Control valve and valve with same

A technology for controlling valves and control valves, applied in valve operation/release devices, lift valves, valve details, etc., can solve problems affecting the vital economic interests of enterprises, institutions and properties, energy waste, and manual valves without energy-saving control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

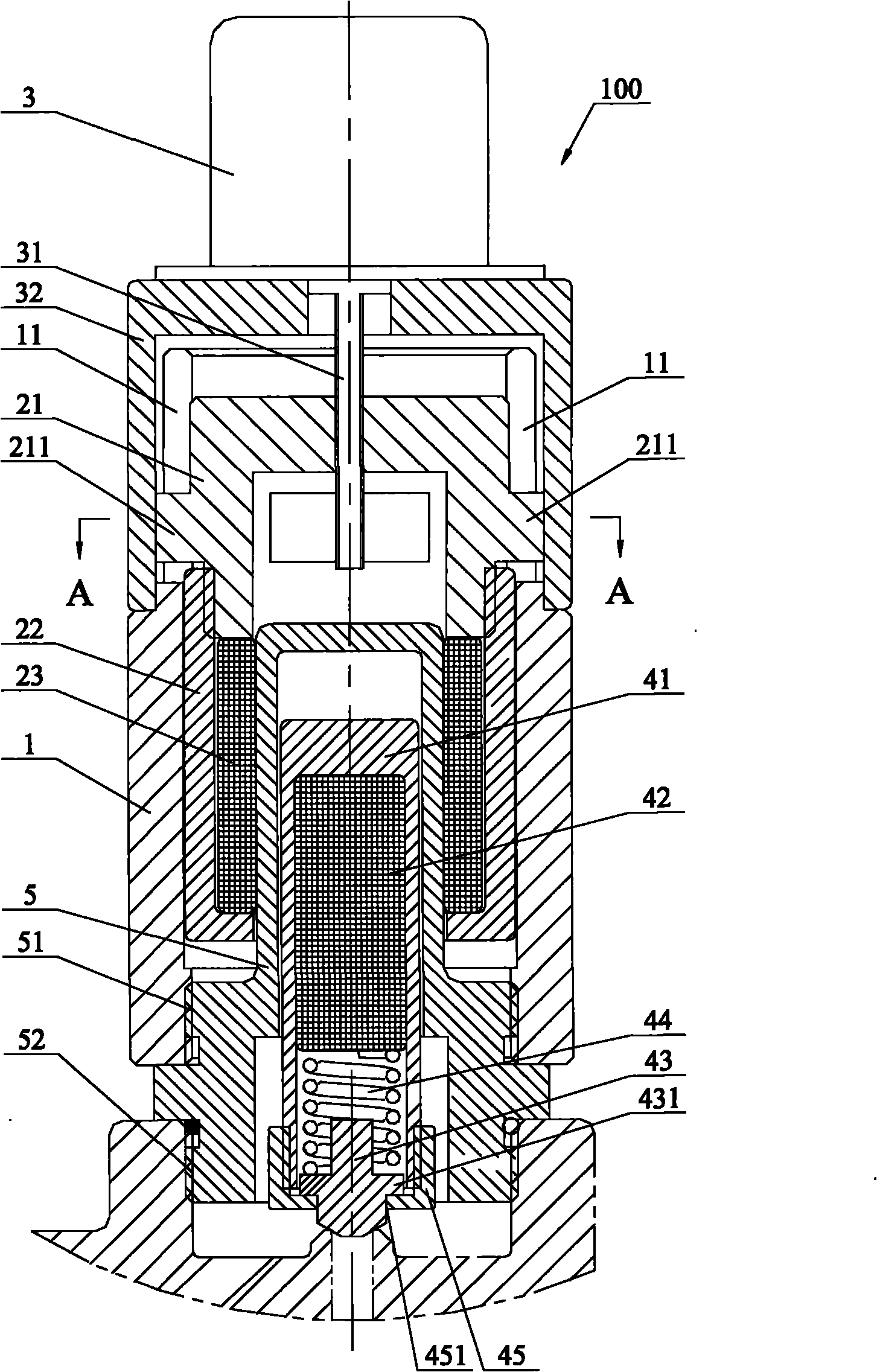

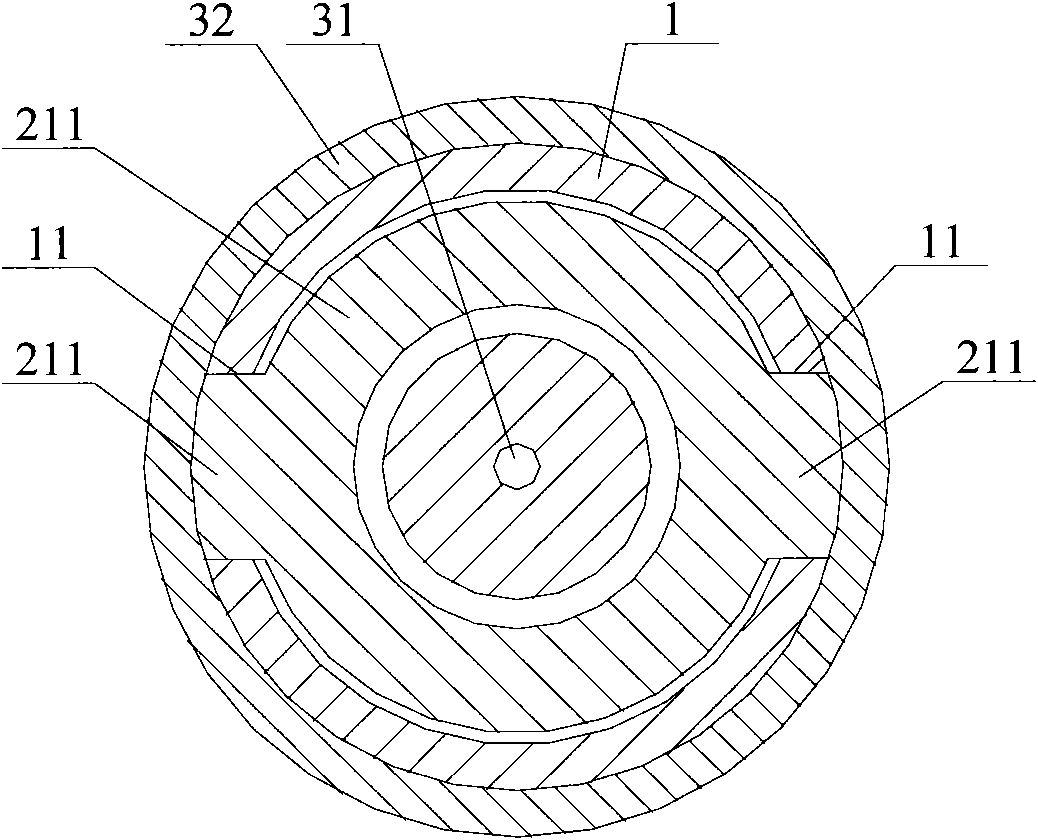

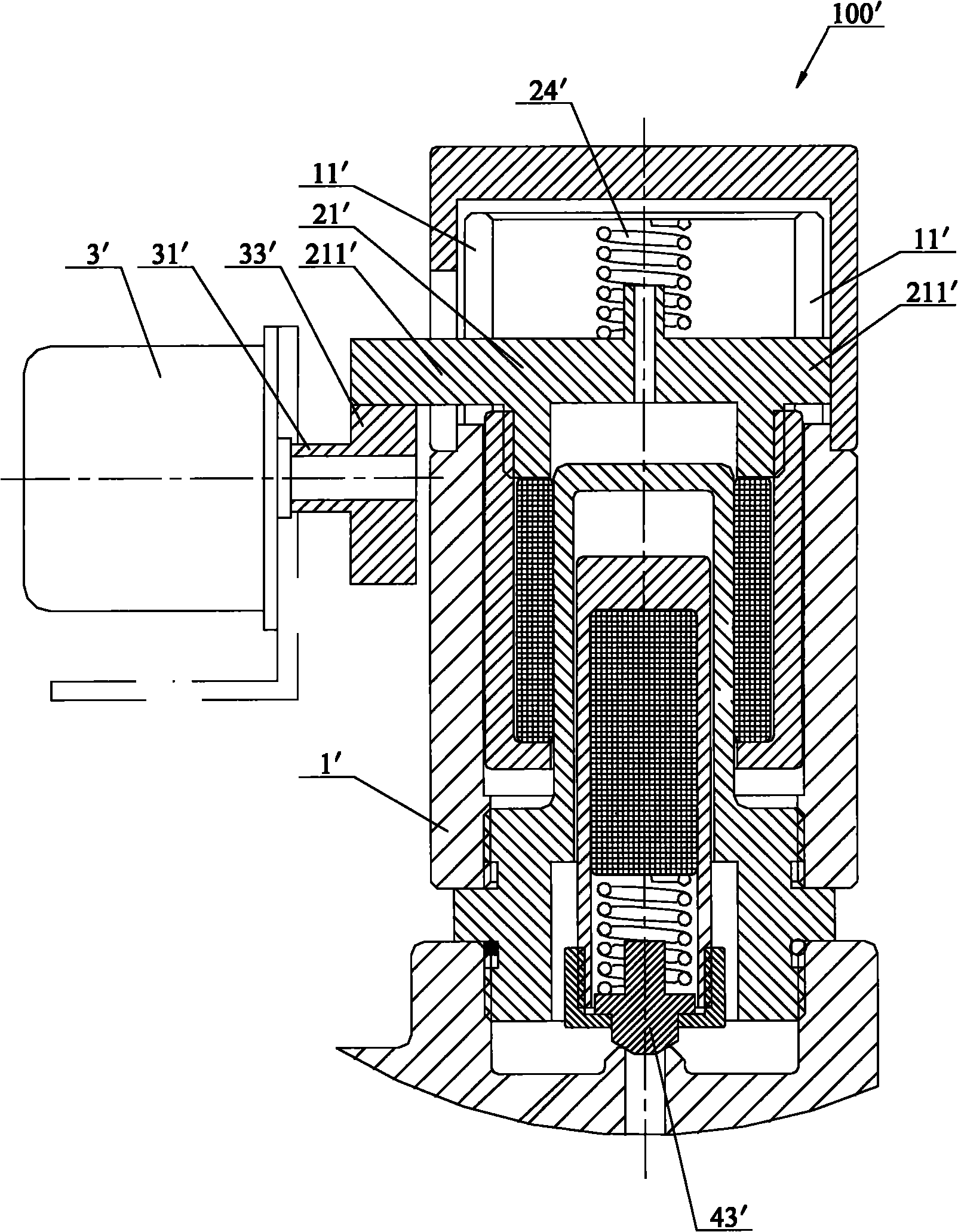

[0036] The core of the present invention is to provide a control valve, which is used to control the conduction state between the valve inlet and outlet, which mainly includes a valve body casing, a driving motor, a magnetic ring assembly and a magnetic core assembly; wherein, the driving motor is arranged on the valve The outer side of the body casing; the magnetic ring assembly is arranged in the valve body casing, the magnetic ring assembly is connected to the output shaft of the drive motor; the magnetic core assembly is nested inside the magnetic ring assembly, Its lower end is used to offset or separate from the flow channel between the inlet and outlet of the valve to realize the opening and closing of the valve; The magnetic core assembly moves axially, so as to resist or separate the magnetic core assembly from the valve flow channel. The invention utilizes the principle of magnetic coupling, and the movement of the magnetic ring assembly drives the magnetic core asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com