Hydraulic control system for automatic transmission

A technology of automatic transmission and oil pressure control, which is applied in transmission control, components with teeth, belts/chains/gears, etc., and can solve problems such as complex circuit composition and unfavorable device compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

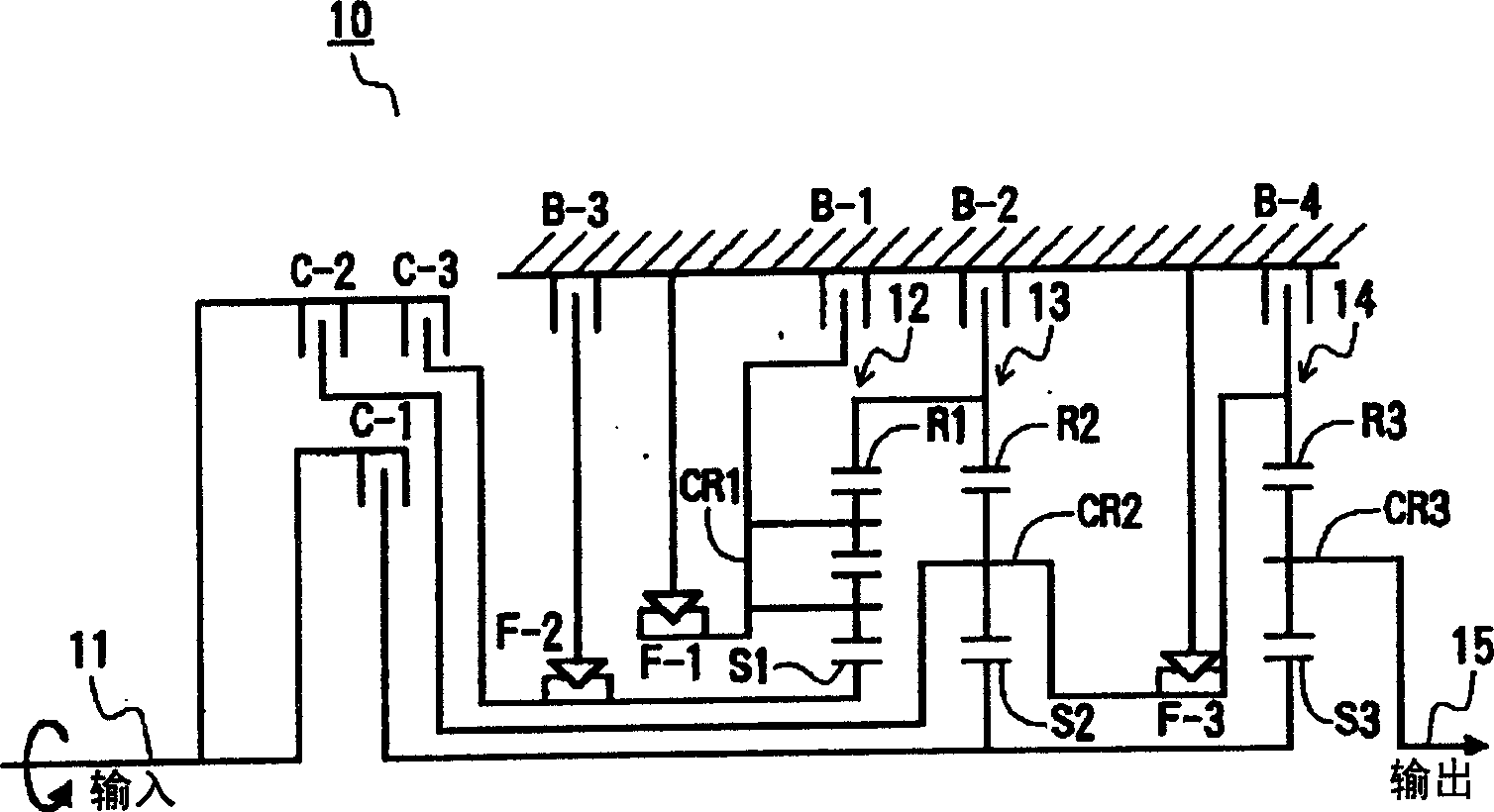

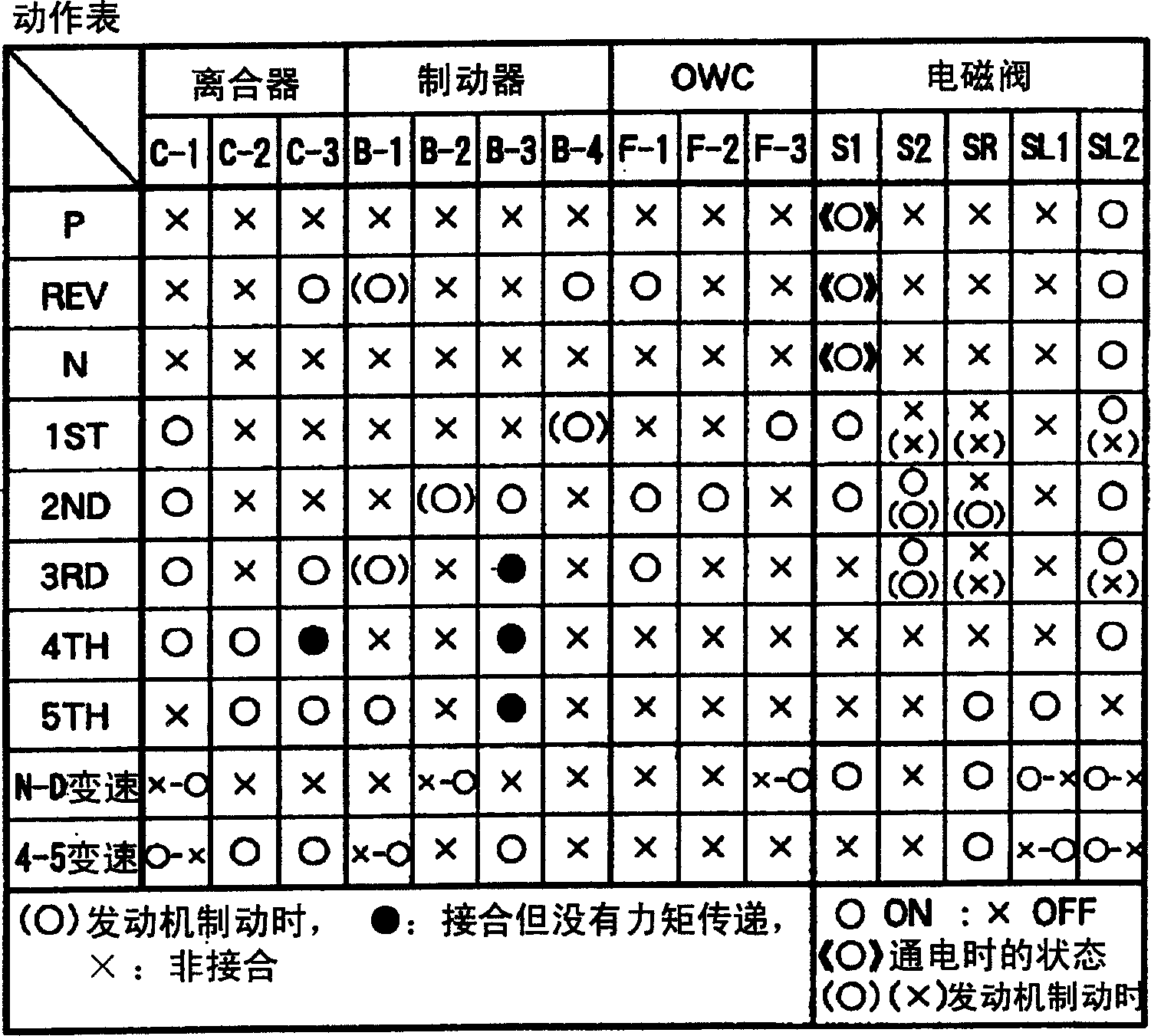

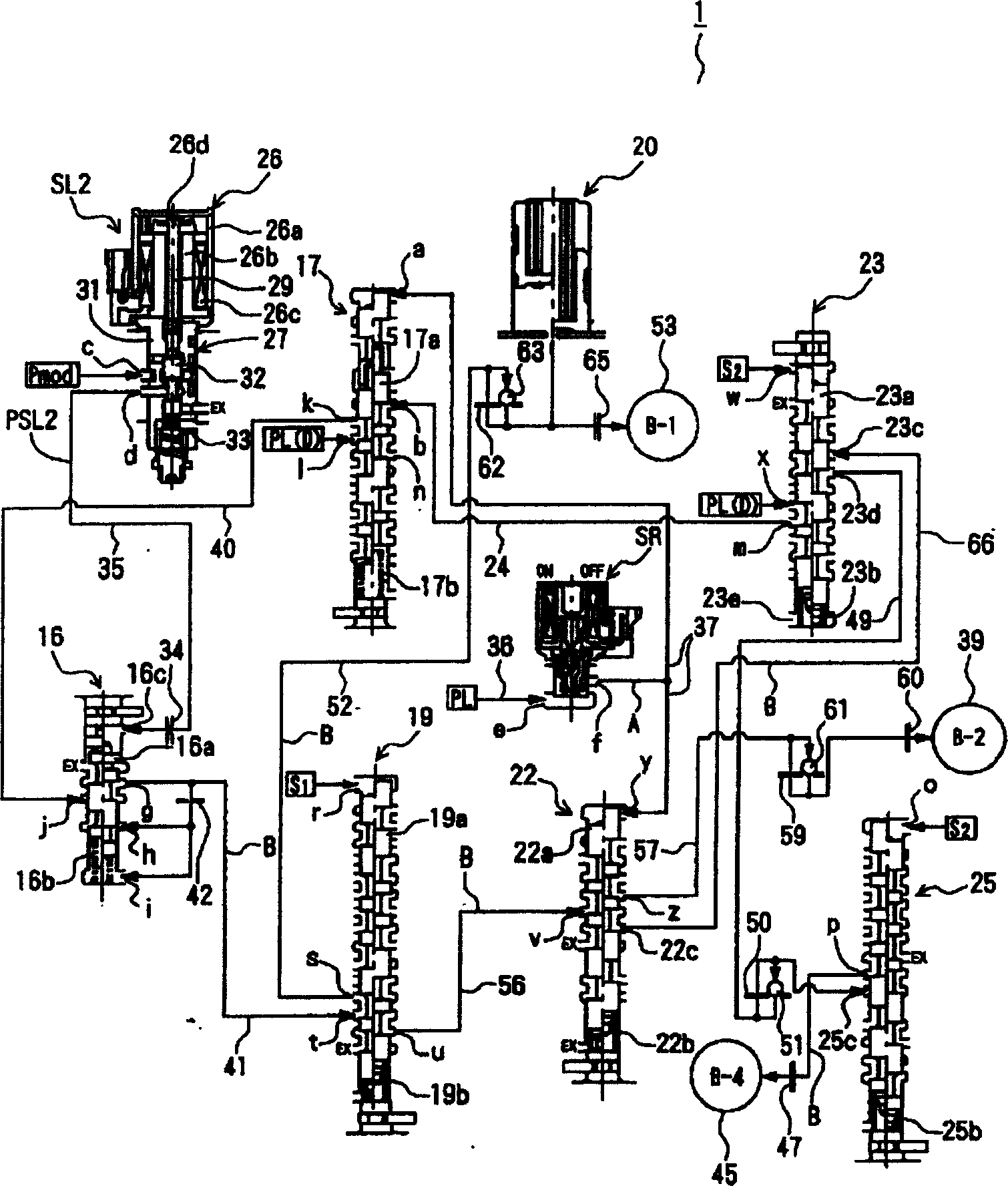

[0055] Embodiments of the present invention are described below with reference to the drawings. figure 1 is a schematic diagram showing an automatic transmission mechanism to which the present invention is applied, figure 2 It is an action table showing the action state of the automatic transmission mechanism in the transmission (D) position, image 3 It is a schematic diagram showing the hydraulic control device of the present invention.

[0056] In addition, in figure 2 In the column of clutches, brakes, and one-way clutches (OWC), (○) indicates engagement during engine braking, ● indicates engagement that does not participate in the realization of the shift speed, and × indicates non-engagement. In the display column of the solenoid valve, ○ indicates that it is in the ON state, × indicates that it is in the OFF state, (○) and (×) indicate the ON and OFF states when the engine is braked, and indicates that the ignition key is in the ON state (when the power is on ). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com