Method of treating a workpiece comprising a titanium metal and object

A processing method and technology of titanium metal, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of weak support and long cost of hard and brittle nitride layer, eliminate residual stress, improve Mechanical properties, the effect of eliminating internal porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

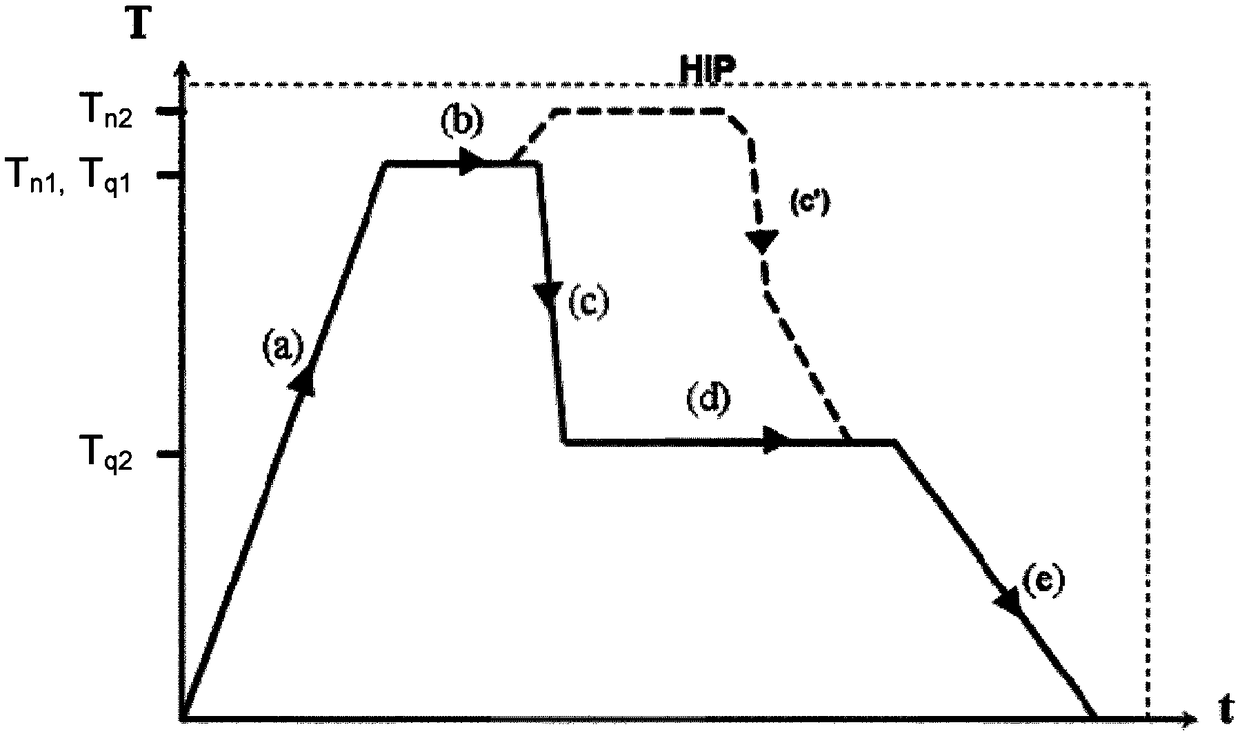

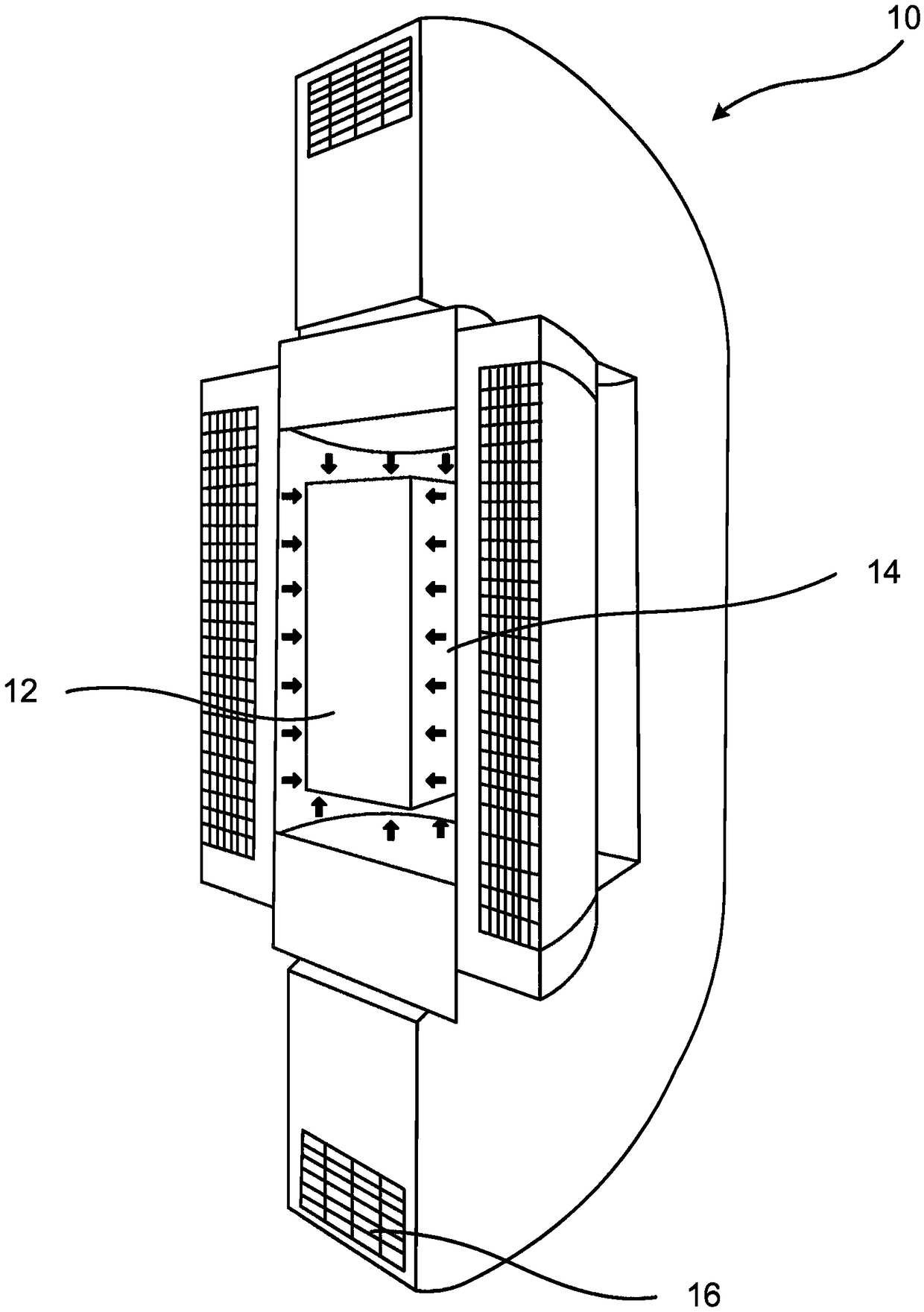

[0069] A workpiece comprising commercially pure titanium (grade 2) in the form of a thin-walled tube (t = 1.0 mm) was placed in figure 2 in a hot isostatic press of the type shown. Nitrogen N 2 into the chamber of the press 10.

[0070] During step a), the gas temperature was increased until the workpiece temperature reached 960°C. At the same time, the gas pressure increased to 170MPa.

[0071] In step b), the same temperature and gas pressure were maintained for 2 hours.

[0072] Since this temperature is already above the "beta transus" temperature, the titanium alloy does not require an increase in temperature in step b).

[0073] In step c), the workpiece is quenched by cooling nitrogen gas according to the following gas cooling rate:

[0074] Between 960 and 900°C, 3600K / min,

[0075] Between 900 and 800°C, 2460K / min,

[0076] Between 800 and 700°C, 1440K / min,

[0077] Between 700 and 600°C, 1020K / min, and

[0078] Between 600 and 500°C, 600K / min,

[0079] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com