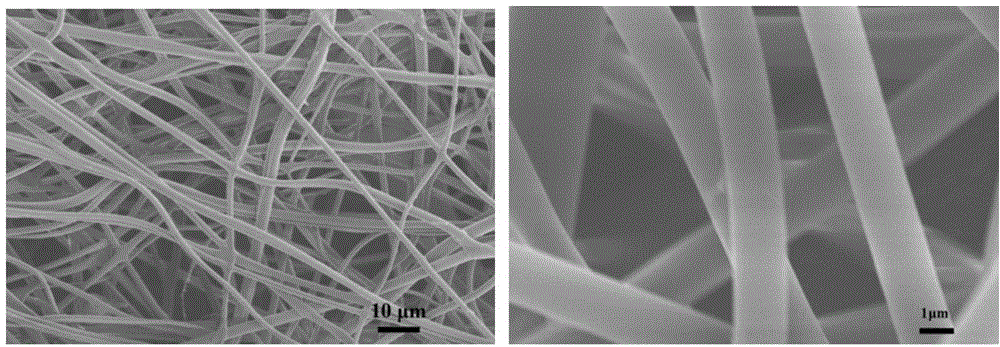

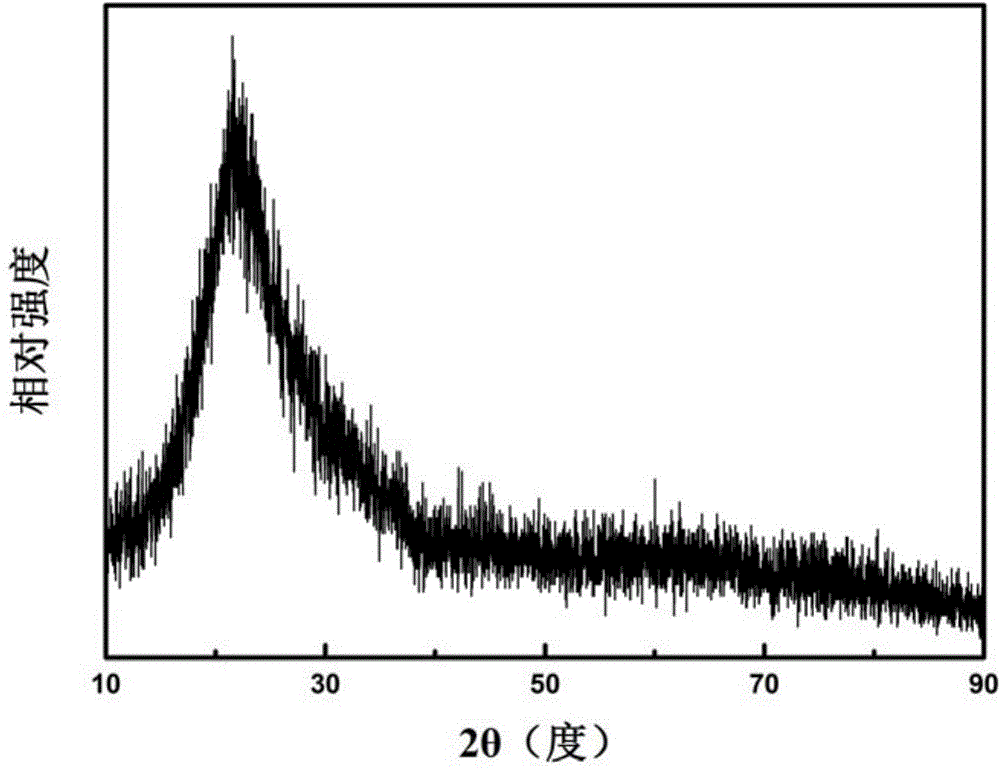

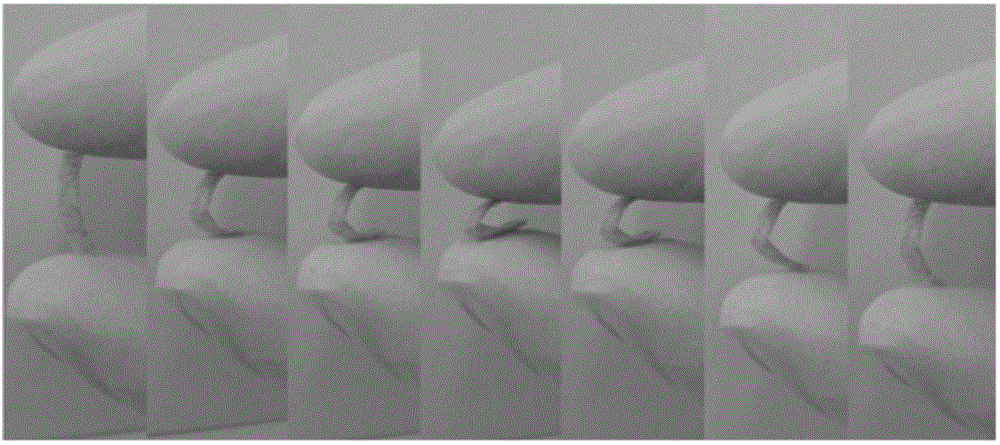

Preparation method of flexible silicon dioxide fiber film

A technology of silica and fiber membranes, applied in fiber treatment, fiber chemical characteristics, textiles and papermaking, etc., can solve problems such as resistance to organic solvents, poor flexibility, high temperature resistance of ordinary fiber membranes, etc., to achieve good flexibility, Good high temperature resistance, simple and feasible preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) At room temperature, use an analytical balance to weigh 10g, 10g, and 0.1g of tetraethyl orthosilicate, ultrapure water, and phosphoric acid, and mix ethyl orthosilicate and ultrapure water at a ratio of 1:1 while stirring Add phosphoric acid dropwise, and stir magnetically for 4 hours until a clear and transparent silicon source solution is obtained;

[0028] (2) Dissolve 1 g of polyvinyl alcohol (polymerization degree 1700, alcoholysis degree 50%) in 11.5 g of ultrapure water, heat and stir in an oil bath at 80°C for 5 hours, and obtain a polyvinyl alcohol solution with a mass fraction of 8%. ;

[0029] (3) At room temperature, use an analytical balance to weigh 6g each of the silicon source solution and the polyvinyl alcohol solution, stir magnetically for 4 hours until a clear and transparent spinning solution is obtained, and let it stand for 40 hours; extract the above spinning solution with a disposable syringe, The electrospinning conditions are micropump p...

Embodiment 2

[0033] (1) At room temperature, use an analytical balance to weigh 10g, 12g, and 0.1g of ethyl orthosilicate, ultrapure water, and phosphoric acid, and mix ethyl orthosilicate and ultrapure water at a ratio of 1:1.2 while stirring Add phosphoric acid dropwise, and stir magnetically for 5 hours until a clear and transparent silicon source solution is obtained;

[0034] (2) Dissolve 1 g of polyvinyl alcohol (polymerization degree 1700, alcoholysis degree 50%) in 10.1 g of ultrapure water, heat and stir in an oil bath at 85°C for 4.5 hours to obtain polyvinyl alcohol with a mass fraction of 9% solution;

[0035] (3) At room temperature, use an analytical balance to weigh 6g and 6.6g of the silicon source solution and the polyvinyl alcohol solution, stir magnetically for 4 hours until a clear and transparent spinning solution is obtained, and let it stand for 40 hours; draw 5ml of the above-mentioned solution with a disposable syringe Spinning solution, electrospinning conditions...

Embodiment 3

[0038] (1) At room temperature, use an analytical balance to weigh 10g, 15g, and 0.1g of tetraethyl orthosilicate, ultrapure water, and phosphoric acid, and mix ethyl orthosilicate and ultrapure water at a ratio of 1:1.5 while stirring Add phosphoric acid drop by drop, and magnetically stir for 6 hours until a clear and transparent silicon source solution is obtained;

[0039] (2) Dissolve 1 g of polyvinyl alcohol (polymerization degree 1700, alcoholysis degree 50%) in 9 g of ultrapure water, heat and stir in an oil bath at 90°C for 4 hours to obtain a polyvinyl alcohol solution with a mass fraction of 10%;

[0040] (3) At room temperature, use an analytical balance to weigh 6g and 7.2g of the silicon source solution and the polyvinyl alcohol solution, stir magnetically for 5 hours until a clear and transparent spinning solution is obtained, and let it stand for 40 hours; use a disposable syringe to draw 5ml of the above Spinning liquid, the condition of electrospinning is mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com