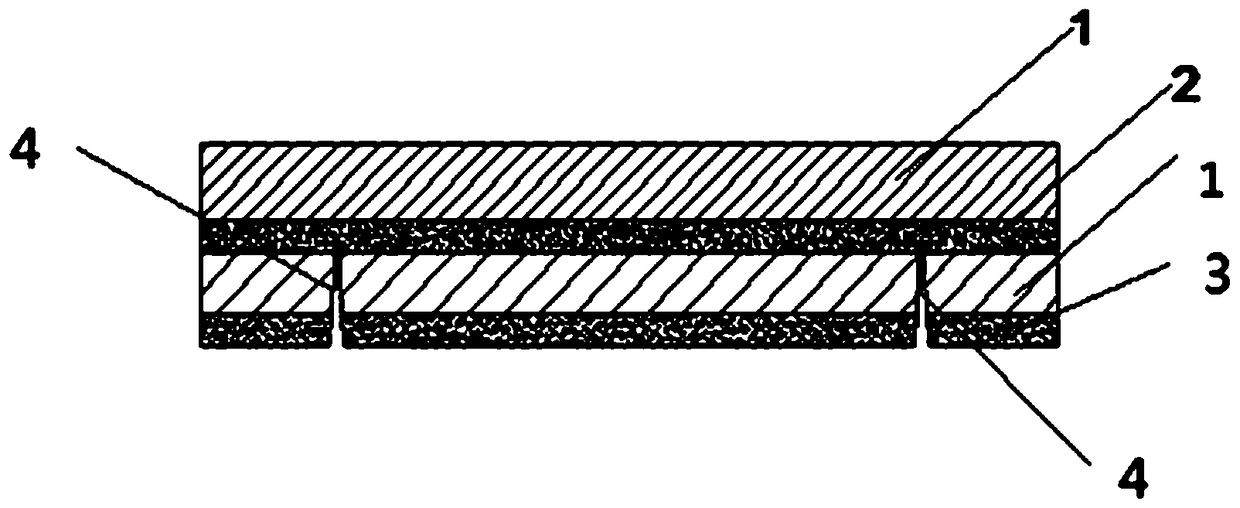

Cover strip structure

A cover tape, integrated technology, applied in packaging and other directions, can solve problems such as unfavorable operation of electronic components, easily damaged electronic components, electronic components shake out, etc., to achieve uniform peel strength, stable peel strength, and peel strength temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The above-mentioned cover tape structure is adopted, wherein, the material of the base film layer 1 in the surface layer is PET, and the thickness is 30 μm, and the material of the base film layer 1 in the middle layer is EVA, and the thickness is 15 μm, and the first adhesive layer 2 It is a pressure-sensitive adhesive, and the second adhesive layer 3 is a heat-sensitive adhesive.

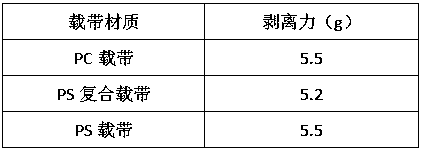

[0016] The cover tape in Example 1 and the carrier tapes of the three materials in Table 1 were respectively sealed under the same sealing conditions by the sealing instrument VANGUARD SYSTEMS VN-1100, and then tested by the peel force testing instrument VANGUARD SYSTEMS VG-20. Peel the cover tape under the same peeling conditions, and the test results shown in Table 1 can be obtained. Among them, the range value of the fluctuation range of the peeling force is controlled at 0g<F≤10g, and the fluctuation range of the peeling force in the industry is the peeling force. The difference between...

Embodiment 2

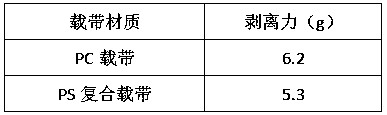

[0022] On the basis of Example 1, the material of the base film layer 1 of the intermediate layer was changed to PE, and the rest of the content was the same as that of Example 1. The test results are shown in Table 2.

[0023] Table 2

[0024]

Embodiment 3

[0026] On the basis of Example 1, the material of the base film layer 1 of the middle layer was changed to PP, and the material of the first adhesive layer 1 was changed to a heat-sensitive adhesive. The rest of the content was the same as that of Example 1. The test results as shown in Table 3.

[0027] table 3

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com