White fiber high-performance C50 pump concrete

A high-performance pumping concrete technology, applied in the field of white fiber high-performance C50 pumping concrete and fair-faced concrete, can solve the problem of reducing service life, safety, applicability and durability, increasing manpower, material resources and time costs, and concrete tower surface numbness Problems such as surfaces and cracks, to achieve good construction pumping performance, rich decorative effects, and less air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment C50 pumping concrete comprises the following components: cement 405kg / m 3 , fly ash 25kg / m 3 , slag fine powder 50kg / m 3 , silica fume 10kg / m 3 , basalt fiber 3.2kg / m 3 , Quartz sand 736kg / m 3 , gravel 1151kg / m 3 , Admixture 5.5kg / m 3 , mixing water 147kg / m 3 , titanium dioxide pigment 3kg / m 3 .

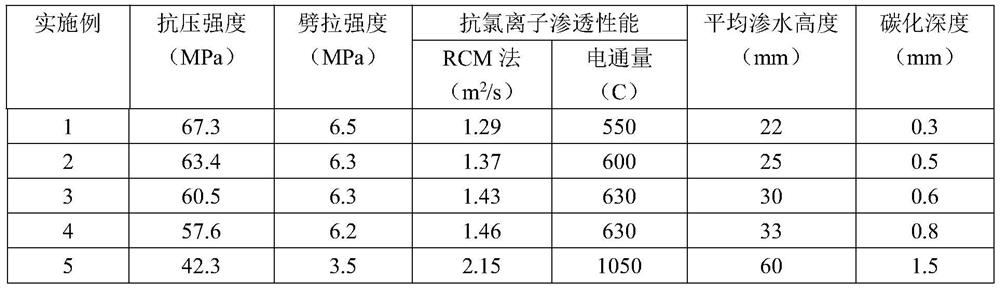

[0036] The performance parameters of the C50 pumped concrete obtained in this example are shown in Table 1.

Embodiment 2

[0038] The present embodiment C50 pumping concrete comprises the following components: cement 386kg / m 3 , fly ash 25kg / m 3 , slag fine powder 50kg / m 3 , silica fume 20kg / m 3 , basalt fiber 4.6kg / m 3 , Quartz sand 786kg / m 3 , gravel 1131kg / m 3 , Admixture 5.0kg / m 3 , mixing water 150kg / m 3 , titanium dioxide pigment 4kg / m 3 .

[0039] The performance parameters of the C50 pumped concrete obtained in this example are shown in Table 1.

Embodiment 3

[0041] The present embodiment C50 pumping concrete comprises the following components: cement 347kg / m 3 , fly ash 35kg / m 3 , slag fine powder 58kg / m 3 , silica fume 25kg / m 3 , basalt fiber 6.9kg / m 3 , Quartz sand 780kg / m 3 , gravel 1075kg / m 3 , Admixture 4.5kg / m 3 , mixing water 154kg / m 3 , titanium dioxide pigment 6kg / m 3 .

[0042] The performance parameters of the C50 pumped concrete obtained in this example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com