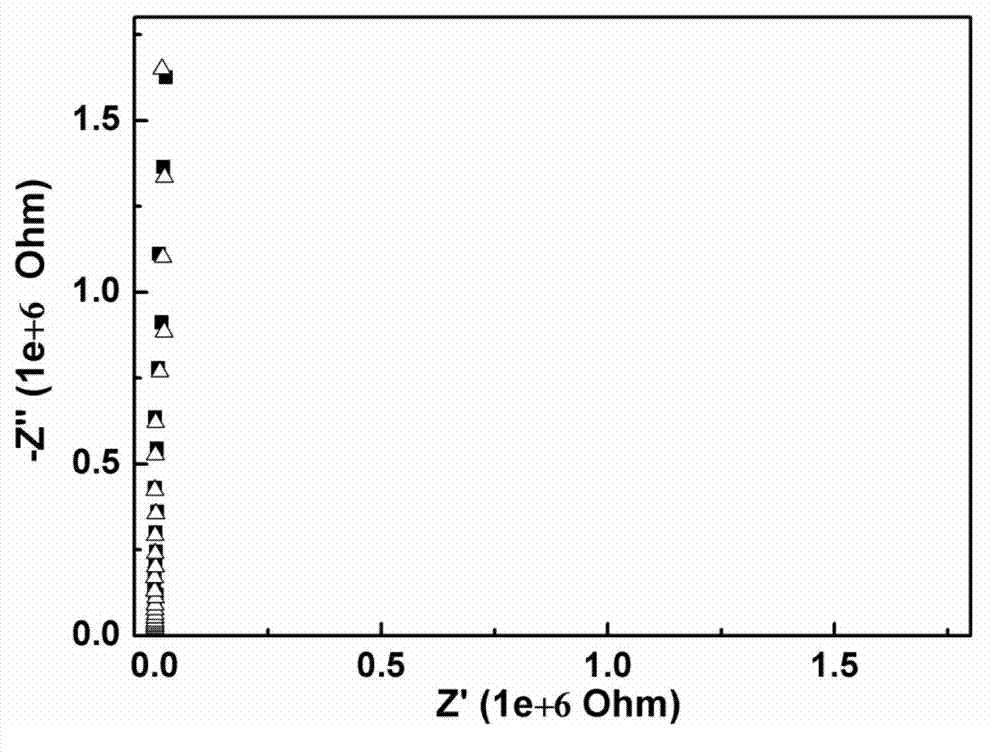

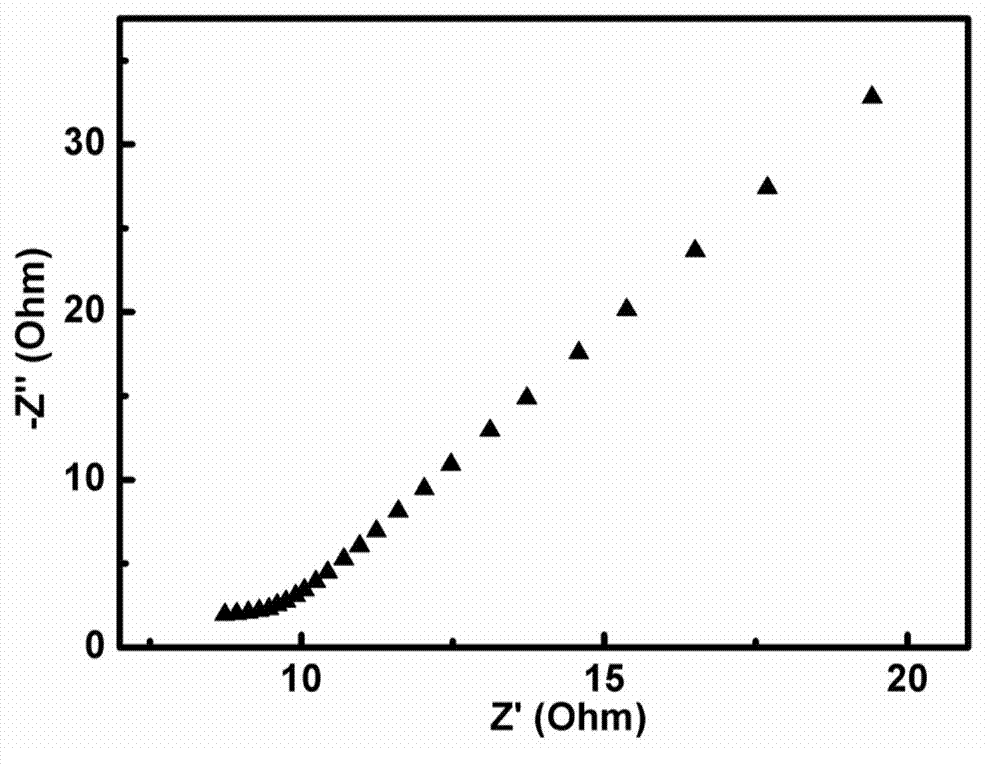

[0037] After 10 days, the diaphragm was taken out to obtain the treated diaphragm, and the electrochemical impedance behavior of the diaphragm before and after the treatment was measured by AC impedance technology. The measurement was carried out in the form of a stainless steel blocking cell on the PARSTAT2273 electrochemical workstation (Prin...

Embodiment 2

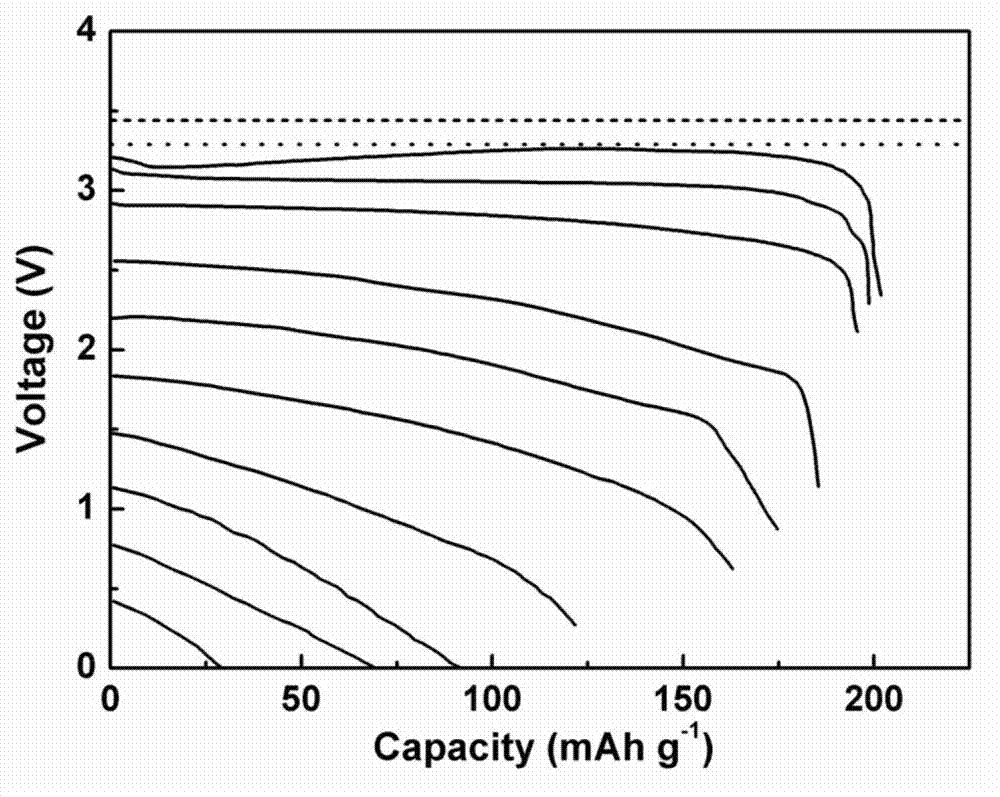

[0041]A kind of biphasic electrolyte lithium-silver battery, described battery comprises biphasic electrolyte, positive pole, negative pole and wire; Described biphasic electrolyte is the aqueous solution electrolyte and hydrophobic organic electrolyte that embodiment 1 makes, aqueous solution electrolyte and hydrophobic organic electrolyte The two phases are separated by a diaphragm; the aqueous electrolyte is used for the positive electrode, and the hydrophobic organic electrolyte is used for the negative electrode; the positive electrode is a silver oxide electrode, which is placed in the aqueous electrolyte; the negative electrode is a metal lithium electrode, which is placed in the hydrophobic organic electrolyte. Middle; the external circuit between the positive pole and the negative pole is connected through a wire and an external load, the wire is wrapped with an insulating material, and the metal at both ends of the wire is fixedly connected to the positive pole and the...

Embodiment 3

[0050] The infrared spectrum of the diaphragm was measured by an infrared tester before and after 10 days of treatment in the aqueous electrolyte in Example 1, before and after 10 days of treatment in the hydrophobic organic electrolyte, and before and after 10 days of treatment in the dual-phase electrolyte lithium-silver battery in Example 2 As shown in the figure, the test was carried out on a Thermo Scientific Nicolet iS10 (Thermo Fisher Corporation, USA).

[0051] Described infrared spectrogram draws by following method:

[0052] Measure the background infrared spectrum under air conditions, when measuring the infrared spectrum of the membrane before and after treatment, load the background infrared spectrum, at 400 ~ 4000cm -1 Test the infrared spectrum in the wavenumber range, the resolution is 1cm -1 , the obtained infrared spectrum is as Figure 5 shown.

[0053] Figure 5 The horizontal axis in the figure is the wavenumber range of the scan, and the vertical axis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com