Quantitative determination method for natural colored cotton fiber blending ratio

A technology of natural colored cotton and fiber blending, which is applied in the measurement of color/spectral properties, etc., can solve the problems of low accuracy of experimental results, destructive samples, and unsuitable for analyzing small batch samples, and achieves the effect of strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

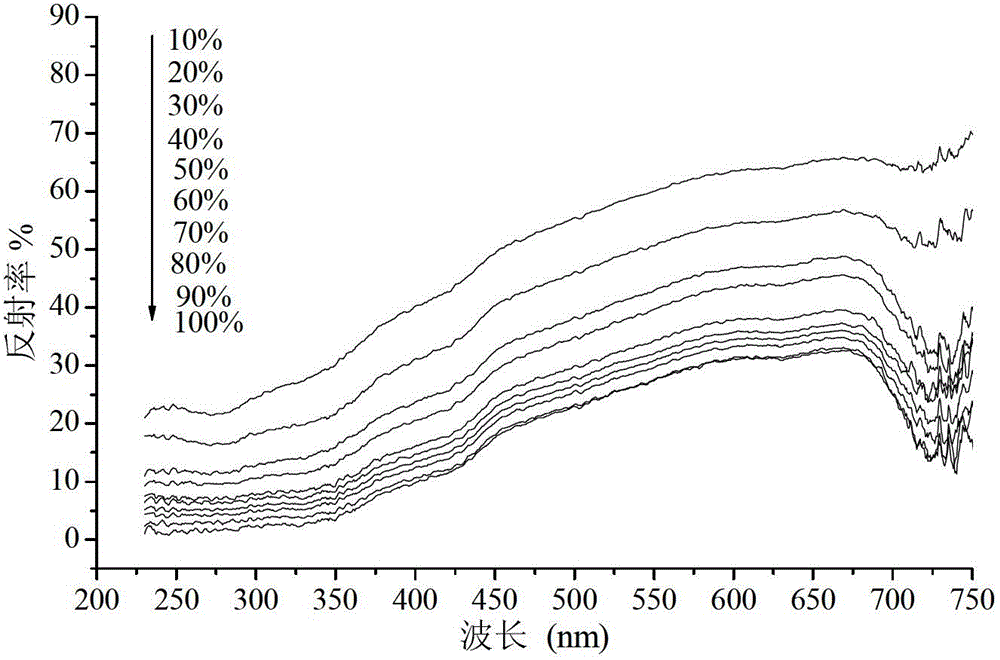

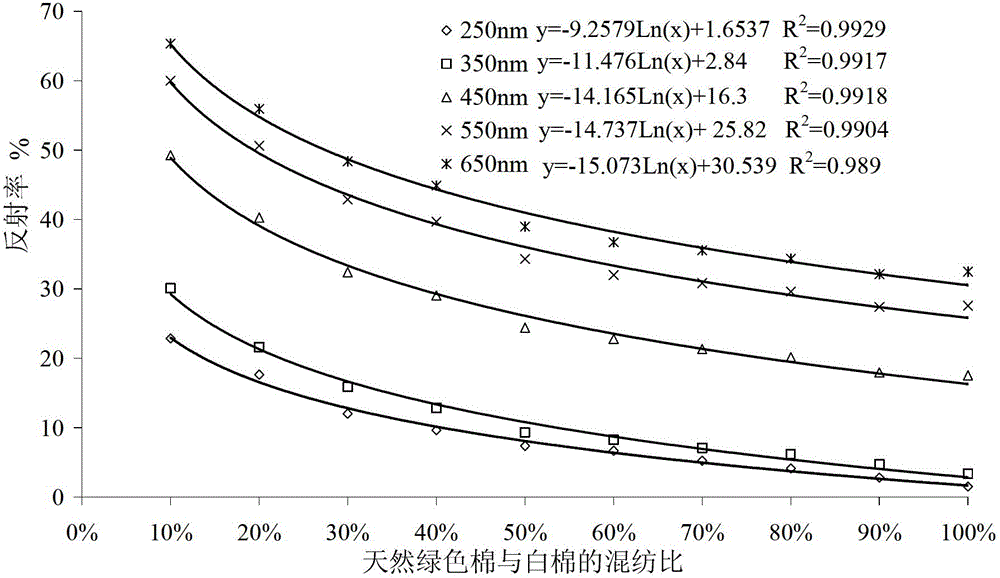

[0044]First, ordinary white cotton fiber and natural green cotton fiber (produced by the Cotton Research Institute of Zhejiang Academy of Agricultural Sciences) are crushed into fiber powders of more than 80 meshes, and then the two fiber powders are mixed evenly in a certain proportion. A certain proportion refers to the percentage of the mass of natural green cotton fiber powder in the mass of the mixed powder, which are 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, and 100%, respectively. Then use the ultraviolet-visible spectrophotometer with integrating sphere accessories to measure the ultraviolet diffuse reflectance spectrum, so as to establish the relationship curve between reflectivity and wavelength under different mixing ratios, as shown in figure 1 . Then establish the correlation curve of reflectance y and fiber powder ratio x at different wavelengths, such as figure 2 . details as follows:

[0045] At 250nm, y=-9.2579Ln(x)+1.6537, the square of the correlation...

Embodiment 2

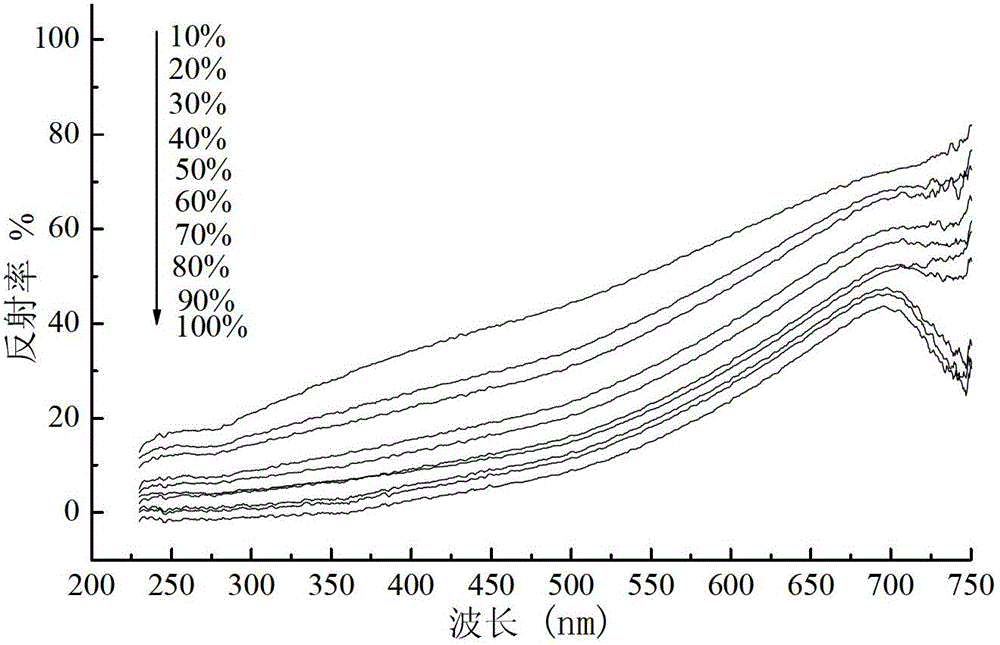

[0074] Firstly, ordinary white cotton fiber and natural brown cotton fiber (produced by the Cotton Research Institute of Zhejiang Academy of Agricultural Sciences) are crushed into fiber powders of more than 80 meshes, and then the two fiber powders are mixed evenly in a certain proportion. A certain proportion refers to the percentage of the mass of natural brown cotton fiber powder in the mass of the mixed powder, which are 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, and 100%, respectively. Then use the ultraviolet-visible spectrophotometer with integrating sphere accessories to measure the ultraviolet diffuse reflectance spectrum, so as to establish the relationship curve between reflectivity and wavelength under different mixing ratios, as shown in image 3 . Then establish the correlation curve of reflectance y and fiber powder ratio x at different wavelengths, such as Figure 4 . Specifically:

[0075] At 250nm, y=-8.3181Ln(x)-0.2914, the square of the correlation co...

Embodiment 3

[0093] First, ordinary white polyester and natural brown cotton (produced by the Cotton Research Institute of Zhejiang Academy of Agricultural Sciences) fibers are crushed into fiber powders of more than 80 meshes, and then the two fiber powders are mixed evenly in a certain proportion. A certain proportion refers to the percentage of the mass of natural brown cotton fiber powder in the mass of the mixed powder, which are 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90%, and 100%, respectively. Then use the ultraviolet-visible spectrophotometer with integrating sphere accessories to measure the ultraviolet diffuse reflectance spectrum, so as to establish the relationship curve between reflectivity and wavelength under different mixing ratios, as shown in Figure 5 . Then establish the correlation curve of reflectivity and fiber powder ratio at different wavelengths, such as Figure 6 . Specifically:

[0094] At 450nm, y= -12.447Ln(x)+6.3317, the square of the correlation coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com