Braking force generator for a hydraulic vehicle braking system

A technology of hydraulic braking and braking force, applied in the direction of braking safety systems, brakes, braking transmission devices, etc., can solve the problems of increased manufacturing costs, large equipment costs, etc., and achieve the effect of improving vulnerability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

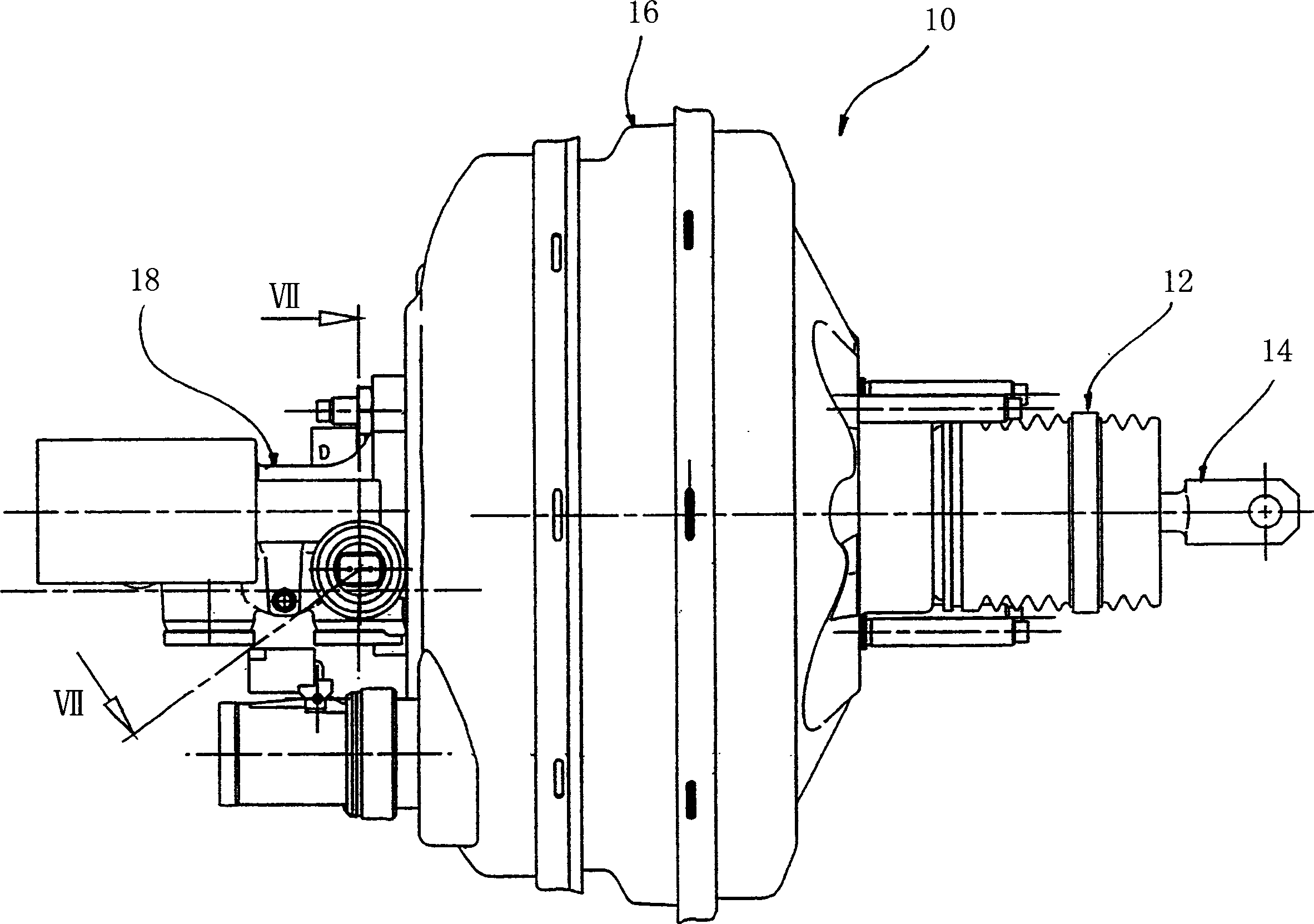

[0038] exist figure 2 In , the brake force generator according to the invention is shown in side view and is indicated as a whole by the reference number 10 . The brake force generator comprises an actuation unit 12 into which a force input element 14 is introduced. Force input element 14 can be connected with brake pedal ( figure 2 not shown) connected. The actuation unit 12 is connected to the chamber structure 16 . Part of the cylinder housing 18 of the master cylinder is visible on the side of the chamber structure 16 facing away from the actuating unit 12 .

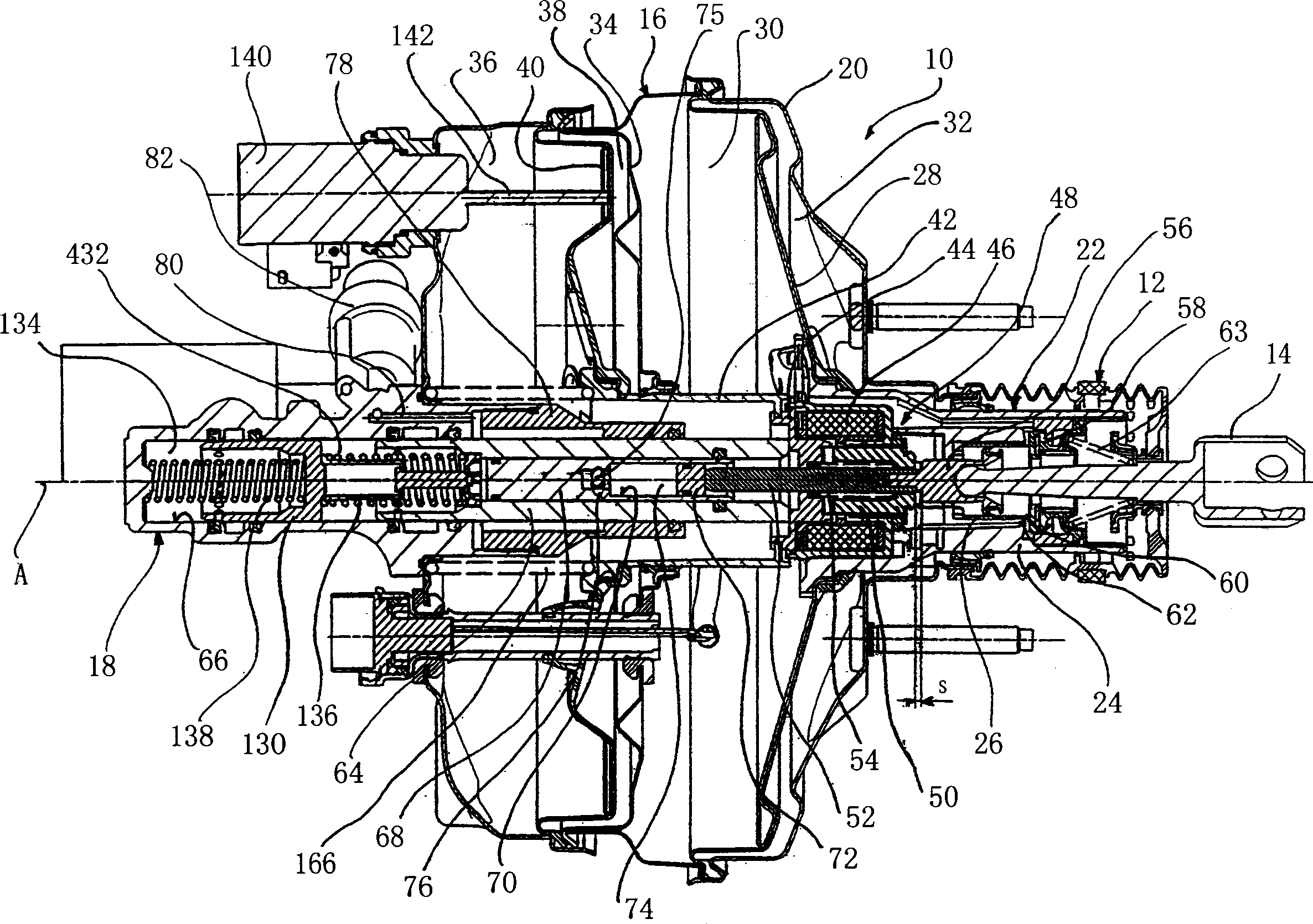

[0039] In order to describe in detail the structure of the braking force generator 10 according to the present invention, refer to image 3 . The basic structure of the brake force generator 10 according to the invention consists of two modules, namely: on the one hand the cylinder housing 18 and on the other hand the brake force generator housing 20 into which the cylinder housing 18 is inserted. body 20 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com